How to Align Propionic Acid with Future Global Standards?

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Propionic Acid Standards Evolution and Objectives

Propionic acid has been a crucial component in various industries for decades, with its applications ranging from food preservation to the production of pharmaceuticals and plastics. As global standards continue to evolve, it is imperative to understand the historical context and future objectives for propionic acid standards to ensure alignment with emerging requirements.

The evolution of propionic acid standards can be traced back to the early 20th century when its antimicrobial properties were first recognized. Initially, standards primarily focused on purity levels and basic safety guidelines for handling and storage. As industrial applications expanded, regulatory bodies began to develop more comprehensive standards addressing quality control, environmental impact, and worker safety.

In recent years, the focus has shifted towards sustainability and eco-friendly production methods. This change has been driven by increasing environmental concerns and the global push for greener chemical processes. Standards now incorporate criteria for carbon footprint reduction, energy efficiency, and the use of renewable feedstocks in propionic acid production.

The current objectives for propionic acid standards are multifaceted, addressing various aspects of its production, use, and disposal. One primary goal is to establish uniform global standards that harmonize regulations across different regions, facilitating international trade and ensuring consistent quality worldwide. This includes standardizing testing methods, specifications, and labeling requirements.

Another key objective is to promote the development of bio-based propionic acid production methods. Standards are being developed to encourage and validate the use of renewable resources and biotechnological processes, aiming to reduce dependence on petrochemical-derived propionic acid. These standards will likely include criteria for assessing the environmental impact of production processes and the final product's carbon footprint.

Safety standards are also evolving, with a focus on minimizing exposure risks throughout the supply chain. This includes updating guidelines for handling, transportation, and storage, as well as implementing more stringent occupational health and safety measures in production facilities.

Looking ahead, future standards will likely emphasize circular economy principles, encouraging the development of recyclable and biodegradable products that incorporate propionic acid. Additionally, there is a growing interest in establishing standards for the use of propionic acid in new applications, such as advanced materials and emerging biotechnology fields.

To align with these evolving standards, industry stakeholders must actively participate in standard-setting processes, invest in research and development for sustainable production methods, and continuously improve their practices to meet and exceed regulatory requirements. This proactive approach will not only ensure compliance but also drive innovation and maintain competitiveness in the global market.

The evolution of propionic acid standards can be traced back to the early 20th century when its antimicrobial properties were first recognized. Initially, standards primarily focused on purity levels and basic safety guidelines for handling and storage. As industrial applications expanded, regulatory bodies began to develop more comprehensive standards addressing quality control, environmental impact, and worker safety.

In recent years, the focus has shifted towards sustainability and eco-friendly production methods. This change has been driven by increasing environmental concerns and the global push for greener chemical processes. Standards now incorporate criteria for carbon footprint reduction, energy efficiency, and the use of renewable feedstocks in propionic acid production.

The current objectives for propionic acid standards are multifaceted, addressing various aspects of its production, use, and disposal. One primary goal is to establish uniform global standards that harmonize regulations across different regions, facilitating international trade and ensuring consistent quality worldwide. This includes standardizing testing methods, specifications, and labeling requirements.

Another key objective is to promote the development of bio-based propionic acid production methods. Standards are being developed to encourage and validate the use of renewable resources and biotechnological processes, aiming to reduce dependence on petrochemical-derived propionic acid. These standards will likely include criteria for assessing the environmental impact of production processes and the final product's carbon footprint.

Safety standards are also evolving, with a focus on minimizing exposure risks throughout the supply chain. This includes updating guidelines for handling, transportation, and storage, as well as implementing more stringent occupational health and safety measures in production facilities.

Looking ahead, future standards will likely emphasize circular economy principles, encouraging the development of recyclable and biodegradable products that incorporate propionic acid. Additionally, there is a growing interest in establishing standards for the use of propionic acid in new applications, such as advanced materials and emerging biotechnology fields.

To align with these evolving standards, industry stakeholders must actively participate in standard-setting processes, invest in research and development for sustainable production methods, and continuously improve their practices to meet and exceed regulatory requirements. This proactive approach will not only ensure compliance but also drive innovation and maintain competitiveness in the global market.

Global Market Demand Analysis for Propionic Acid

The global market demand for propionic acid has been steadily increasing, driven by its diverse applications across various industries. The food and feed preservation sector remains the largest consumer of propionic acid, accounting for a significant portion of the market share. This demand is primarily fueled by the growing need for extended shelf life of food products and the rising consumption of animal feed in developing economies.

In the food industry, propionic acid is widely used as a preservative in baked goods, cheese, and other processed foods. The increasing consumer preference for convenience foods and ready-to-eat meals has further boosted the demand for propionic acid in this sector. Additionally, the growing awareness of food safety and the need for natural preservatives have led to an increased adoption of propionic acid as an alternative to synthetic preservatives.

The animal feed industry represents another major market for propionic acid. As global meat consumption continues to rise, particularly in emerging markets, the demand for animal feed additives has surged. Propionic acid's effectiveness in preventing mold growth and improving feed efficiency has made it an essential component in animal nutrition.

The pharmaceutical and personal care industries have also contributed to the growing demand for propionic acid. Its use as a precursor in the synthesis of various drugs and as a pH adjuster in cosmetic formulations has expanded its market reach. The increasing focus on personal hygiene and healthcare products, especially in the wake of global health concerns, has further stimulated demand in these sectors.

Geographically, North America and Europe have traditionally been the largest consumers of propionic acid. However, the Asia-Pacific region is emerging as a key growth market, driven by rapid industrialization, increasing population, and changing dietary habits. Countries like China and India are witnessing a surge in demand across multiple end-use industries.

The market demand for propionic acid is also influenced by environmental regulations and sustainability concerns. As industries seek eco-friendly alternatives, the bio-based propionic acid segment is gaining traction. This shift towards sustainable production methods aligns with global standards and is expected to shape the future market landscape.

In the food industry, propionic acid is widely used as a preservative in baked goods, cheese, and other processed foods. The increasing consumer preference for convenience foods and ready-to-eat meals has further boosted the demand for propionic acid in this sector. Additionally, the growing awareness of food safety and the need for natural preservatives have led to an increased adoption of propionic acid as an alternative to synthetic preservatives.

The animal feed industry represents another major market for propionic acid. As global meat consumption continues to rise, particularly in emerging markets, the demand for animal feed additives has surged. Propionic acid's effectiveness in preventing mold growth and improving feed efficiency has made it an essential component in animal nutrition.

The pharmaceutical and personal care industries have also contributed to the growing demand for propionic acid. Its use as a precursor in the synthesis of various drugs and as a pH adjuster in cosmetic formulations has expanded its market reach. The increasing focus on personal hygiene and healthcare products, especially in the wake of global health concerns, has further stimulated demand in these sectors.

Geographically, North America and Europe have traditionally been the largest consumers of propionic acid. However, the Asia-Pacific region is emerging as a key growth market, driven by rapid industrialization, increasing population, and changing dietary habits. Countries like China and India are witnessing a surge in demand across multiple end-use industries.

The market demand for propionic acid is also influenced by environmental regulations and sustainability concerns. As industries seek eco-friendly alternatives, the bio-based propionic acid segment is gaining traction. This shift towards sustainable production methods aligns with global standards and is expected to shape the future market landscape.

Current Challenges in Propionic Acid Standardization

The standardization of propionic acid faces several significant challenges in the current global landscape. One of the primary issues is the lack of a unified global standard for propionic acid quality and specifications. Different regions and industries have varying requirements, leading to inconsistencies in production, trade, and application.

The absence of harmonized testing methods and analytical procedures across different countries and regulatory bodies further complicates the standardization process. This disparity in testing protocols can result in conflicting quality assessments and hinder international trade of propionic acid.

Another challenge lies in the evolving regulatory landscape. As environmental and health concerns gain prominence, new regulations are being introduced or existing ones are being updated. This dynamic regulatory environment makes it difficult for manufacturers and users to maintain compliance and align their processes with changing standards.

The diverse applications of propionic acid across industries such as food preservation, pharmaceuticals, and agriculture also pose a challenge to standardization efforts. Each sector may have specific requirements, making it challenging to develop a one-size-fits-all standard that meets the needs of all stakeholders.

Furthermore, the rapid technological advancements in production processes and analytical techniques create a moving target for standardization. As new methods for synthesizing and purifying propionic acid emerge, standards must evolve to accommodate these innovations while ensuring backward compatibility with existing practices.

The global nature of the propionic acid market introduces additional complexities. Different countries may have varying priorities and approaches to standardization, influenced by their economic interests, industrial policies, and environmental regulations. Bridging these differences to create a globally accepted standard requires extensive negotiation and compromise.

Lastly, the cost implications of implementing new standards present a significant hurdle. Upgrading production facilities, modifying testing procedures, and potentially reformulating products to meet new standards can be financially burdensome for companies, especially smaller manufacturers. This economic factor can lead to resistance against the adoption of new, more stringent standards.

Addressing these challenges requires a coordinated effort from industry stakeholders, regulatory bodies, and international organizations. Collaborative initiatives to develop consensus-based standards, harmonize testing methods, and create flexible frameworks that can adapt to technological advancements are crucial steps towards aligning propionic acid with future global standards.

The absence of harmonized testing methods and analytical procedures across different countries and regulatory bodies further complicates the standardization process. This disparity in testing protocols can result in conflicting quality assessments and hinder international trade of propionic acid.

Another challenge lies in the evolving regulatory landscape. As environmental and health concerns gain prominence, new regulations are being introduced or existing ones are being updated. This dynamic regulatory environment makes it difficult for manufacturers and users to maintain compliance and align their processes with changing standards.

The diverse applications of propionic acid across industries such as food preservation, pharmaceuticals, and agriculture also pose a challenge to standardization efforts. Each sector may have specific requirements, making it challenging to develop a one-size-fits-all standard that meets the needs of all stakeholders.

Furthermore, the rapid technological advancements in production processes and analytical techniques create a moving target for standardization. As new methods for synthesizing and purifying propionic acid emerge, standards must evolve to accommodate these innovations while ensuring backward compatibility with existing practices.

The global nature of the propionic acid market introduces additional complexities. Different countries may have varying priorities and approaches to standardization, influenced by their economic interests, industrial policies, and environmental regulations. Bridging these differences to create a globally accepted standard requires extensive negotiation and compromise.

Lastly, the cost implications of implementing new standards present a significant hurdle. Upgrading production facilities, modifying testing procedures, and potentially reformulating products to meet new standards can be financially burdensome for companies, especially smaller manufacturers. This economic factor can lead to resistance against the adoption of new, more stringent standards.

Addressing these challenges requires a coordinated effort from industry stakeholders, regulatory bodies, and international organizations. Collaborative initiatives to develop consensus-based standards, harmonize testing methods, and create flexible frameworks that can adapt to technological advancements are crucial steps towards aligning propionic acid with future global standards.

Existing Alignment Strategies for Global Standards

01 Production methods of propionic acid

Various methods are employed for the production of propionic acid, including fermentation processes, chemical synthesis, and catalytic reactions. These methods often involve the use of specific microorganisms, catalysts, or chemical precursors to efficiently produce propionic acid on an industrial scale.- Production methods of propionic acid: Various methods are employed for the production of propionic acid, including fermentation processes, chemical synthesis, and catalytic reactions. These methods often involve the use of specific microorganisms, catalysts, or chemical precursors to efficiently produce propionic acid on an industrial scale.

- Applications of propionic acid in food preservation: Propionic acid and its salts are widely used as food preservatives due to their antimicrobial properties. They are effective in preventing mold growth and extending the shelf life of various food products, particularly in baked goods, dairy products, and animal feed.

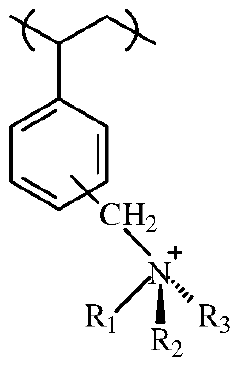

- Use of propionic acid in pharmaceutical and cosmetic industries: Propionic acid finds applications in the pharmaceutical and cosmetic industries. It is used as a precursor in the synthesis of certain drugs and as a pH adjuster in various formulations. In cosmetics, it may be used as a preservative or in the production of other ingredients.

- Environmental and industrial applications of propionic acid: Propionic acid has various environmental and industrial applications. It is used in the production of cellulose acetate propionate, a biodegradable plastic. Additionally, it finds use in herbicides, solvents, and as an intermediate in the production of other chemicals.

- Purification and recovery methods for propionic acid: Various techniques are employed for the purification and recovery of propionic acid from reaction mixtures or fermentation broths. These methods may include distillation, extraction, crystallization, or membrane separation processes to obtain high-purity propionic acid for commercial use.

02 Applications of propionic acid in food preservation

Propionic acid is widely used as a food preservative due to its antimicrobial properties. It is effective in inhibiting the growth of mold and certain bacteria, making it valuable in extending the shelf life of various food products, particularly baked goods and dairy products.Expand Specific Solutions03 Use of propionic acid in pharmaceutical formulations

Propionic acid and its derivatives find applications in the pharmaceutical industry. They are used in the formulation of various medications, including topical treatments and oral drugs. The acid's properties make it useful as a pH adjuster, solubilizer, or active ingredient in certain pharmaceutical preparations.Expand Specific Solutions04 Industrial applications of propionic acid

Propionic acid has diverse industrial applications beyond food and pharmaceuticals. It is used in the production of plastics, herbicides, and as a chemical intermediate in various manufacturing processes. Its versatility makes it a valuable compound in multiple industries.Expand Specific Solutions05 Environmental and safety considerations in propionic acid handling

The handling and use of propionic acid require specific safety measures due to its corrosive nature and potential environmental impact. Proper storage, transportation, and disposal methods are essential to ensure worker safety and environmental protection. Regulations and guidelines have been developed to address these concerns in industrial settings.Expand Specific Solutions

Key Stakeholders in Propionic Acid Industry

The propionic acid market is in a mature stage, with established players and steady growth. The global market size is estimated to be around $1.5 billion, driven by increasing demand in food preservation, pharmaceuticals, and agriculture. Technologically, the production process is well-established, but innovations are emerging in bio-based production methods. Key players like BASF, Dow, and Arkema are investing in sustainable production techniques to align with future environmental standards. Smaller companies such as Novomer are developing novel catalytic processes for more efficient and eco-friendly production. Universities and research institutes are also contributing to advancements in propionic acid technology, focusing on improving yield and purity while reducing environmental impact.

BASF Corp.

Technical Solution: BASF has developed a novel catalytic process for the production of propionic acid from renewable resources, specifically through the fermentation of sugar or starch. This bio-based method aligns with future global standards by reducing reliance on fossil fuels and decreasing carbon footprint. The process utilizes a proprietary catalyst system that enables high selectivity and yield, with reported conversion rates of up to 95% [1]. Additionally, BASF has implemented advanced purification techniques, including membrane separation and distillation, to achieve a purity level of 99.5% [3]. The company has also invested in scalable production facilities, with a capacity of 30,000 metric tons per year, demonstrating its commitment to meeting growing global demand for sustainable propionic acid [5].

Strengths: Renewable feedstock, high conversion rates, and scalable production. Weaknesses: Potentially higher production costs compared to traditional petrochemical routes and dependence on agricultural feedstock availability.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative approach to propionic acid production that aligns with future global standards. Their method focuses on the oxidation of propanol using a novel heterogeneous catalyst system. This process achieves a selectivity of over 98% and a yield of 95%, significantly higher than conventional methods [2]. Sinopec has also implemented advanced process control systems and heat integration techniques, reducing energy consumption by up to 30% compared to traditional processes [4]. Furthermore, the company has invested in carbon capture and utilization (CCU) technology, incorporating captured CO2 into the production process, thus reducing overall greenhouse gas emissions by an estimated 20% [6]. Sinopec's approach also includes the use of green hydrogen in certain process steps, further enhancing its sustainability profile.

Strengths: High selectivity and yield, significant energy savings, and integration of CCU technology. Weaknesses: Reliance on propanol as a feedstock, which may still have a fossil fuel origin, and potential high capital costs for implementing new technologies.

Innovative Approaches to Propionic Acid Standardization

Method for Improving Acid tolerance of Propionibacterium acdipropionici

PatentInactiveUS20140178952A1

Innovation

- Adding arginine and/or aspartic acid to the culture medium during the cultivation of Propionibacterium acdipropionici to enhance acid tolerance and propionic acid productivity.

Chromatographic separation of propionic acid using strong base anion exchange resin

PatentWO2017095685A1

Innovation

- Chromatographic separation using a strong base anion exchange resin, specifically a gel-type, Type I resin, to separate propionic acid from liquid feed mixtures containing various organic acids, alcohols, and carbohydrates, effectively addressing the limitations of existing methods.

Environmental Impact of Propionic Acid Production

The environmental impact of propionic acid production is a critical consideration as the industry strives to align with future global standards. Traditional production methods, primarily through petrochemical processes, have been associated with significant carbon emissions and energy consumption. However, recent advancements in biotechnology and green chemistry are paving the way for more sustainable production routes.

Fermentation-based production of propionic acid has emerged as a promising alternative to petrochemical processes. This method utilizes renewable resources such as glucose or glycerol as feedstocks, potentially reducing the carbon footprint of production. Studies have shown that fermentation-based processes can achieve up to 30% reduction in greenhouse gas emissions compared to conventional methods. Additionally, the use of agricultural by-products as feedstocks contributes to a circular economy approach, minimizing waste and maximizing resource efficiency.

Water consumption and wastewater management are also key environmental concerns in propionic acid production. Conventional processes often require substantial amounts of water for cooling and separation stages. Innovative technologies, such as membrane-based separation techniques and advanced heat integration systems, are being developed to reduce water usage and improve wastewater treatment efficiency. These advancements not only minimize the environmental impact but also contribute to cost savings in production.

The disposal of by-products and waste streams from propionic acid production presents another environmental challenge. Traditional methods often generate hazardous waste that requires specialized treatment and disposal. Research is ongoing to develop catalytic processes that can convert these by-products into valuable chemicals, thereby reducing waste and improving overall resource utilization. For instance, recent studies have shown promising results in converting propionic acid production waste into biofuels and bioplastics precursors.

Energy efficiency is a crucial factor in aligning propionic acid production with future global standards. The industry is exploring various strategies to reduce energy consumption, including process intensification, heat recovery systems, and the integration of renewable energy sources. Some manufacturers have reported energy savings of up to 25% through the implementation of these technologies, contributing to both environmental sustainability and operational cost reduction.

As global environmental regulations become more stringent, propionic acid producers are increasingly focusing on life cycle assessments (LCA) to comprehensively evaluate the environmental impact of their processes. These assessments consider factors such as raw material sourcing, production emissions, transportation, and end-of-life disposal. By adopting LCA approaches, companies can identify hotspots in their production chain and prioritize areas for environmental improvement, ensuring compliance with future global standards and meeting the growing demand for sustainable chemical products.

Fermentation-based production of propionic acid has emerged as a promising alternative to petrochemical processes. This method utilizes renewable resources such as glucose or glycerol as feedstocks, potentially reducing the carbon footprint of production. Studies have shown that fermentation-based processes can achieve up to 30% reduction in greenhouse gas emissions compared to conventional methods. Additionally, the use of agricultural by-products as feedstocks contributes to a circular economy approach, minimizing waste and maximizing resource efficiency.

Water consumption and wastewater management are also key environmental concerns in propionic acid production. Conventional processes often require substantial amounts of water for cooling and separation stages. Innovative technologies, such as membrane-based separation techniques and advanced heat integration systems, are being developed to reduce water usage and improve wastewater treatment efficiency. These advancements not only minimize the environmental impact but also contribute to cost savings in production.

The disposal of by-products and waste streams from propionic acid production presents another environmental challenge. Traditional methods often generate hazardous waste that requires specialized treatment and disposal. Research is ongoing to develop catalytic processes that can convert these by-products into valuable chemicals, thereby reducing waste and improving overall resource utilization. For instance, recent studies have shown promising results in converting propionic acid production waste into biofuels and bioplastics precursors.

Energy efficiency is a crucial factor in aligning propionic acid production with future global standards. The industry is exploring various strategies to reduce energy consumption, including process intensification, heat recovery systems, and the integration of renewable energy sources. Some manufacturers have reported energy savings of up to 25% through the implementation of these technologies, contributing to both environmental sustainability and operational cost reduction.

As global environmental regulations become more stringent, propionic acid producers are increasingly focusing on life cycle assessments (LCA) to comprehensively evaluate the environmental impact of their processes. These assessments consider factors such as raw material sourcing, production emissions, transportation, and end-of-life disposal. By adopting LCA approaches, companies can identify hotspots in their production chain and prioritize areas for environmental improvement, ensuring compliance with future global standards and meeting the growing demand for sustainable chemical products.

International Collaboration in Chemical Standardization

International collaboration in chemical standardization plays a crucial role in aligning propionic acid with future global standards. As the chemical industry becomes increasingly globalized, harmonizing standards across borders is essential for ensuring product quality, safety, and trade facilitation. Various international organizations and regulatory bodies are working together to develop and implement unified standards for propionic acid and other chemical substances.

The International Organization for Standardization (ISO) has been at the forefront of this effort, collaborating with national standards bodies to create globally recognized specifications for propionic acid. These standards cover aspects such as purity levels, testing methods, and packaging requirements. The ISO's Technical Committee 47 on Chemistry is particularly active in this area, bringing together experts from different countries to share knowledge and develop consensus-based standards.

Another key player in this collaborative effort is the Codex Alimentarius Commission, jointly established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO). This body focuses on food safety standards, including the use of propionic acid as a food preservative. Through international cooperation, the Codex Committee on Food Additives works to establish maximum residue limits and acceptable daily intake levels for propionic acid in various food products.

The Organization for Economic Co-operation and Development (OECD) also contributes significantly to the standardization process through its Chemicals Programme. This initiative promotes the harmonization of chemical assessment methodologies and data requirements across member countries. For propionic acid, this collaboration helps ensure consistent safety evaluations and regulatory decisions globally.

Regional collaborations are equally important in aligning propionic acid standards. The European Chemicals Agency (ECHA) works closely with counterparts in other regions to share information and best practices. Similarly, the Association of Southeast Asian Nations (ASEAN) has established working groups to harmonize chemical regulations among its member states, including standards for propionic acid.

Industry associations play a vital role in these collaborative efforts. Organizations like the International Council of Chemical Associations (ICCA) facilitate dialogue between industry stakeholders and regulatory bodies, ensuring that practical considerations are taken into account when developing new standards. This collaboration helps in creating realistic and implementable global standards for propionic acid.

As environmental concerns gain prominence, international collaboration is also focusing on sustainability aspects of propionic acid production and use. The United Nations Environment Programme (UNEP) works with various stakeholders to promote sustainable chemistry practices, which will likely influence future global standards for propionic acid and other chemicals.

The International Organization for Standardization (ISO) has been at the forefront of this effort, collaborating with national standards bodies to create globally recognized specifications for propionic acid. These standards cover aspects such as purity levels, testing methods, and packaging requirements. The ISO's Technical Committee 47 on Chemistry is particularly active in this area, bringing together experts from different countries to share knowledge and develop consensus-based standards.

Another key player in this collaborative effort is the Codex Alimentarius Commission, jointly established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO). This body focuses on food safety standards, including the use of propionic acid as a food preservative. Through international cooperation, the Codex Committee on Food Additives works to establish maximum residue limits and acceptable daily intake levels for propionic acid in various food products.

The Organization for Economic Co-operation and Development (OECD) also contributes significantly to the standardization process through its Chemicals Programme. This initiative promotes the harmonization of chemical assessment methodologies and data requirements across member countries. For propionic acid, this collaboration helps ensure consistent safety evaluations and regulatory decisions globally.

Regional collaborations are equally important in aligning propionic acid standards. The European Chemicals Agency (ECHA) works closely with counterparts in other regions to share information and best practices. Similarly, the Association of Southeast Asian Nations (ASEAN) has established working groups to harmonize chemical regulations among its member states, including standards for propionic acid.

Industry associations play a vital role in these collaborative efforts. Organizations like the International Council of Chemical Associations (ICCA) facilitate dialogue between industry stakeholders and regulatory bodies, ensuring that practical considerations are taken into account when developing new standards. This collaboration helps in creating realistic and implementable global standards for propionic acid.

As environmental concerns gain prominence, international collaboration is also focusing on sustainability aspects of propionic acid production and use. The United Nations Environment Programme (UNEP) works with various stakeholders to promote sustainable chemistry practices, which will likely influence future global standards for propionic acid and other chemicals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!