Propionic Acid Applications in Cutting-Edge Chemical Processes

JUL 3, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Propionic Acid Evolution

Propionic acid has undergone a significant evolution in its applications within cutting-edge chemical processes over the past decades. Initially used primarily as a food preservative and flavoring agent, its role has expanded dramatically across various industries.

In the early stages of its industrial use, propionic acid was mainly employed in the production of cellulose acetate propionate, a thermoplastic used in various consumer goods. As research progressed, its potential as an intermediate in the synthesis of pharmaceuticals and pesticides became apparent, leading to increased demand in these sectors.

The 1980s and 1990s saw a surge in propionic acid's use as a mold inhibitor in animal feed and grain storage. This application revolutionized the agricultural industry by significantly reducing feed spoilage and improving livestock health. Concurrently, its role in the production of herbicides expanded, contributing to more efficient crop management practices.

The turn of the millennium marked a new era for propionic acid in chemical processes. Its use in the production of propionic anhydride, a key component in many polymer formulations, gained traction. This development opened up new avenues in the plastics and coatings industries, where propionic acid derivatives found applications in everything from automotive parts to packaging materials.

In recent years, the focus has shifted towards more sustainable and environmentally friendly applications. Propionic acid has emerged as a promising platform chemical for the production of bio-based materials. Its fermentation from renewable resources has gained attention as a greener alternative to petrochemical-based production methods.

The pharmaceutical industry has also seen an increased use of propionic acid in the synthesis of various drugs, particularly those targeting metabolic disorders. Its role as a precursor in the production of vitamin E has further solidified its importance in the nutraceutical sector.

Looking ahead, the evolution of propionic acid applications is likely to continue in the direction of green chemistry and sustainable processes. Research is ongoing into its potential use in biodegradable plastics and as a building block for novel biomaterials. The development of more efficient catalytic processes for its production and transformation is expected to further expand its utility in cutting-edge chemical applications.

In the early stages of its industrial use, propionic acid was mainly employed in the production of cellulose acetate propionate, a thermoplastic used in various consumer goods. As research progressed, its potential as an intermediate in the synthesis of pharmaceuticals and pesticides became apparent, leading to increased demand in these sectors.

The 1980s and 1990s saw a surge in propionic acid's use as a mold inhibitor in animal feed and grain storage. This application revolutionized the agricultural industry by significantly reducing feed spoilage and improving livestock health. Concurrently, its role in the production of herbicides expanded, contributing to more efficient crop management practices.

The turn of the millennium marked a new era for propionic acid in chemical processes. Its use in the production of propionic anhydride, a key component in many polymer formulations, gained traction. This development opened up new avenues in the plastics and coatings industries, where propionic acid derivatives found applications in everything from automotive parts to packaging materials.

In recent years, the focus has shifted towards more sustainable and environmentally friendly applications. Propionic acid has emerged as a promising platform chemical for the production of bio-based materials. Its fermentation from renewable resources has gained attention as a greener alternative to petrochemical-based production methods.

The pharmaceutical industry has also seen an increased use of propionic acid in the synthesis of various drugs, particularly those targeting metabolic disorders. Its role as a precursor in the production of vitamin E has further solidified its importance in the nutraceutical sector.

Looking ahead, the evolution of propionic acid applications is likely to continue in the direction of green chemistry and sustainable processes. Research is ongoing into its potential use in biodegradable plastics and as a building block for novel biomaterials. The development of more efficient catalytic processes for its production and transformation is expected to further expand its utility in cutting-edge chemical applications.

Market Demand Analysis

The market demand for propionic acid in cutting-edge chemical processes has been steadily increasing, driven by its versatile applications across various industries. The global propionic acid market is projected to grow significantly in the coming years, with a compound annual growth rate (CAGR) exceeding 3% from 2021 to 2026.

One of the primary drivers of market demand is the food and beverage industry, where propionic acid is widely used as a preservative. With the growing consumer preference for natural and clean-label products, propionic acid's role as an effective antimicrobial agent has become increasingly important. This trend is particularly evident in the bakery sector, where propionic acid helps extend the shelf life of bread and other baked goods.

In the pharmaceutical industry, propionic acid is gaining traction as a key ingredient in the production of various medications and supplements. Its antimicrobial properties make it valuable in the formulation of topical ointments and creams. Additionally, propionic acid is used in the synthesis of certain active pharmaceutical ingredients, contributing to the overall growth of the market.

The agriculture sector represents another significant area of demand for propionic acid. Its application as a grain preservative has become crucial in reducing post-harvest losses and ensuring food security. As global food production continues to increase to meet the needs of a growing population, the demand for effective grain preservation solutions is expected to rise, further boosting the propionic acid market.

In the chemical industry, propionic acid serves as a vital intermediate in the production of various chemicals, including cellulose acetate propionate, herbicides, and plasticizers. The growing demand for these end-products, particularly in emerging economies, is driving the need for propionic acid in chemical processes.

The personal care and cosmetics industry is also contributing to the market growth of propionic acid. Its use as a pH adjuster and preservative in various skincare and haircare products aligns with the increasing consumer demand for effective and safe personal care items.

Environmental concerns and sustainability initiatives are influencing the market dynamics of propionic acid. As industries seek eco-friendly alternatives to traditional chemicals, propionic acid's biodegradability and lower environmental impact make it an attractive option in various applications, potentially opening up new market opportunities.

One of the primary drivers of market demand is the food and beverage industry, where propionic acid is widely used as a preservative. With the growing consumer preference for natural and clean-label products, propionic acid's role as an effective antimicrobial agent has become increasingly important. This trend is particularly evident in the bakery sector, where propionic acid helps extend the shelf life of bread and other baked goods.

In the pharmaceutical industry, propionic acid is gaining traction as a key ingredient in the production of various medications and supplements. Its antimicrobial properties make it valuable in the formulation of topical ointments and creams. Additionally, propionic acid is used in the synthesis of certain active pharmaceutical ingredients, contributing to the overall growth of the market.

The agriculture sector represents another significant area of demand for propionic acid. Its application as a grain preservative has become crucial in reducing post-harvest losses and ensuring food security. As global food production continues to increase to meet the needs of a growing population, the demand for effective grain preservation solutions is expected to rise, further boosting the propionic acid market.

In the chemical industry, propionic acid serves as a vital intermediate in the production of various chemicals, including cellulose acetate propionate, herbicides, and plasticizers. The growing demand for these end-products, particularly in emerging economies, is driving the need for propionic acid in chemical processes.

The personal care and cosmetics industry is also contributing to the market growth of propionic acid. Its use as a pH adjuster and preservative in various skincare and haircare products aligns with the increasing consumer demand for effective and safe personal care items.

Environmental concerns and sustainability initiatives are influencing the market dynamics of propionic acid. As industries seek eco-friendly alternatives to traditional chemicals, propionic acid's biodegradability and lower environmental impact make it an attractive option in various applications, potentially opening up new market opportunities.

Technical Challenges

The application of propionic acid in cutting-edge chemical processes faces several technical challenges that require innovative solutions. One of the primary obstacles is the corrosive nature of propionic acid, which can lead to equipment degradation and increased maintenance costs. This necessitates the development of advanced materials and coatings that can withstand prolonged exposure to the acid without compromising process efficiency or safety.

Another significant challenge lies in the purification and separation of propionic acid from reaction mixtures. Traditional distillation methods often result in azeotrope formation, making it difficult to achieve high purity levels required for certain applications. This has spurred research into novel separation techniques, such as reactive distillation and membrane-based processes, which show promise but still require optimization for large-scale implementation.

The energy-intensive nature of propionic acid production poses both economic and environmental challenges. Current manufacturing processes, particularly those based on petrochemical feedstocks, have a substantial carbon footprint. Developing more sustainable and energy-efficient production routes, possibly through bio-based fermentation or catalytic processes, is a key area of focus for researchers and industry professionals alike.

Catalyst design and optimization represent another critical technical hurdle. Existing catalysts for propionic acid synthesis and its derivatives often suffer from low selectivity, limited lifespan, and sensitivity to process conditions. Enhancing catalyst performance, particularly in terms of selectivity and stability, is crucial for improving overall process efficiency and reducing waste generation.

Scale-up and process integration challenges also persist, especially when incorporating propionic acid into novel chemical processes. Ensuring consistent product quality and process stability at industrial scales remains a significant technical barrier. This is particularly evident in emerging applications such as the production of biodegradable polymers or specialty chemicals, where precise control over reaction conditions is paramount.

Lastly, the development of in-situ monitoring and control systems for propionic acid-based processes presents a unique set of challenges. The aggressive nature of the acid complicates the use of conventional sensors and analytical techniques. Advances in real-time monitoring technologies, such as spectroscopic methods or advanced process analytical tools, are needed to enable better process control and quality assurance in cutting-edge applications.

Another significant challenge lies in the purification and separation of propionic acid from reaction mixtures. Traditional distillation methods often result in azeotrope formation, making it difficult to achieve high purity levels required for certain applications. This has spurred research into novel separation techniques, such as reactive distillation and membrane-based processes, which show promise but still require optimization for large-scale implementation.

The energy-intensive nature of propionic acid production poses both economic and environmental challenges. Current manufacturing processes, particularly those based on petrochemical feedstocks, have a substantial carbon footprint. Developing more sustainable and energy-efficient production routes, possibly through bio-based fermentation or catalytic processes, is a key area of focus for researchers and industry professionals alike.

Catalyst design and optimization represent another critical technical hurdle. Existing catalysts for propionic acid synthesis and its derivatives often suffer from low selectivity, limited lifespan, and sensitivity to process conditions. Enhancing catalyst performance, particularly in terms of selectivity and stability, is crucial for improving overall process efficiency and reducing waste generation.

Scale-up and process integration challenges also persist, especially when incorporating propionic acid into novel chemical processes. Ensuring consistent product quality and process stability at industrial scales remains a significant technical barrier. This is particularly evident in emerging applications such as the production of biodegradable polymers or specialty chemicals, where precise control over reaction conditions is paramount.

Lastly, the development of in-situ monitoring and control systems for propionic acid-based processes presents a unique set of challenges. The aggressive nature of the acid complicates the use of conventional sensors and analytical techniques. Advances in real-time monitoring technologies, such as spectroscopic methods or advanced process analytical tools, are needed to enable better process control and quality assurance in cutting-edge applications.

Current Applications

01 Production methods of propionic acid

Various methods are employed for the production of propionic acid, including fermentation processes, chemical synthesis, and catalytic reactions. These methods often involve the use of specific microorganisms, catalysts, or chemical precursors to efficiently produce propionic acid on an industrial scale.- Production methods of propionic acid: Various methods are employed for the production of propionic acid, including fermentation processes, chemical synthesis, and catalytic reactions. These methods often involve the use of specific microorganisms, catalysts, or chemical precursors to efficiently produce propionic acid on an industrial scale.

- Applications of propionic acid in food preservation: Propionic acid is widely used as a food preservative due to its antimicrobial properties. It is effective in preventing mold growth and extending the shelf life of various food products, particularly in baked goods, dairy products, and animal feed.

- Use of propionic acid in pharmaceutical industry: Propionic acid and its derivatives find applications in the pharmaceutical industry. They are used in the synthesis of various drugs, as intermediates in the production of active pharmaceutical ingredients, and in some cases, as therapeutic agents themselves.

- Environmental and industrial applications of propionic acid: Propionic acid is utilized in various environmental and industrial applications. These include its use as a chemical intermediate in the production of plastics, herbicides, and other industrial chemicals. It also finds applications in wastewater treatment and as a de-icing agent.

- Purification and analysis methods for propionic acid: Various techniques are employed for the purification and analysis of propionic acid. These methods are crucial for ensuring the quality and purity of propionic acid for different applications. They may include distillation, chromatography, and spectroscopic techniques for both purification and analytical purposes.

02 Applications of propionic acid in food preservation

Propionic acid and its salts are widely used as food preservatives due to their antimicrobial properties. They are effective in preventing mold growth and extending the shelf life of various food products, particularly in bakery items and dairy products.Expand Specific Solutions03 Use of propionic acid in pharmaceutical formulations

Propionic acid and its derivatives find applications in the pharmaceutical industry. They are used in the formulation of various medications, including topical treatments and oral drugs, due to their antimicrobial properties and ability to enhance drug absorption.Expand Specific Solutions04 Propionic acid in agricultural applications

Propionic acid is utilized in agriculture for various purposes, including as a feed preservative for livestock and as a component in herbicides and fungicides. It helps in maintaining the quality of animal feed and controlling plant diseases in crops.Expand Specific Solutions05 Environmental and safety considerations in propionic acid handling

The production, storage, and use of propionic acid require careful consideration of environmental and safety factors. This includes proper handling techniques, waste management, and the development of environmentally friendly production methods to minimize ecological impact and ensure worker safety.Expand Specific Solutions

Industry Leaders

The propionic acid applications market in cutting-edge chemical processes is in a growth phase, driven by increasing demand across various industries. The market size is expanding, with major players like BASF, Eastman Chemical, and Dow Chemical leading the way. Technological advancements are pushing the market towards maturity, with companies like China Petroleum & Chemical Corp. and PetroChina investing in research and development. Academic institutions such as Nanjing Tech University and The University of Queensland are contributing to innovation in this field, enhancing the overall technological maturity. The competitive landscape is diverse, with both established chemical companies and specialized firms like Membrane Technology & Research participating in the market.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced catalytic processes for propionic acid production from ethylene and carbon monoxide. Their technology utilizes a novel rhodium-based catalyst system that achieves high selectivity and yield[1]. The process operates under milder conditions compared to traditional methods, with temperatures around 150-200°C and pressures of 30-50 bar[3]. Sinopec has also implemented an innovative separation and purification system, employing reactive distillation to enhance product purity while reducing energy consumption[5]. Additionally, they have explored the integration of propionic acid production with their existing petrochemical operations, creating synergies in feedstock supply and utility usage[7].

Strengths: Integrated production with existing petrochemical infrastructure, advanced catalyst technology, and energy-efficient purification. Weaknesses: Reliance on fossil fuel-based feedstocks and potential environmental concerns associated with large-scale chemical production.

Eastman Chemical Co.

Technical Solution: Eastman Chemical Co. has pioneered a bio-based route for propionic acid production using renewable feedstocks. Their process employs genetically engineered microorganisms to ferment sugar-rich biomass, primarily corn-based glucose[2]. The company has optimized the fermentation conditions to achieve productivity rates of up to 2.5 g/L/h[4]. Eastman has also developed a proprietary downstream processing technique that combines membrane filtration and electrodialysis to efficiently separate and purify the propionic acid[6]. This approach significantly reduces the environmental footprint compared to traditional petrochemical routes. Furthermore, Eastman has explored the use of propionic acid in advanced polymer applications, particularly in biodegradable plastics and specialty coatings[8].

Strengths: Sustainable bio-based production, reduced carbon footprint, and integration with advanced materials development. Weaknesses: Potential competition for agricultural resources and sensitivity to feedstock price fluctuations.

Key Innovations

Methods for producing propionic acid

PatentWO2024226289A1

Innovation

- A method involving the dehydration of 3-hydroxypropionic acid to form acrylic acid using a first catalyst, followed by hydrogenation of acrylic acid to propionic acid using a second catalyst, with specific temperature and pressure conditions, and optionally using a polymerization inhibitor to prevent acrylic acid polymerization.

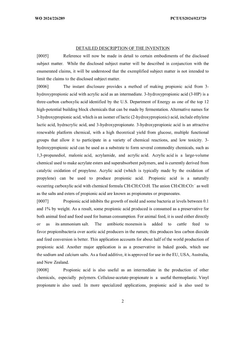

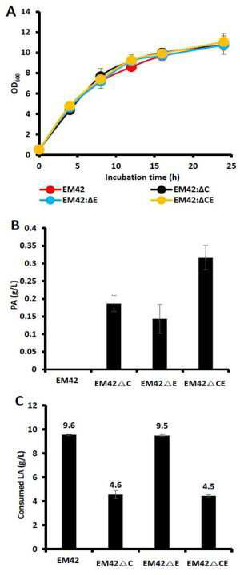

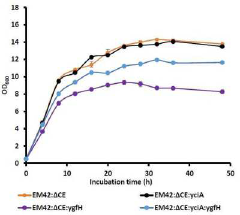

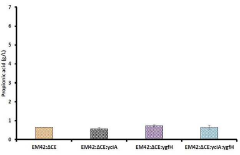

Bioproduction of Propionic Acid from Levulinic Acid by Utilizing Recombinant Pseudomonas putida

PatentInactiveKR1020240029628A

Innovation

- A transgenic Pseudomonas putida strain is developed by deleting prpC and prpE genes and expressing yciA and ygfH genes, utilizing levulinic acid as a substrate to enhance propionic acid production through a levulinic acid-inducible expression system, optimizing the metabolic pathway to improve titer and yield.

Environmental Impact

The environmental impact of propionic acid applications in cutting-edge chemical processes is a critical consideration for sustainable industrial development. As the use of propionic acid expands in various sectors, it is essential to assess its ecological footprint and potential consequences on ecosystems.

One of the primary environmental concerns associated with propionic acid production is the emission of greenhouse gases. Traditional manufacturing methods often rely on petrochemical feedstocks, contributing to carbon dioxide emissions. However, recent advancements in bio-based production techniques offer promising alternatives with reduced carbon footprints. These innovative approaches utilize renewable resources and fermentation processes, potentially mitigating the environmental impact of propionic acid production.

Water pollution is another significant environmental factor to consider. Propionic acid and its derivatives can contaminate water sources if not properly managed during production, transportation, or application processes. Implementing robust wastewater treatment systems and adopting closed-loop manufacturing practices are crucial steps in minimizing the risk of water pollution and protecting aquatic ecosystems.

The use of propionic acid in agricultural applications, particularly as a feed preservative, raises concerns about soil and groundwater contamination. While propionic acid is biodegradable, its widespread use may lead to accumulation in soil and potential leaching into groundwater. Careful monitoring and controlled application are necessary to prevent adverse effects on soil microbiota and maintain overall soil health.

On the positive side, propionic acid's antimicrobial properties contribute to food preservation and reduction of food waste. This indirect environmental benefit helps conserve resources and reduce the carbon footprint associated with food production and disposal. Additionally, the use of propionic acid in biofuels and green solvents aligns with the global shift towards more sustainable chemical processes.

The environmental impact of propionic acid extends to air quality as well. Volatile organic compound (VOC) emissions during production and application processes can contribute to air pollution and smog formation. Implementing advanced emission control technologies and optimizing production processes are essential for minimizing these air quality impacts.

As the chemical industry continues to evolve, life cycle assessments (LCAs) of propionic acid applications become increasingly important. These comprehensive analyses help identify environmental hotspots throughout the product's life cycle, from raw material extraction to end-of-life disposal. By conducting thorough LCAs, industries can make informed decisions to improve the overall environmental performance of propionic acid-based processes and products.

One of the primary environmental concerns associated with propionic acid production is the emission of greenhouse gases. Traditional manufacturing methods often rely on petrochemical feedstocks, contributing to carbon dioxide emissions. However, recent advancements in bio-based production techniques offer promising alternatives with reduced carbon footprints. These innovative approaches utilize renewable resources and fermentation processes, potentially mitigating the environmental impact of propionic acid production.

Water pollution is another significant environmental factor to consider. Propionic acid and its derivatives can contaminate water sources if not properly managed during production, transportation, or application processes. Implementing robust wastewater treatment systems and adopting closed-loop manufacturing practices are crucial steps in minimizing the risk of water pollution and protecting aquatic ecosystems.

The use of propionic acid in agricultural applications, particularly as a feed preservative, raises concerns about soil and groundwater contamination. While propionic acid is biodegradable, its widespread use may lead to accumulation in soil and potential leaching into groundwater. Careful monitoring and controlled application are necessary to prevent adverse effects on soil microbiota and maintain overall soil health.

On the positive side, propionic acid's antimicrobial properties contribute to food preservation and reduction of food waste. This indirect environmental benefit helps conserve resources and reduce the carbon footprint associated with food production and disposal. Additionally, the use of propionic acid in biofuels and green solvents aligns with the global shift towards more sustainable chemical processes.

The environmental impact of propionic acid extends to air quality as well. Volatile organic compound (VOC) emissions during production and application processes can contribute to air pollution and smog formation. Implementing advanced emission control technologies and optimizing production processes are essential for minimizing these air quality impacts.

As the chemical industry continues to evolve, life cycle assessments (LCAs) of propionic acid applications become increasingly important. These comprehensive analyses help identify environmental hotspots throughout the product's life cycle, from raw material extraction to end-of-life disposal. By conducting thorough LCAs, industries can make informed decisions to improve the overall environmental performance of propionic acid-based processes and products.

Regulatory Framework

The regulatory framework surrounding propionic acid applications in cutting-edge chemical processes is complex and multifaceted, reflecting the diverse uses of this compound across various industries. At the international level, organizations such as the World Health Organization (WHO) and the Food and Agriculture Organization (FAO) have established guidelines for the safe use of propionic acid in food preservation and animal feed applications.

In the United States, the Food and Drug Administration (FDA) regulates propionic acid under the Federal Food, Drug, and Cosmetic Act. It is classified as Generally Recognized as Safe (GRAS) for use as a food additive and preservative. The Environmental Protection Agency (EPA) also oversees its use in pesticides and antimicrobial applications, with specific regulations outlined in the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA).

The European Union has implemented stringent regulations through the European Food Safety Authority (EFSA) and the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) program. These frameworks ensure the safe use of propionic acid in food, feed, and industrial applications while minimizing environmental and health risks.

In emerging applications, such as the production of biodegradable plastics and advanced materials, regulatory bodies are adapting their frameworks to address new challenges. For instance, the use of propionic acid in the synthesis of cellulose-based materials for biomedical applications is subject to rigorous safety assessments and quality control measures.

The chemical industry's self-regulation also plays a crucial role in ensuring responsible use of propionic acid. Organizations like the American Chemistry Council (ACC) and the European Chemical Industry Council (CEFIC) have developed voluntary initiatives and best practices for handling and using propionic acid in industrial processes.

As research into novel applications of propionic acid continues, regulatory agencies are working to stay ahead of potential risks and benefits. This includes ongoing toxicological studies, environmental impact assessments, and the development of new analytical methods for detecting and measuring propionic acid in various matrices.

The global nature of the chemical industry necessitates harmonization of regulatory approaches. Efforts are underway to align standards and regulations across different regions, facilitating international trade while maintaining high safety and quality standards. This includes initiatives like the Globally Harmonized System of Classification and Labelling of Chemicals (GHS), which aims to standardize hazard communication worldwide.

In the United States, the Food and Drug Administration (FDA) regulates propionic acid under the Federal Food, Drug, and Cosmetic Act. It is classified as Generally Recognized as Safe (GRAS) for use as a food additive and preservative. The Environmental Protection Agency (EPA) also oversees its use in pesticides and antimicrobial applications, with specific regulations outlined in the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA).

The European Union has implemented stringent regulations through the European Food Safety Authority (EFSA) and the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) program. These frameworks ensure the safe use of propionic acid in food, feed, and industrial applications while minimizing environmental and health risks.

In emerging applications, such as the production of biodegradable plastics and advanced materials, regulatory bodies are adapting their frameworks to address new challenges. For instance, the use of propionic acid in the synthesis of cellulose-based materials for biomedical applications is subject to rigorous safety assessments and quality control measures.

The chemical industry's self-regulation also plays a crucial role in ensuring responsible use of propionic acid. Organizations like the American Chemistry Council (ACC) and the European Chemical Industry Council (CEFIC) have developed voluntary initiatives and best practices for handling and using propionic acid in industrial processes.

As research into novel applications of propionic acid continues, regulatory agencies are working to stay ahead of potential risks and benefits. This includes ongoing toxicological studies, environmental impact assessments, and the development of new analytical methods for detecting and measuring propionic acid in various matrices.

The global nature of the chemical industry necessitates harmonization of regulatory approaches. Efforts are underway to align standards and regulations across different regions, facilitating international trade while maintaining high safety and quality standards. This includes initiatives like the Globally Harmonized System of Classification and Labelling of Chemicals (GHS), which aims to standardize hazard communication worldwide.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!