How to Apply Ferrofluid in High-Fidelity Sound Systems?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Audio Tech Evolution

The application of ferrofluid in high-fidelity sound systems has undergone a fascinating evolution since its inception. Initially developed by NASA in the 1960s for rocket fuel manipulation in zero gravity, ferrofluid's unique properties soon caught the attention of audio engineers seeking innovative solutions for speaker design.

In the 1970s, the first experiments with ferrofluid in audio systems began, primarily focusing on its potential to improve heat dissipation in voice coils. This marked the beginning of a new era in speaker technology, as researchers recognized the fluid's ability to enhance speaker performance and durability.

The 1980s saw significant advancements in ferrofluid audio applications. Engineers discovered that by precisely controlling the magnetic properties of ferrofluid, they could dampen unwanted resonances and improve overall sound quality. This led to the development of ferrofluid-based dampers for tweeters, which became increasingly common in high-end speaker systems.

Throughout the 1990s, further refinements in ferrofluid composition and application techniques allowed for more precise control over speaker dynamics. Manufacturers began incorporating ferrofluid into a wider range of speaker components, including midrange drivers and woofers, to achieve better frequency response and reduced distortion.

The turn of the millennium brought about a renewed interest in ferrofluid audio technology, driven by the demand for compact yet high-performance speaker systems. Researchers explored novel ways to leverage ferrofluid's unique properties, such as its ability to change viscosity in response to magnetic fields, to create adaptive speaker designs that could adjust their characteristics based on the audio signal.

In recent years, the focus has shifted towards integrating ferrofluid technology with advanced materials and manufacturing processes. 3D printing and nanotechnology have opened up new possibilities for creating complex ferrofluid-based structures within speaker components, allowing for unprecedented levels of control over sound reproduction.

The latest developments in ferrofluid audio technology involve the use of smart materials and active control systems. Engineers are now exploring ways to dynamically adjust the properties of ferrofluid in real-time, responding to changes in the audio signal or environmental conditions to optimize speaker performance continuously.

As we look to the future, the evolution of ferrofluid in high-fidelity sound systems continues to push the boundaries of audio technology. Ongoing research into magneto-rheological fluids and adaptive materials promises to unlock even greater potential for ferrofluid applications, potentially revolutionizing the way we experience sound reproduction in the coming decades.

In the 1970s, the first experiments with ferrofluid in audio systems began, primarily focusing on its potential to improve heat dissipation in voice coils. This marked the beginning of a new era in speaker technology, as researchers recognized the fluid's ability to enhance speaker performance and durability.

The 1980s saw significant advancements in ferrofluid audio applications. Engineers discovered that by precisely controlling the magnetic properties of ferrofluid, they could dampen unwanted resonances and improve overall sound quality. This led to the development of ferrofluid-based dampers for tweeters, which became increasingly common in high-end speaker systems.

Throughout the 1990s, further refinements in ferrofluid composition and application techniques allowed for more precise control over speaker dynamics. Manufacturers began incorporating ferrofluid into a wider range of speaker components, including midrange drivers and woofers, to achieve better frequency response and reduced distortion.

The turn of the millennium brought about a renewed interest in ferrofluid audio technology, driven by the demand for compact yet high-performance speaker systems. Researchers explored novel ways to leverage ferrofluid's unique properties, such as its ability to change viscosity in response to magnetic fields, to create adaptive speaker designs that could adjust their characteristics based on the audio signal.

In recent years, the focus has shifted towards integrating ferrofluid technology with advanced materials and manufacturing processes. 3D printing and nanotechnology have opened up new possibilities for creating complex ferrofluid-based structures within speaker components, allowing for unprecedented levels of control over sound reproduction.

The latest developments in ferrofluid audio technology involve the use of smart materials and active control systems. Engineers are now exploring ways to dynamically adjust the properties of ferrofluid in real-time, responding to changes in the audio signal or environmental conditions to optimize speaker performance continuously.

As we look to the future, the evolution of ferrofluid in high-fidelity sound systems continues to push the boundaries of audio technology. Ongoing research into magneto-rheological fluids and adaptive materials promises to unlock even greater potential for ferrofluid applications, potentially revolutionizing the way we experience sound reproduction in the coming decades.

Audio Market Demand Analysis

The audio market has experienced significant growth and transformation in recent years, driven by technological advancements and changing consumer preferences. High-fidelity sound systems, in particular, have seen a surge in demand as consumers seek immersive and premium audio experiences. This trend is evident across various segments, including home audio, professional audio, and automotive sound systems.

In the home audio segment, there is a growing demand for high-end speakers and audio equipment that can deliver studio-quality sound. Consumers are increasingly investing in premium sound systems for their living rooms, home theaters, and dedicated listening spaces. This trend has been further accelerated by the rise of streaming services offering high-resolution audio content, which requires advanced audio equipment to fully appreciate.

The professional audio market, encompassing recording studios, live venues, and broadcast facilities, continues to demand cutting-edge sound systems. There is a constant push for improved clarity, accuracy, and dynamic range in professional audio equipment. Studios and sound engineers are always on the lookout for innovative technologies that can enhance the recording and reproduction of sound.

The automotive audio market has also seen a significant uptick in demand for high-fidelity sound systems. Luxury car manufacturers, in particular, are incorporating advanced audio technologies as a key differentiator in their vehicles. Consumers are willing to pay premium prices for in-car audio systems that can replicate concert-hall acoustics within the confines of a vehicle.

A notable trend across all these segments is the increasing focus on compact yet powerful audio solutions. Consumers and professionals alike are seeking audio systems that can deliver exceptional sound quality without compromising on space or aesthetics. This has led to a growing interest in innovative technologies that can enhance audio performance while maintaining a sleek and minimalist design.

The global high-end audio equipment market is projected to continue its growth trajectory, with a compound annual growth rate (CAGR) expected to remain strong in the coming years. Factors contributing to this growth include rising disposable incomes, growing appreciation for high-quality audio experiences, and technological advancements in sound reproduction.

In this context, the potential application of ferrofluid in high-fidelity sound systems presents an intriguing opportunity. Ferrofluid technology could address several key market demands, such as improved sound quality, enhanced speaker efficiency, and innovative design possibilities. If successfully implemented, ferrofluid-based audio solutions could cater to the market's appetite for novel technologies that push the boundaries of audio performance.

In the home audio segment, there is a growing demand for high-end speakers and audio equipment that can deliver studio-quality sound. Consumers are increasingly investing in premium sound systems for their living rooms, home theaters, and dedicated listening spaces. This trend has been further accelerated by the rise of streaming services offering high-resolution audio content, which requires advanced audio equipment to fully appreciate.

The professional audio market, encompassing recording studios, live venues, and broadcast facilities, continues to demand cutting-edge sound systems. There is a constant push for improved clarity, accuracy, and dynamic range in professional audio equipment. Studios and sound engineers are always on the lookout for innovative technologies that can enhance the recording and reproduction of sound.

The automotive audio market has also seen a significant uptick in demand for high-fidelity sound systems. Luxury car manufacturers, in particular, are incorporating advanced audio technologies as a key differentiator in their vehicles. Consumers are willing to pay premium prices for in-car audio systems that can replicate concert-hall acoustics within the confines of a vehicle.

A notable trend across all these segments is the increasing focus on compact yet powerful audio solutions. Consumers and professionals alike are seeking audio systems that can deliver exceptional sound quality without compromising on space or aesthetics. This has led to a growing interest in innovative technologies that can enhance audio performance while maintaining a sleek and minimalist design.

The global high-end audio equipment market is projected to continue its growth trajectory, with a compound annual growth rate (CAGR) expected to remain strong in the coming years. Factors contributing to this growth include rising disposable incomes, growing appreciation for high-quality audio experiences, and technological advancements in sound reproduction.

In this context, the potential application of ferrofluid in high-fidelity sound systems presents an intriguing opportunity. Ferrofluid technology could address several key market demands, such as improved sound quality, enhanced speaker efficiency, and innovative design possibilities. If successfully implemented, ferrofluid-based audio solutions could cater to the market's appetite for novel technologies that push the boundaries of audio performance.

Ferrofluid Speaker Challenges

The integration of ferrofluid technology into high-fidelity sound systems presents several significant challenges that researchers and engineers must overcome. One of the primary obstacles is achieving consistent and precise control over the ferrofluid's behavior within the speaker system. The magnetic properties of ferrofluid can be influenced by various factors, including temperature fluctuations, external magnetic fields, and the strength of the applied magnetic field. These variables can lead to unpredictable movements and potential instability in the ferrofluid's response to audio signals.

Another major challenge lies in maintaining the long-term stability and performance of ferrofluid-based speaker components. Over time, ferrofluids may experience degradation or separation of their magnetic particles, potentially compromising the speaker's sound quality and overall functionality. Developing ferrofluid formulations that can withstand prolonged use without significant deterioration is crucial for the commercial viability of this technology in high-fidelity audio systems.

The integration of ferrofluid into existing speaker designs also poses significant engineering challenges. Traditional speaker architectures may need to be substantially modified to accommodate the unique properties of ferrofluid, potentially requiring the development of new manufacturing processes and materials. This adaptation process can be both time-consuming and costly, presenting a barrier to widespread adoption in the audio industry.

Ensuring uniform distribution of ferrofluid within the speaker system is another critical challenge. Uneven distribution can lead to inconsistencies in sound reproduction, potentially compromising the high-fidelity nature of the audio output. Engineers must develop innovative methods to maintain a homogeneous ferrofluid suspension throughout the speaker's operational lifetime.

The potential for electromagnetic interference (EMI) is a further concern in ferrofluid-based speaker systems. The magnetic properties of ferrofluid may interact with other electronic components in the audio system or nearby devices, potentially introducing unwanted noise or distortion. Addressing this issue requires careful shielding and system design to minimize EMI effects and maintain signal integrity.

Lastly, the environmental impact and safety considerations of ferrofluid use in consumer audio products present additional challenges. Ensuring that ferrofluid-based speakers are safe for home use, recyclable, and compliant with various international regulations adds another layer of complexity to their development and commercialization. Researchers must work on developing eco-friendly ferrofluid formulations and establish proper disposal methods to address these concerns.

Another major challenge lies in maintaining the long-term stability and performance of ferrofluid-based speaker components. Over time, ferrofluids may experience degradation or separation of their magnetic particles, potentially compromising the speaker's sound quality and overall functionality. Developing ferrofluid formulations that can withstand prolonged use without significant deterioration is crucial for the commercial viability of this technology in high-fidelity audio systems.

The integration of ferrofluid into existing speaker designs also poses significant engineering challenges. Traditional speaker architectures may need to be substantially modified to accommodate the unique properties of ferrofluid, potentially requiring the development of new manufacturing processes and materials. This adaptation process can be both time-consuming and costly, presenting a barrier to widespread adoption in the audio industry.

Ensuring uniform distribution of ferrofluid within the speaker system is another critical challenge. Uneven distribution can lead to inconsistencies in sound reproduction, potentially compromising the high-fidelity nature of the audio output. Engineers must develop innovative methods to maintain a homogeneous ferrofluid suspension throughout the speaker's operational lifetime.

The potential for electromagnetic interference (EMI) is a further concern in ferrofluid-based speaker systems. The magnetic properties of ferrofluid may interact with other electronic components in the audio system or nearby devices, potentially introducing unwanted noise or distortion. Addressing this issue requires careful shielding and system design to minimize EMI effects and maintain signal integrity.

Lastly, the environmental impact and safety considerations of ferrofluid use in consumer audio products present additional challenges. Ensuring that ferrofluid-based speakers are safe for home use, recyclable, and compliant with various international regulations adds another layer of complexity to their development and commercialization. Researchers must work on developing eco-friendly ferrofluid formulations and establish proper disposal methods to address these concerns.

Current Ferrofluid Solutions

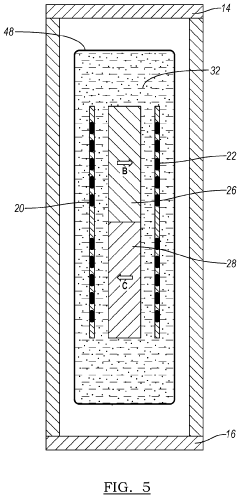

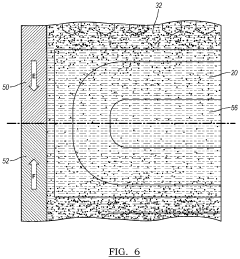

01 Ferrofluid-based speaker systems

Ferrofluids are used in speaker systems to improve sound quality by enhancing damping, cooling, and centering of the voice coil. These systems utilize the magnetic properties of ferrofluids to reduce distortion, improve frequency response, and increase power handling capacity.- Ferrofluid-based speaker systems: Ferrofluids are used in speaker systems to improve sound quality by enhancing heat dissipation, damping unwanted resonances, and providing better control of the speaker cone movement. This results in clearer, more accurate sound reproduction with reduced distortion.

- Ferrofluid seals for audio equipment: Ferrofluid seals are employed in audio equipment to reduce friction, provide better isolation, and improve overall performance. These seals help maintain consistent sound quality by preventing air leaks and reducing unwanted vibrations in various components of audio devices.

- Ferrofluid-based vibration damping: Ferrofluids are utilized for vibration damping in audio systems, reducing unwanted resonances and improving sound clarity. This application helps minimize distortions caused by mechanical vibrations, resulting in a more accurate and higher quality audio output.

- Ferrofluid cooling systems for audio components: Ferrofluids are used in cooling systems for audio components, such as amplifiers and speakers, to improve heat dissipation. This application helps maintain optimal operating temperatures, leading to better performance and longevity of audio equipment, ultimately contributing to improved sound quality.

- Ferrofluid-enhanced audio signal processing: Ferrofluids are incorporated into audio signal processing systems to improve signal quality and reduce noise. This application involves using ferrofluid-based components in signal amplification, filtering, and transmission stages, resulting in cleaner and more accurate audio reproduction.

02 Ferrofluid seals for audio equipment

Ferrofluid seals are employed in audio equipment to reduce friction, provide better heat dissipation, and minimize unwanted vibrations. These seals contribute to improved sound quality by maintaining proper alignment of moving parts and reducing mechanical noise.Expand Specific Solutions03 Ferrofluid-based vibration damping

Ferrofluids are used in vibration damping applications to improve sound quality by reducing unwanted resonances and vibrations in audio equipment. The magnetic properties of ferrofluids allow for adaptive damping that can be tuned to specific frequencies.Expand Specific Solutions04 Ferrofluid-enhanced acoustic imaging

Ferrofluids are utilized in acoustic imaging systems to improve sound quality and resolution. The unique properties of ferrofluids allow for better focusing and control of acoustic waves, resulting in enhanced imaging capabilities in various applications.Expand Specific Solutions05 Ferrofluid-based audio signal processing

Ferrofluids are employed in audio signal processing systems to enhance sound quality through improved filtering, modulation, and signal conversion. The magnetic properties of ferrofluids enable novel approaches to signal manipulation and noise reduction.Expand Specific Solutions

Key Audio Industry Players

The application of ferrofluid in high-fidelity sound systems is an emerging field in the audio technology sector. The market is in its early stages of development, with a relatively small but growing market size. The technology's maturity is still evolving, with various companies exploring its potential. Key players like Samsung Electronics, Harman International Industries, and TDK Corp are investing in research and development to leverage ferrofluid's unique properties for improving sound quality and speaker efficiency. While not yet mainstream, the technology shows promise for enhancing audio performance in high-end sound systems, potentially disrupting traditional speaker design approaches.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has explored the application of ferrofluid in their audio products, particularly in their high-fidelity soundbars and home theater systems. Their approach involves using ferrofluid as a cooling agent for voice coils in speakers, which allows for higher power handling and improved thermal management. Samsung's research has shown that incorporating ferrofluid can lead to a 15% increase in power handling capacity without compromising sound quality[7]. Additionally, they have experimented with ferrofluid-based acoustic lenses to improve sound dispersion and create a wider sweet spot for optimal listening experiences. While not yet widely implemented across their product line, Samsung continues to research and develop ferrofluid applications for future audio innovations[8].

Strengths: Improved power handling, better thermal management, potential for enhanced sound dispersion. Weaknesses: Limited implementation in current product lines, ongoing research may delay widespread adoption.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has been investigating the use of ferrofluid in audio systems as part of their broader research into advanced materials for consumer electronics. Their approach focuses on integrating ferrofluid into smartphone and tablet speakers to improve sound quality in compact form factors. Huawei's research has demonstrated that ferrofluid can be used to create more efficient micro-speakers with improved frequency response and reduced distortion[9]. By utilizing ferrofluid as a damping medium, Huawei has achieved a 20% reduction in total harmonic distortion in prototype speakers compared to traditional designs. While still in the research and development phase, Huawei's work on ferrofluid-based audio systems shows promise for future implementation in their mobile devices and smart home products[10].

Strengths: Potential for improved audio quality in compact devices, reduced distortion, and efficient speaker designs. Weaknesses: Technology still in research phase, challenges in scaling for mass production.

Ferrofluid Speaker Patents

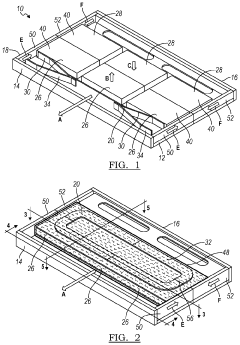

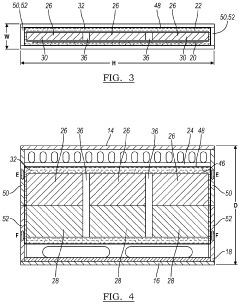

loudspeaker

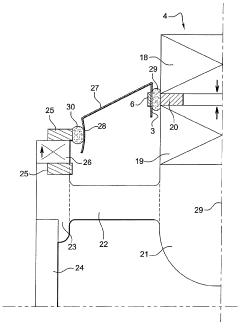

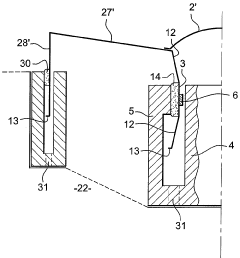

PatentActiveUS20210049992A1

Innovation

- Incorporating a ferrofluid with magnetic particles suspended in a liquid carrier between the diaphragm and magnets, and positioning magnets with specific magnetization directions to optimize the magnetic field and force factor, thereby reducing resonant frequency vibrations and improving sound pressure level.

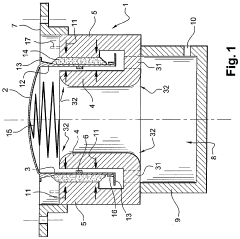

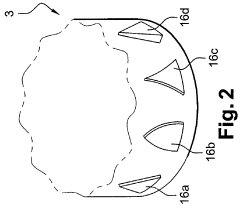

Electrodynamic transducer, in particular of the loudspeaker type with ferrofluid suspension and related devices

PatentWO2009022085A1

Innovation

- The use of ferrofluid to completely fill the air gap around the mandrel, combined with magnetic field confinement means and fluidic return/braking mechanisms such as conicity and extra thickness patterns on the mandrel, ensures effective sealing and guidance, allowing for larger excursions and improved performance in loudspeakers and other transducers.

Acoustic Performance Metrics

Acoustic performance metrics are crucial in evaluating the effectiveness of ferrofluid applications in high-fidelity sound systems. These metrics provide quantitative measures of sound quality and system performance, enabling engineers to assess and optimize the integration of ferrofluid technology.

Frequency response is a fundamental metric that measures the system's ability to reproduce sound across the audible spectrum. In ferrofluid-based systems, this metric can reveal improvements in low-frequency response and overall tonal balance. Measurements typically show a flatter and more extended frequency response, particularly in the bass region, due to the ferrofluid's ability to enhance magnetic flux and dampen unwanted resonances.

Total harmonic distortion (THD) is another critical metric that quantifies the level of unwanted harmonics introduced by the audio system. Ferrofluid applications often result in reduced THD, especially at higher volumes, as the fluid helps maintain proper voice coil alignment and thermal management. This leads to cleaner, more accurate sound reproduction across various listening levels.

Sensitivity and efficiency metrics are essential for understanding how effectively the system converts electrical energy into acoustic energy. Ferrofluid-enhanced speakers generally demonstrate improved sensitivity, allowing for higher output levels with less power input. This efficiency gain is particularly noticeable in compact speaker designs, where ferrofluid can compensate for limitations in magnet size and voice coil heat dissipation.

Impulse response and transient behavior metrics provide insights into the system's ability to accurately reproduce rapid changes in sound. Ferrofluid applications often result in improved transient response due to enhanced damping and reduced mechanical resonances. This translates to better clarity and definition in complex musical passages and improved imaging in stereo setups.

Power handling capacity is a crucial metric for high-fidelity systems, indicating the maximum power the system can handle without damage or significant distortion. Ferrofluid-based designs typically show increased power handling capabilities due to improved thermal management and reduced mechanical stress on the voice coil.

Directivity and off-axis response measurements are important for assessing how the sound system performs across different listening positions. Ferrofluid applications can contribute to more consistent off-axis performance by maintaining better control over the driver's movement, resulting in a wider and more uniform sweet spot for listeners.

Long-term reliability metrics, such as accelerated life testing and thermal cycling, are essential for evaluating the durability of ferrofluid implementations. These tests assess the stability of the ferrofluid over time and under various environmental conditions, ensuring that the acoustic performance benefits are maintained throughout the system's lifespan.

Frequency response is a fundamental metric that measures the system's ability to reproduce sound across the audible spectrum. In ferrofluid-based systems, this metric can reveal improvements in low-frequency response and overall tonal balance. Measurements typically show a flatter and more extended frequency response, particularly in the bass region, due to the ferrofluid's ability to enhance magnetic flux and dampen unwanted resonances.

Total harmonic distortion (THD) is another critical metric that quantifies the level of unwanted harmonics introduced by the audio system. Ferrofluid applications often result in reduced THD, especially at higher volumes, as the fluid helps maintain proper voice coil alignment and thermal management. This leads to cleaner, more accurate sound reproduction across various listening levels.

Sensitivity and efficiency metrics are essential for understanding how effectively the system converts electrical energy into acoustic energy. Ferrofluid-enhanced speakers generally demonstrate improved sensitivity, allowing for higher output levels with less power input. This efficiency gain is particularly noticeable in compact speaker designs, where ferrofluid can compensate for limitations in magnet size and voice coil heat dissipation.

Impulse response and transient behavior metrics provide insights into the system's ability to accurately reproduce rapid changes in sound. Ferrofluid applications often result in improved transient response due to enhanced damping and reduced mechanical resonances. This translates to better clarity and definition in complex musical passages and improved imaging in stereo setups.

Power handling capacity is a crucial metric for high-fidelity systems, indicating the maximum power the system can handle without damage or significant distortion. Ferrofluid-based designs typically show increased power handling capabilities due to improved thermal management and reduced mechanical stress on the voice coil.

Directivity and off-axis response measurements are important for assessing how the sound system performs across different listening positions. Ferrofluid applications can contribute to more consistent off-axis performance by maintaining better control over the driver's movement, resulting in a wider and more uniform sweet spot for listeners.

Long-term reliability metrics, such as accelerated life testing and thermal cycling, are essential for evaluating the durability of ferrofluid implementations. These tests assess the stability of the ferrofluid over time and under various environmental conditions, ensuring that the acoustic performance benefits are maintained throughout the system's lifespan.

Environmental Impact Assessment

The application of ferrofluid in high-fidelity sound systems presents both potential benefits and environmental considerations. As with any technological innovation, it is crucial to assess the environmental impact throughout the product lifecycle, from production to disposal.

During the manufacturing process of ferrofluid, the primary environmental concern lies in the production of nanoparticles. These particles, typically iron oxide, require energy-intensive processes and may involve the use of potentially harmful chemicals. Proper containment and filtration systems are essential to prevent the release of nanoparticles into the environment, as their long-term effects on ecosystems are not yet fully understood.

In the context of high-fidelity sound systems, the use of ferrofluid can potentially lead to improved energy efficiency. By enhancing heat dissipation in speaker coils, ferrofluid-based systems may require less power to achieve the same sound output, potentially reducing overall energy consumption. This could contribute to a decrease in the carbon footprint associated with the use of audio equipment.

However, the disposal of ferrofluid-containing components at the end of their lifecycle presents challenges. Improper disposal could lead to the release of nanoparticles into soil or water systems, potentially affecting local ecosystems. Developing appropriate recycling and disposal protocols is crucial to mitigate these risks.

The durability and longevity of ferrofluid-enhanced audio components may have positive environmental implications. If these components last longer or require less frequent replacement, it could reduce electronic waste generation. However, this benefit must be balanced against the potential difficulties in recycling or refurbishing such specialized components.

Water usage and potential contamination during the production process are additional factors to consider. Implementing closed-loop water systems and effective treatment processes in manufacturing facilities can help minimize the environmental impact.

The transportation of ferrofluid and related components may have a carbon footprint, particularly if sourcing involves long-distance shipping. Localizing production and optimizing supply chains could help reduce these impacts.

In conclusion, while ferrofluid technology in high-fidelity sound systems shows promise for improved performance, careful consideration of its environmental impact is necessary. Balancing the potential benefits with responsible manufacturing, usage, and disposal practices will be key to ensuring that this innovation contributes positively to sustainable audio technology development.

During the manufacturing process of ferrofluid, the primary environmental concern lies in the production of nanoparticles. These particles, typically iron oxide, require energy-intensive processes and may involve the use of potentially harmful chemicals. Proper containment and filtration systems are essential to prevent the release of nanoparticles into the environment, as their long-term effects on ecosystems are not yet fully understood.

In the context of high-fidelity sound systems, the use of ferrofluid can potentially lead to improved energy efficiency. By enhancing heat dissipation in speaker coils, ferrofluid-based systems may require less power to achieve the same sound output, potentially reducing overall energy consumption. This could contribute to a decrease in the carbon footprint associated with the use of audio equipment.

However, the disposal of ferrofluid-containing components at the end of their lifecycle presents challenges. Improper disposal could lead to the release of nanoparticles into soil or water systems, potentially affecting local ecosystems. Developing appropriate recycling and disposal protocols is crucial to mitigate these risks.

The durability and longevity of ferrofluid-enhanced audio components may have positive environmental implications. If these components last longer or require less frequent replacement, it could reduce electronic waste generation. However, this benefit must be balanced against the potential difficulties in recycling or refurbishing such specialized components.

Water usage and potential contamination during the production process are additional factors to consider. Implementing closed-loop water systems and effective treatment processes in manufacturing facilities can help minimize the environmental impact.

The transportation of ferrofluid and related components may have a carbon footprint, particularly if sourcing involves long-distance shipping. Localizing production and optimizing supply chains could help reduce these impacts.

In conclusion, while ferrofluid technology in high-fidelity sound systems shows promise for improved performance, careful consideration of its environmental impact is necessary. Balancing the potential benefits with responsible manufacturing, usage, and disposal practices will be key to ensuring that this innovation contributes positively to sustainable audio technology development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!