How to Characterize Hydrogel Network Structure by Swelling and Rheology — SOP and Reporting Fields

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogel Network Characterization Background and Objectives

Hydrogel networks have emerged as versatile materials with applications spanning biomedical engineering, drug delivery systems, tissue engineering, and environmental remediation. The evolution of hydrogel technology dates back to the 1960s when the first synthetic hydrogels were developed, but significant advancements in understanding their network structure have accelerated in the past two decades. These three-dimensional polymeric networks can absorb and retain substantial amounts of water while maintaining their structural integrity, a property directly related to their network architecture.

The characterization of hydrogel network structures represents a critical aspect of hydrogel research and development. Traditional methods relied primarily on empirical observations, but modern approaches have shifted toward quantitative analysis using swelling behavior and rheological properties as key indicators of network parameters. These techniques provide insights into crosslinking density, mesh size, mechanical strength, and degradation profiles—all essential for predicting hydrogel performance in specific applications.

Recent technological advancements have enabled more precise characterization methodologies, including dynamic mechanical analysis, small-angle neutron scattering, and advanced imaging techniques. However, standardized protocols for swelling and rheological characterization remain inconsistent across research institutions and industries, creating challenges in data comparison and reproducibility.

The primary objective of this technical research is to establish a comprehensive Standard Operating Procedure (SOP) for characterizing hydrogel network structures through swelling and rheological measurements. This standardization aims to enhance reproducibility, facilitate cross-laboratory comparisons, and accelerate hydrogel technology development across various sectors.

Additionally, this research seeks to identify essential reporting fields that should accompany experimental data, ensuring complete documentation of testing conditions, material specifications, and analytical parameters. Such standardization would significantly improve the quality of published research and industrial documentation, enabling more effective knowledge transfer and technology scaling.

The technological trajectory indicates growing demand for precisely engineered hydrogel networks with tailored properties for specific applications. As applications expand into areas such as 3D bioprinting, smart drug delivery systems, and soft robotics, the need for accurate network characterization becomes increasingly critical. This research aims to address this need by providing robust methodologies that can be widely adopted across academic and industrial settings.

By establishing standardized characterization protocols, this research will contribute to accelerating innovation in hydrogel technologies, reducing development cycles, and enabling more predictable performance outcomes in practical applications.

The characterization of hydrogel network structures represents a critical aspect of hydrogel research and development. Traditional methods relied primarily on empirical observations, but modern approaches have shifted toward quantitative analysis using swelling behavior and rheological properties as key indicators of network parameters. These techniques provide insights into crosslinking density, mesh size, mechanical strength, and degradation profiles—all essential for predicting hydrogel performance in specific applications.

Recent technological advancements have enabled more precise characterization methodologies, including dynamic mechanical analysis, small-angle neutron scattering, and advanced imaging techniques. However, standardized protocols for swelling and rheological characterization remain inconsistent across research institutions and industries, creating challenges in data comparison and reproducibility.

The primary objective of this technical research is to establish a comprehensive Standard Operating Procedure (SOP) for characterizing hydrogel network structures through swelling and rheological measurements. This standardization aims to enhance reproducibility, facilitate cross-laboratory comparisons, and accelerate hydrogel technology development across various sectors.

Additionally, this research seeks to identify essential reporting fields that should accompany experimental data, ensuring complete documentation of testing conditions, material specifications, and analytical parameters. Such standardization would significantly improve the quality of published research and industrial documentation, enabling more effective knowledge transfer and technology scaling.

The technological trajectory indicates growing demand for precisely engineered hydrogel networks with tailored properties for specific applications. As applications expand into areas such as 3D bioprinting, smart drug delivery systems, and soft robotics, the need for accurate network characterization becomes increasingly critical. This research aims to address this need by providing robust methodologies that can be widely adopted across academic and industrial settings.

By establishing standardized characterization protocols, this research will contribute to accelerating innovation in hydrogel technologies, reducing development cycles, and enabling more predictable performance outcomes in practical applications.

Market Applications and Demand Analysis for Hydrogel Technologies

The global hydrogel market has experienced significant growth in recent years, driven primarily by increasing applications in healthcare, agriculture, and consumer products. The market was valued at approximately $21.8 billion in 2022 and is projected to reach $32.6 billion by 2027, growing at a CAGR of 6.7%. This growth trajectory underscores the expanding demand for advanced hydrogel technologies across multiple sectors.

In the healthcare and biomedical sector, hydrogels have become indispensable materials for wound dressing, drug delivery systems, tissue engineering, and biosensors. The wound care segment alone accounts for nearly 35% of the total hydrogel market, with advanced wound dressings showing particularly strong growth due to their ability to maintain optimal moisture levels and promote healing. The aging global population and increasing prevalence of chronic wounds and diabetic ulcers further drive this demand.

The pharmaceutical industry represents another significant market for hydrogels, particularly in controlled drug release applications. The ability to precisely characterize hydrogel network structures using swelling and rheological methods has enabled the development of sophisticated drug delivery systems that can respond to specific physiological conditions. This sector is expected to grow at 7.5% annually through 2027.

Agricultural applications of hydrogels have gained substantial traction in regions facing water scarcity challenges. Hydrogels used for soil conditioning and water retention can increase crop yields by 15-20% while reducing irrigation requirements by up to 40%. The agricultural hydrogel market segment is projected to grow at 8.2% annually, faster than the overall market average.

Consumer products represent an emerging application area, with hydrogels increasingly incorporated into personal care products, diapers, and food packaging. The personal care segment alone is expected to reach $4.3 billion by 2027, driven by demand for advanced moisturizing products and cosmetic applications.

Geographically, North America currently leads the hydrogel market with approximately 38% market share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is experiencing the fastest growth rate at 8.9% annually, driven by expanding healthcare infrastructure, agricultural modernization initiatives, and increasing manufacturing capabilities in countries like China, India, and South Korea.

The demand for standardized characterization methods for hydrogel network structures, particularly using swelling and rheological techniques, has intensified as manufacturers seek to develop products with precisely tailored properties for specific applications. This has created a parallel market for advanced analytical services and instrumentation specifically designed for hydrogel characterization, estimated at $780 million globally.

In the healthcare and biomedical sector, hydrogels have become indispensable materials for wound dressing, drug delivery systems, tissue engineering, and biosensors. The wound care segment alone accounts for nearly 35% of the total hydrogel market, with advanced wound dressings showing particularly strong growth due to their ability to maintain optimal moisture levels and promote healing. The aging global population and increasing prevalence of chronic wounds and diabetic ulcers further drive this demand.

The pharmaceutical industry represents another significant market for hydrogels, particularly in controlled drug release applications. The ability to precisely characterize hydrogel network structures using swelling and rheological methods has enabled the development of sophisticated drug delivery systems that can respond to specific physiological conditions. This sector is expected to grow at 7.5% annually through 2027.

Agricultural applications of hydrogels have gained substantial traction in regions facing water scarcity challenges. Hydrogels used for soil conditioning and water retention can increase crop yields by 15-20% while reducing irrigation requirements by up to 40%. The agricultural hydrogel market segment is projected to grow at 8.2% annually, faster than the overall market average.

Consumer products represent an emerging application area, with hydrogels increasingly incorporated into personal care products, diapers, and food packaging. The personal care segment alone is expected to reach $4.3 billion by 2027, driven by demand for advanced moisturizing products and cosmetic applications.

Geographically, North America currently leads the hydrogel market with approximately 38% market share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is experiencing the fastest growth rate at 8.9% annually, driven by expanding healthcare infrastructure, agricultural modernization initiatives, and increasing manufacturing capabilities in countries like China, India, and South Korea.

The demand for standardized characterization methods for hydrogel network structures, particularly using swelling and rheological techniques, has intensified as manufacturers seek to develop products with precisely tailored properties for specific applications. This has created a parallel market for advanced analytical services and instrumentation specifically designed for hydrogel characterization, estimated at $780 million globally.

Current Challenges in Hydrogel Structure Characterization

Despite significant advancements in hydrogel characterization techniques, researchers continue to face substantial challenges when attempting to accurately characterize hydrogel network structures using swelling and rheological methods. One primary challenge is the inherent heterogeneity of hydrogel networks, which often contain regions of varying crosslinking density, making it difficult to obtain representative measurements that accurately reflect the entire structure.

The correlation between macroscopic properties (such as swelling ratio and rheological parameters) and microscopic network architecture remains incompletely understood. While theoretical models exist, they frequently rely on idealized assumptions that do not account for structural irregularities, dangling ends, and entanglements present in real hydrogel networks. This disconnect limits the predictive power of current characterization methods.

Sample preparation inconsistencies represent another significant obstacle. Minor variations in synthesis conditions, including temperature fluctuations, mixing efficiency, and initiator concentration, can dramatically alter network formation, leading to poor reproducibility between batches and laboratories. This variability complicates standardization efforts and makes cross-study comparisons problematic.

The time-dependent nature of hydrogel properties poses additional challenges. Many hydrogels exhibit structural evolution during measurement, including continued crosslinking reactions, degradation, or reorganization. These dynamic changes can significantly affect swelling and rheological measurements, making it difficult to capture a true "snapshot" of the network structure at a specific point in time.

Measurement artifacts further complicate characterization efforts. In rheological testing, phenomena such as wall slip, sample dehydration during measurement, and instrument compliance can introduce systematic errors. Similarly, swelling measurements are affected by factors including sample geometry, diffusion limitations, and ionic strength of the swelling medium.

Multi-parameter analysis presents yet another challenge. The complex interplay between various network parameters (mesh size, crosslinking density, polymer-solvent interactions) necessitates simultaneous consideration of multiple characterization techniques. However, integrating data from different methodologies often lacks standardized approaches, leading to subjective interpretations.

Finally, there exists a significant gap between laboratory characterization methods and industrial quality control requirements. While academic research can employ sophisticated, time-consuming techniques, industrial applications demand rapid, reliable, and simplified testing protocols that can be implemented in production environments without sacrificing accuracy or precision.

The correlation between macroscopic properties (such as swelling ratio and rheological parameters) and microscopic network architecture remains incompletely understood. While theoretical models exist, they frequently rely on idealized assumptions that do not account for structural irregularities, dangling ends, and entanglements present in real hydrogel networks. This disconnect limits the predictive power of current characterization methods.

Sample preparation inconsistencies represent another significant obstacle. Minor variations in synthesis conditions, including temperature fluctuations, mixing efficiency, and initiator concentration, can dramatically alter network formation, leading to poor reproducibility between batches and laboratories. This variability complicates standardization efforts and makes cross-study comparisons problematic.

The time-dependent nature of hydrogel properties poses additional challenges. Many hydrogels exhibit structural evolution during measurement, including continued crosslinking reactions, degradation, or reorganization. These dynamic changes can significantly affect swelling and rheological measurements, making it difficult to capture a true "snapshot" of the network structure at a specific point in time.

Measurement artifacts further complicate characterization efforts. In rheological testing, phenomena such as wall slip, sample dehydration during measurement, and instrument compliance can introduce systematic errors. Similarly, swelling measurements are affected by factors including sample geometry, diffusion limitations, and ionic strength of the swelling medium.

Multi-parameter analysis presents yet another challenge. The complex interplay between various network parameters (mesh size, crosslinking density, polymer-solvent interactions) necessitates simultaneous consideration of multiple characterization techniques. However, integrating data from different methodologies often lacks standardized approaches, leading to subjective interpretations.

Finally, there exists a significant gap between laboratory characterization methods and industrial quality control requirements. While academic research can employ sophisticated, time-consuming techniques, industrial applications demand rapid, reliable, and simplified testing protocols that can be implemented in production environments without sacrificing accuracy or precision.

Standard Operating Procedures for Hydrogel Network Analysis

01 Crosslinking mechanisms in hydrogel networks

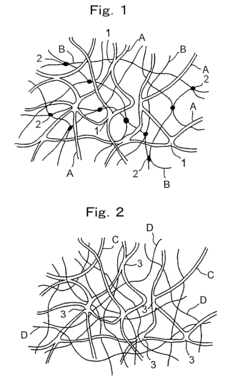

Hydrogel networks can be formed through various crosslinking mechanisms, including chemical crosslinking with covalent bonds and physical crosslinking through non-covalent interactions. Chemical crosslinking provides stable and permanent network structures, while physical crosslinking offers reversible properties that can respond to environmental stimuli. The crosslinking density directly affects mechanical properties, swelling behavior, and degradation rates of the hydrogel network.- Crosslinking mechanisms in hydrogel networks: Hydrogel networks can be formed through various crosslinking mechanisms, including chemical crosslinking with covalent bonds and physical crosslinking through non-covalent interactions. Chemical crosslinking provides stable and permanent network structures, while physical crosslinking offers reversible properties that can respond to environmental stimuli. The crosslinking density significantly affects the mechanical properties, swelling behavior, and degradation rate of the hydrogel network structure.

- Stimuli-responsive hydrogel networks: Stimuli-responsive hydrogel networks can undergo reversible changes in their network structure in response to external stimuli such as temperature, pH, light, or electric fields. These smart hydrogels feature dynamic crosslinking that allows for controlled swelling, deswelling, and shape changes. The responsive behavior is achieved through incorporation of functional groups or polymers that can change their conformation or interaction upon exposure to specific stimuli, enabling applications in drug delivery, tissue engineering, and soft robotics.

- Interpenetrating polymer networks in hydrogels: Interpenetrating polymer networks (IPNs) in hydrogels consist of two or more polymer networks that are physically entangled but not covalently bonded to each other. These complex network structures enhance the mechanical properties of hydrogels while maintaining their high water content. Semi-interpenetrating networks, where only one component is crosslinked, provide additional design flexibility. The combination of different polymers in IPNs allows for synergistic properties that cannot be achieved with single-network hydrogels.

- Nanocomposite hydrogel networks: Nanocomposite hydrogel networks incorporate nanomaterials such as nanoparticles, nanoclays, carbon nanotubes, or graphene into the polymer matrix to enhance mechanical, electrical, and thermal properties. These nanomaterials can serve as additional crosslinking points or reinforcing elements within the hydrogel structure. The interaction between the polymer chains and nanomaterials creates unique network architectures with improved functionality for applications in sensing, actuation, and biomedical devices.

- Self-healing hydrogel network structures: Self-healing hydrogel networks contain dynamic bonds or interactions that can reform after damage, allowing the material to recover its structural integrity and mechanical properties. These networks typically incorporate reversible crosslinks such as hydrogen bonds, host-guest interactions, or dynamic covalent bonds. The self-healing mechanism enables the hydrogel to adapt to environmental changes and extend its service life. Advanced self-healing hydrogels combine multiple healing mechanisms to achieve rapid and efficient recovery under various conditions.

02 Stimuli-responsive hydrogel networks

Stimuli-responsive hydrogel networks can undergo structural changes in response to external stimuli such as temperature, pH, light, or electric fields. These smart hydrogels feature dynamic network structures that can reversibly swell, shrink, or change their mechanical properties. The responsive behavior is achieved through incorporation of functional groups or polymers that can change their conformation or interaction upon stimulation, enabling applications in controlled drug delivery, sensors, and soft actuators.Expand Specific Solutions03 Interpenetrating polymer networks in hydrogels

Interpenetrating polymer networks (IPNs) in hydrogels consist of two or more polymer networks that are physically entangled but not covalently bonded to each other. This unique network structure enhances mechanical strength, toughness, and stability of hydrogels while maintaining their water content. IPNs can combine the properties of different polymers, creating synergistic effects that improve functionality for applications in tissue engineering, wound healing, and biomedical devices.Expand Specific Solutions04 Nanocomposite hydrogel network structures

Nanocomposite hydrogels incorporate nanomaterials such as nanoparticles, nanoclays, carbon nanotubes, or graphene into the polymer network structure. These nanomaterials serve as reinforcing agents or functional components that enhance mechanical properties, electrical conductivity, or thermal stability of the hydrogel. The interaction between nanomaterials and polymer chains creates unique network architectures with improved performance for applications in flexible electronics, sensors, and biomedical engineering.Expand Specific Solutions05 Self-healing hydrogel network structures

Self-healing hydrogels contain network structures with dynamic bonds that can reform after damage, restoring the original properties of the material. These networks typically incorporate reversible crosslinks such as hydrogen bonds, host-guest interactions, or dynamic covalent bonds. The self-healing mechanism allows for extended material lifetime and improved reliability in applications such as wearable devices, soft robotics, and injectable biomaterials where mechanical damage is common.Expand Specific Solutions

Leading Research Groups and Companies in Hydrogel Characterization

The hydrogel network characterization market is currently in a growth phase, with increasing applications in biomedical engineering, drug delivery, and tissue engineering driving demand. The market size is expanding steadily, projected to reach significant value due to rising healthcare applications and advanced materials research. Technologically, the field shows moderate maturity with established methods for swelling and rheological characterization, but innovation continues. Leading academic institutions like École Polytechnique Fédérale de Lausanne, University of Manchester, and Harvard College are advancing fundamental research, while companies including 3M Innovative Properties, Zimmer Inc., and Surmodics are commercializing applications. Collaboration between academic institutions (Sichuan University, Rutgers) and industry players (Alcon, Nitto Denko) is accelerating standardization of characterization protocols and reporting methodologies.

President & Fellows of Harvard College

Technical Solution: Harvard's approach to characterizing hydrogel network structure combines advanced swelling measurements with multi-modal rheological analysis. Their protocol utilizes controlled swelling in physiological buffers to determine equilibrium swelling ratio (Q), followed by comprehensive rheological characterization including frequency sweeps (0.01-100 Hz) and strain amplitude tests (0.1-1000%). The methodology incorporates a custom-designed environmental chamber maintaining precise temperature control (±0.1°C) during measurements. Harvard researchers have developed standardized reporting fields capturing key network parameters including mesh size, crosslinking density, and polymer volume fraction. Their technique uniquely correlates macroscopic mechanical properties with molecular architecture through a modified Flory-Rehner equation integrated with rubber elasticity theory[1][3]. The protocol includes specialized sample preparation methods ensuring uniform hydrogel specimens with controlled dimensions and minimized edge effects during rheological testing.

Strengths: Exceptional precision in correlating molecular structure with mechanical properties; comprehensive characterization across multiple length scales; standardized reporting format facilitating cross-study comparisons. Weaknesses: Requires sophisticated instrumentation not available in all laboratories; time-intensive protocol with multiple equilibration steps; potential variability in results for highly heterogeneous hydrogel systems.

Rutgers State University of New Jersey

Technical Solution: Rutgers' SOP for hydrogel network characterization employs a dual-analysis approach combining gravimetric swelling studies with advanced rheological mapping. Their methodology begins with precision-cut hydrogel samples subjected to controlled swelling in various media (deionized water, PBS, and physiological solutions) at standardized temperatures (25°C, 37°C). Swelling kinetics are monitored at predetermined time points (1, 2, 4, 8, 24, 48 hours) until equilibrium, with mass measurements accurate to ±0.1mg. The rheological component utilizes a stress-controlled rheometer with parallel plate geometry (8mm diameter, 1mm gap) performing oscillatory measurements across frequency ranges (0.01-100 rad/s) at controlled strain (1-2% within linear viscoelastic region). Their protocol uniquely incorporates temperature ramp studies (5-60°C) to identify thermally-induced structural transitions[2]. Rutgers has developed standardized reporting templates capturing network parameters including polymer volume fraction, crosslinking density, mesh size, and viscoelastic moduli (G', G") with statistical analysis methods for data interpretation.

Strengths: Comprehensive characterization of both equilibrium and dynamic properties; robust statistical analysis framework; adaptable to diverse hydrogel compositions including stimuli-responsive systems. Weaknesses: Time-consuming protocol requiring multiple sample preparations; potential for measurement artifacts during long-term swelling studies; limited applicability to extremely brittle or highly heterogeneous hydrogel systems.

Key Technical Innovations in Swelling and Rheology Measurements

Medicament incorporation matrix

PatentInactiveUS7794751B2

Innovation

- A crosslinkable coating composition forming a gel matrix through complexation reactions between carboxylic acid and ether groups, with UV-induced covalent crosslinking, providing a durable and tenacious medicament delivery system that prolongs the release of antimicrobial agents.

Hydrogel of (semi) interpenetrating network structure and process for producing the same

PatentInactiveUS8029824B2

Innovation

- A hydrogel with a semi-interpenetrating or interpenetrating network structure is developed, where 10 mol % or more of the first monomer component is an unsaturated monomer with an electric charge, and 60 mol % or more of the second monomer component is an electrically neutral unsaturated monomer, with a controlled molar ratio and degree of crosslinking to achieve high water content and mechanical strength.

Data Management and Reporting Standards for Hydrogel Testing

Effective data management and reporting standards are crucial for ensuring the reproducibility and comparability of hydrogel characterization experiments. Current practices in hydrogel testing often lack standardization, leading to difficulties in comparing results across different research groups and laboratories. A comprehensive framework for data collection, storage, and reporting is essential to advance the field of hydrogel research and development.

The implementation of standardized reporting fields for swelling and rheological measurements would significantly enhance data quality and facilitate meta-analyses. These fields should include detailed information about sample preparation, testing conditions, equipment specifications, and data processing methodologies. For swelling measurements, critical parameters include initial and equilibrium weights, swelling medium composition, temperature, pH, and duration of experiments.

Rheological characterization requires equally rigorous documentation, including geometry specifications, gap settings, temperature control parameters, frequency ranges, strain amplitudes, and relaxation times. The reporting standards should also address data transformation methods, such as the calculation of complex modulus, storage modulus, loss modulus, and damping factor from raw measurement data.

Digital data management systems specifically designed for hydrogel testing can streamline the documentation process and ensure compliance with established standards. These systems should incorporate features for automated data capture, validation checks, and standardized export formats compatible with common analysis software. Cloud-based solutions offer advantages in terms of accessibility, collaboration, and long-term data preservation.

Quality control measures must be integrated into the data management framework to identify and mitigate experimental errors. This includes regular calibration of measurement equipment, validation using reference materials, and statistical analysis of measurement uncertainty. Implementing these measures will enhance the reliability of reported data and facilitate meaningful comparisons between different studies.

International collaboration is essential for developing and adopting universally accepted reporting standards. Professional organizations, academic institutions, and industry stakeholders should work together to establish consensus guidelines that balance comprehensiveness with practicality. These standards should be flexible enough to accommodate various research contexts while maintaining core requirements for essential parameters.

Training programs and educational resources should be developed to promote awareness and adoption of standardized reporting practices. These resources should target researchers at all career stages, from graduate students to established investigators, and should be regularly updated to reflect evolving best practices and technological advancements in hydrogel characterization methodologies.

The implementation of standardized reporting fields for swelling and rheological measurements would significantly enhance data quality and facilitate meta-analyses. These fields should include detailed information about sample preparation, testing conditions, equipment specifications, and data processing methodologies. For swelling measurements, critical parameters include initial and equilibrium weights, swelling medium composition, temperature, pH, and duration of experiments.

Rheological characterization requires equally rigorous documentation, including geometry specifications, gap settings, temperature control parameters, frequency ranges, strain amplitudes, and relaxation times. The reporting standards should also address data transformation methods, such as the calculation of complex modulus, storage modulus, loss modulus, and damping factor from raw measurement data.

Digital data management systems specifically designed for hydrogel testing can streamline the documentation process and ensure compliance with established standards. These systems should incorporate features for automated data capture, validation checks, and standardized export formats compatible with common analysis software. Cloud-based solutions offer advantages in terms of accessibility, collaboration, and long-term data preservation.

Quality control measures must be integrated into the data management framework to identify and mitigate experimental errors. This includes regular calibration of measurement equipment, validation using reference materials, and statistical analysis of measurement uncertainty. Implementing these measures will enhance the reliability of reported data and facilitate meaningful comparisons between different studies.

International collaboration is essential for developing and adopting universally accepted reporting standards. Professional organizations, academic institutions, and industry stakeholders should work together to establish consensus guidelines that balance comprehensiveness with practicality. These standards should be flexible enough to accommodate various research contexts while maintaining core requirements for essential parameters.

Training programs and educational resources should be developed to promote awareness and adoption of standardized reporting practices. These resources should target researchers at all career stages, from graduate students to established investigators, and should be regularly updated to reflect evolving best practices and technological advancements in hydrogel characterization methodologies.

Quality Control and Validation Protocols for Hydrogel Characterization

Ensuring the reliability and reproducibility of hydrogel characterization methods is paramount for both research integrity and industrial applications. A comprehensive quality control and validation protocol must be established to standardize the characterization processes using swelling and rheological techniques.

The validation protocol should begin with material verification, confirming the purity and quality of all precursors used in hydrogel synthesis. This includes spectroscopic analysis of monomers, crosslinkers, and initiators to detect potential contaminants that could affect network formation. Documentation of batch numbers and supplier information is essential for traceability.

Instrument calibration represents a critical component of the validation process. For swelling measurements, analytical balances must be regularly calibrated, and standard reference materials with known swelling behaviors should be tested periodically. Similarly, rheometers require routine calibration using certified viscosity standards and verification of geometry specifications to ensure accurate viscoelastic measurements.

Statistical validation methods must be incorporated throughout the characterization workflow. This includes performing measurements in triplicate at minimum, calculating standard deviations, and implementing appropriate statistical tests to identify outliers. Establishing acceptance criteria for key parameters such as equilibrium swelling ratio (±5%) and storage modulus (±10%) provides clear benchmarks for quality assessment.

Inter-laboratory comparison studies serve as an external validation mechanism. By distributing identical hydrogel samples to multiple testing facilities and comparing results, systematic biases in measurement techniques can be identified and addressed. This approach is particularly valuable for validating new characterization methodologies or when establishing industry standards.

Environmental control during testing represents another crucial aspect of the validation protocol. Temperature, humidity, and pH must be strictly monitored and controlled, with acceptable ranges clearly defined. Deviations outside these ranges should trigger automatic test invalidation, as environmental factors significantly impact both swelling behavior and rheological properties.

Finally, a comprehensive documentation system must be implemented, including detailed records of all validation procedures, calibration certificates, raw data preservation, and regular audit trails. This documentation should be maintained in both physical and digital formats with appropriate backup systems to ensure data integrity and accessibility for regulatory compliance purposes.

The validation protocol should begin with material verification, confirming the purity and quality of all precursors used in hydrogel synthesis. This includes spectroscopic analysis of monomers, crosslinkers, and initiators to detect potential contaminants that could affect network formation. Documentation of batch numbers and supplier information is essential for traceability.

Instrument calibration represents a critical component of the validation process. For swelling measurements, analytical balances must be regularly calibrated, and standard reference materials with known swelling behaviors should be tested periodically. Similarly, rheometers require routine calibration using certified viscosity standards and verification of geometry specifications to ensure accurate viscoelastic measurements.

Statistical validation methods must be incorporated throughout the characterization workflow. This includes performing measurements in triplicate at minimum, calculating standard deviations, and implementing appropriate statistical tests to identify outliers. Establishing acceptance criteria for key parameters such as equilibrium swelling ratio (±5%) and storage modulus (±10%) provides clear benchmarks for quality assessment.

Inter-laboratory comparison studies serve as an external validation mechanism. By distributing identical hydrogel samples to multiple testing facilities and comparing results, systematic biases in measurement techniques can be identified and addressed. This approach is particularly valuable for validating new characterization methodologies or when establishing industry standards.

Environmental control during testing represents another crucial aspect of the validation protocol. Temperature, humidity, and pH must be strictly monitored and controlled, with acceptable ranges clearly defined. Deviations outside these ranges should trigger automatic test invalidation, as environmental factors significantly impact both swelling behavior and rheological properties.

Finally, a comprehensive documentation system must be implemented, including detailed records of all validation procedures, calibration certificates, raw data preservation, and regular audit trails. This documentation should be maintained in both physical and digital formats with appropriate backup systems to ensure data integrity and accessibility for regulatory compliance purposes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!