How to Measure Drug Release Kinetics from Hydrogel Matrices — HPLC Protocol and Data Formats

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogel Drug Release Kinetics Background and Objectives

Hydrogel drug delivery systems have evolved significantly over the past four decades, emerging as a revolutionary platform for controlled release of therapeutic agents. Since the pioneering work of Wichterle and Lím in the 1960s on hydrophilic networks of poly(2-hydroxyethyl methacrylate), hydrogels have transformed from simple drug carriers to sophisticated responsive matrices capable of delivering pharmaceuticals with precise temporal and spatial control.

The fundamental principle behind hydrogel-based drug delivery lies in their unique three-dimensional polymeric networks that can absorb substantial amounts of water while maintaining structural integrity. This characteristic enables hydrogels to encapsulate drugs and subsequently release them through various mechanisms including diffusion, swelling, erosion, or responsive behavior to specific stimuli such as pH, temperature, or enzymatic activity.

Recent technological advancements have expanded hydrogel applications beyond conventional drug delivery to include targeted therapy, protein delivery, gene therapy, and tissue engineering. The integration of nanotechnology with hydrogel science has further enhanced their capabilities, allowing for improved bioavailability and reduced side effects of encapsulated drugs.

Understanding drug release kinetics from hydrogel matrices represents a critical aspect of pharmaceutical development, as it directly influences therapeutic efficacy and safety profiles. The quantification of release patterns typically follows mathematical models such as zero-order, first-order, Higuchi, or Korsmeyer-Peppas models, each describing different release mechanisms and providing insights into the underlying physical phenomena.

High-Performance Liquid Chromatography (HPLC) has emerged as the gold standard analytical technique for measuring drug release kinetics due to its exceptional sensitivity, specificity, and reproducibility. However, standardized protocols for sample preparation, chromatographic conditions, and data analysis remain inconsistent across research laboratories, creating challenges for result comparison and validation.

The primary objective of this technical research is to establish a comprehensive and standardized HPLC protocol for measuring drug release kinetics from hydrogel matrices. This includes optimizing sample preparation techniques, defining chromatographic parameters, and standardizing data formats to ensure reproducibility and comparability across different research settings.

Additionally, this research aims to correlate HPLC-derived release profiles with hydrogel structural properties and drug characteristics, thereby developing predictive models that can accelerate formulation development. The ultimate goal is to bridge the gap between fundamental hydrogel science and practical pharmaceutical applications, facilitating the translation of innovative hydrogel technologies into clinically viable drug delivery systems.

The fundamental principle behind hydrogel-based drug delivery lies in their unique three-dimensional polymeric networks that can absorb substantial amounts of water while maintaining structural integrity. This characteristic enables hydrogels to encapsulate drugs and subsequently release them through various mechanisms including diffusion, swelling, erosion, or responsive behavior to specific stimuli such as pH, temperature, or enzymatic activity.

Recent technological advancements have expanded hydrogel applications beyond conventional drug delivery to include targeted therapy, protein delivery, gene therapy, and tissue engineering. The integration of nanotechnology with hydrogel science has further enhanced their capabilities, allowing for improved bioavailability and reduced side effects of encapsulated drugs.

Understanding drug release kinetics from hydrogel matrices represents a critical aspect of pharmaceutical development, as it directly influences therapeutic efficacy and safety profiles. The quantification of release patterns typically follows mathematical models such as zero-order, first-order, Higuchi, or Korsmeyer-Peppas models, each describing different release mechanisms and providing insights into the underlying physical phenomena.

High-Performance Liquid Chromatography (HPLC) has emerged as the gold standard analytical technique for measuring drug release kinetics due to its exceptional sensitivity, specificity, and reproducibility. However, standardized protocols for sample preparation, chromatographic conditions, and data analysis remain inconsistent across research laboratories, creating challenges for result comparison and validation.

The primary objective of this technical research is to establish a comprehensive and standardized HPLC protocol for measuring drug release kinetics from hydrogel matrices. This includes optimizing sample preparation techniques, defining chromatographic parameters, and standardizing data formats to ensure reproducibility and comparability across different research settings.

Additionally, this research aims to correlate HPLC-derived release profiles with hydrogel structural properties and drug characteristics, thereby developing predictive models that can accelerate formulation development. The ultimate goal is to bridge the gap between fundamental hydrogel science and practical pharmaceutical applications, facilitating the translation of innovative hydrogel technologies into clinically viable drug delivery systems.

Market Analysis for Controlled Drug Delivery Systems

The controlled drug delivery systems market has experienced significant growth over the past decade, driven by increasing prevalence of chronic diseases and demand for more effective therapeutic approaches. The global market for controlled drug delivery systems was valued at approximately $36.2 billion in 2022 and is projected to reach $69.8 billion by 2030, growing at a CAGR of 8.5% during the forecast period.

Hydrogel-based drug delivery systems represent a rapidly expanding segment within this market, accounting for roughly 18% of the total market share. This growth is attributed to hydrogels' unique properties including biocompatibility, tunable degradation rates, and ability to mimic natural tissue environments. The pharmaceutical industry has shown particular interest in hydrogel matrices for sustained and targeted drug release applications.

Regional analysis indicates North America dominates the controlled drug delivery market with approximately 42% market share, followed by Europe (28%) and Asia-Pacific (22%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 10.2% annually, driven by increasing healthcare expenditure, growing pharmaceutical manufacturing capabilities, and rising chronic disease prevalence in countries like China and India.

By therapeutic application, cancer treatment represents the largest application segment (34%), followed by diabetes management (22%), cardiovascular diseases (18%), and central nervous system disorders (12%). The remaining 14% encompasses various conditions including infectious diseases and pain management. This distribution reflects the critical need for precise drug delivery in conditions requiring long-term medication management.

Key market drivers include the growing aging population, increasing prevalence of chronic diseases, and rising demand for minimally invasive drug delivery methods. Additionally, technological advancements in polymer science and analytical techniques like HPLC have accelerated innovation in controlled release formulations, particularly for hydrogel-based systems.

Market challenges include stringent regulatory requirements, high development costs, and technical difficulties in achieving precise control over drug release kinetics. The complexity of standardizing HPLC protocols for hydrogel drug release measurement represents a significant technical barrier that impacts product development timelines and costs.

Consumer trends indicate growing preference for personalized medicine approaches and increased acceptance of novel drug delivery systems that offer improved patient compliance through reduced dosing frequency. Healthcare providers increasingly favor controlled release systems that demonstrate clear therapeutic advantages and cost-effectiveness in long-term disease management.

Hydrogel-based drug delivery systems represent a rapidly expanding segment within this market, accounting for roughly 18% of the total market share. This growth is attributed to hydrogels' unique properties including biocompatibility, tunable degradation rates, and ability to mimic natural tissue environments. The pharmaceutical industry has shown particular interest in hydrogel matrices for sustained and targeted drug release applications.

Regional analysis indicates North America dominates the controlled drug delivery market with approximately 42% market share, followed by Europe (28%) and Asia-Pacific (22%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 10.2% annually, driven by increasing healthcare expenditure, growing pharmaceutical manufacturing capabilities, and rising chronic disease prevalence in countries like China and India.

By therapeutic application, cancer treatment represents the largest application segment (34%), followed by diabetes management (22%), cardiovascular diseases (18%), and central nervous system disorders (12%). The remaining 14% encompasses various conditions including infectious diseases and pain management. This distribution reflects the critical need for precise drug delivery in conditions requiring long-term medication management.

Key market drivers include the growing aging population, increasing prevalence of chronic diseases, and rising demand for minimally invasive drug delivery methods. Additionally, technological advancements in polymer science and analytical techniques like HPLC have accelerated innovation in controlled release formulations, particularly for hydrogel-based systems.

Market challenges include stringent regulatory requirements, high development costs, and technical difficulties in achieving precise control over drug release kinetics. The complexity of standardizing HPLC protocols for hydrogel drug release measurement represents a significant technical barrier that impacts product development timelines and costs.

Consumer trends indicate growing preference for personalized medicine approaches and increased acceptance of novel drug delivery systems that offer improved patient compliance through reduced dosing frequency. Healthcare providers increasingly favor controlled release systems that demonstrate clear therapeutic advantages and cost-effectiveness in long-term disease management.

Current HPLC Methodologies and Technical Limitations

High-performance liquid chromatography (HPLC) represents the gold standard analytical technique for quantifying drug release from hydrogel matrices due to its exceptional sensitivity, specificity, and reproducibility. Current HPLC methodologies for measuring drug release kinetics typically employ reverse-phase chromatography, where a non-polar stationary phase interacts with analytes based on their hydrophobicity. The most common detection methods include UV-Vis spectrophotometry, fluorescence detection, and mass spectrometry, with selection depending on the physicochemical properties of the drug molecule.

Standard protocols involve sample preparation through filtration or centrifugation to remove hydrogel particles, followed by dilution to bring concentrations within the linear range of detection. Gradient elution methods are frequently employed to enhance separation efficiency, particularly for complex drug formulations or when analyzing multiple active pharmaceutical ingredients simultaneously.

Despite its widespread adoption, HPLC analysis of hydrogel drug release faces several technical limitations. Sample preparation represents a significant challenge, as incomplete separation of drug molecules from the hydrogel matrix can lead to underestimation of release rates. Additionally, drug molecules may adsorb to filters or container surfaces during sample processing, introducing systematic errors in quantification.

Matrix effects pose another substantial challenge, particularly with complex hydrogel compositions. Components of the hydrogel matrix may co-elute with the drug of interest, causing signal interference or ion suppression in mass spectrometry detection. This necessitates extensive method development and validation to ensure specificity.

The analysis of highly hydrophilic drugs presents particular difficulties in reverse-phase HPLC, often requiring specialized columns or ion-pairing reagents. Conversely, extremely hydrophobic compounds may exhibit poor recovery due to retention within the hydrogel network or adsorption to chromatographic equipment.

Temporal resolution represents another limitation, as traditional HPLC methods typically provide discrete time points rather than continuous monitoring of release profiles. This can obscure the detection of burst release phenomena or complex release kinetics, particularly in the initial phases of drug release.

Method standardization across different laboratories remains challenging, with variations in equipment, columns, and mobile phase compositions contributing to inter-laboratory variability. This hampers direct comparison of results between research groups and complicates regulatory submissions for hydrogel-based drug delivery systems.

Standard protocols involve sample preparation through filtration or centrifugation to remove hydrogel particles, followed by dilution to bring concentrations within the linear range of detection. Gradient elution methods are frequently employed to enhance separation efficiency, particularly for complex drug formulations or when analyzing multiple active pharmaceutical ingredients simultaneously.

Despite its widespread adoption, HPLC analysis of hydrogel drug release faces several technical limitations. Sample preparation represents a significant challenge, as incomplete separation of drug molecules from the hydrogel matrix can lead to underestimation of release rates. Additionally, drug molecules may adsorb to filters or container surfaces during sample processing, introducing systematic errors in quantification.

Matrix effects pose another substantial challenge, particularly with complex hydrogel compositions. Components of the hydrogel matrix may co-elute with the drug of interest, causing signal interference or ion suppression in mass spectrometry detection. This necessitates extensive method development and validation to ensure specificity.

The analysis of highly hydrophilic drugs presents particular difficulties in reverse-phase HPLC, often requiring specialized columns or ion-pairing reagents. Conversely, extremely hydrophobic compounds may exhibit poor recovery due to retention within the hydrogel network or adsorption to chromatographic equipment.

Temporal resolution represents another limitation, as traditional HPLC methods typically provide discrete time points rather than continuous monitoring of release profiles. This can obscure the detection of burst release phenomena or complex release kinetics, particularly in the initial phases of drug release.

Method standardization across different laboratories remains challenging, with variations in equipment, columns, and mobile phase compositions contributing to inter-laboratory variability. This hampers direct comparison of results between research groups and complicates regulatory submissions for hydrogel-based drug delivery systems.

Standard HPLC Protocols for Hydrogel Drug Release Analysis

01 Hydrogel composition and structure for controlled drug release

Hydrogels with specific compositions and structural characteristics can be designed to control drug release kinetics. These include cross-linking density, polymer type, and network architecture that affect water content, swelling behavior, and mesh size. By manipulating these parameters, drug release can be tailored from rapid to sustained delivery, with some formulations allowing for pulsatile or stimuli-responsive release patterns.- Hydrogel composition and structure for controlled release: Hydrogels can be designed with specific compositions and structures to control drug release kinetics. By manipulating cross-linking density, polymer concentration, and molecular weight, the mesh size and swelling properties can be tailored to achieve desired release profiles. These structural modifications affect diffusion pathways and interactions between the drug and hydrogel matrix, enabling sustained or pulsatile release patterns for optimal therapeutic outcomes.

- Stimuli-responsive hydrogels for targeted drug delivery: Stimuli-responsive hydrogels can change their properties in response to environmental triggers such as pH, temperature, or specific biomolecules. These smart materials enable site-specific drug release by responding to physiological conditions at target sites. For example, pH-sensitive hydrogels can release drugs selectively in acidic tumor environments or specific regions of the gastrointestinal tract, while temperature-sensitive systems can respond to pathological conditions like inflammation, providing precise control over drug release kinetics.

- Mathematical modeling of drug release kinetics: Mathematical models are essential for predicting and understanding drug release kinetics from hydrogel matrices. Various models including Higuchi, Korsmeyer-Peppas, zero-order, and first-order kinetics are used to characterize release mechanisms such as diffusion, erosion, or swelling-controlled release. These models help in optimizing hydrogel formulations by quantifying parameters like diffusion coefficients and release exponents, enabling the design of delivery systems with predetermined release profiles tailored to specific therapeutic requirements.

- Composite and nanostructured hydrogels: Composite and nanostructured hydrogels incorporate additional components like nanoparticles, liposomes, or secondary polymers to enhance drug delivery capabilities. These advanced systems can overcome limitations of conventional hydrogels by improving mechanical properties, providing multiple release mechanisms, or enabling sequential release of multiple drugs. Nanocomposite hydrogels can also enhance drug stability and bioavailability while providing precise control over release kinetics through engineered interfaces and compartmentalization strategies.

- In situ forming hydrogels for minimally invasive delivery: In situ forming hydrogels transition from injectable solutions to solid hydrogel matrices upon administration, enabling minimally invasive delivery. These systems utilize various gelation mechanisms including temperature changes, pH shifts, ionic interactions, or photopolymerization. The gelation kinetics significantly impacts drug distribution within the matrix and subsequent release behavior. By controlling the sol-gel transition rate and final network properties, these systems can provide localized drug delivery with customizable release profiles for applications ranging from wound healing to cancer therapy.

02 Stimuli-responsive hydrogel systems

Hydrogels that respond to environmental stimuli such as pH, temperature, ionic strength, or specific biomolecules can provide targeted and controlled drug release. These smart hydrogels undergo reversible volume or structural changes in response to external triggers, allowing for site-specific and on-demand drug delivery. This approach is particularly valuable for delivering therapeutics to specific physiological environments or disease states.Expand Specific Solutions03 Mathematical modeling of drug release kinetics

Various mathematical models are employed to predict and analyze drug release kinetics from hydrogel matrices. These include zero-order, first-order, Higuchi, Korsmeyer-Peppas, and other models that account for diffusion, erosion, swelling, and polymer relaxation mechanisms. Such models help in understanding the release mechanisms and optimizing hydrogel formulations for desired release profiles.Expand Specific Solutions04 Composite and multi-layered hydrogel systems

Composite hydrogels incorporating nanoparticles, microparticles, or multiple polymer types can achieve complex drug release profiles. Multi-layered or gradient hydrogel systems allow for sequential or simultaneous release of multiple drugs with different kinetics. These advanced systems can overcome limitations of conventional hydrogels by combining different release mechanisms and improving mechanical properties.Expand Specific Solutions05 Biodegradable hydrogels for sustained release

Biodegradable hydrogels offer the advantage of controlled drug release coupled with matrix degradation, eliminating the need for implant removal. These systems utilize polymers that undergo hydrolytic or enzymatic degradation at rates that can be tailored to match desired drug release profiles. The degradation kinetics can be modulated through polymer composition, cross-linking density, and incorporation of enzyme-sensitive linkages.Expand Specific Solutions

Leading Research Groups and Pharmaceutical Companies

The hydrogel drug release kinetics measurement field is currently in a growth phase, with an estimated global market size of $5-7 billion and expanding at 8-10% annually. The technology has reached moderate maturity, with established protocols using HPLC for quantification, but standardization remains challenging. Leading pharmaceutical companies like Novo Nordisk, Allergan, and Regeneron are advancing commercial applications, while academic institutions including Zhejiang University and University of Florida are driving fundamental research innovations. Biotechnology specialists such as DURECT Corp. and InSitu Biologics are developing proprietary hydrogel delivery platforms, while companies like Nektar Therapeutics and Galapagos NV are exploring advanced controlled-release formulations for targeted therapeutic applications. The competitive landscape shows increasing collaboration between academia and industry to overcome technical barriers in measurement precision and reproducibility.

Evonik Operations GmbH

Technical Solution: Evonik Operations GmbH has established a standardized HPLC protocol for evaluating drug release kinetics from their RESOMER® biodegradable polymer and hydrogel systems. Their methodology employs a flow-through cell apparatus that simulates physiological conditions while allowing for automated sampling at programmed intervals. The company's approach begins with precise preparation of hydrogel formulations with controlled drug loading, followed by placement in USP-compliant dissolution apparatus modified for hydrogel matrices. Their HPLC analysis utilizes validated methods with column selection based on drug physicochemical properties, typically employing C18 or C8 columns for small molecules and size-exclusion chromatography for larger biomolecules. Evonik has developed specialized mobile phase compositions that prevent interference from hydrogel degradation products during analysis. Their data processing system incorporates mathematical modeling to distinguish between diffusion-controlled, swelling-controlled, and erosion-based release mechanisms, with capabilities to predict in vivo performance based on in vitro release data through established in vitro-in vivo correlation (IVIVC) models.

Strengths: Comprehensive approach covering formulation through analysis; established protocols compatible with regulatory requirements; extensive experience with diverse polymer systems and drug types. Weaknesses: Methods may be optimized primarily for their own polymer systems; some protocols may require specialized dissolution equipment not standard in all laboratories.

Genzyme Ltd

Technical Solution: Genzyme has developed a sophisticated HPLC-based methodology for characterizing drug release from their hyaluronic acid and other biopolymer-based hydrogel delivery systems. Their protocol employs a multi-faceted approach that combines traditional dissolution testing with advanced chromatographic techniques. The company's method begins with preparation of standardized hydrogel samples containing therapeutic proteins or small molecules, followed by immersion in physiologically relevant media under controlled temperature and agitation conditions. Their sampling approach involves careful extraction of aliquots at predetermined timepoints, with specialized sample preparation techniques to separate released drug from hydrogel components. Genzyme's HPLC analysis employs both reversed-phase and size-exclusion chromatography depending on the nature of the therapeutic agent, with particular emphasis on maintaining protein stability and bioactivity throughout the analytical process. Their data analysis platform incorporates mathematical modeling to characterize release kinetics, with specialized algorithms to account for the complex interactions between therapeutic proteins and hydrogel matrices, including potential adsorption/desorption phenomena and protein structural changes during release.

Strengths: Specialized expertise in protein and peptide delivery from hydrogels; methods designed to preserve bioactivity of sensitive biologics; extensive experience with complex biopolymer matrices. Weaknesses: Protocols may be more complex and time-consuming than those for small molecules; specialized equipment and expertise required for protein analysis may limit accessibility.

Critical Parameters and Data Processing Methods

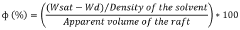

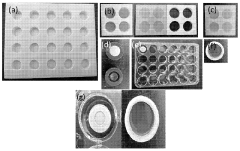

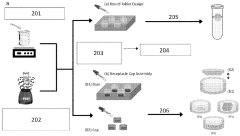

Ultra-long floating hydrogel raft for prolonged gastric retention & applications requiring buoyancy with controlled-release

PatentWO2023158377A2

Innovation

- A pharmaceutical flotation device comprising a polymeric matrix of sodium alginate and kappa-carrageenan with calcium carbonate as a crosslinking agent, forming a hydrogel network that provides prolonged floatation and controlled release of drugs through a dual gel network, oil incorporation, and pH-responsive crosslinking, allowing for extended gastric retention and versatile drug encapsulation.

High-performance liquid chromatography with a controllable transverse flow inducer

PatentWO2017009438A1

Innovation

- The use of a controllable transverse flow inducer, such as an array of electrodes generating an alternating current electrokinetic field, to create micro-scale vortices that reduce dispersion and enhance mass transfer between support structures in the chromatography column, allowing for efficient separation without permanent surface charges and minimizing direct contact with electrodes.

Regulatory Compliance in Drug Release Testing

Regulatory compliance in drug release testing represents a critical framework that pharmaceutical companies must navigate when developing and testing hydrogel-based drug delivery systems. The FDA, EMA, and other global regulatory bodies have established specific guidelines that govern the validation and standardization of drug release testing methodologies, particularly those involving HPLC protocols for hydrogel matrices.

The FDA's guidance document on "Dissolution Testing of Immediate Release Solid Oral Dosage Forms" provides foundational principles that can be adapted for hydrogel systems, emphasizing the importance of method validation, equipment qualification, and data integrity. For HPLC-based release kinetics measurements, compliance with USP <711> (Dissolution) and USP <1092> (The Dissolution Procedure: Development and Validation) is essential, even when working with non-traditional delivery systems like hydrogels.

Regulatory bodies require comprehensive documentation of analytical method validation, including specificity, linearity, accuracy, precision, range, and robustness. For hydrogel matrices specifically, additional considerations such as matrix interference validation and extraction efficiency must be addressed to ensure compliance with ICH Q2(R1) guidelines on analytical validation.

Data formats for regulatory submission must adhere to standardized protocols. The Common Technical Document (CTD) format, particularly Module 3 (Quality) and Module 5 (Clinical Study Reports), requires specific presentation of drug release kinetics data. Electronic submissions typically follow the eCTD format, with raw HPLC data preserved in compliance with 21 CFR Part 11 for electronic records and signatures.

Quality control measures for HPLC protocols must demonstrate adherence to Good Laboratory Practices (GLP) and Good Manufacturing Practices (GMP). This includes regular calibration of HPLC systems, use of certified reference standards, and implementation of system suitability tests before each analytical run measuring drug release from hydrogels.

International harmonization efforts through ICH have established the Q6A guideline for specifications, which impacts how release kinetics acceptance criteria are established. For novel hydrogel delivery systems, regulatory agencies often require comparative dissolution profiles using model-independent approaches such as similarity factor (f2) calculations to establish equivalence with reference products or between formulation iterations.

Regulatory compliance also extends to stability testing protocols, where drug release kinetics must be monitored throughout the product's shelf life under ICH Q1A(R2) conditions, with particular attention to potential changes in hydrogel matrix properties over time that might affect drug release mechanisms and rates.

The FDA's guidance document on "Dissolution Testing of Immediate Release Solid Oral Dosage Forms" provides foundational principles that can be adapted for hydrogel systems, emphasizing the importance of method validation, equipment qualification, and data integrity. For HPLC-based release kinetics measurements, compliance with USP <711> (Dissolution) and USP <1092> (The Dissolution Procedure: Development and Validation) is essential, even when working with non-traditional delivery systems like hydrogels.

Regulatory bodies require comprehensive documentation of analytical method validation, including specificity, linearity, accuracy, precision, range, and robustness. For hydrogel matrices specifically, additional considerations such as matrix interference validation and extraction efficiency must be addressed to ensure compliance with ICH Q2(R1) guidelines on analytical validation.

Data formats for regulatory submission must adhere to standardized protocols. The Common Technical Document (CTD) format, particularly Module 3 (Quality) and Module 5 (Clinical Study Reports), requires specific presentation of drug release kinetics data. Electronic submissions typically follow the eCTD format, with raw HPLC data preserved in compliance with 21 CFR Part 11 for electronic records and signatures.

Quality control measures for HPLC protocols must demonstrate adherence to Good Laboratory Practices (GLP) and Good Manufacturing Practices (GMP). This includes regular calibration of HPLC systems, use of certified reference standards, and implementation of system suitability tests before each analytical run measuring drug release from hydrogels.

International harmonization efforts through ICH have established the Q6A guideline for specifications, which impacts how release kinetics acceptance criteria are established. For novel hydrogel delivery systems, regulatory agencies often require comparative dissolution profiles using model-independent approaches such as similarity factor (f2) calculations to establish equivalence with reference products or between formulation iterations.

Regulatory compliance also extends to stability testing protocols, where drug release kinetics must be monitored throughout the product's shelf life under ICH Q1A(R2) conditions, with particular attention to potential changes in hydrogel matrix properties over time that might affect drug release mechanisms and rates.

Data Standardization and Interoperability Frameworks

In the rapidly evolving field of drug release kinetics measurement from hydrogel matrices, data standardization and interoperability frameworks have become increasingly critical. The current landscape reveals significant fragmentation in how researchers collect, format, and share HPLC data related to drug release studies, creating barriers to reproducibility and cross-laboratory validation.

Existing data formats for HPLC measurements vary widely across instrument manufacturers, with proprietary formats from companies like Agilent, Waters, and Shimadzu dominating the market. These formats often lack compatibility with each other, forcing researchers to use conversion tools that may compromise data integrity or metadata preservation.

Several initiatives have emerged to address these challenges. The Allotrope Foundation's data format framework represents a significant advancement, offering a standardized approach to analytical chemistry data, including HPLC measurements. This framework incorporates semantic web technologies to ensure that contextual information about experimental conditions remains linked to raw data.

The Analytical Information Markup Language (AnIML) provides another promising standard specifically designed for analytical chemistry data exchange. For hydrogel drug release studies, AnIML offers specialized templates that capture critical parameters such as sampling intervals, buffer composition, and temperature conditions alongside chromatographic data.

Pharmaceutical industry consortia have also developed domain-specific standards like SEND (Standard for Exchange of Nonclinical Data) that include provisions for drug release kinetics data. These standards facilitate regulatory submissions while ensuring data integrity throughout the product development lifecycle.

Cloud-based laboratory informatics platforms are increasingly incorporating standardized APIs that allow seamless data exchange between HPLC instruments and analysis software. These platforms implement standardized data models that preserve both raw chromatograms and processed kinetics calculations, enabling more robust meta-analyses across multiple studies.

The implementation of FAIR (Findable, Accessible, Interoperable, Reusable) data principles has gained traction in the pharmaceutical research community, with specific guidelines now available for hydrogel drug release studies. These guidelines recommend standardized metadata schemas that capture matrix composition, crosslinking density, and other hydrogel-specific parameters that influence release kinetics.

Looking forward, blockchain-based data integrity solutions are emerging as potential frameworks for ensuring the immutability and provenance of drug release kinetics data. These systems could provide trusted verification of experimental conditions and raw data, addressing reproducibility challenges that have plagued the field.

Existing data formats for HPLC measurements vary widely across instrument manufacturers, with proprietary formats from companies like Agilent, Waters, and Shimadzu dominating the market. These formats often lack compatibility with each other, forcing researchers to use conversion tools that may compromise data integrity or metadata preservation.

Several initiatives have emerged to address these challenges. The Allotrope Foundation's data format framework represents a significant advancement, offering a standardized approach to analytical chemistry data, including HPLC measurements. This framework incorporates semantic web technologies to ensure that contextual information about experimental conditions remains linked to raw data.

The Analytical Information Markup Language (AnIML) provides another promising standard specifically designed for analytical chemistry data exchange. For hydrogel drug release studies, AnIML offers specialized templates that capture critical parameters such as sampling intervals, buffer composition, and temperature conditions alongside chromatographic data.

Pharmaceutical industry consortia have also developed domain-specific standards like SEND (Standard for Exchange of Nonclinical Data) that include provisions for drug release kinetics data. These standards facilitate regulatory submissions while ensuring data integrity throughout the product development lifecycle.

Cloud-based laboratory informatics platforms are increasingly incorporating standardized APIs that allow seamless data exchange between HPLC instruments and analysis software. These platforms implement standardized data models that preserve both raw chromatograms and processed kinetics calculations, enabling more robust meta-analyses across multiple studies.

The implementation of FAIR (Findable, Accessible, Interoperable, Reusable) data principles has gained traction in the pharmaceutical research community, with specific guidelines now available for hydrogel drug release studies. These guidelines recommend standardized metadata schemas that capture matrix composition, crosslinking density, and other hydrogel-specific parameters that influence release kinetics.

Looking forward, blockchain-based data integrity solutions are emerging as potential frameworks for ensuring the immutability and provenance of drug release kinetics data. These systems could provide trusted verification of experimental conditions and raw data, addressing reproducibility challenges that have plagued the field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!