How to Scale Hydrogel Production: Mixing, Casting and Drying Considerations

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogel Production Background and Objectives

Hydrogels have emerged as versatile materials with applications spanning across healthcare, agriculture, personal care, and industrial sectors. These three-dimensional networks of hydrophilic polymers can absorb and retain significant amounts of water while maintaining their structural integrity. The evolution of hydrogel technology dates back to the 1960s when the first synthetic hydrogels were developed. Since then, continuous advancements in polymer chemistry and processing techniques have expanded their functionality and application scope.

The current technological trajectory in hydrogel development focuses on enhancing mechanical properties, biocompatibility, stimuli-responsiveness, and scalable manufacturing processes. Recent innovations include double-network hydrogels with improved strength, self-healing hydrogels, and biodegradable variants for environmental sustainability. The convergence of nanotechnology with hydrogel science has further accelerated development, enabling precise control over material properties at the molecular level.

Despite significant progress in laboratory-scale production, scaling up hydrogel manufacturing presents substantial challenges. Traditional batch processes often struggle with consistency issues when production volumes increase. The critical processes of mixing, casting, and drying require careful optimization to maintain product quality during scale-up. Variations in crosslinking density, polymer distribution, and water content can significantly impact the final product performance.

The primary technical objectives for scaling hydrogel production include developing continuous manufacturing processes that ensure homogeneous mixing of precursors, precise control over gelation kinetics, and uniform drying conditions. Additionally, there is a pressing need for in-line monitoring technologies to provide real-time feedback on critical quality attributes during production. Process automation represents another key goal to reduce variability and enhance reproducibility.

Energy efficiency in drying operations presents a particular challenge, as conventional methods can be energy-intensive and potentially damaging to the hydrogel structure. Advanced drying technologies such as supercritical drying, freeze-drying, and microwave-assisted drying offer promising alternatives but require further development for industrial-scale implementation.

The ultimate aim is to establish robust, cost-effective manufacturing protocols that can reliably produce hydrogels with consistent properties at commercial scales. This would enable broader adoption across industries and unlock new application possibilities. As demand grows for specialized hydrogels in fields such as tissue engineering, drug delivery, and smart materials, the importance of scalable production technologies becomes increasingly critical to bridge the gap between laboratory innovation and commercial viability.

The current technological trajectory in hydrogel development focuses on enhancing mechanical properties, biocompatibility, stimuli-responsiveness, and scalable manufacturing processes. Recent innovations include double-network hydrogels with improved strength, self-healing hydrogels, and biodegradable variants for environmental sustainability. The convergence of nanotechnology with hydrogel science has further accelerated development, enabling precise control over material properties at the molecular level.

Despite significant progress in laboratory-scale production, scaling up hydrogel manufacturing presents substantial challenges. Traditional batch processes often struggle with consistency issues when production volumes increase. The critical processes of mixing, casting, and drying require careful optimization to maintain product quality during scale-up. Variations in crosslinking density, polymer distribution, and water content can significantly impact the final product performance.

The primary technical objectives for scaling hydrogel production include developing continuous manufacturing processes that ensure homogeneous mixing of precursors, precise control over gelation kinetics, and uniform drying conditions. Additionally, there is a pressing need for in-line monitoring technologies to provide real-time feedback on critical quality attributes during production. Process automation represents another key goal to reduce variability and enhance reproducibility.

Energy efficiency in drying operations presents a particular challenge, as conventional methods can be energy-intensive and potentially damaging to the hydrogel structure. Advanced drying technologies such as supercritical drying, freeze-drying, and microwave-assisted drying offer promising alternatives but require further development for industrial-scale implementation.

The ultimate aim is to establish robust, cost-effective manufacturing protocols that can reliably produce hydrogels with consistent properties at commercial scales. This would enable broader adoption across industries and unlock new application possibilities. As demand grows for specialized hydrogels in fields such as tissue engineering, drug delivery, and smart materials, the importance of scalable production technologies becomes increasingly critical to bridge the gap between laboratory innovation and commercial viability.

Market Analysis for Industrial Hydrogel Applications

The global hydrogel market has been experiencing significant growth, with a market value estimated at $21.8 billion in 2022 and projected to reach $35.2 billion by 2028, growing at a CAGR of 6.9%. This growth is primarily driven by increasing applications across various industries including healthcare, agriculture, personal care, and industrial sectors.

In the healthcare sector, hydrogels are extensively used in wound dressings, drug delivery systems, tissue engineering, and hygiene products. The wound care segment alone accounts for approximately 32% of the total hydrogel market, with advanced wound dressings showing particularly strong growth due to rising chronic wound prevalence and an aging global population.

Agricultural applications represent another rapidly expanding market segment, with hydrogels being utilized as soil conditioners and water retention agents. This segment is growing at approximately 7.5% annually, driven by increasing water scarcity concerns and the push for sustainable farming practices. Hydrogels can reduce irrigation requirements by up to 50% in certain applications, making them increasingly valuable in drought-prone regions.

The personal care industry constitutes about 28% of the hydrogel market, with applications in cosmetics, diapers, and feminine hygiene products. Consumer preference for natural and biodegradable materials is driving innovation in this sector, with plant-based hydrogels gaining significant market share.

Industrial applications, including wastewater treatment, mining, and construction, represent emerging opportunities for hydrogel technology. The wastewater treatment segment is growing particularly fast at 8.2% annually, as environmental regulations become more stringent globally.

Geographically, North America currently leads the market with a 35% share, followed by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to show the highest growth rate over the next five years due to rapid industrialization, increasing healthcare expenditure, and agricultural modernization efforts.

Key market challenges include high production costs, scaling difficulties, and environmental concerns regarding synthetic hydrogels. The average production cost remains 30-40% higher than traditional alternatives, creating a significant barrier to wider adoption in price-sensitive markets.

Customer demand is increasingly focused on customizable hydrogel properties, consistent quality at industrial scales, and environmentally sustainable formulations. The ability to scale production while maintaining precise control over hydrogel characteristics represents a critical competitive advantage in this evolving market landscape.

In the healthcare sector, hydrogels are extensively used in wound dressings, drug delivery systems, tissue engineering, and hygiene products. The wound care segment alone accounts for approximately 32% of the total hydrogel market, with advanced wound dressings showing particularly strong growth due to rising chronic wound prevalence and an aging global population.

Agricultural applications represent another rapidly expanding market segment, with hydrogels being utilized as soil conditioners and water retention agents. This segment is growing at approximately 7.5% annually, driven by increasing water scarcity concerns and the push for sustainable farming practices. Hydrogels can reduce irrigation requirements by up to 50% in certain applications, making them increasingly valuable in drought-prone regions.

The personal care industry constitutes about 28% of the hydrogel market, with applications in cosmetics, diapers, and feminine hygiene products. Consumer preference for natural and biodegradable materials is driving innovation in this sector, with plant-based hydrogels gaining significant market share.

Industrial applications, including wastewater treatment, mining, and construction, represent emerging opportunities for hydrogel technology. The wastewater treatment segment is growing particularly fast at 8.2% annually, as environmental regulations become more stringent globally.

Geographically, North America currently leads the market with a 35% share, followed by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to show the highest growth rate over the next five years due to rapid industrialization, increasing healthcare expenditure, and agricultural modernization efforts.

Key market challenges include high production costs, scaling difficulties, and environmental concerns regarding synthetic hydrogels. The average production cost remains 30-40% higher than traditional alternatives, creating a significant barrier to wider adoption in price-sensitive markets.

Customer demand is increasingly focused on customizable hydrogel properties, consistent quality at industrial scales, and environmentally sustainable formulations. The ability to scale production while maintaining precise control over hydrogel characteristics represents a critical competitive advantage in this evolving market landscape.

Current Production Challenges and Technical Limitations

The scaling of hydrogel production faces significant technical challenges across multiple process stages. Current mixing technologies struggle with maintaining homogeneity when batch sizes increase beyond laboratory scale. Conventional mechanical stirrers become inefficient with high-viscosity precursor solutions, leading to inconsistent crosslinking density and material properties. Temperature control during mixing presents another critical limitation, as exothermic reactions in larger volumes can create thermal gradients that affect gelation kinetics and final product quality.

Casting operations encounter precision and reproducibility issues when transitioning from small to industrial scale. The current equipment design often fails to accommodate the time-sensitive nature of hydrogel precursors, which may begin crosslinking before complete distribution in molds. Surface tension effects and air entrapment become more pronounced in larger casting operations, resulting in structural defects and compromised mechanical integrity. Additionally, the industry lacks standardized casting equipment specifically designed for hydrogel materials with varying viscosities and gelation times.

Drying processes represent perhaps the most significant bottleneck in scaled hydrogel production. Conventional air-drying methods that work effectively for small samples create unacceptable shrinkage and deformation in larger products due to uneven moisture removal. Freeze-drying, while preserving structure, remains prohibitively expensive and time-consuming for industrial-scale operations. The energy consumption of current drying technologies also poses sustainability concerns as production volumes increase.

Quality control systems have not kept pace with production scaling needs. Real-time monitoring technologies for assessing crosslinking density, water content, and mechanical properties during production remain underdeveloped. This creates a reliance on post-production testing, increasing waste and production costs when batches fail to meet specifications.

Material handling between production stages presents additional complications. Hydrogel precursors and partially formed gels are often sensitive to mechanical stress, making automated transfer systems challenging to implement without damaging the developing network structure. Current conveyor and pumping systems designed for conventional polymers frequently cause shear damage to hydrogel materials.

Regulatory compliance adds another layer of complexity, particularly for medical and food-grade applications. Existing production equipment often fails to meet cleanroom standards or allow for the documentation and traceability required by regulatory bodies. The lack of standardized production protocols further complicates validation procedures necessary for scaled manufacturing of hydrogels for regulated applications.

Casting operations encounter precision and reproducibility issues when transitioning from small to industrial scale. The current equipment design often fails to accommodate the time-sensitive nature of hydrogel precursors, which may begin crosslinking before complete distribution in molds. Surface tension effects and air entrapment become more pronounced in larger casting operations, resulting in structural defects and compromised mechanical integrity. Additionally, the industry lacks standardized casting equipment specifically designed for hydrogel materials with varying viscosities and gelation times.

Drying processes represent perhaps the most significant bottleneck in scaled hydrogel production. Conventional air-drying methods that work effectively for small samples create unacceptable shrinkage and deformation in larger products due to uneven moisture removal. Freeze-drying, while preserving structure, remains prohibitively expensive and time-consuming for industrial-scale operations. The energy consumption of current drying technologies also poses sustainability concerns as production volumes increase.

Quality control systems have not kept pace with production scaling needs. Real-time monitoring technologies for assessing crosslinking density, water content, and mechanical properties during production remain underdeveloped. This creates a reliance on post-production testing, increasing waste and production costs when batches fail to meet specifications.

Material handling between production stages presents additional complications. Hydrogel precursors and partially formed gels are often sensitive to mechanical stress, making automated transfer systems challenging to implement without damaging the developing network structure. Current conveyor and pumping systems designed for conventional polymers frequently cause shear damage to hydrogel materials.

Regulatory compliance adds another layer of complexity, particularly for medical and food-grade applications. Existing production equipment often fails to meet cleanroom standards or allow for the documentation and traceability required by regulatory bodies. The lack of standardized production protocols further complicates validation procedures necessary for scaled manufacturing of hydrogels for regulated applications.

Current Scalable Production Methodologies

01 Continuous production methods for hydrogels

Continuous production methods are essential for scaling up hydrogel manufacturing. These methods involve the use of specialized equipment such as extruders, continuous reactors, and inline mixing systems that allow for uninterrupted production flow. Continuous processes offer advantages over batch production including consistent quality, reduced labor costs, and higher throughput. These methods often incorporate real-time monitoring and control systems to maintain product specifications throughout extended production runs.- Continuous production methods for hydrogels: Continuous production methods enable large-scale manufacturing of hydrogels with consistent quality. These methods involve continuous mixing of monomers, crosslinkers, and initiators in specialized reactors that allow for controlled polymerization conditions. Continuous processes offer advantages over batch production including higher throughput, reduced labor costs, and improved product uniformity. These methods can be adapted for various hydrogel compositions and can incorporate in-line monitoring systems to ensure quality control during scale-up.

- Equipment and reactor design for scaled hydrogel production: Specialized equipment and reactor designs are crucial for scaling up hydrogel production. These include custom reactors with efficient heat transfer capabilities, controlled mixing systems, and appropriate geometry to ensure uniform polymerization. Advanced reactor designs may incorporate features such as temperature control zones, specialized agitators, and automated feeding systems. The equipment must be designed to handle the increasing viscosity during polymerization while maintaining uniform conditions throughout the reaction vessel.

- Process optimization and parameter control: Successful scaling of hydrogel production requires careful optimization of process parameters including temperature, concentration, mixing speed, and reaction time. Mathematical modeling and design of experiments approaches can be used to identify optimal conditions and understand the relationships between process variables. Automated control systems help maintain these parameters during scale-up, ensuring consistent product quality. Critical parameters must be monitored and adjusted in real-time to accommodate the different heat and mass transfer dynamics that occur at larger scales.

- Novel crosslinking and polymerization techniques: Advanced crosslinking and polymerization techniques enable efficient large-scale hydrogel production. These include photo-initiated polymerization, enzymatic crosslinking, and controlled radical polymerization methods that can be implemented in continuous flow systems. Some techniques utilize dual-curing mechanisms or sequential polymerization steps to achieve desired mechanical properties. These methods often allow for faster reaction rates, lower energy consumption, and better control over the final hydrogel properties during industrial-scale manufacturing.

- Formulation strategies for scalable hydrogel production: Specialized formulation strategies are essential for successful scaling of hydrogel production. These include the use of rheology modifiers to control viscosity during processing, stabilizers to prevent premature gelation, and dispersants to ensure uniform distribution of components. Some formulations incorporate phase separation techniques or template-based approaches that facilitate large-scale manufacturing. The selection of appropriate solvents, initiator systems, and monomer ratios must be optimized specifically for industrial-scale production to ensure consistent product quality and process efficiency.

02 Cross-linking techniques for large-scale hydrogel production

Various cross-linking techniques have been developed to enable efficient large-scale hydrogel production. These include physical cross-linking methods (using temperature, pH, or ionic interactions), chemical cross-linking (using cross-linking agents), and radiation-induced cross-linking (using UV light or gamma radiation). The selection of appropriate cross-linking methods significantly impacts production efficiency, hydrogel properties, and scalability. Advanced cross-linking approaches allow for precise control of hydrogel network formation while maintaining production speed.Expand Specific Solutions03 Equipment and reactor design for industrial hydrogel production

Specialized equipment and reactor designs are crucial for industrial-scale hydrogel production. These include custom-designed reactors with enhanced mixing capabilities, temperature control systems, and specialized material handling equipment. Reactor designs often incorporate features to manage the increasing viscosity during polymerization and to ensure uniform distribution of components. Advanced equipment may include automated feeding systems, in-line quality monitoring, and integrated packaging solutions to streamline the production process.Expand Specific Solutions04 Novel formulations for improved scalability

Innovative hydrogel formulations have been developed specifically to address scalability challenges. These formulations may include modified polymer compositions, alternative initiator systems, or specialized additives that improve processing characteristics. Some formulations are designed to reduce reaction exotherm, decrease gelation time, or enhance stability during large-scale production. These novel approaches often balance the need for desirable end-product properties with practical manufacturing considerations.Expand Specific Solutions05 Post-processing techniques for industrial hydrogel applications

Post-processing techniques are essential for preparing hydrogels for specific industrial applications after bulk production. These techniques include purification methods to remove unreacted components, drying processes to control water content, sterilization procedures for medical applications, and size reduction or shaping operations. Advanced post-processing may involve surface modifications, incorporation of active ingredients, or packaging under controlled conditions. These steps are critical for ensuring product quality and functionality at industrial scale.Expand Specific Solutions

Leading Manufacturers and Industry Competitors

The hydrogel production scaling market is currently in a growth phase, with increasing applications across medical, agricultural, and industrial sectors. The market size is expanding rapidly, projected to reach significant value due to rising demand in wound care, drug delivery, and water retention applications. Technologically, the field shows varying maturity levels across different production aspects. Leading companies like DuPont, BASF, and LG Chem have established advanced mixing and casting technologies, while academic institutions such as Carnegie Mellon University and Chinese University of Hong Kong are pioneering novel drying techniques. Nippon Shokubai and Nissan Chemical have developed specialized formulations for superabsorbent polymers, indicating technical leadership in specific hydrogel applications. The competitive landscape features both chemical conglomerates and specialized materials companies working to overcome scale-up challenges.

LG Chem Ltd.

Technical Solution: LG Chem has engineered a comprehensive hydrogel manufacturing platform that addresses scaling challenges through innovative process integration. Their system employs a combination of high-precision static and dynamic mixers arranged in series to achieve optimal dispersion while preventing premature gelation. The mixing units incorporate advanced cooling systems that precisely control reaction exotherms during polymerization. For casting, LG Chem utilizes a proprietary continuous sheet formation technology with adjustable thickness control that can produce uniform hydrogel sheets up to 3 meters wide. Their drying technology features a zoned environmental control system that creates carefully managed temperature and humidity gradients to remove moisture uniformly throughout the product. This approach has been demonstrated to reduce drying-related defects by over 40% compared to conventional methods. The entire production line is monitored through an integrated digital control system that collects real-time data on over 200 process parameters to ensure consistent quality during scale-up operations.

Strengths: Excellent integration of process steps reduces handling and contamination; sophisticated digital monitoring enables precise quality control; system designed for minimal downtime during product changeovers. Weaknesses: High initial capital investment; requires specialized operator training; system optimization can be time-consuming for new formulations.

Nippon Shokubai Co., Ltd.

Technical Solution: Nippon Shokubai has developed an industrial-scale hydrogel production system leveraging their expertise in superabsorbent polymer manufacturing. Their approach centers on a continuous-flow reactor design that enables precise control of polymerization kinetics and crosslinking density. The mixing system incorporates specially designed static mixers with optimized geometries that ensure uniform distribution of initiators and crosslinkers while minimizing energy consumption. For large-scale casting, they employ a patented extrusion-spreading technology that can produce continuous sheets with controlled thickness and density gradients when desired. Their drying technology utilizes a multi-stage process combining infrared pre-heating with carefully controlled convection drying, which has been shown to reduce energy consumption by approximately 30% compared to conventional methods. The system also features advanced moisture profiling sensors that continuously monitor water content throughout the drying process, allowing for real-time adjustments to optimize product quality and production efficiency.

Strengths: Exceptional expertise in superabsorbent polymer chemistry; highly energy-efficient process design; excellent scalability from pilot to full production. Weaknesses: System optimization requires significant technical expertise; capital equipment costs are substantial; technology is most suited to high-volume production rather than small specialty batches.

Key Patents in Hydrogel Manufacturing Processes

Hydrogel-forming material

PatentWO2014054699A1

Innovation

- A hydrogel-forming material using a low-molecular-weight lipid peptide-type compound with a specific fatty acid salt additive allows for hydrogel formation during cooling while stirring and re-formation after being dried, addressing the issues of scalability and repeated use.

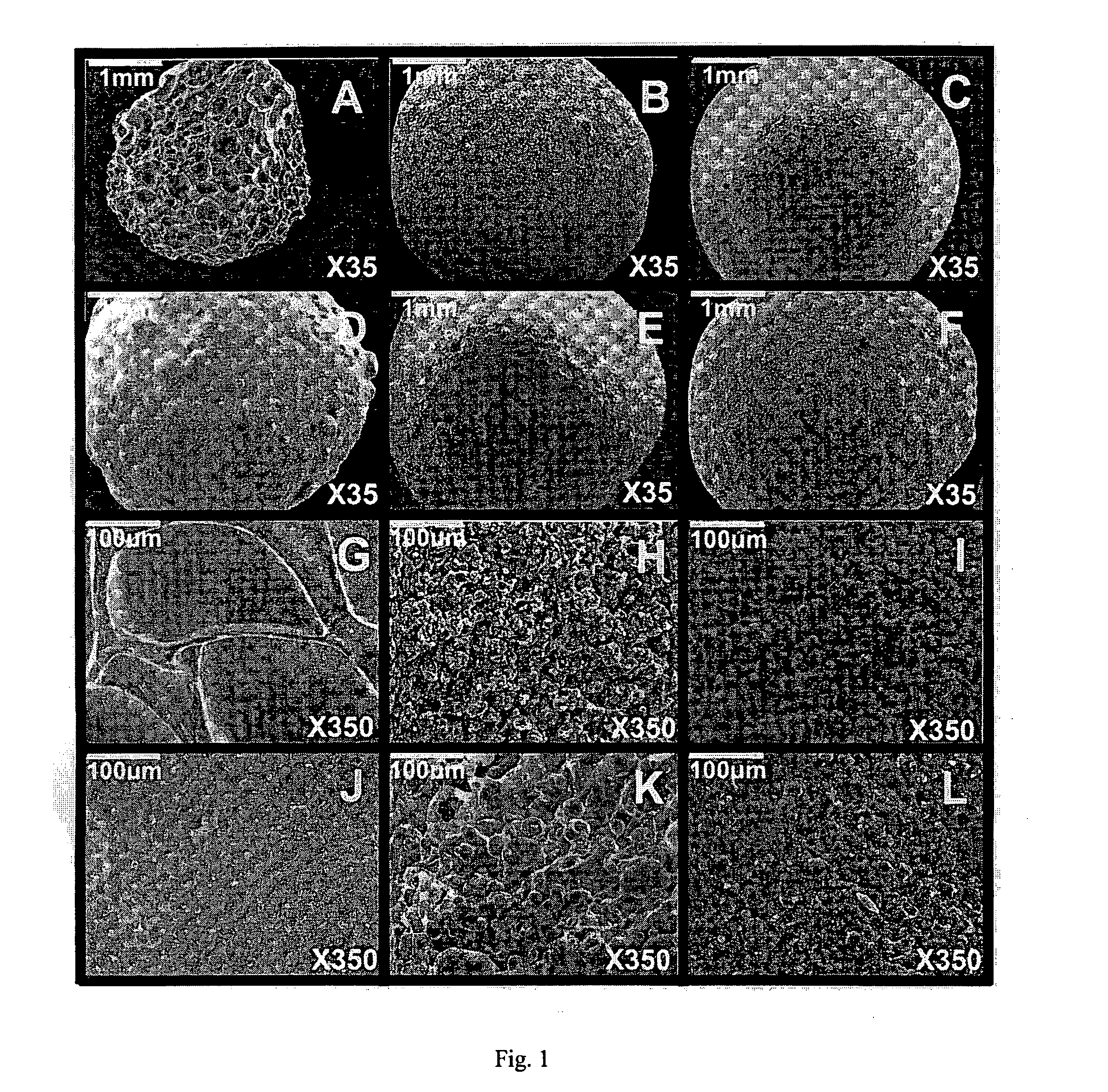

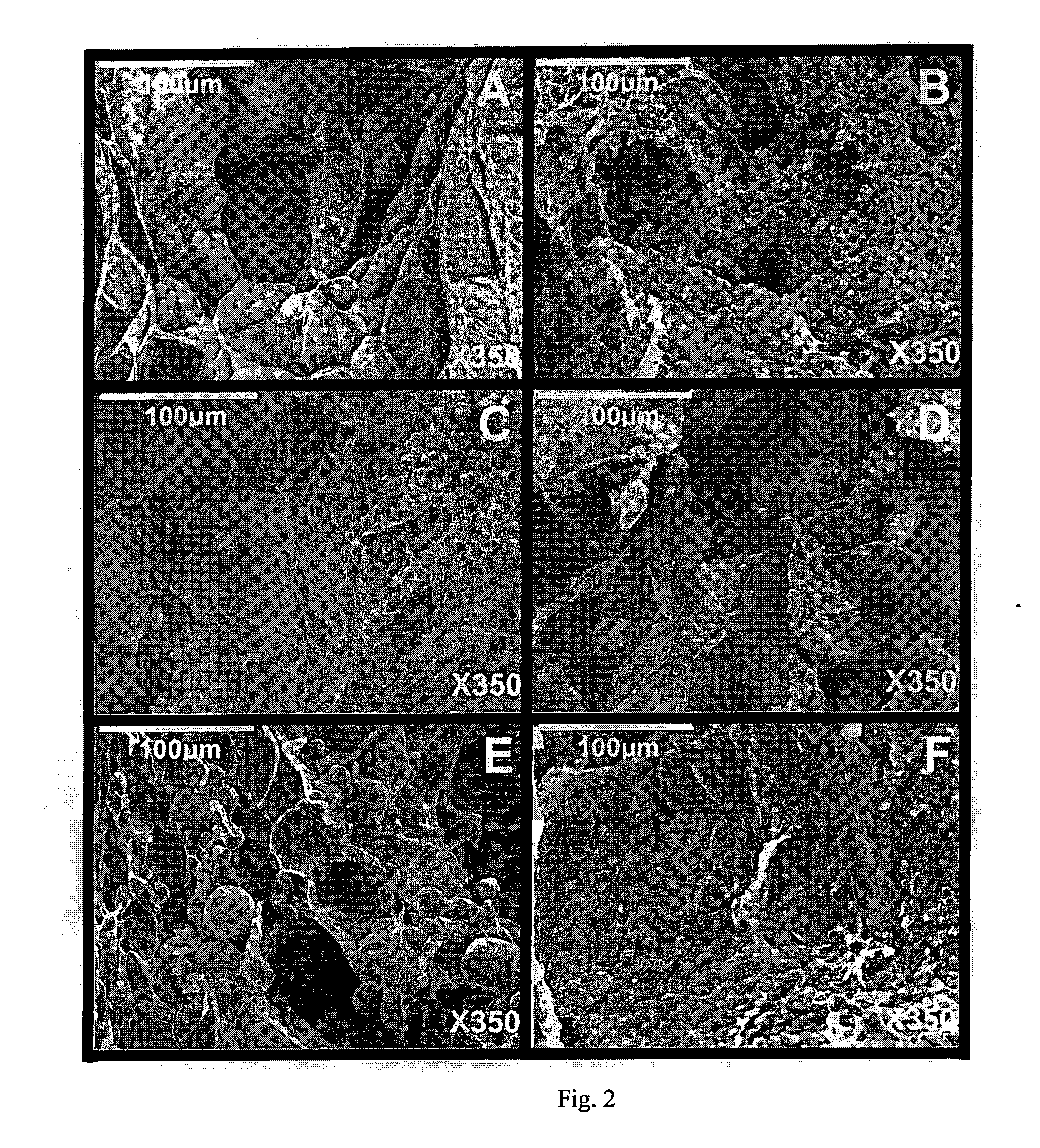

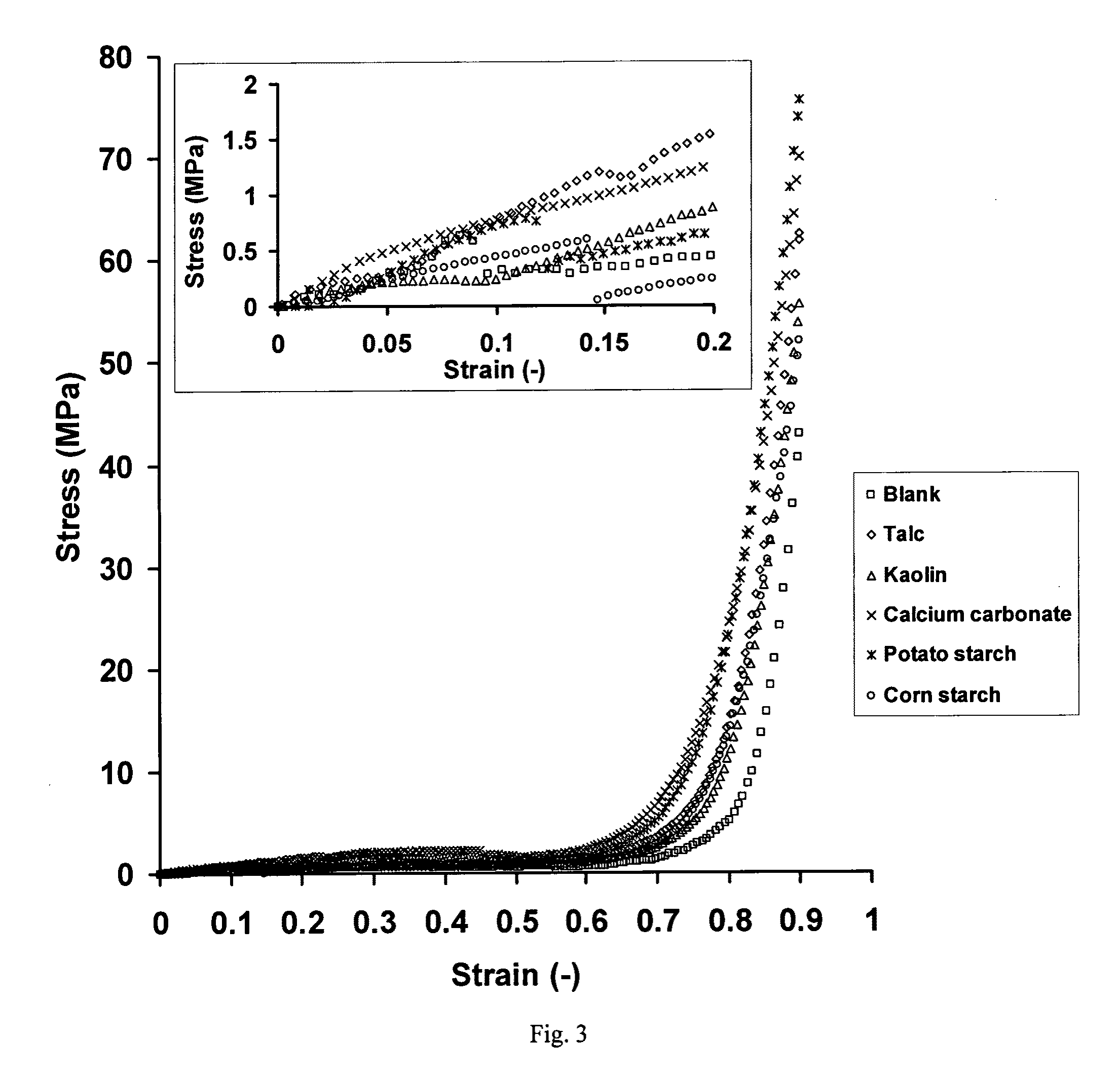

Hydrocolloid carrier beads with inert filler material

PatentInactiveUS20100015192A1

Innovation

- Incorporating inert filler materials into hydrocolloid beads, such as talc, kaolin, or calcium carbonate, to enhance mechanical strength, reduce porosity, and control the release rate of active agents, thereby improving the stability and durability of the carrier system.

Quality Control and Standardization Protocols

Quality control and standardization protocols are essential components for successful scaling of hydrogel production processes. Establishing robust quality assurance frameworks ensures consistency across batches while maintaining desired physical, chemical, and mechanical properties throughout the production lifecycle. These protocols must address each stage of production: mixing, casting, and drying.

For mixing processes, standardized testing procedures should include viscosity measurements at defined shear rates and temperatures, as these parameters directly impact homogeneity and subsequent gelation behavior. Rheological profiling using oscillatory tests can provide critical information about the structural development of hydrogels during mixing. Implementation of in-line monitoring systems utilizing spectroscopic techniques (NIR or Raman) enables real-time assessment of mixing efficiency and component distribution.

Casting operations require dimensional accuracy verification through standardized mold calibration procedures. Surface roughness measurements and defect analysis protocols help identify inconsistencies that could compromise final product integrity. Temperature mapping during casting ensures uniform thermal conditions, which is particularly crucial for thermally-triggered gelation mechanisms. Documentation systems should track environmental parameters including humidity, temperature, and particulate levels in clean room environments.

The drying phase demands precise moisture content determination protocols using gravimetric analysis, Karl Fischer titration, or non-destructive techniques such as NIR spectroscopy. Establishing drying curves for specific formulations provides benchmarks for process validation. Shrinkage measurements and dimensional stability tests help quantify the physical changes during moisture removal, enabling predictive modeling for scaled production.

Statistical process control (SPC) methodologies should be implemented across all production stages, with defined sampling plans and acceptance criteria. Control charts for critical parameters help identify process drift before specification limits are exceeded. Design of Experiments (DoE) approaches can optimize sampling frequency and locations within large-scale equipment.

Documentation standards must include detailed Standard Operating Procedures (SOPs), batch records, and equipment qualification protocols. Traceability systems linking raw materials to finished products facilitate root cause analysis when deviations occur. Automated data collection and centralized database management enhance the reliability of quality records while reducing human error.

Regulatory considerations should guide the development of these protocols, particularly for hydrogels intended for medical or pharmaceutical applications. Alignment with ISO standards (such as ISO 13485 for medical devices) or GMP requirements ensures compliance with international quality expectations and facilitates market access for the scaled production output.

For mixing processes, standardized testing procedures should include viscosity measurements at defined shear rates and temperatures, as these parameters directly impact homogeneity and subsequent gelation behavior. Rheological profiling using oscillatory tests can provide critical information about the structural development of hydrogels during mixing. Implementation of in-line monitoring systems utilizing spectroscopic techniques (NIR or Raman) enables real-time assessment of mixing efficiency and component distribution.

Casting operations require dimensional accuracy verification through standardized mold calibration procedures. Surface roughness measurements and defect analysis protocols help identify inconsistencies that could compromise final product integrity. Temperature mapping during casting ensures uniform thermal conditions, which is particularly crucial for thermally-triggered gelation mechanisms. Documentation systems should track environmental parameters including humidity, temperature, and particulate levels in clean room environments.

The drying phase demands precise moisture content determination protocols using gravimetric analysis, Karl Fischer titration, or non-destructive techniques such as NIR spectroscopy. Establishing drying curves for specific formulations provides benchmarks for process validation. Shrinkage measurements and dimensional stability tests help quantify the physical changes during moisture removal, enabling predictive modeling for scaled production.

Statistical process control (SPC) methodologies should be implemented across all production stages, with defined sampling plans and acceptance criteria. Control charts for critical parameters help identify process drift before specification limits are exceeded. Design of Experiments (DoE) approaches can optimize sampling frequency and locations within large-scale equipment.

Documentation standards must include detailed Standard Operating Procedures (SOPs), batch records, and equipment qualification protocols. Traceability systems linking raw materials to finished products facilitate root cause analysis when deviations occur. Automated data collection and centralized database management enhance the reliability of quality records while reducing human error.

Regulatory considerations should guide the development of these protocols, particularly for hydrogels intended for medical or pharmaceutical applications. Alignment with ISO standards (such as ISO 13485 for medical devices) or GMP requirements ensures compliance with international quality expectations and facilitates market access for the scaled production output.

Environmental Impact and Sustainability Considerations

The scaling of hydrogel production processes necessitates careful consideration of environmental impacts and sustainability factors. Traditional hydrogel manufacturing often involves energy-intensive processes and potentially harmful chemicals that can contribute to environmental degradation. Water consumption represents a significant concern, as hydrogel production typically requires substantial volumes of water for synthesis, purification, and processing stages. Implementing closed-loop water systems and advanced filtration technologies can reduce freshwater demand by up to 40-60%, significantly improving the water footprint of large-scale operations.

Chemical waste management presents another critical environmental challenge. Many conventional hydrogel formulations utilize crosslinking agents and solvents that may pose ecological risks if improperly handled. The transition toward green chemistry principles has enabled the development of environmentally benign alternatives, including bio-based crosslinkers and water-based processing methods that minimize hazardous waste generation while maintaining product performance characteristics.

Energy efficiency during the drying phase deserves particular attention, as this stage typically accounts for 30-45% of the total energy consumption in hydrogel manufacturing. Advanced drying technologies such as microwave-assisted drying and supercritical CO2 drying offer promising alternatives to conventional thermal methods, potentially reducing energy requirements by 25-35% while simultaneously improving product quality and consistency at industrial scales.

Carbon footprint reduction strategies should be integrated throughout the production pipeline. Life cycle assessment (LCA) studies indicate that optimizing mixing parameters and casting techniques can reduce greenhouse gas emissions by 15-20% compared to non-optimized processes. Furthermore, the implementation of renewable energy sources for powering production facilities represents a viable pathway toward carbon-neutral hydrogel manufacturing.

Biodegradability and end-of-life considerations must be addressed during formulation development. The growing market demand for environmentally responsible materials has accelerated research into fully biodegradable hydrogels derived from renewable resources such as cellulose, chitosan, and alginate. These bio-based alternatives not only reduce dependence on petroleum-derived precursors but also offer enhanced biodegradability profiles that minimize environmental persistence.

Regulatory compliance and certification standards increasingly influence production scaling decisions. Major markets are implementing stricter environmental regulations that impact chemical usage, waste disposal, and emissions reporting. Forward-thinking manufacturers are proactively adopting sustainable practices that exceed minimum compliance requirements, positioning themselves advantageously as regulatory frameworks continue to evolve toward greater environmental protection.

Chemical waste management presents another critical environmental challenge. Many conventional hydrogel formulations utilize crosslinking agents and solvents that may pose ecological risks if improperly handled. The transition toward green chemistry principles has enabled the development of environmentally benign alternatives, including bio-based crosslinkers and water-based processing methods that minimize hazardous waste generation while maintaining product performance characteristics.

Energy efficiency during the drying phase deserves particular attention, as this stage typically accounts for 30-45% of the total energy consumption in hydrogel manufacturing. Advanced drying technologies such as microwave-assisted drying and supercritical CO2 drying offer promising alternatives to conventional thermal methods, potentially reducing energy requirements by 25-35% while simultaneously improving product quality and consistency at industrial scales.

Carbon footprint reduction strategies should be integrated throughout the production pipeline. Life cycle assessment (LCA) studies indicate that optimizing mixing parameters and casting techniques can reduce greenhouse gas emissions by 15-20% compared to non-optimized processes. Furthermore, the implementation of renewable energy sources for powering production facilities represents a viable pathway toward carbon-neutral hydrogel manufacturing.

Biodegradability and end-of-life considerations must be addressed during formulation development. The growing market demand for environmentally responsible materials has accelerated research into fully biodegradable hydrogels derived from renewable resources such as cellulose, chitosan, and alginate. These bio-based alternatives not only reduce dependence on petroleum-derived precursors but also offer enhanced biodegradability profiles that minimize environmental persistence.

Regulatory compliance and certification standards increasingly influence production scaling decisions. Major markets are implementing stricter environmental regulations that impact chemical usage, waste disposal, and emissions reporting. Forward-thinking manufacturers are proactively adopting sustainable practices that exceed minimum compliance requirements, positioning themselves advantageously as regulatory frameworks continue to evolve toward greater environmental protection.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!