Hydrogel Mechanical Tuning: Crosslink Density vs Elastic Modulus — Test Protocols and Data Table

AUG 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogel Mechanical Properties Background and Objectives

Hydrogels have emerged as versatile biomaterials with applications spanning from tissue engineering to drug delivery systems, owing to their unique mechanical properties that can mimic natural tissues. The evolution of hydrogel technology has progressed significantly since its inception in the 1960s, with a particular focus on understanding and controlling mechanical properties to enhance functionality in various biomedical applications.

The relationship between crosslink density and elastic modulus represents a fundamental aspect of hydrogel mechanics that has been extensively studied over the past decades. Early research primarily focused on simple hydrogel systems with uniform crosslinking, while recent advancements have explored complex architectures including double-network hydrogels, nanocomposite hydrogels, and stimuli-responsive systems that exhibit dynamic mechanical properties.

Current technological trends in hydrogel mechanical tuning include the development of precise control mechanisms for spatial and temporal modulation of crosslinking density, enabling the creation of gradient materials that better replicate the heterogeneous nature of biological tissues. Additionally, there is growing interest in establishing standardized testing protocols that allow for reliable comparison of mechanical properties across different hydrogel formulations and research laboratories.

The primary objective of this technical investigation is to establish a comprehensive understanding of the correlation between crosslink density and elastic modulus in hydrogel systems, with particular emphasis on quantitative relationships that can guide rational design. This includes evaluating existing test protocols for measuring these properties and compiling a standardized data table that facilitates comparison across different hydrogel compositions.

Furthermore, this research aims to identify key parameters that influence the crosslink density-elastic modulus relationship, including polymer concentration, molecular weight, crosslinker type, and environmental conditions such as temperature, pH, and ionic strength. Understanding these influences will enable more precise tuning of hydrogel mechanical properties for specific applications.

An additional goal is to explore the limitations of current theoretical models that describe the relationship between network structure and mechanical properties, particularly for complex hydrogel systems with heterogeneous crosslinking or those incorporating multiple network components. This analysis will help identify gaps in current understanding and highlight opportunities for developing improved predictive models.

Ultimately, this technical exploration seeks to establish a foundation for designing hydrogels with precisely tailored mechanical properties, thereby advancing their utility in applications ranging from artificial cartilage and soft robotics to controlled drug release systems and 3D bioprinting substrates.

The relationship between crosslink density and elastic modulus represents a fundamental aspect of hydrogel mechanics that has been extensively studied over the past decades. Early research primarily focused on simple hydrogel systems with uniform crosslinking, while recent advancements have explored complex architectures including double-network hydrogels, nanocomposite hydrogels, and stimuli-responsive systems that exhibit dynamic mechanical properties.

Current technological trends in hydrogel mechanical tuning include the development of precise control mechanisms for spatial and temporal modulation of crosslinking density, enabling the creation of gradient materials that better replicate the heterogeneous nature of biological tissues. Additionally, there is growing interest in establishing standardized testing protocols that allow for reliable comparison of mechanical properties across different hydrogel formulations and research laboratories.

The primary objective of this technical investigation is to establish a comprehensive understanding of the correlation between crosslink density and elastic modulus in hydrogel systems, with particular emphasis on quantitative relationships that can guide rational design. This includes evaluating existing test protocols for measuring these properties and compiling a standardized data table that facilitates comparison across different hydrogel compositions.

Furthermore, this research aims to identify key parameters that influence the crosslink density-elastic modulus relationship, including polymer concentration, molecular weight, crosslinker type, and environmental conditions such as temperature, pH, and ionic strength. Understanding these influences will enable more precise tuning of hydrogel mechanical properties for specific applications.

An additional goal is to explore the limitations of current theoretical models that describe the relationship between network structure and mechanical properties, particularly for complex hydrogel systems with heterogeneous crosslinking or those incorporating multiple network components. This analysis will help identify gaps in current understanding and highlight opportunities for developing improved predictive models.

Ultimately, this technical exploration seeks to establish a foundation for designing hydrogels with precisely tailored mechanical properties, thereby advancing their utility in applications ranging from artificial cartilage and soft robotics to controlled drug release systems and 3D bioprinting substrates.

Market Applications and Demand Analysis for Tunable Hydrogels

The global hydrogel market has experienced significant growth in recent years, with tunable hydrogels emerging as a particularly promising segment. Current market valuations indicate that the hydrogel sector is expanding at a compound annual growth rate of approximately 6-7%, driven primarily by biomedical applications. The ability to precisely tune mechanical properties through crosslink density manipulation has opened new commercial opportunities across multiple industries.

In the biomedical field, demand for mechanically tunable hydrogels is particularly robust. Tissue engineering applications require biomaterials with elastic moduli matching specific tissue types - from soft neural tissue (0.1-1 kPa) to stiffer cartilage (400-800 kPa). This precise mechanical matching capability has created a specialized market segment with premium pricing potential. Hospital systems and research institutions represent the primary customer base, with growing interest from pharmaceutical companies for drug delivery applications.

The cosmetic industry represents another significant market for tunable hydrogels, particularly those with adjustable elastic properties. Premium skincare brands are incorporating advanced hydrogel technologies in products commanding higher price points. Consumer preference for "smart" materials that adapt to skin conditions is driving innovation in this sector, with particular emphasis on hydrogels whose crosslink density can be manipulated to deliver customized performance.

Agricultural applications are emerging as a promising growth area. Hydrogels with tunable water retention properties, directly related to crosslink density and elastic modulus, are being developed for drought-resistant farming systems. Market research indicates farmers are willing to invest in advanced hydrogel solutions that demonstrably improve crop yields in water-stressed conditions, creating a substantial market opportunity in regions facing climate change challenges.

Industrial applications, including sensors and actuators, represent a smaller but rapidly growing segment. The correlation between crosslink density and elastic response makes tunable hydrogels valuable for developing responsive materials in manufacturing and automation contexts. This sector shows strong growth potential as Industry 4.0 adoption accelerates globally.

Market barriers include production scaling challenges and cost considerations. Current production methods for precisely tuned hydrogels often involve laboratory-scale processes that are difficult to scale industrially while maintaining precise control over crosslink density and resulting elastic properties. This creates a premium price structure that limits mass-market adoption in cost-sensitive applications.

Regulatory considerations vary significantly by application field, with medical applications facing the most stringent requirements. The pathway to market for tunable hydrogels in medical contexts requires extensive testing protocols to verify consistent mechanical properties, creating both a barrier to entry and a competitive advantage for companies with established testing expertise.

In the biomedical field, demand for mechanically tunable hydrogels is particularly robust. Tissue engineering applications require biomaterials with elastic moduli matching specific tissue types - from soft neural tissue (0.1-1 kPa) to stiffer cartilage (400-800 kPa). This precise mechanical matching capability has created a specialized market segment with premium pricing potential. Hospital systems and research institutions represent the primary customer base, with growing interest from pharmaceutical companies for drug delivery applications.

The cosmetic industry represents another significant market for tunable hydrogels, particularly those with adjustable elastic properties. Premium skincare brands are incorporating advanced hydrogel technologies in products commanding higher price points. Consumer preference for "smart" materials that adapt to skin conditions is driving innovation in this sector, with particular emphasis on hydrogels whose crosslink density can be manipulated to deliver customized performance.

Agricultural applications are emerging as a promising growth area. Hydrogels with tunable water retention properties, directly related to crosslink density and elastic modulus, are being developed for drought-resistant farming systems. Market research indicates farmers are willing to invest in advanced hydrogel solutions that demonstrably improve crop yields in water-stressed conditions, creating a substantial market opportunity in regions facing climate change challenges.

Industrial applications, including sensors and actuators, represent a smaller but rapidly growing segment. The correlation between crosslink density and elastic response makes tunable hydrogels valuable for developing responsive materials in manufacturing and automation contexts. This sector shows strong growth potential as Industry 4.0 adoption accelerates globally.

Market barriers include production scaling challenges and cost considerations. Current production methods for precisely tuned hydrogels often involve laboratory-scale processes that are difficult to scale industrially while maintaining precise control over crosslink density and resulting elastic properties. This creates a premium price structure that limits mass-market adoption in cost-sensitive applications.

Regulatory considerations vary significantly by application field, with medical applications facing the most stringent requirements. The pathway to market for tunable hydrogels in medical contexts requires extensive testing protocols to verify consistent mechanical properties, creating both a barrier to entry and a competitive advantage for companies with established testing expertise.

Current Challenges in Hydrogel Mechanical Characterization

Despite significant advancements in hydrogel technology, the mechanical characterization of these materials continues to present substantial challenges for researchers and industry professionals. The correlation between crosslink density and elastic modulus, while theoretically established, remains difficult to quantify consistently across different hydrogel systems due to several persistent issues.

Test protocol standardization represents a primary challenge in the field. Currently, various laboratories employ different testing methodologies—compression, tension, shear, and indentation—often yielding inconsistent results for identical hydrogel compositions. This lack of standardization makes cross-study comparisons nearly impossible and hinders the establishment of reliable structure-property relationships.

Sample preparation variability further complicates mechanical characterization efforts. Factors such as polymerization conditions, environmental humidity, temperature during crosslinking, and sample storage conditions can dramatically alter the final mechanical properties of hydrogels. Even minor variations in these parameters can lead to significant differences in measured elastic moduli, making reproducibility a persistent issue.

The viscoelastic nature of hydrogels presents another major challenge. Unlike purely elastic materials, hydrogels exhibit time-dependent mechanical behavior, with properties varying based on testing rate, duration, and loading history. Many current testing protocols fail to adequately account for this viscoelasticity, leading to oversimplified characterization that doesn't reflect real-world material performance.

Hydration state control during testing remains problematic. Hydrogels can rapidly dehydrate during testing, particularly in open-air environments, causing continuous changes in mechanical properties throughout the measurement process. While testing in submerged conditions can mitigate this issue, it introduces other variables such as swelling dynamics and ion exchange with the surrounding medium.

Instrument sensitivity limitations also affect measurement accuracy, particularly for soft hydrogels with elastic moduli below 10 kPa. Standard mechanical testing equipment often lacks the sensitivity required for precise measurements in this range, necessitating specialized instrumentation that may not be widely available.

Data analysis and modeling approaches vary widely across the field, with researchers employing different mathematical models to extract elastic moduli from raw data. The choice of model can significantly impact the reported values, making it difficult to establish true correlations between crosslink density and mechanical properties without standardized analysis frameworks.

These challenges collectively highlight the need for comprehensive standardization efforts in hydrogel mechanical characterization, including established test protocols, sample preparation guidelines, and data analysis methodologies that account for the unique properties of these complex materials.

Test protocol standardization represents a primary challenge in the field. Currently, various laboratories employ different testing methodologies—compression, tension, shear, and indentation—often yielding inconsistent results for identical hydrogel compositions. This lack of standardization makes cross-study comparisons nearly impossible and hinders the establishment of reliable structure-property relationships.

Sample preparation variability further complicates mechanical characterization efforts. Factors such as polymerization conditions, environmental humidity, temperature during crosslinking, and sample storage conditions can dramatically alter the final mechanical properties of hydrogels. Even minor variations in these parameters can lead to significant differences in measured elastic moduli, making reproducibility a persistent issue.

The viscoelastic nature of hydrogels presents another major challenge. Unlike purely elastic materials, hydrogels exhibit time-dependent mechanical behavior, with properties varying based on testing rate, duration, and loading history. Many current testing protocols fail to adequately account for this viscoelasticity, leading to oversimplified characterization that doesn't reflect real-world material performance.

Hydration state control during testing remains problematic. Hydrogels can rapidly dehydrate during testing, particularly in open-air environments, causing continuous changes in mechanical properties throughout the measurement process. While testing in submerged conditions can mitigate this issue, it introduces other variables such as swelling dynamics and ion exchange with the surrounding medium.

Instrument sensitivity limitations also affect measurement accuracy, particularly for soft hydrogels with elastic moduli below 10 kPa. Standard mechanical testing equipment often lacks the sensitivity required for precise measurements in this range, necessitating specialized instrumentation that may not be widely available.

Data analysis and modeling approaches vary widely across the field, with researchers employing different mathematical models to extract elastic moduli from raw data. The choice of model can significantly impact the reported values, making it difficult to establish true correlations between crosslink density and mechanical properties without standardized analysis frameworks.

These challenges collectively highlight the need for comprehensive standardization efforts in hydrogel mechanical characterization, including established test protocols, sample preparation guidelines, and data analysis methodologies that account for the unique properties of these complex materials.

Standard Test Protocols for Elastic Modulus Measurement

01 Measurement techniques for hydrogel elastic modulus

Various techniques are employed to measure the elastic modulus of hydrogels, including rheological testing, atomic force microscopy, and compression testing. These methods allow for accurate determination of mechanical properties under different conditions, which is crucial for characterizing hydrogels for specific applications. The measurements can be conducted under varying temperatures, pH levels, and other environmental factors to understand how these conditions affect the elastic properties of hydrogels.- Measurement techniques for hydrogel elastic modulus: Various techniques are employed to measure the elastic modulus of hydrogels, including rheological testing, atomic force microscopy, and compression testing. These methods allow for accurate determination of mechanical properties under different conditions, which is crucial for characterizing hydrogels for specific applications. The measurements can be conducted in different environments to simulate in vivo conditions and provide data on how the elastic modulus changes with external stimuli.

- Composition factors affecting hydrogel elastic modulus: The elastic modulus of hydrogels can be tuned by adjusting their composition, including crosslinking density, polymer concentration, and the incorporation of reinforcing agents. Higher crosslinking density typically results in increased elastic modulus, while the addition of nanoparticles or fibers can significantly enhance mechanical strength. The type of polymer used also plays a crucial role in determining the final elastic properties of the hydrogel.

- Stimuli-responsive hydrogels with tunable elastic modulus: Stimuli-responsive hydrogels can change their elastic modulus in response to external triggers such as temperature, pH, light, or electrical stimuli. This dynamic behavior allows for the development of smart materials with adaptable mechanical properties. These hydrogels can transition between soft and rigid states, making them valuable for applications requiring on-demand changes in mechanical properties.

- Biomedical applications of hydrogels with specific elastic modulus: Hydrogels with tailored elastic modulus are utilized in various biomedical applications, including tissue engineering, drug delivery systems, and wound healing. The elastic modulus of these hydrogels can be designed to match specific tissues, promoting better cell adhesion, proliferation, and differentiation. Soft hydrogels may mimic neural tissue, while stiffer ones can be used for cartilage or bone tissue engineering applications.

- Relationship between hydrogel structure and elastic modulus: The microstructure and network architecture of hydrogels significantly influence their elastic modulus. Factors such as pore size, pore distribution, and network homogeneity affect how hydrogels respond to mechanical stress. Advanced imaging and characterization techniques help establish structure-property relationships, enabling the design of hydrogels with predictable elastic behavior for specific applications.

02 Tuning elastic modulus through crosslinking density

The elastic modulus of hydrogels can be controlled by adjusting the crosslinking density within the polymer network. Higher crosslinking density typically results in stiffer hydrogels with increased elastic modulus, while lower crosslinking density leads to softer, more compliant materials. This property can be manipulated by varying the concentration of crosslinking agents, reaction time, or using different types of crosslinkers to achieve desired mechanical properties for specific applications.Expand Specific Solutions03 Composite hydrogels with enhanced elastic properties

Incorporating nanoparticles, fibers, or secondary polymer networks into hydrogels can significantly enhance their elastic modulus. These composite structures provide reinforcement to the hydrogel matrix, resulting in improved mechanical strength and tunable elastic properties. The type, concentration, and distribution of these reinforcing components can be optimized to achieve specific elastic modulus values while maintaining other desirable properties such as biocompatibility or stimuli-responsiveness.Expand Specific Solutions04 Stimuli-responsive hydrogels with variable elastic modulus

Hydrogels can be designed to change their elastic modulus in response to external stimuli such as temperature, pH, light, or electric fields. This dynamic behavior allows for smart materials that can adapt their mechanical properties based on environmental conditions. These stimuli-responsive hydrogels are particularly valuable in applications requiring on-demand stiffness changes, such as controlled drug delivery systems, soft robotics, or tissue engineering scaffolds that mimic the dynamic nature of biological tissues.Expand Specific Solutions05 Biomimetic hydrogels with tissue-matching elastic modulus

Hydrogels can be engineered to match the elastic modulus of specific biological tissues, making them ideal for tissue engineering and biomedical applications. By carefully selecting polymer compositions and crosslinking strategies, researchers can create hydrogels with elastic properties similar to soft tissues like brain, muscle, or cartilage. These biomimetic materials provide appropriate mechanical cues to cells, supporting proper cell function, differentiation, and tissue development when used as scaffolds or implants.Expand Specific Solutions

Leading Research Groups and Companies in Hydrogel Engineering

The hydrogel mechanical tuning market is currently in a growth phase, with increasing applications across biomedical, pharmaceutical, and materials science sectors. The market size is estimated to reach $3.5-4 billion by 2027, driven by demand for advanced biomaterials with tunable properties. The relationship between crosslink density and elastic modulus represents a critical technical challenge that major players are addressing through different approaches. Academic institutions like MIT, Harvard, and Johns Hopkins University lead fundamental research, while commercial entities including Ethicon (Johnson & Johnson), 3M Innovative Properties, and Teoxane SA focus on practical applications. Emerging players from Asia, such as Eyebright Medical Technology and Niterra Co., are rapidly advancing their technological capabilities, particularly in specialized medical applications where precise mechanical tuning is essential for product performance.

Massachusetts Institute of Technology

Technical Solution: MIT has developed a comprehensive approach to hydrogel mechanical tuning through precise control of crosslink density using photo-initiated polymerization systems. Their technology employs UV-responsive crosslinkers that allow spatial and temporal control over the crosslinking process, enabling the creation of hydrogels with gradient mechanical properties. MIT researchers have established standardized protocols for measuring the relationship between crosslink density and elastic modulus using atomic force microscopy (AFM) and nanoindentation techniques. Their data collection methodology includes high-throughput mechanical characterization across various hydrogel formulations, with automated systems capable of generating extensive data tables correlating crosslinker concentration, UV exposure time, and resulting mechanical properties. The institute has pioneered the use of machine learning algorithms to predict mechanical properties based on crosslinking parameters, creating predictive models that accelerate hydrogel design for specific applications.

Strengths: Exceptional precision in controlling crosslink density through light-based polymerization techniques, allowing for complex patterning of mechanical properties within a single hydrogel. Their high-throughput testing protocols generate comprehensive datasets ideal for material optimization. Weaknesses: Their photo-initiated systems may have limitations in thick hydrogel samples due to light penetration constraints, and some of their advanced characterization techniques require specialized equipment not widely available.

President & Fellows of Harvard College

Technical Solution: Harvard's approach to hydrogel mechanical tuning focuses on developing advanced double-network hydrogels with precisely controlled crosslink density. Their technology utilizes a combination of covalent and ionic crosslinking mechanisms to achieve tunable elastic moduli ranging from 0.1 to 10 MPa. The research team has pioneered a systematic protocol for correlating crosslink density with mechanical properties through rheological characterization and tensile testing. Their methodology includes quantitative measurement of crosslinking efficiency using fluorescent tagging of crosslink points and advanced imaging techniques. Harvard researchers have developed standardized test protocols that include cyclic compression testing, stress relaxation measurements, and dynamic mechanical analysis to generate comprehensive data tables relating crosslink parameters to resulting mechanical properties across different strain rates and environmental conditions.

Strengths: Exceptional precision in controlling crosslink density gradients within a single hydrogel structure, allowing for spatially varied mechanical properties. Their protocols provide highly reproducible data with statistical validation across multiple sample preparations. Weaknesses: Their approaches often require sophisticated equipment and complex synthesis procedures that may limit industrial scalability and increase production costs.

Key Innovations in Crosslink Density Control Mechanisms

Systems and devices for dispensing biocompatible reactive formulations and controlling cross-linking of the reactive components of the biocompatible reactive formulations

PatentWO2022175840A1

Innovation

- An applicator instrument that mixes and expresses biocompatible reactive formulations by combining three fluid components, including a first reactive fluid, a second reactive fluid, and a neutralizing buffer, allowing for controlled chemical reactions and adjustable properties through a spray tip assembly with interchangeable mixing elements.

Hydrogel and method for producing hydrogel

PatentWO2019208576A1

Innovation

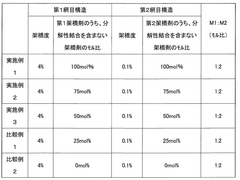

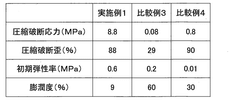

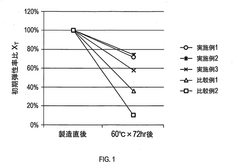

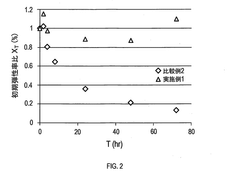

- A hydrogel comprising a first network structure crosslinked with a first crosslinking agent containing 50 mol% or more non-degradable bonds, and a second network structure crosslinked with a second crosslinking agent also containing 50 mol% or more non-degradable bonds, which prevents hydrolysis of crosslinking points even under acidic conditions, thereby maintaining the hydrogel's elastic modulus and strength.

Biocompatibility and Safety Considerations for Tunable Hydrogels

The biocompatibility and safety profile of tunable hydrogels represents a critical consideration in their development for biomedical applications. When manipulating crosslink density to achieve specific elastic moduli, researchers must carefully evaluate how these modifications affect the material's interaction with biological systems. Current evidence suggests that crosslink density directly influences not only mechanical properties but also cytotoxicity profiles, inflammatory responses, and degradation characteristics.

Systematic cytotoxicity testing protocols have been established to evaluate hydrogel formulations with varying crosslink densities. These typically include direct contact assays, extract testing, and metabolic activity assessments using standardized cell lines. Data tables from recent studies demonstrate a non-linear relationship between crosslink density and cellular viability, with optimal biocompatibility often occurring within specific elastic modulus ranges (typically 5-15 kPa for soft tissue applications).

Inflammatory response testing represents another crucial safety parameter for tunable hydrogels. Current protocols employ both in vitro macrophage activation assays and in vivo implantation studies to quantify pro-inflammatory cytokine production. Interestingly, recent data tables indicate that moderately crosslinked hydrogels (elastic modulus 10-20 kPa) often elicit minimal inflammatory responses compared to either highly rigid or extremely soft formulations.

Degradation kinetics and byproduct safety must be thoroughly characterized when tuning hydrogel mechanical properties. Standard test protocols include accelerated degradation studies, byproduct identification via mass spectrometry, and toxicological evaluation of degradation products. Comprehensive data tables from multiple research groups reveal that crosslinking agents significantly impact degradation profiles, with glutaraldehyde-based crosslinks generally showing higher cytotoxicity than carbodiimide or enzymatically-mediated crosslinks.

Sterilization compatibility represents a frequently overlooked safety consideration in mechanically tunable hydrogels. Test protocols must verify that sterilization methods (gamma irradiation, ethylene oxide, autoclaving) do not adversely affect crosslink integrity or introduce toxic residues. Recent comparative data tables demonstrate that gamma irradiation often reduces elastic modulus by 15-30% in highly crosslinked systems, potentially compromising mechanical performance in clinical applications.

Regulatory considerations for tunable hydrogels have evolved significantly, with both FDA and EMA now requiring comprehensive biocompatibility testing that specifically addresses the relationship between mechanical properties and safety profiles. Current test protocols must adhere to ISO 10993 standards, with particular emphasis on parts 5 (cytotoxicity), 10 (irritation), and 11 (systemic toxicity) when evaluating hydrogels with manipulated crosslink densities and elastic moduli.

Systematic cytotoxicity testing protocols have been established to evaluate hydrogel formulations with varying crosslink densities. These typically include direct contact assays, extract testing, and metabolic activity assessments using standardized cell lines. Data tables from recent studies demonstrate a non-linear relationship between crosslink density and cellular viability, with optimal biocompatibility often occurring within specific elastic modulus ranges (typically 5-15 kPa for soft tissue applications).

Inflammatory response testing represents another crucial safety parameter for tunable hydrogels. Current protocols employ both in vitro macrophage activation assays and in vivo implantation studies to quantify pro-inflammatory cytokine production. Interestingly, recent data tables indicate that moderately crosslinked hydrogels (elastic modulus 10-20 kPa) often elicit minimal inflammatory responses compared to either highly rigid or extremely soft formulations.

Degradation kinetics and byproduct safety must be thoroughly characterized when tuning hydrogel mechanical properties. Standard test protocols include accelerated degradation studies, byproduct identification via mass spectrometry, and toxicological evaluation of degradation products. Comprehensive data tables from multiple research groups reveal that crosslinking agents significantly impact degradation profiles, with glutaraldehyde-based crosslinks generally showing higher cytotoxicity than carbodiimide or enzymatically-mediated crosslinks.

Sterilization compatibility represents a frequently overlooked safety consideration in mechanically tunable hydrogels. Test protocols must verify that sterilization methods (gamma irradiation, ethylene oxide, autoclaving) do not adversely affect crosslink integrity or introduce toxic residues. Recent comparative data tables demonstrate that gamma irradiation often reduces elastic modulus by 15-30% in highly crosslinked systems, potentially compromising mechanical performance in clinical applications.

Regulatory considerations for tunable hydrogels have evolved significantly, with both FDA and EMA now requiring comprehensive biocompatibility testing that specifically addresses the relationship between mechanical properties and safety profiles. Current test protocols must adhere to ISO 10993 standards, with particular emphasis on parts 5 (cytotoxicity), 10 (irritation), and 11 (systemic toxicity) when evaluating hydrogels with manipulated crosslink densities and elastic moduli.

Scalability and Manufacturing Challenges for Precision Hydrogels

The scaling of precision hydrogel manufacturing from laboratory to industrial scale presents significant challenges that must be addressed for commercial viability. Current laboratory-scale production methods for hydrogels with precisely controlled crosslink density and elastic modulus often rely on batch processes with limited throughput and high variability between batches.

A primary challenge lies in maintaining consistent crosslink density across large production volumes. Laboratory protocols typically involve precise control of reaction conditions, including temperature, pH, and reagent concentrations. When scaled up, heat and mass transfer limitations can create gradients within reaction vessels, leading to heterogeneous crosslinking and inconsistent mechanical properties throughout the material.

Equipment design represents another critical barrier to scalability. Most crosslinking protocols require specialized equipment for UV exposure, temperature control, or mechanical mixing that may not translate directly to industrial settings. The capital investment required for custom manufacturing equipment capable of maintaining precise crosslinking conditions at scale can be prohibitively expensive for many companies entering this space.

Quality control and testing methodologies also face scaling challenges. Current elastic modulus testing protocols often involve destructive testing of small samples, which becomes impractical for large-scale production. Non-destructive testing methods that can rapidly assess crosslink density and mechanical properties in real-time during manufacturing are largely underdeveloped for hydrogel systems.

Raw material consistency presents additional complications. Industrial-scale production requires large quantities of precursors with batch-to-batch consistency. Variations in molecular weight distribution, purity, or functional group density of polymer precursors can significantly impact crosslinking efficiency and resultant mechanical properties, necessitating robust supplier qualification and material testing protocols.

Regulatory considerations further complicate manufacturing scale-up, particularly for biomedical applications. Documentation of manufacturing processes, validation protocols, and quality control measures must demonstrate that scaled production maintains the precise mechanical properties established in laboratory testing. This regulatory burden adds significant time and cost to commercialization efforts.

Cost-effective manufacturing remains perhaps the greatest challenge. Current precision hydrogels often rely on expensive precursors, catalysts, or crosslinking agents. Identifying alternative materials or developing more efficient crosslinking chemistries that maintain precise control over elastic modulus while reducing production costs represents a critical research direction for commercial viability.

A primary challenge lies in maintaining consistent crosslink density across large production volumes. Laboratory protocols typically involve precise control of reaction conditions, including temperature, pH, and reagent concentrations. When scaled up, heat and mass transfer limitations can create gradients within reaction vessels, leading to heterogeneous crosslinking and inconsistent mechanical properties throughout the material.

Equipment design represents another critical barrier to scalability. Most crosslinking protocols require specialized equipment for UV exposure, temperature control, or mechanical mixing that may not translate directly to industrial settings. The capital investment required for custom manufacturing equipment capable of maintaining precise crosslinking conditions at scale can be prohibitively expensive for many companies entering this space.

Quality control and testing methodologies also face scaling challenges. Current elastic modulus testing protocols often involve destructive testing of small samples, which becomes impractical for large-scale production. Non-destructive testing methods that can rapidly assess crosslink density and mechanical properties in real-time during manufacturing are largely underdeveloped for hydrogel systems.

Raw material consistency presents additional complications. Industrial-scale production requires large quantities of precursors with batch-to-batch consistency. Variations in molecular weight distribution, purity, or functional group density of polymer precursors can significantly impact crosslinking efficiency and resultant mechanical properties, necessitating robust supplier qualification and material testing protocols.

Regulatory considerations further complicate manufacturing scale-up, particularly for biomedical applications. Documentation of manufacturing processes, validation protocols, and quality control measures must demonstrate that scaled production maintains the precise mechanical properties established in laboratory testing. This regulatory burden adds significant time and cost to commercialization efforts.

Cost-effective manufacturing remains perhaps the greatest challenge. Current precision hydrogels often rely on expensive precursors, catalysts, or crosslinking agents. Identifying alternative materials or developing more efficient crosslinking chemistries that maintain precise control over elastic modulus while reducing production costs represents a critical research direction for commercial viability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!