How to Choose Conformal Coating for Low-Pressure Applications

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conformal Coating Background and Objectives

Conformal coatings have evolved significantly since their introduction in the mid-20th century, initially developed for military and aerospace applications where electronic components needed protection from harsh environmental conditions. These specialized protective materials form a thin polymeric film that conforms to the topology of printed circuit boards (PCBs), providing a barrier against moisture, dust, chemicals, and temperature extremes that could otherwise compromise electronic functionality.

The evolution of conformal coating technology has been driven by increasing demands for miniaturization, reliability, and performance in electronic devices across various industries. From early acrylic and silicone formulations, the technology has expanded to include urethane, epoxy, and more recently, parylene and nano-coatings, each offering distinct protective properties and application methods.

Low-pressure applications present unique challenges for conformal coating selection, as these environments can affect coating adhesion, outgassing characteristics, and overall protective efficacy. The vacuum or near-vacuum conditions found in aerospace, satellite, high-altitude equipment, and certain medical devices require specialized coating solutions that maintain their protective properties while minimizing volatile emissions.

The primary technical objective in selecting conformal coatings for low-pressure environments is to identify materials that provide comprehensive protection against potential failure mechanisms while maintaining dimensional stability and minimal outgassing under reduced atmospheric pressure. This includes protection against corona discharge, which becomes more prevalent in low-pressure environments, as well as resistance to extreme temperature cycling common in space applications.

Current industry trends indicate a growing focus on environmentally friendly coating options with reduced volatile organic compound (VOC) content, improved application efficiency, and enhanced performance in specialized environments. The development of hybrid coating systems that combine the advantages of different polymer types represents a significant advancement in addressing the complex requirements of low-pressure applications.

The technical goals for conformal coating selection in low-pressure scenarios include optimizing the balance between protection level, weight considerations, application process compatibility, and long-term reliability. Additionally, there is increasing emphasis on coatings that facilitate rework and repair while maintaining their protective integrity throughout the product lifecycle.

Understanding the fundamental principles governing conformal coating behavior under low-pressure conditions is essential for making informed selection decisions that align with specific application requirements and environmental constraints.

The evolution of conformal coating technology has been driven by increasing demands for miniaturization, reliability, and performance in electronic devices across various industries. From early acrylic and silicone formulations, the technology has expanded to include urethane, epoxy, and more recently, parylene and nano-coatings, each offering distinct protective properties and application methods.

Low-pressure applications present unique challenges for conformal coating selection, as these environments can affect coating adhesion, outgassing characteristics, and overall protective efficacy. The vacuum or near-vacuum conditions found in aerospace, satellite, high-altitude equipment, and certain medical devices require specialized coating solutions that maintain their protective properties while minimizing volatile emissions.

The primary technical objective in selecting conformal coatings for low-pressure environments is to identify materials that provide comprehensive protection against potential failure mechanisms while maintaining dimensional stability and minimal outgassing under reduced atmospheric pressure. This includes protection against corona discharge, which becomes more prevalent in low-pressure environments, as well as resistance to extreme temperature cycling common in space applications.

Current industry trends indicate a growing focus on environmentally friendly coating options with reduced volatile organic compound (VOC) content, improved application efficiency, and enhanced performance in specialized environments. The development of hybrid coating systems that combine the advantages of different polymer types represents a significant advancement in addressing the complex requirements of low-pressure applications.

The technical goals for conformal coating selection in low-pressure scenarios include optimizing the balance between protection level, weight considerations, application process compatibility, and long-term reliability. Additionally, there is increasing emphasis on coatings that facilitate rework and repair while maintaining their protective integrity throughout the product lifecycle.

Understanding the fundamental principles governing conformal coating behavior under low-pressure conditions is essential for making informed selection decisions that align with specific application requirements and environmental constraints.

Market Analysis for Low-Pressure Applications

The global market for conformal coatings in low-pressure applications is experiencing significant growth, driven by expanding applications in aerospace, medical devices, and advanced electronics. Current market valuation stands at approximately 2.1 billion USD with projections indicating a compound annual growth rate of 5.7% through 2028, according to industry reports from Grand View Research and MarketsandMarkets.

Low-pressure environments present unique challenges that have created distinct market segments within the conformal coating industry. The aerospace sector remains the dominant consumer, accounting for roughly 38% of market share, followed by medical devices at 24% and specialized electronics at 21%. The remaining market is distributed among automotive, defense, and emerging applications in renewable energy systems.

Regional analysis reveals North America leads the market with approximately 35% share, benefiting from its strong aerospace and defense industries. Asia-Pacific represents the fastest-growing region with annual growth exceeding 7%, primarily driven by electronics manufacturing expansion in China, South Korea, and Taiwan. Europe maintains a stable 28% market share, with particular strength in medical device applications.

Customer demand patterns show increasing preference for environmentally compliant coatings, with VOC-free and halogen-free formulations gaining traction. This shift is particularly pronounced in European markets where regulatory frameworks like RoHS and REACH have accelerated adoption of green alternatives. Market research indicates customers are willing to pay premium prices (typically 15-20% higher) for coatings that offer enhanced performance in low-pressure environments while meeting sustainability requirements.

Competition analysis reveals a market dominated by established chemical companies including Henkel, Dow Corning, Chase Corporation, and Dymax Corporation. However, specialized manufacturers focusing exclusively on low-pressure applications have gained market share, with companies like HumiSeal and Electrolube demonstrating strong growth trajectories. The competitive landscape is characterized by increasing focus on product differentiation through enhanced performance metrics specifically targeting vacuum stability, outgassing properties, and thermal cycling resistance.

Future market trends indicate growing demand for multi-functional coatings that combine traditional protection with additional properties such as EMI shielding, thermal management, and self-healing capabilities. The miniaturization trend in electronics is also driving demand for thinner coatings with equivalent or superior performance characteristics, creating new market opportunities for innovative formulations specifically designed for low-pressure environments.

Low-pressure environments present unique challenges that have created distinct market segments within the conformal coating industry. The aerospace sector remains the dominant consumer, accounting for roughly 38% of market share, followed by medical devices at 24% and specialized electronics at 21%. The remaining market is distributed among automotive, defense, and emerging applications in renewable energy systems.

Regional analysis reveals North America leads the market with approximately 35% share, benefiting from its strong aerospace and defense industries. Asia-Pacific represents the fastest-growing region with annual growth exceeding 7%, primarily driven by electronics manufacturing expansion in China, South Korea, and Taiwan. Europe maintains a stable 28% market share, with particular strength in medical device applications.

Customer demand patterns show increasing preference for environmentally compliant coatings, with VOC-free and halogen-free formulations gaining traction. This shift is particularly pronounced in European markets where regulatory frameworks like RoHS and REACH have accelerated adoption of green alternatives. Market research indicates customers are willing to pay premium prices (typically 15-20% higher) for coatings that offer enhanced performance in low-pressure environments while meeting sustainability requirements.

Competition analysis reveals a market dominated by established chemical companies including Henkel, Dow Corning, Chase Corporation, and Dymax Corporation. However, specialized manufacturers focusing exclusively on low-pressure applications have gained market share, with companies like HumiSeal and Electrolube demonstrating strong growth trajectories. The competitive landscape is characterized by increasing focus on product differentiation through enhanced performance metrics specifically targeting vacuum stability, outgassing properties, and thermal cycling resistance.

Future market trends indicate growing demand for multi-functional coatings that combine traditional protection with additional properties such as EMI shielding, thermal management, and self-healing capabilities. The miniaturization trend in electronics is also driving demand for thinner coatings with equivalent or superior performance characteristics, creating new market opportunities for innovative formulations specifically designed for low-pressure environments.

Current Challenges in Low-Pressure Coating Technology

Despite significant advancements in conformal coating technologies, the application of these protective materials in low-pressure environments presents several persistent challenges. The primary difficulty stems from the behavior of coating materials under reduced atmospheric pressure, where conventional application methods often fail to achieve uniform coverage. Vacuum conditions can cause premature evaporation of solvents, resulting in inconsistent coating thickness and compromised protection integrity.

Material compatibility issues represent another significant hurdle. Many traditional conformal coatings exhibit outgassing tendencies when exposed to low-pressure environments, potentially contaminating sensitive components or creating voids in the protective layer. This phenomenon is particularly problematic in aerospace, satellite, and high-altitude applications where equipment reliability is critical and maintenance opportunities are limited or nonexistent.

The curing process presents unique challenges in low-pressure settings. Conventional UV-cured and moisture-cured systems may behave unpredictably when atmospheric moisture and oxygen levels are reduced. This can lead to incomplete polymerization, resulting in coatings with suboptimal mechanical and dielectric properties that fail to provide adequate protection against environmental stressors.

Testing and qualification methodologies for low-pressure applications remain inadequately standardized. While MIL-I-46058C and IPC-CC-830B provide general guidelines for conformal coating performance, they do not specifically address the unique requirements of low-pressure environments. This regulatory gap complicates material selection and quality assurance processes for manufacturers developing products for these specialized applications.

Application equipment designed for standard atmospheric conditions often requires significant modification for low-pressure environments. Spray systems must be recalibrated to account for altered fluid dynamics, while dipping and automated selective coating systems may require complete redesign to function effectively in vacuum or near-vacuum conditions.

The cost-effectiveness of specialized low-pressure coating solutions presents an economic challenge. The development of custom formulations and application processes for low-pressure environments typically involves significant R&D investment, resulting in higher material and implementation costs that may be prohibitive for smaller manufacturers or lower-volume applications.

Thermal management during coating application and curing represents another technical obstacle. The reduced heat transfer efficiency in low-pressure environments can lead to localized overheating or incomplete curing, potentially compromising the protective capabilities of the coating or damaging sensitive electronic components.

Material compatibility issues represent another significant hurdle. Many traditional conformal coatings exhibit outgassing tendencies when exposed to low-pressure environments, potentially contaminating sensitive components or creating voids in the protective layer. This phenomenon is particularly problematic in aerospace, satellite, and high-altitude applications where equipment reliability is critical and maintenance opportunities are limited or nonexistent.

The curing process presents unique challenges in low-pressure settings. Conventional UV-cured and moisture-cured systems may behave unpredictably when atmospheric moisture and oxygen levels are reduced. This can lead to incomplete polymerization, resulting in coatings with suboptimal mechanical and dielectric properties that fail to provide adequate protection against environmental stressors.

Testing and qualification methodologies for low-pressure applications remain inadequately standardized. While MIL-I-46058C and IPC-CC-830B provide general guidelines for conformal coating performance, they do not specifically address the unique requirements of low-pressure environments. This regulatory gap complicates material selection and quality assurance processes for manufacturers developing products for these specialized applications.

Application equipment designed for standard atmospheric conditions often requires significant modification for low-pressure environments. Spray systems must be recalibrated to account for altered fluid dynamics, while dipping and automated selective coating systems may require complete redesign to function effectively in vacuum or near-vacuum conditions.

The cost-effectiveness of specialized low-pressure coating solutions presents an economic challenge. The development of custom formulations and application processes for low-pressure environments typically involves significant R&D investment, resulting in higher material and implementation costs that may be prohibitive for smaller manufacturers or lower-volume applications.

Thermal management during coating application and curing represents another technical obstacle. The reduced heat transfer efficiency in low-pressure environments can lead to localized overheating or incomplete curing, potentially compromising the protective capabilities of the coating or damaging sensitive electronic components.

Existing Coating Types and Selection Criteria

01 Types and compositions of conformal coatings

Various types of conformal coatings are used in electronics protection, including acrylic, silicone, polyurethane, and epoxy-based formulations. These coatings differ in their chemical compositions, offering varying degrees of protection against moisture, chemicals, and temperature fluctuations. The composition can be tailored with specific additives to enhance properties such as flexibility, adhesion, and thermal conductivity, making them suitable for different application environments and requirements.- Types and compositions of conformal coatings: Various types of conformal coatings are used in electronics protection, including acrylic, silicone, polyurethane, epoxy, and parylene. These coatings differ in their chemical compositions, providing specific properties such as moisture resistance, chemical resistance, flexibility, and thermal stability. The selection of coating material depends on the application requirements, environmental conditions, and the level of protection needed for electronic components.

- Application methods for conformal coatings: Conformal coatings can be applied using various techniques including spraying, dipping, brushing, selective coating, and vapor deposition. Each method offers different advantages in terms of coverage, thickness control, and suitability for specific component geometries. Automated application systems can improve consistency and efficiency in the coating process, while selective coating technologies allow for precise application to specific areas while keeping connectors and test points free from coating.

- Protection of electronic components and circuit boards: Conformal coatings provide critical protection for electronic components and printed circuit boards (PCBs) against environmental factors such as moisture, dust, chemicals, and temperature fluctuations. These protective layers help prevent corrosion, electrical shorts, and mechanical damage, thereby extending the lifespan and reliability of electronic devices. The coatings are particularly important in harsh environments or applications where failure is not an option, such as automotive, aerospace, and medical devices.

- Specialized conformal coatings for specific applications: Specialized conformal coatings have been developed for specific applications with unique requirements. These include coatings with enhanced thermal conductivity for heat management, UV-curable formulations for rapid processing, flame-retardant coatings for safety-critical applications, and coatings with electromagnetic interference (EMI) shielding properties. Advanced formulations may incorporate nanomaterials or specific additives to achieve properties such as self-healing capabilities, antimicrobial protection, or improved adhesion to difficult substrates.

- Curing and removal processes for conformal coatings: Conformal coatings require specific curing processes to achieve optimal performance, including thermal curing, UV curing, moisture curing, or room temperature curing depending on the coating type. The curing method affects properties such as adhesion strength, hardness, and chemical resistance. In some applications, coatings may need to be removed for rework or repair of electronic components, requiring specialized removal techniques and solvents that can dissolve the coating without damaging the underlying components.

02 Application methods for conformal coatings

Conformal coatings can be applied using various techniques including spray coating, dip coating, brush application, and automated selective coating. Each method offers different advantages in terms of coverage, thickness control, and production efficiency. Spray application provides uniform coverage for complex geometries, while dip coating ensures complete coverage but may require masking of sensitive areas. Automated selective coating systems allow precise deposition only where needed, reducing material waste and processing time.Expand Specific Solutions03 Protection mechanisms for electronic components

Conformal coatings provide critical protection for electronic components against environmental factors such as moisture, dust, chemicals, and mechanical stress. These protective layers prevent corrosion, electrical shorts, and component degradation, thereby extending the operational life of electronic assemblies. Advanced formulations can also offer additional benefits such as thermal management, vibration dampening, and protection against fungal growth, making them essential for electronics used in harsh or demanding environments.Expand Specific Solutions04 Curing and processing technologies

Various curing methods are employed for conformal coatings, including UV curing, thermal curing, moisture curing, and room temperature vulcanization. These processes transform the liquid coating into a solid protective film through polymerization or cross-linking reactions. The selection of curing method affects production speed, energy consumption, and the final properties of the coating. Advanced curing technologies can reduce processing time while ensuring complete polymerization and optimal protective characteristics.Expand Specific Solutions05 Specialized conformal coatings for emerging technologies

Specialized conformal coating formulations have been developed for emerging technologies such as flexible electronics, high-frequency devices, and automotive electronics. These advanced coatings address specific challenges like maintaining flexibility while providing protection, minimizing signal interference in RF applications, and withstanding extreme temperature cycling. Innovations include nanoparticle-enhanced coatings, low-dielectric formulations, and environmentally friendly water-based systems that comply with increasingly stringent regulations while delivering superior protection.Expand Specific Solutions

Leading Manufacturers and Industry Landscape

The conformal coating market for low-pressure applications is in a growth phase, with increasing demand driven by electronics miniaturization and reliability requirements. The market is projected to reach significant expansion as industries like automotive, aerospace, and consumer electronics adopt advanced protection solutions. Technologically, the field shows varying maturity levels, with established players like Nordson Corp., 3M Innovative Properties, and HzO offering traditional solutions, while innovative companies such as Semblant, FUJIFILM, and Favored Nanotechnology are developing next-generation nano-coating technologies. The competitive landscape features diversification between chemical manufacturers (Wacker Chemie, Sika Technology), equipment providers (Applied Materials), and specialized coating solution developers, with increasing focus on environmentally friendly formulations and plasma-based application methods for challenging low-pressure environments.

Nordson Corp.

Technical Solution: Nordson has developed advanced conformal coating solutions specifically engineered for low-pressure applications. Their technology utilizes precision automated dispensing systems that apply thin, uniform protective layers while maintaining consistent coverage at reduced atmospheric pressures. Their approach combines selective coating technology with specialized material formulations that maintain proper flow characteristics and adhesion properties even in vacuum or near-vacuum environments. Nordson's systems incorporate closed-loop feedback mechanisms that continuously monitor and adjust coating parameters based on environmental conditions, ensuring optimal material deposition regardless of pressure fluctuations. Their conformal coatings feature modified viscosity profiles that prevent outgassing issues common in low-pressure environments, while their proprietary dispensing nozzles are designed to maintain precise spray patterns without the atomization challenges typically encountered in reduced-pressure conditions[1][3].

Strengths: Superior precision dispensing capabilities allowing for selective coating application; advanced automation systems that maintain consistency across production runs; extensive material compatibility. Weaknesses: Higher initial equipment investment compared to manual coating methods; requires specialized technical expertise for system optimization; some solutions may have longer curing times in low-pressure environments.

3M Innovative Properties Co.

Technical Solution: 3M has pioneered fluoropolymer-based conformal coating solutions specifically engineered for low-pressure applications. Their technology utilizes modified fluorochemical polymers that maintain stable physical properties across varying pressure environments, from atmospheric to near-vacuum conditions. The company's conformal coatings feature proprietary cross-linking chemistry that creates moisture-resistant barriers while allowing for controlled gas permeability - critical for preventing delamination in pressure-fluctuating environments. 3M's coatings incorporate nano-scale fillers that enhance mechanical strength without compromising flexibility, enabling the material to withstand thermal cycling and mechanical stress common in aerospace and high-altitude applications. Their formulations are specifically designed to minimize outgassing, with volatile organic compound (VOC) content typically below 50g/L, making them suitable for sensitive electronic components operating in sealed low-pressure environments[2][5]. The coatings achieve hydrophobicity ratings exceeding 110° contact angle, providing exceptional moisture protection.

Strengths: Exceptional chemical resistance against a wide range of contaminants; superior moisture protection with hydrophobic properties; minimal outgassing suitable for sealed environments; excellent adhesion across diverse substrate materials. Weaknesses: Higher material cost compared to conventional acrylics; some formulations require specialized application equipment; longer curing times for certain high-performance variants.

Key Technical Innovations in Coating Materials

Conformal Coating

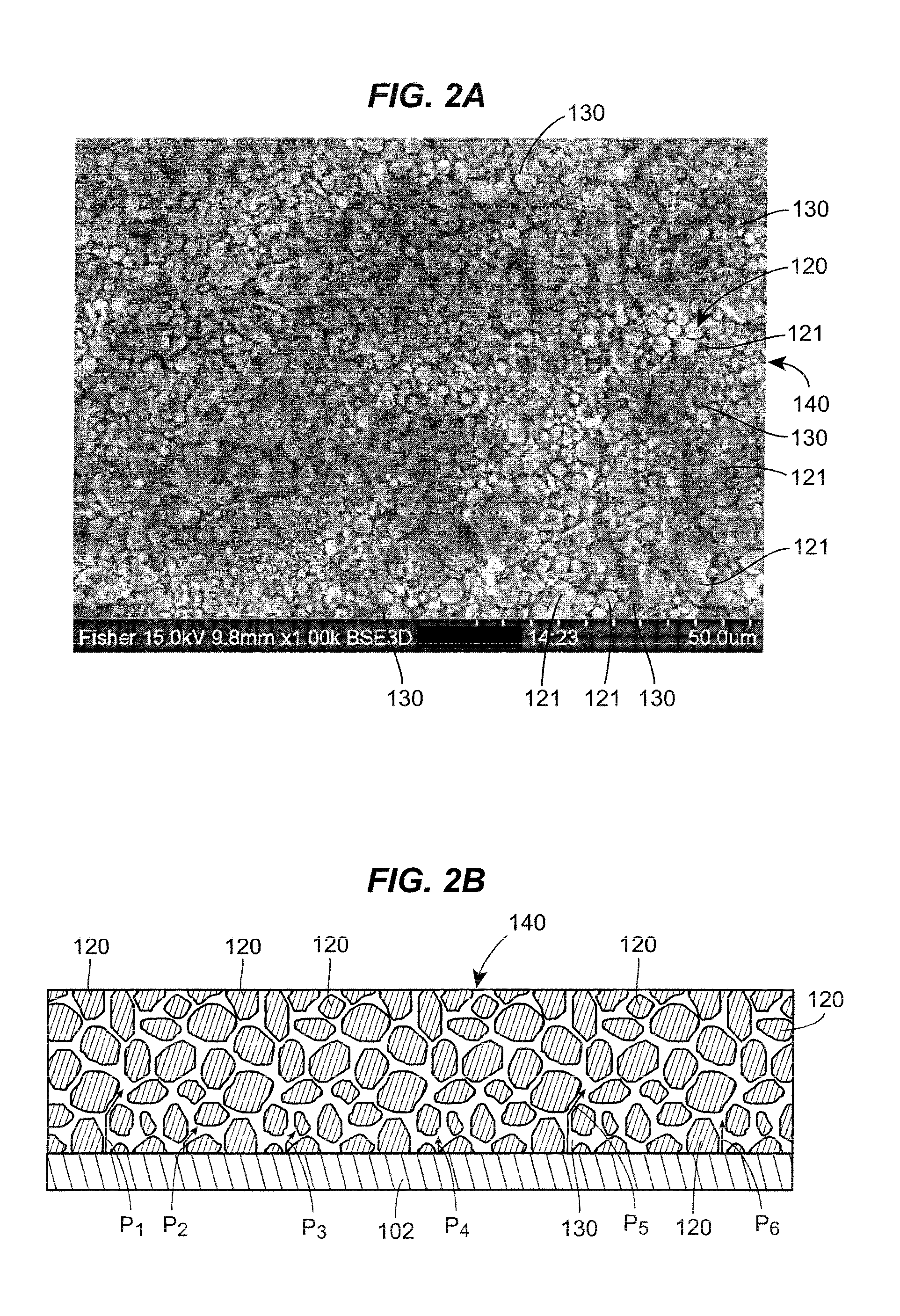

PatentInactiveUS20080216704A1

Innovation

- A multi-phase conformal coating system comprising a binding layer and electrically non-conductive particulates that form a tortuous path to inhibit the growth of conductive crystalline structures, providing sufficient hardness to block or deflect their growth.

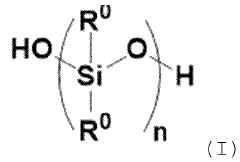

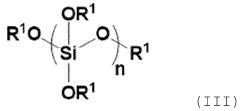

Moisture-curing conformal coating compositions

PatentWO2021259460A1

Innovation

- A solvent-free, one-component moisture-curing conformal coating composition comprising linear hydroxyl terminated organopolysiloxanes, organopolysiloxane resins, organosilicates, alkoxysilanes with tertiary amino groups, and UV-fluorescent pigments, which provides fast curing, excellent adhesion, and thermal stability without the use of metal catalysts.

Environmental Compliance and Sustainability Factors

Environmental regulations and sustainability considerations have become increasingly critical factors in conformal coating selection for low-pressure applications. The global regulatory landscape continues to evolve, with organizations such as the European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) imposing strict limitations on potentially harmful substances. When selecting conformal coatings, manufacturers must ensure compliance with these regulations to avoid penalties and maintain market access.

Volatile Organic Compound (VOC) content represents a primary environmental concern in conformal coating formulations. Traditional solvent-based coatings often contain high levels of VOCs that contribute to air pollution and pose health risks. The industry trend is moving toward water-based, UV-curable, and solvent-free alternatives that significantly reduce VOC emissions while maintaining performance in low-pressure environments.

Halogen-free formulations have gained prominence as environmental awareness increases. Coatings free from bromine, chlorine, and other halogens reduce the potential for harmful dioxin formation during disposal and recycling processes. For low-pressure applications where thermal stability is less critical, these environmentally friendly alternatives often provide adequate protection without compromising performance.

End-of-life considerations must also factor into coating selection decisions. Recyclability and biodegradability characteristics affect a product's overall environmental footprint. Some newer coating technologies incorporate bio-based materials or design features that facilitate easier separation during recycling processes, supporting circular economy principles even in specialized low-pressure applications.

Energy consumption during application and curing processes represents another sustainability dimension. UV-curable coatings typically require less energy than thermal-cure systems, potentially reducing carbon footprint. However, their suitability for low-pressure environments must be carefully evaluated, as some formulations may outgas under reduced atmospheric conditions, compromising coating integrity.

Manufacturing facilities increasingly implement closed-loop systems for coating application to minimize waste and environmental impact. These systems recover and reuse excess materials, reducing both environmental impact and operational costs. When selecting coatings for low-pressure applications, compatibility with such recovery systems should be considered alongside performance characteristics.

Carbon footprint considerations extend to transportation and storage requirements. Coatings with longer shelf lives and less stringent storage conditions generally contribute to reduced environmental impact. Additionally, locally sourced materials may reduce transportation-related emissions, though this benefit must be balanced against performance requirements specific to low-pressure environments.

Volatile Organic Compound (VOC) content represents a primary environmental concern in conformal coating formulations. Traditional solvent-based coatings often contain high levels of VOCs that contribute to air pollution and pose health risks. The industry trend is moving toward water-based, UV-curable, and solvent-free alternatives that significantly reduce VOC emissions while maintaining performance in low-pressure environments.

Halogen-free formulations have gained prominence as environmental awareness increases. Coatings free from bromine, chlorine, and other halogens reduce the potential for harmful dioxin formation during disposal and recycling processes. For low-pressure applications where thermal stability is less critical, these environmentally friendly alternatives often provide adequate protection without compromising performance.

End-of-life considerations must also factor into coating selection decisions. Recyclability and biodegradability characteristics affect a product's overall environmental footprint. Some newer coating technologies incorporate bio-based materials or design features that facilitate easier separation during recycling processes, supporting circular economy principles even in specialized low-pressure applications.

Energy consumption during application and curing processes represents another sustainability dimension. UV-curable coatings typically require less energy than thermal-cure systems, potentially reducing carbon footprint. However, their suitability for low-pressure environments must be carefully evaluated, as some formulations may outgas under reduced atmospheric conditions, compromising coating integrity.

Manufacturing facilities increasingly implement closed-loop systems for coating application to minimize waste and environmental impact. These systems recover and reuse excess materials, reducing both environmental impact and operational costs. When selecting coatings for low-pressure applications, compatibility with such recovery systems should be considered alongside performance characteristics.

Carbon footprint considerations extend to transportation and storage requirements. Coatings with longer shelf lives and less stringent storage conditions generally contribute to reduced environmental impact. Additionally, locally sourced materials may reduce transportation-related emissions, though this benefit must be balanced against performance requirements specific to low-pressure environments.

Cost-Benefit Analysis of Coating Options

When evaluating conformal coating options for low-pressure applications, a comprehensive cost-benefit analysis is essential to ensure optimal resource allocation and performance outcomes. Initial acquisition costs vary significantly across coating types, with acrylic coatings typically representing the most economical option at $5-10 per square foot, while silicone and parylene coatings command premium prices of $15-25 and $30-50 per square foot respectively due to their specialized properties and application processes.

Beyond material costs, application methodology significantly impacts the total investment. Spray application systems require initial equipment investments of $5,000-15,000, while automated selective coating systems may exceed $100,000. However, these higher upfront costs often yield substantial long-term savings through reduced material waste, improved consistency, and decreased labor requirements in high-volume production environments.

Operational efficiency considerations reveal that UV-curable coatings offer rapid processing times, enabling throughput rates up to 300% higher than traditional thermal-cure alternatives. This acceleration in production capacity can offset higher material costs through improved manufacturing efficiency and reduced work-in-progress inventory.

Maintenance requirements and coating longevity represent critical factors in the total cost of ownership calculation. Silicone coatings, while initially more expensive, demonstrate superior durability in low-pressure environments with service lifespans often exceeding 10 years, compared to 3-5 years for acrylic alternatives. This extended performance interval reduces replacement frequency and associated downtime costs.

Rework and repair considerations must also factor into the analysis. Urethane coatings present challenges for rework operations, often requiring specialized solvents and extended processing times, while acrylic coatings offer simpler removal processes that reduce repair costs by approximately 40-60% compared to other options.

Environmental compliance costs vary substantially based on coating chemistry. Traditional solvent-based formulations may require specialized ventilation systems costing $20,000-50,000 and ongoing emission monitoring, while water-based and UV-curable alternatives minimize these regulatory expenses.

Return on investment calculations indicate that despite higher initial costs, premium coating options like parylene often deliver superior value in critical low-pressure applications where failure consequences are severe. Case studies from aerospace and medical device manufacturers demonstrate that investing in higher-performance coatings can reduce warranty claims by 70-85% and extend product lifecycles by 30-50%, yielding positive ROI within 18-24 months for most applications.

Beyond material costs, application methodology significantly impacts the total investment. Spray application systems require initial equipment investments of $5,000-15,000, while automated selective coating systems may exceed $100,000. However, these higher upfront costs often yield substantial long-term savings through reduced material waste, improved consistency, and decreased labor requirements in high-volume production environments.

Operational efficiency considerations reveal that UV-curable coatings offer rapid processing times, enabling throughput rates up to 300% higher than traditional thermal-cure alternatives. This acceleration in production capacity can offset higher material costs through improved manufacturing efficiency and reduced work-in-progress inventory.

Maintenance requirements and coating longevity represent critical factors in the total cost of ownership calculation. Silicone coatings, while initially more expensive, demonstrate superior durability in low-pressure environments with service lifespans often exceeding 10 years, compared to 3-5 years for acrylic alternatives. This extended performance interval reduces replacement frequency and associated downtime costs.

Rework and repair considerations must also factor into the analysis. Urethane coatings present challenges for rework operations, often requiring specialized solvents and extended processing times, while acrylic coatings offer simpler removal processes that reduce repair costs by approximately 40-60% compared to other options.

Environmental compliance costs vary substantially based on coating chemistry. Traditional solvent-based formulations may require specialized ventilation systems costing $20,000-50,000 and ongoing emission monitoring, while water-based and UV-curable alternatives minimize these regulatory expenses.

Return on investment calculations indicate that despite higher initial costs, premium coating options like parylene often deliver superior value in critical low-pressure applications where failure consequences are severe. Case studies from aerospace and medical device manufacturers demonstrate that investing in higher-performance coatings can reduce warranty claims by 70-85% and extend product lifecycles by 30-50%, yielding positive ROI within 18-24 months for most applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!