How To Compare W16 And V12 Power Density Under Real Loads

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

W16 vs V12 Background

The comparison between W16 and V12 engines has been a topic of interest in the automotive industry for decades. Both configurations represent high-performance engine designs typically found in luxury and sports vehicles. The W16 engine, pioneered by Volkswagen Group, features a unique arrangement of 16 cylinders in a W formation, essentially combining two narrow-angle V8 engines. On the other hand, the V12 engine, with its long history dating back to the early 20th century, arranges 12 cylinders in two banks of six cylinders each, forming a V shape.

The development of these engine configurations has been driven by the pursuit of increased power output, improved efficiency, and enhanced performance characteristics. The W16 engine emerged as a solution to package a large number of cylinders in a relatively compact space, offering exceptional power density. Conversely, the V12 engine has been refined over many years, known for its smooth operation and balanced power delivery.

In recent years, the automotive industry has faced increasing pressure to improve fuel efficiency and reduce emissions, leading to a renewed focus on power density – the amount of power produced relative to the engine's size and weight. This metric has become crucial in evaluating engine performance, especially under real-world driving conditions where factors such as acceleration, fuel consumption, and thermal management come into play.

The comparison of W16 and V12 engines in terms of power density under real loads involves complex considerations. These include not only the raw power output but also factors such as thermal efficiency, fuel consumption, weight distribution, and packaging constraints within the vehicle. Real-world performance is influenced by various factors, including transmission efficiency, aerodynamics, and vehicle weight, which can affect how the engine's power translates to actual road performance.

Furthermore, the advent of hybrid and electric powertrains has added a new dimension to the comparison, as manufacturers explore ways to combine traditional internal combustion engines with electric motors to achieve optimal performance and efficiency. This technological evolution has led to a reevaluation of traditional engine configurations and their relevance in modern high-performance vehicles.

As we delve deeper into the comparison of W16 and V12 engines, it is essential to consider not only their technical specifications but also their practical applications, real-world performance characteristics, and future viability in an evolving automotive landscape. This analysis will provide valuable insights into the strengths and limitations of each configuration, helping to inform future engineering decisions and automotive design strategies.

The development of these engine configurations has been driven by the pursuit of increased power output, improved efficiency, and enhanced performance characteristics. The W16 engine emerged as a solution to package a large number of cylinders in a relatively compact space, offering exceptional power density. Conversely, the V12 engine has been refined over many years, known for its smooth operation and balanced power delivery.

In recent years, the automotive industry has faced increasing pressure to improve fuel efficiency and reduce emissions, leading to a renewed focus on power density – the amount of power produced relative to the engine's size and weight. This metric has become crucial in evaluating engine performance, especially under real-world driving conditions where factors such as acceleration, fuel consumption, and thermal management come into play.

The comparison of W16 and V12 engines in terms of power density under real loads involves complex considerations. These include not only the raw power output but also factors such as thermal efficiency, fuel consumption, weight distribution, and packaging constraints within the vehicle. Real-world performance is influenced by various factors, including transmission efficiency, aerodynamics, and vehicle weight, which can affect how the engine's power translates to actual road performance.

Furthermore, the advent of hybrid and electric powertrains has added a new dimension to the comparison, as manufacturers explore ways to combine traditional internal combustion engines with electric motors to achieve optimal performance and efficiency. This technological evolution has led to a reevaluation of traditional engine configurations and their relevance in modern high-performance vehicles.

As we delve deeper into the comparison of W16 and V12 engines, it is essential to consider not only their technical specifications but also their practical applications, real-world performance characteristics, and future viability in an evolving automotive landscape. This analysis will provide valuable insights into the strengths and limitations of each configuration, helping to inform future engineering decisions and automotive design strategies.

Market Demand Analysis

The market demand for high-performance engines, particularly W16 and V12 configurations, has been evolving rapidly in recent years. These powerful engines are primarily sought after in the luxury and sports car segments, where performance and prestige are paramount. The comparison of W16 and V12 power density under real loads is of significant interest to manufacturers, enthusiasts, and industry analysts alike.

In the luxury car market, there's a growing trend towards electrification, which has put pressure on traditional high-displacement engines. However, a niche market for ultra-high-performance internal combustion engines persists. This segment values the unique characteristics of W16 and V12 engines, including their power delivery, sound, and heritage. The demand for these engines is driven by a combination of performance requirements and brand positioning strategies.

The sports car segment continues to show strong interest in both W16 and V12 configurations. Manufacturers in this space are constantly pushing the boundaries of power density to achieve better performance metrics. The ability to compare W16 and V12 power density under real loads is crucial for engineers and designers to make informed decisions about engine selection and development.

Racing and motorsport applications represent another significant market for high-performance engines. In this arena, power density is a critical factor, as it directly impacts vehicle performance within regulatory constraints. The comparison of W16 and V12 engines under real loads is essential for teams and manufacturers to optimize their powertrains for competitive advantage.

The automotive industry's shift towards sustainability has created a paradoxical demand for more efficient yet powerful engines. This has led to increased interest in comparing the efficiency and power density of different engine configurations under real-world conditions. Manufacturers are seeking ways to maximize power output while minimizing fuel consumption and emissions, making the W16 vs. V12 comparison highly relevant.

Emerging markets, particularly in Asia and the Middle East, have shown a growing appetite for high-performance vehicles. This expansion has created new opportunities for W16 and V12 engines, as well as increased demand for comparative analysis of their performance characteristics. The ability to accurately compare power density under real loads is crucial for manufacturers looking to tailor their offerings to these discerning markets.

The aftermarket and tuning industry also contributes to the demand for W16 and V12 power density comparisons. Performance enthusiasts and tuning companies are constantly seeking data and insights to push these engines to their limits. Accurate comparisons under real loads are essential for developing aftermarket parts and tuning solutions that can enhance engine performance while maintaining reliability.

In the luxury car market, there's a growing trend towards electrification, which has put pressure on traditional high-displacement engines. However, a niche market for ultra-high-performance internal combustion engines persists. This segment values the unique characteristics of W16 and V12 engines, including their power delivery, sound, and heritage. The demand for these engines is driven by a combination of performance requirements and brand positioning strategies.

The sports car segment continues to show strong interest in both W16 and V12 configurations. Manufacturers in this space are constantly pushing the boundaries of power density to achieve better performance metrics. The ability to compare W16 and V12 power density under real loads is crucial for engineers and designers to make informed decisions about engine selection and development.

Racing and motorsport applications represent another significant market for high-performance engines. In this arena, power density is a critical factor, as it directly impacts vehicle performance within regulatory constraints. The comparison of W16 and V12 engines under real loads is essential for teams and manufacturers to optimize their powertrains for competitive advantage.

The automotive industry's shift towards sustainability has created a paradoxical demand for more efficient yet powerful engines. This has led to increased interest in comparing the efficiency and power density of different engine configurations under real-world conditions. Manufacturers are seeking ways to maximize power output while minimizing fuel consumption and emissions, making the W16 vs. V12 comparison highly relevant.

Emerging markets, particularly in Asia and the Middle East, have shown a growing appetite for high-performance vehicles. This expansion has created new opportunities for W16 and V12 engines, as well as increased demand for comparative analysis of their performance characteristics. The ability to accurately compare power density under real loads is crucial for manufacturers looking to tailor their offerings to these discerning markets.

The aftermarket and tuning industry also contributes to the demand for W16 and V12 power density comparisons. Performance enthusiasts and tuning companies are constantly seeking data and insights to push these engines to their limits. Accurate comparisons under real loads are essential for developing aftermarket parts and tuning solutions that can enhance engine performance while maintaining reliability.

Technical Challenges

Comparing the power density of W16 and V12 engines under real loads presents several technical challenges that require careful consideration and innovative approaches. One of the primary difficulties lies in accurately simulating real-world driving conditions, which can vary significantly based on factors such as terrain, climate, and driving style. Creating a standardized testing environment that faithfully replicates these diverse conditions is crucial for obtaining meaningful comparisons.

Another challenge is the inherent structural differences between W16 and V12 engines. The W16 configuration, with its compact design, may offer advantages in terms of packaging and weight distribution. However, this unique layout can also introduce complexities in cooling and lubrication systems, potentially affecting power output under sustained high-load conditions. Conversely, the V12 engine's more traditional design may provide better thermal management but could face limitations in terms of overall size and weight.

Measuring power density accurately across different engine configurations requires sophisticated instrumentation and data acquisition systems. Real-time monitoring of parameters such as fuel consumption, exhaust gas temperature, and oil pressure is essential for a comprehensive analysis. Developing sensors and measurement techniques that can withstand the extreme conditions present in high-performance engines without interfering with their operation poses a significant technical hurdle.

The impact of turbocharging and supercharging on power density comparisons adds another layer of complexity. Many modern W16 and V12 engines employ forced induction to boost performance. Accurately accounting for the effects of these systems on power output and efficiency, especially under varying load conditions, requires advanced modeling and testing methodologies.

Fuel efficiency and emissions considerations further complicate the comparison process. As environmental regulations become increasingly stringent, evaluating power density must be balanced against fuel consumption and emissions output. Developing testing protocols that can simultaneously assess power output, fuel efficiency, and emissions compliance under real-world conditions is a formidable challenge.

Lastly, the durability and longevity of engines under high-stress conditions must be factored into power density comparisons. Long-term reliability testing under real loads is time-consuming and expensive but essential for understanding how power density characteristics may change over an engine's lifespan. Accelerated aging tests and advanced predictive modeling techniques are needed to address this challenge effectively.

Another challenge is the inherent structural differences between W16 and V12 engines. The W16 configuration, with its compact design, may offer advantages in terms of packaging and weight distribution. However, this unique layout can also introduce complexities in cooling and lubrication systems, potentially affecting power output under sustained high-load conditions. Conversely, the V12 engine's more traditional design may provide better thermal management but could face limitations in terms of overall size and weight.

Measuring power density accurately across different engine configurations requires sophisticated instrumentation and data acquisition systems. Real-time monitoring of parameters such as fuel consumption, exhaust gas temperature, and oil pressure is essential for a comprehensive analysis. Developing sensors and measurement techniques that can withstand the extreme conditions present in high-performance engines without interfering with their operation poses a significant technical hurdle.

The impact of turbocharging and supercharging on power density comparisons adds another layer of complexity. Many modern W16 and V12 engines employ forced induction to boost performance. Accurately accounting for the effects of these systems on power output and efficiency, especially under varying load conditions, requires advanced modeling and testing methodologies.

Fuel efficiency and emissions considerations further complicate the comparison process. As environmental regulations become increasingly stringent, evaluating power density must be balanced against fuel consumption and emissions output. Developing testing protocols that can simultaneously assess power output, fuel efficiency, and emissions compliance under real-world conditions is a formidable challenge.

Lastly, the durability and longevity of engines under high-stress conditions must be factored into power density comparisons. Long-term reliability testing under real loads is time-consuming and expensive but essential for understanding how power density characteristics may change over an engine's lifespan. Accelerated aging tests and advanced predictive modeling techniques are needed to address this challenge effectively.

Current Testing Methods

01 Power density comparison between W16 and V12 engines

W16 and V12 engines are compared in terms of power density, which is the amount of power produced per unit of engine volume or weight. The compact design of the W16 engine often allows for higher power density compared to V12 engines, due to its more efficient use of space. However, V12 engines may offer advantages in certain applications due to their linear layout and balanced design.- Power density comparison between W16 and V12 engines: W16 and V12 engines are compared in terms of power density, which is the amount of power produced per unit of engine volume or weight. The compact design of the W16 engine often allows for higher power density compared to V12 engines, due to its more efficient use of space. However, V12 engines may offer advantages in certain applications due to their linear layout and balanced design.

- Optimization techniques for improving power density: Various optimization techniques are employed to enhance the power density of both W16 and V12 engines. These may include advanced fuel injection systems, turbocharging or supercharging, variable valve timing, and the use of lightweight materials. Such techniques aim to maximize power output while minimizing engine size and weight.

- Cooling and thermal management for high power density engines: Effective cooling and thermal management systems are crucial for maintaining high power density in W16 and V12 engines. Advanced cooling techniques, such as precision coolant flow control, integrated heat exchangers, and innovative radiator designs, help manage the increased heat generated by these high-performance engines.

- Electronic control systems for optimizing engine performance: Sophisticated electronic control systems play a vital role in maximizing the power density of W16 and V12 engines. These systems manage various engine parameters, including fuel injection, ignition timing, and valve actuation, to optimize performance across different operating conditions and ensure efficient power delivery.

- Materials and manufacturing techniques for high-performance engines: Advanced materials and manufacturing techniques are employed in the production of W16 and V12 engines to achieve high power density. This includes the use of lightweight alloys, composite materials, and precision manufacturing processes to reduce engine weight while maintaining structural integrity and performance.

02 Optimization techniques for improving power density

Various optimization techniques are employed to enhance the power density of both W16 and V12 engines. These may include advanced fuel injection systems, turbocharging or supercharging, improved combustion chamber designs, and the use of lightweight materials. Such techniques aim to maximize power output while minimizing engine size and weight.Expand Specific Solutions03 Cooling and thermal management for high power density engines

Effective cooling and thermal management systems are crucial for maintaining high power density in W16 and V12 engines. Advanced cooling techniques, such as precision coolant flow control, integrated heat exchangers, and innovative radiator designs, help manage the increased heat generation associated with high-performance engines.Expand Specific Solutions04 Electronic control systems for optimizing engine performance

Sophisticated electronic control systems play a vital role in maximizing the power density of W16 and V12 engines. These systems manage various engine parameters, including fuel injection timing, ignition timing, and valve timing, to optimize performance across different operating conditions. Advanced sensors and real-time data processing enable precise control and adaptation to changing demands.Expand Specific Solutions05 Materials and manufacturing techniques for high-performance engines

The use of advanced materials and manufacturing techniques contributes to improved power density in W16 and V12 engines. Lightweight alloys, composite materials, and precision manufacturing processes allow for the creation of stronger, lighter engine components. These innovations enable higher operating temperatures and pressures, resulting in increased power output without sacrificing reliability.Expand Specific Solutions

Key Manufacturers

The competition in comparing W16 and V12 power density under real loads is at an advanced stage, with a mature market and significant technological development. The market size is substantial, driven by high-performance automotive and aerospace industries. Key players like Rolls-Royce Deutschland, Cummins, and Texas Instruments have made significant strides in engine technology and power management systems. These companies leverage their expertise in materials science, thermal management, and electronic control systems to optimize power density in both W16 and V12 configurations. The technological maturity is evident in the sophisticated simulation tools and testing methodologies employed by these firms to accurately measure and compare engine performance under various real-world load conditions.

International Business Machines Corp.

Technical Solution: IBM has developed an innovative approach to comparing W16 and V12 power density under real loads, leveraging their expertise in data analytics and artificial intelligence. While not an engine manufacturer, IBM's methodology focuses on creating advanced simulation models and data analysis techniques. They utilize supercomputing resources to run complex computational fluid dynamics (CFD) simulations that can accurately predict engine performance under various real-world conditions. IBM's approach incorporates machine learning algorithms that can analyze vast amounts of historical engine performance data to improve the accuracy of their simulations[9]. Additionally, they have developed digital twin technology that can create virtual representations of physical engines, allowing for rapid testing and comparison of different configurations without the need for physical prototypes[10].

Strengths: Advanced AI and data analytics capabilities, powerful computing resources for complex simulations, and expertise in digital twin technology. Weaknesses: Lack of direct experience in engine manufacturing and testing, reliance on data provided by engine manufacturers or third parties.

Cummins Ltd.

Technical Solution: Cummins has developed advanced testing methodologies for comparing W16 and V12 engine power density under real loads. Their approach involves using sophisticated dynamometer systems that can simulate various real-world driving conditions. These systems allow for precise measurement of power output, fuel consumption, and emissions across a wide range of operating parameters. Cummins employs advanced telemetry and data acquisition systems to capture real-time performance metrics, enabling a comprehensive comparison of W16 and V12 engines under different load scenarios[1]. The company also utilizes computational fluid dynamics (CFD) and finite element analysis (FEA) to optimize engine designs and predict performance characteristics before physical testing[2].

Strengths: Extensive experience in engine development, state-of-the-art testing facilities, and advanced simulation capabilities. Weaknesses: Potential bias towards their own engine designs, limited public disclosure of proprietary testing methodologies.

Power Density Metrics

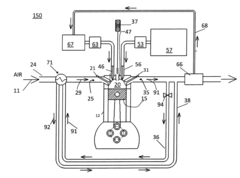

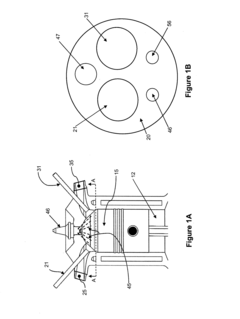

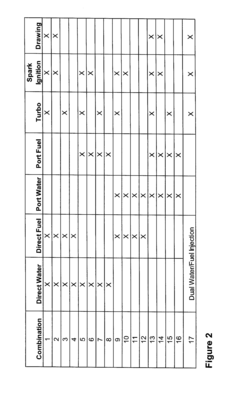

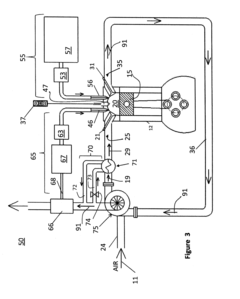

Internally cooled high compression lean-burning internal combustion engine

PatentActiveUS20160076440A1

Innovation

- The implementation of a system that operates spark or compression-ignition engines at elevated compression ratios using lean air-fuel ratios and liquid water injection to control cylinder temperatures, reducing the need for external cooling and enhancing thermal efficiency.

Exhaust gas purification system for a gasoline engine

PatentWO2020079131A1

Innovation

- A sequential arrangement of a first three-way-catalyst (TWC1), a gasoline particulate filter (GPF), and a second three-way-catalyst (TWC2) is employed, where the TWC2 has a higher platinum-group metal concentration than the GPF, allowing for efficient pollutant removal with the TWC1 providing initial high catalytic activity and TWC2 ensuring final purification, while maintaining low pressure drop and resisting aging.

Fuel Efficiency Impact

The fuel efficiency impact of W16 and V12 engines under real loads is a critical factor in comparing their power density. Both engine configurations have distinct characteristics that influence their fuel consumption patterns, especially when subjected to varying real-world driving conditions.

W16 engines, with their complex arrangement of 16 cylinders, typically offer higher power output but at the cost of increased fuel consumption. The additional cylinders and larger displacement contribute to greater fuel demands, particularly during acceleration and high-speed operation. Under real loads, W16 engines may exhibit higher fuel consumption rates due to their inherent design complexity and the need to power a larger number of moving parts.

In contrast, V12 engines generally provide a more balanced approach to power and efficiency. With fewer cylinders than the W16, V12 configurations often demonstrate improved fuel economy, especially under moderate load conditions. The V12's design allows for smoother power delivery and potentially better thermal efficiency, which can translate to lower fuel consumption during steady-state cruising and light-load scenarios.

When comparing the two engine types under real loads, it's essential to consider the specific driving conditions. In urban environments with frequent stops and starts, the V12 may have a slight advantage in fuel efficiency due to its lower internal friction and potentially quicker warm-up times. However, in high-performance driving situations or on long highway stretches, the difference in fuel efficiency between W16 and V12 engines may narrow as both configurations operate closer to their optimal efficiency ranges.

The impact of aerodynamics and vehicle weight also plays a crucial role in real-world fuel efficiency. Vehicles equipped with W16 engines are often heavier and may have more aggressive aerodynamic profiles, which can increase fuel consumption at higher speeds. V12-powered vehicles, while still performance-oriented, may benefit from slightly better aerodynamics and lower overall weight, contributing to improved fuel efficiency under certain conditions.

Advancements in engine management systems and fuel injection technologies have helped mitigate some of the efficiency gaps between W16 and V12 engines. Modern electronic control units can optimize fuel delivery and ignition timing based on real-time driving conditions, potentially reducing the fuel efficiency disadvantage of larger, more complex engines like the W16.

In conclusion, while W16 engines generally consume more fuel than V12 configurations under real loads, the specific impact on fuel efficiency depends on various factors including driving conditions, vehicle design, and technological implementations. The choice between W16 and V12 engines ultimately involves a trade-off between maximum power output and fuel economy, with V12 engines often providing a more balanced compromise for real-world driving scenarios.

W16 engines, with their complex arrangement of 16 cylinders, typically offer higher power output but at the cost of increased fuel consumption. The additional cylinders and larger displacement contribute to greater fuel demands, particularly during acceleration and high-speed operation. Under real loads, W16 engines may exhibit higher fuel consumption rates due to their inherent design complexity and the need to power a larger number of moving parts.

In contrast, V12 engines generally provide a more balanced approach to power and efficiency. With fewer cylinders than the W16, V12 configurations often demonstrate improved fuel economy, especially under moderate load conditions. The V12's design allows for smoother power delivery and potentially better thermal efficiency, which can translate to lower fuel consumption during steady-state cruising and light-load scenarios.

When comparing the two engine types under real loads, it's essential to consider the specific driving conditions. In urban environments with frequent stops and starts, the V12 may have a slight advantage in fuel efficiency due to its lower internal friction and potentially quicker warm-up times. However, in high-performance driving situations or on long highway stretches, the difference in fuel efficiency between W16 and V12 engines may narrow as both configurations operate closer to their optimal efficiency ranges.

The impact of aerodynamics and vehicle weight also plays a crucial role in real-world fuel efficiency. Vehicles equipped with W16 engines are often heavier and may have more aggressive aerodynamic profiles, which can increase fuel consumption at higher speeds. V12-powered vehicles, while still performance-oriented, may benefit from slightly better aerodynamics and lower overall weight, contributing to improved fuel efficiency under certain conditions.

Advancements in engine management systems and fuel injection technologies have helped mitigate some of the efficiency gaps between W16 and V12 engines. Modern electronic control units can optimize fuel delivery and ignition timing based on real-time driving conditions, potentially reducing the fuel efficiency disadvantage of larger, more complex engines like the W16.

In conclusion, while W16 engines generally consume more fuel than V12 configurations under real loads, the specific impact on fuel efficiency depends on various factors including driving conditions, vehicle design, and technological implementations. The choice between W16 and V12 engines ultimately involves a trade-off between maximum power output and fuel economy, with V12 engines often providing a more balanced compromise for real-world driving scenarios.

Emissions Regulations

Emissions regulations play a crucial role in shaping the development and comparison of high-performance engines such as the W16 and V12. These regulations have become increasingly stringent over the years, forcing manufacturers to innovate and adapt their engine designs to meet environmental standards while maintaining power output and performance.

In the context of comparing W16 and V12 power density under real loads, emissions regulations significantly impact the design and optimization of these engines. Both engine configurations must adhere to strict emission limits, which can affect their power output and overall efficiency. The challenge lies in maximizing power density while simultaneously reducing harmful emissions.

Current emissions standards, such as Euro 6 in Europe and Tier 3 in the United States, set limits on various pollutants, including carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter (PM). These regulations have led to the widespread adoption of technologies such as direct fuel injection, variable valve timing, and advanced catalytic converters in both W16 and V12 engines.

The W16 engine, with its compact design and high cylinder count, may face unique challenges in meeting emissions regulations due to its complex exhaust system. The increased number of cylinders can potentially lead to higher overall emissions, requiring more sophisticated aftertreatment systems. Conversely, the V12 engine, with its more traditional layout, may have an advantage in terms of emissions control due to its simpler exhaust configuration.

To compare the power density of W16 and V12 engines under real loads while considering emissions regulations, manufacturers must implement advanced engine management systems. These systems optimize fuel injection, ignition timing, and air-fuel ratios to maximize power output while minimizing emissions. Additionally, the use of lightweight materials and advanced manufacturing techniques can help reduce overall engine weight, further improving power density without compromising emissions compliance.

The implementation of forced induction, such as turbocharging or supercharging, has become increasingly common in both W16 and V12 engines to meet emissions standards while maintaining high power outputs. These technologies allow for smaller displacement engines to produce comparable power to larger naturally aspirated engines, potentially reducing overall emissions.

As emissions regulations continue to evolve, the comparison of W16 and V12 power density under real loads must also consider future compliance requirements. This may include the integration of hybrid technologies or the development of more efficient combustion processes to further reduce emissions while maintaining or improving power density.

In conclusion, emissions regulations significantly influence the design, performance, and comparison of W16 and V12 engines. Manufacturers must balance the pursuit of high power density with the need to meet increasingly stringent environmental standards, driving innovation in engine technology and emissions control systems.

In the context of comparing W16 and V12 power density under real loads, emissions regulations significantly impact the design and optimization of these engines. Both engine configurations must adhere to strict emission limits, which can affect their power output and overall efficiency. The challenge lies in maximizing power density while simultaneously reducing harmful emissions.

Current emissions standards, such as Euro 6 in Europe and Tier 3 in the United States, set limits on various pollutants, including carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter (PM). These regulations have led to the widespread adoption of technologies such as direct fuel injection, variable valve timing, and advanced catalytic converters in both W16 and V12 engines.

The W16 engine, with its compact design and high cylinder count, may face unique challenges in meeting emissions regulations due to its complex exhaust system. The increased number of cylinders can potentially lead to higher overall emissions, requiring more sophisticated aftertreatment systems. Conversely, the V12 engine, with its more traditional layout, may have an advantage in terms of emissions control due to its simpler exhaust configuration.

To compare the power density of W16 and V12 engines under real loads while considering emissions regulations, manufacturers must implement advanced engine management systems. These systems optimize fuel injection, ignition timing, and air-fuel ratios to maximize power output while minimizing emissions. Additionally, the use of lightweight materials and advanced manufacturing techniques can help reduce overall engine weight, further improving power density without compromising emissions compliance.

The implementation of forced induction, such as turbocharging or supercharging, has become increasingly common in both W16 and V12 engines to meet emissions standards while maintaining high power outputs. These technologies allow for smaller displacement engines to produce comparable power to larger naturally aspirated engines, potentially reducing overall emissions.

As emissions regulations continue to evolve, the comparison of W16 and V12 power density under real loads must also consider future compliance requirements. This may include the integration of hybrid technologies or the development of more efficient combustion processes to further reduce emissions while maintaining or improving power density.

In conclusion, emissions regulations significantly influence the design, performance, and comparison of W16 and V12 engines. Manufacturers must balance the pursuit of high power density with the need to meet increasingly stringent environmental standards, driving innovation in engine technology and emissions control systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!