How To Perform Endurance Runs For W16 Prototype Validation

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

W16 Prototype Background

The W16 engine represents a pinnacle of automotive engineering, combining the power of two V8 engines into a single, compact unit. Developed primarily for high-performance sports cars and hypercars, the W16 configuration offers exceptional power output and a unique engine note. The prototype phase of a W16 engine is crucial, as it allows engineers to test and refine the design before moving to production.

The W16 prototype typically consists of four banks of four cylinders arranged in a W configuration. This layout allows for a shorter overall engine length compared to a traditional V16, making it more suitable for mid-engine sports car designs. The complexity of the W16 design presents numerous challenges during the prototype stage, including issues related to cooling, lubrication, and vibration management.

Endurance runs for W16 prototype validation are essential to ensure the engine can withstand prolonged periods of operation under various conditions. These tests aim to identify potential weaknesses in the design, evaluate long-term reliability, and assess the engine's performance characteristics over extended periods. The validation process often involves running the engine continuously for hundreds of hours, simulating real-world driving conditions and pushing the prototype to its limits.

During the prototype phase, engineers focus on optimizing various aspects of the W16 engine. This includes fine-tuning the fuel injection system, improving combustion efficiency, and refining the engine management software. The prototype stage also allows for the evaluation of different materials and manufacturing techniques to enhance durability and reduce weight.

One of the key challenges in W16 prototype development is managing heat dissipation. With 16 cylinders in close proximity, effective cooling becomes critical to prevent overheating and ensure consistent performance. Engineers must design and test sophisticated cooling systems, including advanced radiator designs and precision-engineered coolant channels within the engine block.

Another crucial aspect of W16 prototype validation is the assessment of NVH (Noise, Vibration, and Harshness) characteristics. The unique configuration of the W16 engine can lead to complex vibration patterns, requiring extensive analysis and refinement to achieve smooth operation across the entire RPM range. This often involves the use of advanced balancing techniques and the implementation of specialized engine mounts.

The W16 prototype background also encompasses the development of supporting systems, such as the transmission and exhaust system. These components must be carefully designed to handle the immense power output of the W16 engine while maintaining reliability and meeting stringent emissions regulations. The prototype phase allows engineers to experiment with different transmission configurations and exhaust designs to optimize overall vehicle performance.

The W16 prototype typically consists of four banks of four cylinders arranged in a W configuration. This layout allows for a shorter overall engine length compared to a traditional V16, making it more suitable for mid-engine sports car designs. The complexity of the W16 design presents numerous challenges during the prototype stage, including issues related to cooling, lubrication, and vibration management.

Endurance runs for W16 prototype validation are essential to ensure the engine can withstand prolonged periods of operation under various conditions. These tests aim to identify potential weaknesses in the design, evaluate long-term reliability, and assess the engine's performance characteristics over extended periods. The validation process often involves running the engine continuously for hundreds of hours, simulating real-world driving conditions and pushing the prototype to its limits.

During the prototype phase, engineers focus on optimizing various aspects of the W16 engine. This includes fine-tuning the fuel injection system, improving combustion efficiency, and refining the engine management software. The prototype stage also allows for the evaluation of different materials and manufacturing techniques to enhance durability and reduce weight.

One of the key challenges in W16 prototype development is managing heat dissipation. With 16 cylinders in close proximity, effective cooling becomes critical to prevent overheating and ensure consistent performance. Engineers must design and test sophisticated cooling systems, including advanced radiator designs and precision-engineered coolant channels within the engine block.

Another crucial aspect of W16 prototype validation is the assessment of NVH (Noise, Vibration, and Harshness) characteristics. The unique configuration of the W16 engine can lead to complex vibration patterns, requiring extensive analysis and refinement to achieve smooth operation across the entire RPM range. This often involves the use of advanced balancing techniques and the implementation of specialized engine mounts.

The W16 prototype background also encompasses the development of supporting systems, such as the transmission and exhaust system. These components must be carefully designed to handle the immense power output of the W16 engine while maintaining reliability and meeting stringent emissions regulations. The prototype phase allows engineers to experiment with different transmission configurations and exhaust designs to optimize overall vehicle performance.

Market Analysis

The market for W16 prototype validation through endurance runs is driven by the automotive industry's need for rigorous testing of high-performance engines. As manufacturers push the boundaries of engine design, particularly in the luxury and supercar segments, the demand for specialized validation processes has grown significantly.

Endurance runs for W16 prototypes represent a critical phase in the development of these complex powertrains. The market for such testing services is primarily concentrated in regions with a strong presence of high-end automotive manufacturers, including Germany, Italy, and the United Kingdom in Europe, as well as select locations in North America and Asia.

The global high-performance car market, which is the primary driver for W16 engine development, has been experiencing steady growth. This growth directly correlates with the increased demand for sophisticated endurance testing procedures. As consumer expectations for performance and reliability continue to rise, manufacturers are investing more heavily in comprehensive validation processes.

One of the key market trends is the integration of advanced data analytics and real-time monitoring systems into endurance testing procedures. This has created a secondary market for specialized software and hardware solutions designed to capture, analyze, and interpret the vast amounts of data generated during W16 prototype runs.

Environmental regulations and the push towards sustainable practices are also shaping the market landscape. There is a growing demand for endurance testing facilities that can accommodate these requirements, leading to investments in more efficient and environmentally friendly testing infrastructure.

The competitive landscape for W16 prototype endurance testing is relatively concentrated, with a few specialized facilities and automotive engineering firms dominating the market. These entities often have long-standing relationships with major manufacturers, creating high barriers to entry for new players.

Looking ahead, the market for W16 prototype endurance runs is expected to evolve alongside advancements in engine technology. As manufacturers explore hybrid and electric powertrains, even for high-performance applications, the nature of endurance testing may shift. This could lead to new opportunities for testing facilities and equipment providers who can adapt to these changing requirements.

In conclusion, the market for W16 prototype validation through endurance runs is a niche but crucial segment within the broader automotive testing industry. Its growth is closely tied to the development of ultra-high-performance vehicles and the increasing complexity of powertrain systems. As the automotive landscape continues to evolve, so too will the methodologies and technologies employed in these critical validation processes.

Endurance runs for W16 prototypes represent a critical phase in the development of these complex powertrains. The market for such testing services is primarily concentrated in regions with a strong presence of high-end automotive manufacturers, including Germany, Italy, and the United Kingdom in Europe, as well as select locations in North America and Asia.

The global high-performance car market, which is the primary driver for W16 engine development, has been experiencing steady growth. This growth directly correlates with the increased demand for sophisticated endurance testing procedures. As consumer expectations for performance and reliability continue to rise, manufacturers are investing more heavily in comprehensive validation processes.

One of the key market trends is the integration of advanced data analytics and real-time monitoring systems into endurance testing procedures. This has created a secondary market for specialized software and hardware solutions designed to capture, analyze, and interpret the vast amounts of data generated during W16 prototype runs.

Environmental regulations and the push towards sustainable practices are also shaping the market landscape. There is a growing demand for endurance testing facilities that can accommodate these requirements, leading to investments in more efficient and environmentally friendly testing infrastructure.

The competitive landscape for W16 prototype endurance testing is relatively concentrated, with a few specialized facilities and automotive engineering firms dominating the market. These entities often have long-standing relationships with major manufacturers, creating high barriers to entry for new players.

Looking ahead, the market for W16 prototype endurance runs is expected to evolve alongside advancements in engine technology. As manufacturers explore hybrid and electric powertrains, even for high-performance applications, the nature of endurance testing may shift. This could lead to new opportunities for testing facilities and equipment providers who can adapt to these changing requirements.

In conclusion, the market for W16 prototype validation through endurance runs is a niche but crucial segment within the broader automotive testing industry. Its growth is closely tied to the development of ultra-high-performance vehicles and the increasing complexity of powertrain systems. As the automotive landscape continues to evolve, so too will the methodologies and technologies employed in these critical validation processes.

Technical Challenges

Performing endurance runs for W16 prototype validation presents several significant technical challenges that must be addressed to ensure the reliability and performance of this complex engine design. One of the primary challenges is the development of a robust testing environment capable of simulating real-world conditions over extended periods. This requires sophisticated dynamometer setups with advanced cooling systems to manage the extreme heat generated by the W16 engine during prolonged operation.

Another critical challenge lies in the instrumentation and data acquisition systems needed to monitor the engine's performance continuously. The W16's intricate design, with its multiple banks of cylinders, demands an extensive array of sensors to track temperatures, pressures, vibrations, and emissions across all components. Integrating these sensors without compromising the engine's integrity or performance is a delicate balancing act.

Fuel management poses a unique challenge for W16 endurance testing. The engine's high output and complex fuel delivery system require precise control and monitoring of fuel consumption, quality, and distribution across all cylinders. Ensuring consistent fuel delivery and combustion efficiency throughout the extended run is crucial for validating the engine's long-term performance and reliability.

Thermal management is another significant hurdle in W16 endurance testing. The engine's compact design and high power output generate substantial heat, necessitating advanced cooling solutions. Engineers must develop and validate cooling systems capable of maintaining optimal operating temperatures across all engine components, even under sustained high-load conditions.

Lubrication system performance is critical during endurance runs. The W16's unique configuration demands a sophisticated oil circulation system to ensure all moving parts receive adequate lubrication under various operating conditions. Monitoring oil pressure, temperature, and quality throughout the endurance test is essential for assessing the engine's long-term durability.

Vibration and noise control present additional challenges. The W16's multiple cylinder banks and high-revving nature can generate complex vibration patterns and noise profiles. Developing effective damping solutions and conducting comprehensive NVH (Noise, Vibration, and Harshness) analysis throughout the endurance run is crucial for ensuring passenger comfort and vehicle integrity.

Emissions control during extended operation is a critical aspect of W16 prototype validation. Engineers must ensure that the engine maintains compliance with stringent emissions standards throughout the endurance run, which may involve continuous monitoring and adjustment of the engine management system.

Finally, the sheer duration of endurance runs for W16 validation poses logistical and resource challenges. Coordinating round-the-clock testing, managing fuel and oil supplies, and maintaining a team of skilled technicians for extended periods requires meticulous planning and execution. Additionally, the cost and energy consumption associated with prolonged high-performance engine testing necessitate careful resource management and potentially the development of more efficient testing methodologies.

Another critical challenge lies in the instrumentation and data acquisition systems needed to monitor the engine's performance continuously. The W16's intricate design, with its multiple banks of cylinders, demands an extensive array of sensors to track temperatures, pressures, vibrations, and emissions across all components. Integrating these sensors without compromising the engine's integrity or performance is a delicate balancing act.

Fuel management poses a unique challenge for W16 endurance testing. The engine's high output and complex fuel delivery system require precise control and monitoring of fuel consumption, quality, and distribution across all cylinders. Ensuring consistent fuel delivery and combustion efficiency throughout the extended run is crucial for validating the engine's long-term performance and reliability.

Thermal management is another significant hurdle in W16 endurance testing. The engine's compact design and high power output generate substantial heat, necessitating advanced cooling solutions. Engineers must develop and validate cooling systems capable of maintaining optimal operating temperatures across all engine components, even under sustained high-load conditions.

Lubrication system performance is critical during endurance runs. The W16's unique configuration demands a sophisticated oil circulation system to ensure all moving parts receive adequate lubrication under various operating conditions. Monitoring oil pressure, temperature, and quality throughout the endurance test is essential for assessing the engine's long-term durability.

Vibration and noise control present additional challenges. The W16's multiple cylinder banks and high-revving nature can generate complex vibration patterns and noise profiles. Developing effective damping solutions and conducting comprehensive NVH (Noise, Vibration, and Harshness) analysis throughout the endurance run is crucial for ensuring passenger comfort and vehicle integrity.

Emissions control during extended operation is a critical aspect of W16 prototype validation. Engineers must ensure that the engine maintains compliance with stringent emissions standards throughout the endurance run, which may involve continuous monitoring and adjustment of the engine management system.

Finally, the sheer duration of endurance runs for W16 validation poses logistical and resource challenges. Coordinating round-the-clock testing, managing fuel and oil supplies, and maintaining a team of skilled technicians for extended periods requires meticulous planning and execution. Additionally, the cost and energy consumption associated with prolonged high-performance engine testing necessitate careful resource management and potentially the development of more efficient testing methodologies.

Current Test Methodologies

01 Memory management and endurance optimization

This aspect focuses on improving the endurance of memory systems through efficient management techniques. It involves optimizing data storage, reducing wear on memory cells, and implementing strategies to extend the lifespan of memory devices. These techniques are crucial for enhancing the overall performance and longevity of memory systems in various applications.- Memory management and endurance optimization: Techniques for improving memory endurance in W16 prototypes, including efficient data storage, wear leveling, and optimized read/write operations to extend the lifespan of memory components.

- Power efficiency and thermal management: Methods for enhancing power efficiency and managing thermal output in W16 prototypes, focusing on reducing energy consumption and heat generation to improve overall system endurance.

- Software optimization for improved performance: Software-based approaches to enhance the endurance of W16 prototypes, including code optimization, efficient resource allocation, and performance tuning to reduce system stress and extend operational life.

- Advanced materials and manufacturing techniques: Utilization of innovative materials and manufacturing processes to enhance the durability and longevity of W16 prototype components, improving overall system endurance.

- Adaptive system management and fault tolerance: Implementation of adaptive management systems and fault-tolerant designs in W16 prototypes to enhance reliability, self-healing capabilities, and overall endurance under various operational conditions.

02 Prototype testing and simulation

This category involves methods for testing and simulating prototypes to assess their endurance. It includes techniques for creating virtual environments, conducting stress tests, and analyzing performance under various conditions. These approaches help in evaluating and improving the durability and reliability of prototypes before final production.Expand Specific Solutions03 Energy efficiency in computing systems

This area focuses on developing energy-efficient computing systems to improve endurance. It involves designing low-power components, optimizing power consumption, and implementing energy-saving algorithms. These innovations aim to extend battery life and reduce heat generation in electronic devices, thereby enhancing their overall endurance.Expand Specific Solutions04 Software optimization for system endurance

This point addresses software-level optimizations to enhance system endurance. It includes techniques for efficient code execution, resource management, and error handling. These software improvements aim to reduce system stress, minimize crashes, and maintain performance over extended periods of operation.Expand Specific Solutions05 Data integrity and error correction

This category focuses on maintaining data integrity and implementing error correction mechanisms to improve system endurance. It involves developing robust algorithms for detecting and correcting errors, ensuring data consistency, and implementing redundancy measures. These techniques are essential for enhancing the reliability and longevity of data storage and processing systems.Expand Specific Solutions

Key Industry Players

The endurance testing of W16 prototype engines represents a mature yet evolving field within automotive engineering. The market for high-performance engine validation is relatively niche but significant, driven by luxury and sports car manufacturers. Companies like Nissan Motor Co., Ltd. and Guangzhou Automobile Group Co., Ltd. are likely key players, leveraging their extensive automotive R&D capabilities. The technology's maturity is evident in established testing protocols, but continuous innovation in materials and simulation techniques from entities such as Beihang University and the China Aerodynamics Research & Development Center (CARDC) keeps pushing the boundaries of engine performance and reliability assessment.

Nissan Motor Co., Ltd.

Technical Solution: Nissan employs a comprehensive endurance testing program for their W16 prototype validation. They utilize advanced dynamometer facilities capable of simulating various driving conditions and environmental factors. The company conducts extended durability runs, typically lasting 50,000 to 100,000 miles, to assess engine reliability, performance, and wear characteristics[1]. Nissan's approach includes thermal cycling tests, where the engine is repeatedly heated and cooled to extreme temperatures to evaluate material integrity and component interactions[3]. They also implement real-world road testing on specially designed tracks that incorporate different terrains and driving scenarios to complement laboratory results[5].

Strengths: Extensive testing infrastructure, ability to simulate diverse conditions, and combination of lab and real-world testing. Weaknesses: High costs associated with prolonged testing periods and potential for extended development timelines.

Guangzhou Automobile Group Co., Ltd.

Technical Solution: GAC Group has implemented a comprehensive endurance testing program for W16 prototype validation. Their approach includes a series of graduated tests, starting with component-level evaluations and progressing to full engine endurance runs. GAC utilizes climate-controlled test chambers to subject the W16 prototypes to extreme temperature and humidity conditions, ranging from -40°C to +50°C[8]. The company's endurance protocol involves running the engine at various load points, including extended periods at maximum power output. GAC also incorporates vibration testing, using specialized shaker tables to simulate the harshest road conditions and assess the engine's structural integrity over time[10].

Strengths: Graduated testing approach and ability to simulate extreme environmental conditions. Weaknesses: Possible limitations in replicating all real-world driving scenarios in a controlled environment.

Critical Test Parameters

Method for quickly predicting fatigue life of wrinkle defect-containing main spar in wind turbine blade

PatentActiveUS20220195991A1

Innovation

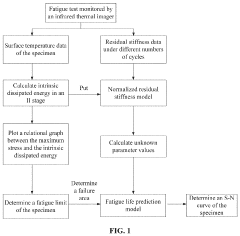

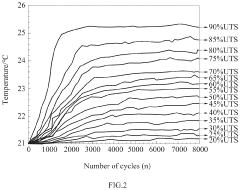

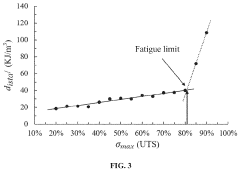

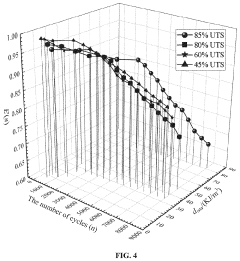

- A method involving universal fatigue testing, infrared thermography, and a normalized residual stiffness model to predict fatigue life by correlating intrinsic dissipated energy and residual stiffness, determining unknown parameters, and establishing a fatigue life prediction model for wrinkle defect-containing main spars.

Regulatory Compliance

Regulatory compliance is a critical aspect of performing endurance runs for W16 prototype validation. The automotive industry is subject to stringent regulations and standards that govern vehicle performance, safety, and environmental impact. When conducting endurance tests for a W16 engine prototype, manufacturers must ensure compliance with various regulatory bodies and their respective requirements.

One of the primary regulatory considerations is emissions standards. Different regions have their own emissions regulations, such as the Euro standards in Europe, EPA standards in the United States, and China's National standards. These regulations set limits on various pollutants, including carbon monoxide, nitrogen oxides, and particulate matter. During endurance runs, the W16 prototype must be continuously monitored to ensure it meets these emissions standards throughout the testing period.

Safety regulations also play a crucial role in endurance testing. Regulatory bodies such as the National Highway Traffic Safety Administration (NHTSA) in the US and the European New Car Assessment Programme (Euro NCAP) set safety standards that vehicles must meet. For a W16 prototype, this includes ensuring the engine's reliability and durability over extended periods of operation, as well as its ability to maintain safe performance levels under various conditions.

Fuel efficiency standards are another important regulatory aspect to consider. Many countries have implemented Corporate Average Fuel Economy (CAFE) standards or similar regulations to promote fuel efficiency and reduce greenhouse gas emissions. During endurance runs, the W16 prototype's fuel consumption must be carefully monitored and evaluated to ensure compliance with these standards.

Noise regulations are also relevant for W16 prototype validation. Many jurisdictions have specific limits on vehicle noise levels, and high-performance engines like the W16 must adhere to these regulations. Endurance runs should include noise level measurements to ensure the prototype meets the required standards throughout its operating range.

Additionally, manufacturers must consider regulations related to engine durability and longevity. Some regulatory bodies require automakers to provide warranties for certain engine components, which necessitates extensive endurance testing to validate the engine's reliability over time.

To ensure regulatory compliance during endurance runs, manufacturers typically employ sophisticated data acquisition systems to continuously monitor and record relevant parameters. This data is then analyzed to verify compliance with various regulatory requirements and to identify any potential issues that may arise during extended operation.

In conclusion, regulatory compliance is a multifaceted aspect of W16 prototype validation that encompasses emissions, safety, fuel efficiency, noise, and durability standards. Manufacturers must carefully design their endurance testing protocols to address all relevant regulatory requirements, ensuring that the W16 prototype meets or exceeds these standards throughout the validation process.

One of the primary regulatory considerations is emissions standards. Different regions have their own emissions regulations, such as the Euro standards in Europe, EPA standards in the United States, and China's National standards. These regulations set limits on various pollutants, including carbon monoxide, nitrogen oxides, and particulate matter. During endurance runs, the W16 prototype must be continuously monitored to ensure it meets these emissions standards throughout the testing period.

Safety regulations also play a crucial role in endurance testing. Regulatory bodies such as the National Highway Traffic Safety Administration (NHTSA) in the US and the European New Car Assessment Programme (Euro NCAP) set safety standards that vehicles must meet. For a W16 prototype, this includes ensuring the engine's reliability and durability over extended periods of operation, as well as its ability to maintain safe performance levels under various conditions.

Fuel efficiency standards are another important regulatory aspect to consider. Many countries have implemented Corporate Average Fuel Economy (CAFE) standards or similar regulations to promote fuel efficiency and reduce greenhouse gas emissions. During endurance runs, the W16 prototype's fuel consumption must be carefully monitored and evaluated to ensure compliance with these standards.

Noise regulations are also relevant for W16 prototype validation. Many jurisdictions have specific limits on vehicle noise levels, and high-performance engines like the W16 must adhere to these regulations. Endurance runs should include noise level measurements to ensure the prototype meets the required standards throughout its operating range.

Additionally, manufacturers must consider regulations related to engine durability and longevity. Some regulatory bodies require automakers to provide warranties for certain engine components, which necessitates extensive endurance testing to validate the engine's reliability over time.

To ensure regulatory compliance during endurance runs, manufacturers typically employ sophisticated data acquisition systems to continuously monitor and record relevant parameters. This data is then analyzed to verify compliance with various regulatory requirements and to identify any potential issues that may arise during extended operation.

In conclusion, regulatory compliance is a multifaceted aspect of W16 prototype validation that encompasses emissions, safety, fuel efficiency, noise, and durability standards. Manufacturers must carefully design their endurance testing protocols to address all relevant regulatory requirements, ensuring that the W16 prototype meets or exceeds these standards throughout the validation process.

Environmental Impact

The environmental impact of endurance runs for W16 prototype validation is a critical consideration in the automotive industry's pursuit of sustainable development. These tests, while essential for ensuring the reliability and performance of high-performance engines, can have significant ecological consequences.

Emissions from prolonged engine operation during endurance runs contribute to air pollution and greenhouse gas levels. The W16 engine, known for its power output, typically consumes substantial amounts of fuel, resulting in increased carbon dioxide emissions. Nitrogen oxides and particulate matter are also released, potentially affecting local air quality and contributing to smog formation in urban areas near testing facilities.

Noise pollution is another environmental concern associated with W16 prototype endurance runs. The high-performance nature of these engines often results in elevated noise levels, which can disturb nearby ecosystems and wildlife habitats. This acoustic impact may lead to behavioral changes in local fauna, affecting their feeding, mating, and migration patterns.

Water consumption and potential contamination are additional environmental factors to consider. Cooling systems for these powerful engines require significant amounts of water, and there is a risk of coolant or oil leaks during extended testing periods. Proper containment and treatment systems must be in place to prevent soil and groundwater contamination.

The energy demands of endurance testing facilities also contribute to the overall environmental footprint. Continuous operation of dynamometers, data acquisition systems, and supporting infrastructure results in increased electricity consumption, often sourced from non-renewable energy grids.

To mitigate these environmental impacts, automotive manufacturers are implementing various strategies. Advanced emission control technologies, such as catalytic converters and particulate filters, are being integrated into testing protocols to reduce harmful exhaust emissions. Some companies are exploring the use of synthetic fuels or biofuels during endurance runs to lower the carbon footprint of the testing process.

Noise reduction techniques, including advanced muffler designs and sound-insulated testing chambers, are being employed to minimize acoustic pollution. Water recycling systems and closed-loop cooling circuits are increasingly common in testing facilities to reduce water consumption and prevent contamination.

Furthermore, the automotive industry is investing in renewable energy sources for testing facilities, such as solar panels and wind turbines, to offset the energy demands of endurance runs. Some manufacturers are also exploring virtual testing and simulation technologies to complement physical endurance runs, potentially reducing the overall environmental impact of the validation process.

As environmental regulations become more stringent, the automotive industry must continue to innovate and adapt its testing methodologies. Balancing the need for thorough prototype validation with environmental responsibility will be crucial for the sustainable development of high-performance engines like the W16.

Emissions from prolonged engine operation during endurance runs contribute to air pollution and greenhouse gas levels. The W16 engine, known for its power output, typically consumes substantial amounts of fuel, resulting in increased carbon dioxide emissions. Nitrogen oxides and particulate matter are also released, potentially affecting local air quality and contributing to smog formation in urban areas near testing facilities.

Noise pollution is another environmental concern associated with W16 prototype endurance runs. The high-performance nature of these engines often results in elevated noise levels, which can disturb nearby ecosystems and wildlife habitats. This acoustic impact may lead to behavioral changes in local fauna, affecting their feeding, mating, and migration patterns.

Water consumption and potential contamination are additional environmental factors to consider. Cooling systems for these powerful engines require significant amounts of water, and there is a risk of coolant or oil leaks during extended testing periods. Proper containment and treatment systems must be in place to prevent soil and groundwater contamination.

The energy demands of endurance testing facilities also contribute to the overall environmental footprint. Continuous operation of dynamometers, data acquisition systems, and supporting infrastructure results in increased electricity consumption, often sourced from non-renewable energy grids.

To mitigate these environmental impacts, automotive manufacturers are implementing various strategies. Advanced emission control technologies, such as catalytic converters and particulate filters, are being integrated into testing protocols to reduce harmful exhaust emissions. Some companies are exploring the use of synthetic fuels or biofuels during endurance runs to lower the carbon footprint of the testing process.

Noise reduction techniques, including advanced muffler designs and sound-insulated testing chambers, are being employed to minimize acoustic pollution. Water recycling systems and closed-loop cooling circuits are increasingly common in testing facilities to reduce water consumption and prevent contamination.

Furthermore, the automotive industry is investing in renewable energy sources for testing facilities, such as solar panels and wind turbines, to offset the energy demands of endurance runs. Some manufacturers are also exploring virtual testing and simulation technologies to complement physical endurance runs, potentially reducing the overall environmental impact of the validation process.

As environmental regulations become more stringent, the automotive industry must continue to innovate and adapt its testing methodologies. Balancing the need for thorough prototype validation with environmental responsibility will be crucial for the sustainable development of high-performance engines like the W16.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!