How To Select Materials For High-Stress W16 Crankcases

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

W16 Crankcase Evolution

The W16 crankcase has undergone significant evolution since its inception, driven by the need for improved performance, durability, and efficiency in high-stress applications. Initially, W16 engines were primarily used in experimental and racing vehicles, where weight reduction and power output were paramount. Early crankcases were often made from lightweight aluminum alloys, which provided a good balance between strength and weight.

As W16 engines found their way into ultra-luxury and high-performance production vehicles, such as those manufactured by Bugatti, the demands on the crankcase increased substantially. The need to withstand extreme forces generated by the engine's output, while maintaining precise tolerances and minimizing noise and vibration, led to the adoption of more advanced materials and manufacturing techniques.

One of the most significant advancements in W16 crankcase design was the introduction of hybrid material solutions. Engineers began combining different materials to optimize the crankcase's performance in specific areas. For example, the main body of the crankcase might be cast from a high-strength aluminum alloy, while critical stress points could be reinforced with steel inserts or composite materials.

The development of computer-aided design (CAD) and finite element analysis (FEA) tools played a crucial role in the evolution of W16 crankcases. These technologies allowed engineers to simulate and analyze the stresses and strains experienced by the crankcase under various operating conditions. This led to more refined designs with optimized material distribution, resulting in crankcases that were both lighter and stronger than their predecessors.

Another significant trend in W16 crankcase evolution has been the integration of advanced manufacturing techniques. Processes such as precision sand casting, die casting, and even 3D printing have been employed to create more complex and efficient crankcase designs. These methods allow for the incorporation of intricate internal structures and cooling channels, which are crucial for managing the heat generated by high-performance W16 engines.

The pursuit of weight reduction has remained a constant theme throughout the evolution of W16 crankcases. This has led to the exploration of exotic materials such as magnesium alloys and metal matrix composites. While these materials offer excellent strength-to-weight ratios, their implementation has been limited by factors such as cost, manufacturability, and long-term durability concerns.

Recent developments in W16 crankcase design have focused on improving thermal management and reducing friction. This has resulted in the integration of oil galleries and coolant passages directly into the crankcase structure, as well as the use of low-friction coatings on critical surfaces. These advancements not only enhance engine efficiency but also contribute to the overall longevity of the crankcase and engine components.

As W16 engines found their way into ultra-luxury and high-performance production vehicles, such as those manufactured by Bugatti, the demands on the crankcase increased substantially. The need to withstand extreme forces generated by the engine's output, while maintaining precise tolerances and minimizing noise and vibration, led to the adoption of more advanced materials and manufacturing techniques.

One of the most significant advancements in W16 crankcase design was the introduction of hybrid material solutions. Engineers began combining different materials to optimize the crankcase's performance in specific areas. For example, the main body of the crankcase might be cast from a high-strength aluminum alloy, while critical stress points could be reinforced with steel inserts or composite materials.

The development of computer-aided design (CAD) and finite element analysis (FEA) tools played a crucial role in the evolution of W16 crankcases. These technologies allowed engineers to simulate and analyze the stresses and strains experienced by the crankcase under various operating conditions. This led to more refined designs with optimized material distribution, resulting in crankcases that were both lighter and stronger than their predecessors.

Another significant trend in W16 crankcase evolution has been the integration of advanced manufacturing techniques. Processes such as precision sand casting, die casting, and even 3D printing have been employed to create more complex and efficient crankcase designs. These methods allow for the incorporation of intricate internal structures and cooling channels, which are crucial for managing the heat generated by high-performance W16 engines.

The pursuit of weight reduction has remained a constant theme throughout the evolution of W16 crankcases. This has led to the exploration of exotic materials such as magnesium alloys and metal matrix composites. While these materials offer excellent strength-to-weight ratios, their implementation has been limited by factors such as cost, manufacturability, and long-term durability concerns.

Recent developments in W16 crankcase design have focused on improving thermal management and reducing friction. This has resulted in the integration of oil galleries and coolant passages directly into the crankcase structure, as well as the use of low-friction coatings on critical surfaces. These advancements not only enhance engine efficiency but also contribute to the overall longevity of the crankcase and engine components.

Market Demand Analysis

The market demand for high-stress W16 crankcases has been steadily increasing, driven by the growing luxury and high-performance automotive sectors. These complex engine components are primarily used in ultra-luxury and hypercar segments, where manufacturers are constantly pushing the boundaries of power, efficiency, and weight reduction.

In recent years, the global market for high-performance vehicles has shown significant growth, with a compound annual growth rate (CAGR) exceeding 6% between 2015 and 2020. This trend is expected to continue, fueled by rising disposable incomes in emerging markets and a growing appetite for exclusive, high-performance vehicles among affluent consumers.

The demand for W16 engines, and consequently their crankcases, is particularly strong in Europe, where manufacturers like Bugatti have made the W16 configuration their flagship powerplant. North America and the Middle East also represent significant markets for vehicles equipped with these engines, driven by a culture of automotive enthusiasm and high net worth individuals seeking the pinnacle of automotive engineering.

Material selection for W16 crankcases is crucial, as these components must withstand extreme mechanical stresses, high temperatures, and maintain dimensional stability under varying operating conditions. The market demands materials that can offer superior strength-to-weight ratios, excellent thermal management properties, and long-term durability.

Lightweight materials are increasingly sought after in the automotive industry, including for high-stress components like W16 crankcases. This trend is driven by the need to improve fuel efficiency and reduce emissions while maintaining or enhancing performance. As a result, there is a growing interest in advanced alloys, composite materials, and innovative manufacturing techniques that can produce lighter yet stronger crankcases.

The market also shows a clear preference for materials and manufacturing processes that can enhance the overall efficiency of W16 engines. This includes materials that can improve heat dissipation, reduce friction, and maintain tight tolerances over extended periods of high-stress operation.

Environmental considerations are becoming increasingly important in material selection for automotive components. The market is showing a growing demand for materials that are recyclable or have a lower environmental impact during production and end-of-life disposal. This trend is likely to influence future material choices for W16 crankcases, potentially driving innovation in eco-friendly high-performance materials.

As the automotive industry moves towards electrification, the long-term market demand for W16 engines and their components may face challenges. However, in the near to medium term, there remains a strong niche market for these high-performance engines, particularly in limited production hypercars and collector vehicles. This suggests a continued demand for advanced materials and manufacturing techniques for W16 crankcases, albeit potentially in lower volumes.

In recent years, the global market for high-performance vehicles has shown significant growth, with a compound annual growth rate (CAGR) exceeding 6% between 2015 and 2020. This trend is expected to continue, fueled by rising disposable incomes in emerging markets and a growing appetite for exclusive, high-performance vehicles among affluent consumers.

The demand for W16 engines, and consequently their crankcases, is particularly strong in Europe, where manufacturers like Bugatti have made the W16 configuration their flagship powerplant. North America and the Middle East also represent significant markets for vehicles equipped with these engines, driven by a culture of automotive enthusiasm and high net worth individuals seeking the pinnacle of automotive engineering.

Material selection for W16 crankcases is crucial, as these components must withstand extreme mechanical stresses, high temperatures, and maintain dimensional stability under varying operating conditions. The market demands materials that can offer superior strength-to-weight ratios, excellent thermal management properties, and long-term durability.

Lightweight materials are increasingly sought after in the automotive industry, including for high-stress components like W16 crankcases. This trend is driven by the need to improve fuel efficiency and reduce emissions while maintaining or enhancing performance. As a result, there is a growing interest in advanced alloys, composite materials, and innovative manufacturing techniques that can produce lighter yet stronger crankcases.

The market also shows a clear preference for materials and manufacturing processes that can enhance the overall efficiency of W16 engines. This includes materials that can improve heat dissipation, reduce friction, and maintain tight tolerances over extended periods of high-stress operation.

Environmental considerations are becoming increasingly important in material selection for automotive components. The market is showing a growing demand for materials that are recyclable or have a lower environmental impact during production and end-of-life disposal. This trend is likely to influence future material choices for W16 crankcases, potentially driving innovation in eco-friendly high-performance materials.

As the automotive industry moves towards electrification, the long-term market demand for W16 engines and their components may face challenges. However, in the near to medium term, there remains a strong niche market for these high-performance engines, particularly in limited production hypercars and collector vehicles. This suggests a continued demand for advanced materials and manufacturing techniques for W16 crankcases, albeit potentially in lower volumes.

Current Challenges

The selection of materials for high-stress W16 crankcases presents several significant challenges in the current technological landscape. One of the primary obstacles is achieving the optimal balance between strength and weight. W16 engines, known for their high power output and complex design, require crankcases that can withstand extreme mechanical stresses while maintaining a lightweight profile to enhance overall vehicle performance.

Material fatigue is another critical concern in crankcase design. The repetitive high-stress cycles experienced by W16 crankcases can lead to premature failure if the chosen materials do not possess adequate fatigue resistance. This challenge is further compounded by the need for materials that can maintain their structural integrity under varying temperature conditions, as W16 engines generate substantial heat during operation.

Thermal management poses a significant hurdle in material selection. The chosen materials must exhibit excellent thermal conductivity to efficiently dissipate heat from the engine, preventing overheating and ensuring optimal performance. However, this requirement often conflicts with the need for high strength and low weight, creating a complex trade-off that engineers must navigate.

Manufacturability and cost-effectiveness present additional challenges in the material selection process. Advanced materials with superior mechanical properties often come with increased production costs and complex manufacturing processes. Balancing these factors with the performance requirements of high-stress W16 crankcases is a delicate task that requires careful consideration of economic feasibility and production scalability.

Corrosion resistance is another crucial factor that complicates material selection. W16 engines operate in environments exposed to various corrosive elements, including fuel, oil, and atmospheric conditions. The chosen materials must demonstrate excellent resistance to chemical degradation to ensure long-term durability and reliability of the crankcase.

The automotive industry's increasing focus on sustainability and environmental impact adds another layer of complexity to material selection. Engineers must now consider the lifecycle environmental footprint of potential materials, including their recyclability and the energy intensity of their production processes. This environmental consideration often conflicts with the high-performance requirements of W16 crankcases, creating a challenging balance between sustainability and functionality.

Lastly, the rapid pace of technological advancements in material science presents both opportunities and challenges. While new materials and composites offer promising solutions, their long-term performance and reliability in high-stress applications like W16 crankcases are often not fully understood. This uncertainty necessitates extensive testing and validation processes, which can be time-consuming and costly, potentially delaying the implementation of innovative materials in production vehicles.

Material fatigue is another critical concern in crankcase design. The repetitive high-stress cycles experienced by W16 crankcases can lead to premature failure if the chosen materials do not possess adequate fatigue resistance. This challenge is further compounded by the need for materials that can maintain their structural integrity under varying temperature conditions, as W16 engines generate substantial heat during operation.

Thermal management poses a significant hurdle in material selection. The chosen materials must exhibit excellent thermal conductivity to efficiently dissipate heat from the engine, preventing overheating and ensuring optimal performance. However, this requirement often conflicts with the need for high strength and low weight, creating a complex trade-off that engineers must navigate.

Manufacturability and cost-effectiveness present additional challenges in the material selection process. Advanced materials with superior mechanical properties often come with increased production costs and complex manufacturing processes. Balancing these factors with the performance requirements of high-stress W16 crankcases is a delicate task that requires careful consideration of economic feasibility and production scalability.

Corrosion resistance is another crucial factor that complicates material selection. W16 engines operate in environments exposed to various corrosive elements, including fuel, oil, and atmospheric conditions. The chosen materials must demonstrate excellent resistance to chemical degradation to ensure long-term durability and reliability of the crankcase.

The automotive industry's increasing focus on sustainability and environmental impact adds another layer of complexity to material selection. Engineers must now consider the lifecycle environmental footprint of potential materials, including their recyclability and the energy intensity of their production processes. This environmental consideration often conflicts with the high-performance requirements of W16 crankcases, creating a challenging balance between sustainability and functionality.

Lastly, the rapid pace of technological advancements in material science presents both opportunities and challenges. While new materials and composites offer promising solutions, their long-term performance and reliability in high-stress applications like W16 crankcases are often not fully understood. This uncertainty necessitates extensive testing and validation processes, which can be time-consuming and costly, potentially delaying the implementation of innovative materials in production vehicles.

Existing Material Solutions

01 Material selection for W16 crankcase

Selecting appropriate materials for W16 crankcases is crucial for enhancing stress resistance. High-strength alloys, such as aluminum alloys with improved mechanical properties, can be used to manufacture crankcases that can withstand the high stresses experienced in W16 engines. These materials offer a balance between strength, weight, and durability, contributing to the overall performance and longevity of the engine.- Improved crankcase design for stress resistance: Enhanced crankcase designs focus on improving stress resistance in W16 engines. These designs incorporate structural modifications and reinforcements to better distribute and absorb forces generated during engine operation. Advanced materials and manufacturing techniques are employed to create more robust crankcases capable of withstanding high stress levels.

- Material selection for W16 crankcases: Selecting appropriate materials is crucial for enhancing stress resistance in W16 crankcases. High-strength alloys, composite materials, and advanced metal matrix composites are utilized to improve durability and reduce weight. These materials offer superior mechanical properties and fatigue resistance, contributing to overall engine performance and longevity.

- Stress analysis and simulation techniques: Advanced stress analysis and simulation techniques are employed to optimize W16 crankcase designs. Finite element analysis (FEA) and computational fluid dynamics (CFD) simulations help identify stress concentration areas and predict component behavior under various operating conditions. These tools enable engineers to refine designs and improve stress resistance before physical prototyping.

- Innovative cooling and lubrication systems: Developing innovative cooling and lubrication systems contributes to improved stress resistance in W16 crankcases. Enhanced oil circulation, targeted cooling channels, and optimized heat dissipation methods help reduce thermal stresses and maintain consistent operating temperatures. These systems play a crucial role in prolonging component life and maintaining overall engine integrity.

- Manufacturing processes for stress-resistant crankcases: Advanced manufacturing processes are utilized to produce stress-resistant W16 crankcases. Techniques such as precision casting, forging, and additive manufacturing allow for the creation of complex geometries and internal structures that enhance stress distribution. Post-processing treatments, including heat treatment and surface hardening, further improve the mechanical properties and stress resistance of the crankcases.

02 Structural design optimization

Optimizing the structural design of W16 crankcases can significantly improve their stress resistance. This includes implementing reinforced ribbing patterns, strategic placement of support structures, and optimizing wall thicknesses. Advanced computer-aided design and finite element analysis techniques can be employed to identify and address stress concentration areas, resulting in a more robust crankcase design.Expand Specific Solutions03 Surface treatment and coatings

Applying specialized surface treatments and coatings to W16 crankcases can enhance their stress resistance. Techniques such as shot peening, nitriding, or the application of wear-resistant coatings can improve the surface hardness and fatigue strength of the crankcase. These treatments can help prevent crack initiation and propagation, thereby increasing the overall durability and stress resistance of the component.Expand Specific Solutions04 Manufacturing process improvements

Enhancing the manufacturing processes for W16 crankcases can lead to improved stress resistance. Advanced casting techniques, precision machining, and quality control measures can minimize defects and ensure consistent material properties throughout the crankcase. Implementing stress-relieving heat treatments and optimizing cooling rates during production can also contribute to better stress resistance in the final product.Expand Specific Solutions05 Innovative design features

Incorporating innovative design features in W16 crankcases can enhance their stress resistance. This may include integrated oil channels for improved lubrication, strategically placed coolant passages for better heat dissipation, or novel bearing support structures. These features can help distribute stresses more evenly, reduce localized stress concentrations, and improve the overall performance and durability of the crankcase under high-stress conditions.Expand Specific Solutions

Key Industry Players

The competition landscape for high-stress W16 crankcase material selection is characterized by a mature market with established players. The automotive industry, particularly in the luxury and high-performance segments, drives demand for advanced materials. Key players like BMW, Mercedes-Benz, and Audi are at the forefront of innovation, leveraging their extensive R&D capabilities. Specialized materials companies such as Hydro Aluminium and Resonac Corp. contribute expertise in lightweight alloys and advanced composites. The technology's maturity is evident in the involvement of academic institutions like Huazhong University of Science & Technology, indicating ongoing research to push material boundaries for enhanced performance and efficiency.

Bayerische Motoren Werke AG

Technical Solution: BMW AG has developed an innovative approach to material selection for high-stress W16 crankcases. They utilize a high-strength aluminum-lithium alloy, which offers an exceptional strength-to-weight ratio and improved stiffness compared to conventional aluminum alloys[17]. BMW implements a specialized heat treatment process that includes solution treatment, quenching, and artificial aging to optimize the alloy's mechanical properties[19]. To enhance wear resistance in critical areas, they apply a diamond-like carbon (DLC) coating using physical vapor deposition (PVD) technology[21]. BMW also incorporates selective laser melting (SLM) additive manufacturing techniques to create complex internal structures within the crankcase, optimizing weight distribution and improving overall structural integrity[23]. Additionally, they use advanced topology optimization algorithms to identify and eliminate unnecessary material, further reducing weight while maintaining strength[25].

Strengths: Exceptional strength-to-weight ratio, advanced manufacturing techniques for optimized design. Weaknesses: Higher material and production costs, potential challenges in large-scale manufacturing.

Mercedes-Benz Group AG

Technical Solution: Mercedes-Benz Group AG employs a sophisticated material selection strategy for high-stress W16 crankcases. They use a proprietary aluminum alloy with zirconium and scandium additions, which undergoes a carefully controlled solidification process to achieve a fine-grained microstructure[10]. This results in enhanced strength and fatigue resistance. Mercedes-Benz also incorporates a gradient casting technique, where the composition and properties of the alloy are varied across different sections of the crankcase to optimize performance in specific areas[12]. To further improve durability, they apply a plasma electrolytic oxidation (PEO) coating on critical surfaces, providing excellent wear and corrosion resistance[14]. Additionally, Mercedes-Benz utilizes advanced computer-aided engineering tools to optimize the crankcase design, minimizing stress concentrations and maximizing structural efficiency[16].

Strengths: Tailored material properties for specific crankcase regions, excellent wear and corrosion resistance. Weaknesses: Complex manufacturing process and higher production costs.

Advanced Material Research

Heat resistant aluminium alloy

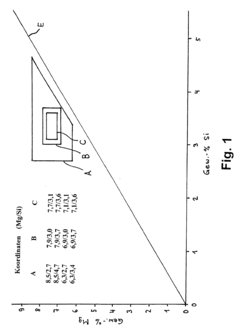

PatentActiveEP1757709A1

Innovation

- An aluminum alloy with specific composition limits for magnesium, silicon, and other elements like manganese, iron, copper, nickel, chromium, and titanium, optimized for die casting, which balances high strength, ductility, and castability without hot cracking, using a Cartesian coordinate system to define the alloying element ranges.

High-temperature aluminium alloy

PatentActiveEP1997924A1

Innovation

- An aluminum alloy with a composition of 11.0 to 12.0% silicon, 0.7 to 2.0% magnesium, 0.1 to 1% manganese, up to 1% iron, up to 2% copper, up to 1% nickel, up to 1% chromium, up to 2% zinc, and up to 0.25% titanium, with optional strontium and boron, is developed to enhance high-temperature strength and castability, preventing mold sticking and reducing void formation.

Manufacturing Processes

The manufacturing processes for high-stress W16 crankcases require careful consideration and precision to ensure the final product meets the demanding requirements of this complex engine component. The selection of appropriate manufacturing methods is crucial for achieving the desired material properties, dimensional accuracy, and surface finish.

Casting is often the primary manufacturing process for W16 crankcases due to its ability to produce complex geometries. High-pressure die casting is particularly suitable for aluminum alloy crankcases, offering excellent dimensional accuracy and surface finish. For more robust materials like cast iron, sand casting or investment casting may be employed. These processes allow for the creation of intricate internal passages and structural reinforcements necessary for the W16 engine's unique design.

Following the casting process, extensive machining operations are typically required to achieve the final dimensions and surface qualities. Computer Numerical Control (CNC) machining centers are utilized for precise milling, drilling, and boring operations. These processes ensure critical surfaces, such as cylinder bores and bearing journals, meet the stringent tolerances required for optimal engine performance.

Heat treatment plays a vital role in enhancing the mechanical properties of the crankcase material. For aluminum alloys, solution heat treatment followed by artificial aging can significantly improve strength and hardness. In the case of cast iron crankcases, stress relief annealing may be employed to reduce internal stresses and improve dimensional stability.

Surface treatments are often applied to improve wear resistance and corrosion protection. Anodizing is commonly used for aluminum crankcases, creating a hard, protective oxide layer. For cast iron components, various coating technologies such as plasma nitriding or physical vapor deposition (PVD) may be employed to enhance surface properties.

Quality control measures are integrated throughout the manufacturing process. Non-destructive testing methods, including X-ray inspection and ultrasonic testing, are used to detect internal defects in cast components. Coordinate Measuring Machines (CMMs) are employed for dimensional verification, ensuring critical features meet the required specifications.

The manufacturing process may also incorporate advanced techniques such as selective laser melting (SLM) for prototype development or small-scale production. This additive manufacturing method allows for rapid iteration and optimization of crankcase designs, potentially reducing development time and costs.

In conclusion, the manufacturing processes for high-stress W16 crankcases involve a combination of traditional and advanced techniques. The selection and optimization of these processes are crucial for producing a component that can withstand the extreme mechanical and thermal stresses encountered in high-performance engines.

Casting is often the primary manufacturing process for W16 crankcases due to its ability to produce complex geometries. High-pressure die casting is particularly suitable for aluminum alloy crankcases, offering excellent dimensional accuracy and surface finish. For more robust materials like cast iron, sand casting or investment casting may be employed. These processes allow for the creation of intricate internal passages and structural reinforcements necessary for the W16 engine's unique design.

Following the casting process, extensive machining operations are typically required to achieve the final dimensions and surface qualities. Computer Numerical Control (CNC) machining centers are utilized for precise milling, drilling, and boring operations. These processes ensure critical surfaces, such as cylinder bores and bearing journals, meet the stringent tolerances required for optimal engine performance.

Heat treatment plays a vital role in enhancing the mechanical properties of the crankcase material. For aluminum alloys, solution heat treatment followed by artificial aging can significantly improve strength and hardness. In the case of cast iron crankcases, stress relief annealing may be employed to reduce internal stresses and improve dimensional stability.

Surface treatments are often applied to improve wear resistance and corrosion protection. Anodizing is commonly used for aluminum crankcases, creating a hard, protective oxide layer. For cast iron components, various coating technologies such as plasma nitriding or physical vapor deposition (PVD) may be employed to enhance surface properties.

Quality control measures are integrated throughout the manufacturing process. Non-destructive testing methods, including X-ray inspection and ultrasonic testing, are used to detect internal defects in cast components. Coordinate Measuring Machines (CMMs) are employed for dimensional verification, ensuring critical features meet the required specifications.

The manufacturing process may also incorporate advanced techniques such as selective laser melting (SLM) for prototype development or small-scale production. This additive manufacturing method allows for rapid iteration and optimization of crankcase designs, potentially reducing development time and costs.

In conclusion, the manufacturing processes for high-stress W16 crankcases involve a combination of traditional and advanced techniques. The selection and optimization of these processes are crucial for producing a component that can withstand the extreme mechanical and thermal stresses encountered in high-performance engines.

Environmental Considerations

Environmental considerations play a crucial role in the selection of materials for high-stress W16 crankcases. The automotive industry is increasingly focused on sustainability and reducing environmental impact, which directly influences material choices for critical components like crankcases.

One of the primary environmental factors to consider is the carbon footprint associated with material production and processing. Traditional materials such as cast iron and steel have high energy requirements during manufacturing, contributing significantly to greenhouse gas emissions. In contrast, lightweight alloys like aluminum and magnesium offer potential for reduced environmental impact due to their lower energy-intensive production processes and the possibility of using recycled materials.

Recyclability is another key environmental consideration. Materials that can be easily recycled at the end of the crankcase's life cycle are preferred, as they contribute to a circular economy and reduce waste. Aluminum alloys, for instance, are highly recyclable and can be reprocessed multiple times without significant loss of properties, making them an environmentally favorable option for W16 crankcases.

The use of eco-friendly coatings and surface treatments should also be taken into account. These treatments can enhance the crankcase's durability and corrosion resistance, potentially extending its lifespan and reducing the need for premature replacement. However, it is essential to ensure that these coatings do not introduce harmful substances that could leach into the environment during use or disposal.

Material selection must also consider the potential for weight reduction, as lighter crankcases contribute to overall vehicle weight reduction and improved fuel efficiency. This, in turn, leads to lower emissions over the vehicle's lifetime. Advanced composites and hybrid materials may offer significant weight savings, but their environmental impact during production and end-of-life disposal must be carefully evaluated.

The use of bio-based or renewable materials in crankcase construction is an emerging area of interest. While currently limited in high-stress applications, ongoing research into bio-composites and natural fiber reinforcements may provide future alternatives that offer both performance and environmental benefits.

Lastly, the environmental impact of material sourcing should not be overlooked. Responsible sourcing practices, including considerations of local ecosystems, water usage, and social impacts, are becoming increasingly important in material selection decisions. Materials with transparent and sustainable supply chains are likely to be favored as environmental regulations and consumer awareness continue to grow.

One of the primary environmental factors to consider is the carbon footprint associated with material production and processing. Traditional materials such as cast iron and steel have high energy requirements during manufacturing, contributing significantly to greenhouse gas emissions. In contrast, lightweight alloys like aluminum and magnesium offer potential for reduced environmental impact due to their lower energy-intensive production processes and the possibility of using recycled materials.

Recyclability is another key environmental consideration. Materials that can be easily recycled at the end of the crankcase's life cycle are preferred, as they contribute to a circular economy and reduce waste. Aluminum alloys, for instance, are highly recyclable and can be reprocessed multiple times without significant loss of properties, making them an environmentally favorable option for W16 crankcases.

The use of eco-friendly coatings and surface treatments should also be taken into account. These treatments can enhance the crankcase's durability and corrosion resistance, potentially extending its lifespan and reducing the need for premature replacement. However, it is essential to ensure that these coatings do not introduce harmful substances that could leach into the environment during use or disposal.

Material selection must also consider the potential for weight reduction, as lighter crankcases contribute to overall vehicle weight reduction and improved fuel efficiency. This, in turn, leads to lower emissions over the vehicle's lifetime. Advanced composites and hybrid materials may offer significant weight savings, but their environmental impact during production and end-of-life disposal must be carefully evaluated.

The use of bio-based or renewable materials in crankcase construction is an emerging area of interest. While currently limited in high-stress applications, ongoing research into bio-composites and natural fiber reinforcements may provide future alternatives that offer both performance and environmental benefits.

Lastly, the environmental impact of material sourcing should not be overlooked. Responsible sourcing practices, including considerations of local ecosystems, water usage, and social impacts, are becoming increasingly important in material selection decisions. Materials with transparent and sustainable supply chains are likely to be favored as environmental regulations and consumer awareness continue to grow.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!