W16 Engine Emissions Management: Aftertreatment Integration Tactics

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

W16 Emission Control Evolution and Objectives

The evolution of W16 engine emissions management has been driven by increasingly stringent environmental regulations and the automotive industry's commitment to reducing its carbon footprint. The primary objective of aftertreatment integration tactics is to minimize harmful emissions while maintaining or improving engine performance and fuel efficiency.

In the early stages of W16 engine development, emissions control primarily focused on optimizing combustion processes and implementing basic catalytic converters. However, as emission standards became more demanding, particularly with the introduction of Euro 6 and EPA Tier 3 regulations, manufacturers had to adopt more sophisticated aftertreatment systems.

The integration of advanced aftertreatment technologies has become a critical aspect of W16 engine design. These systems typically include a combination of Diesel Oxidation Catalysts (DOC), Diesel Particulate Filters (DPF), Selective Catalytic Reduction (SCR), and Ammonia Slip Catalysts (ASC). The challenge lies in seamlessly integrating these components to work in harmony with the engine's unique characteristics.

One of the key objectives in W16 emission control evolution is to achieve near-zero emissions of nitrogen oxides (NOx), particulate matter (PM), and hydrocarbons (HC). This requires a holistic approach that considers not only the aftertreatment system but also engine calibration, thermal management, and exhaust gas recirculation (EGR) strategies.

Another significant goal is to optimize the packaging and integration of aftertreatment components within the limited space available in high-performance vehicles that typically house W16 engines. This involves innovative design solutions to minimize the impact on vehicle aesthetics and performance while ensuring optimal emission control efficiency.

The development of more durable and heat-resistant materials for aftertreatment components is also a crucial objective. These materials must withstand the high temperatures and pressures associated with W16 engine exhaust gases while maintaining their catalytic properties over extended periods.

Furthermore, the integration of advanced sensors and control systems is essential for real-time monitoring and adjustment of the aftertreatment process. This includes the use of NOx sensors, temperature sensors, and pressure differential sensors to ensure optimal performance across various operating conditions.

Looking ahead, the objectives for W16 emission control include further reducing the overall system complexity, improving cold-start emissions performance, and enhancing the regeneration strategies for particulate filters. Additionally, there is a growing focus on developing solutions that can adapt to future fuel types, including synthetic fuels and hydrogen, to ensure long-term viability in an evolving regulatory landscape.

In the early stages of W16 engine development, emissions control primarily focused on optimizing combustion processes and implementing basic catalytic converters. However, as emission standards became more demanding, particularly with the introduction of Euro 6 and EPA Tier 3 regulations, manufacturers had to adopt more sophisticated aftertreatment systems.

The integration of advanced aftertreatment technologies has become a critical aspect of W16 engine design. These systems typically include a combination of Diesel Oxidation Catalysts (DOC), Diesel Particulate Filters (DPF), Selective Catalytic Reduction (SCR), and Ammonia Slip Catalysts (ASC). The challenge lies in seamlessly integrating these components to work in harmony with the engine's unique characteristics.

One of the key objectives in W16 emission control evolution is to achieve near-zero emissions of nitrogen oxides (NOx), particulate matter (PM), and hydrocarbons (HC). This requires a holistic approach that considers not only the aftertreatment system but also engine calibration, thermal management, and exhaust gas recirculation (EGR) strategies.

Another significant goal is to optimize the packaging and integration of aftertreatment components within the limited space available in high-performance vehicles that typically house W16 engines. This involves innovative design solutions to minimize the impact on vehicle aesthetics and performance while ensuring optimal emission control efficiency.

The development of more durable and heat-resistant materials for aftertreatment components is also a crucial objective. These materials must withstand the high temperatures and pressures associated with W16 engine exhaust gases while maintaining their catalytic properties over extended periods.

Furthermore, the integration of advanced sensors and control systems is essential for real-time monitoring and adjustment of the aftertreatment process. This includes the use of NOx sensors, temperature sensors, and pressure differential sensors to ensure optimal performance across various operating conditions.

Looking ahead, the objectives for W16 emission control include further reducing the overall system complexity, improving cold-start emissions performance, and enhancing the regeneration strategies for particulate filters. Additionally, there is a growing focus on developing solutions that can adapt to future fuel types, including synthetic fuels and hydrogen, to ensure long-term viability in an evolving regulatory landscape.

Market Demand for Clean W16 Engines

The market demand for clean W16 engines has been steadily increasing due to stringent environmental regulations and growing consumer awareness of ecological issues. As governments worldwide implement tighter emission standards, automotive manufacturers are under pressure to develop cleaner, more efficient engines. The W16 engine, known for its high performance and unique configuration, faces particular challenges in meeting these standards while maintaining its power output.

In the luxury and high-performance vehicle segments, where W16 engines are primarily used, there is a growing demand for environmentally responsible options. Consumers in these markets are increasingly seeking vehicles that combine exceptional performance with reduced environmental impact. This shift in consumer preferences has created a significant market opportunity for clean W16 engines, as manufacturers strive to balance power and efficiency.

The automotive industry has seen a trend towards electrification and hybrid powertrains, which has also influenced the market for high-performance engines. However, there remains a dedicated market segment that values the unique characteristics of W16 engines, creating a niche demand for cleaner versions of these powerplants. This demand is driven by enthusiasts and collectors who appreciate the engineering prowess and exclusivity of W16-powered vehicles.

Geographically, the demand for clean W16 engines is most pronounced in regions with both strict emission regulations and a strong market for luxury vehicles. Europe, particularly countries like Germany and the United Kingdom, shows significant interest in cleaner high-performance engines. North America and parts of Asia, especially China and Japan, also represent key markets where consumers are willing to pay a premium for environmentally friendlier W16 engines.

The market size for clean W16 engines, while relatively small compared to mainstream engine types, is expected to grow as manufacturers invest in advanced emission control technologies. This growth is supported by the overall trend in the automotive industry towards sustainability, which is pushing innovation in all engine types, including high-performance variants like the W16.

Manufacturers are responding to this demand by exploring various aftertreatment integration tactics. These include advanced catalytic converters, particulate filters, and innovative exhaust gas recirculation systems specifically designed for the unique configuration of W16 engines. The challenge lies in implementing these technologies without significantly compromising the engine's performance characteristics, which are crucial to its market appeal.

In conclusion, the market demand for clean W16 engines represents a specialized but growing segment within the automotive industry. It reflects a broader trend towards environmental responsibility in high-performance vehicles and presents both challenges and opportunities for manufacturers to innovate in emission management technologies.

In the luxury and high-performance vehicle segments, where W16 engines are primarily used, there is a growing demand for environmentally responsible options. Consumers in these markets are increasingly seeking vehicles that combine exceptional performance with reduced environmental impact. This shift in consumer preferences has created a significant market opportunity for clean W16 engines, as manufacturers strive to balance power and efficiency.

The automotive industry has seen a trend towards electrification and hybrid powertrains, which has also influenced the market for high-performance engines. However, there remains a dedicated market segment that values the unique characteristics of W16 engines, creating a niche demand for cleaner versions of these powerplants. This demand is driven by enthusiasts and collectors who appreciate the engineering prowess and exclusivity of W16-powered vehicles.

Geographically, the demand for clean W16 engines is most pronounced in regions with both strict emission regulations and a strong market for luxury vehicles. Europe, particularly countries like Germany and the United Kingdom, shows significant interest in cleaner high-performance engines. North America and parts of Asia, especially China and Japan, also represent key markets where consumers are willing to pay a premium for environmentally friendlier W16 engines.

The market size for clean W16 engines, while relatively small compared to mainstream engine types, is expected to grow as manufacturers invest in advanced emission control technologies. This growth is supported by the overall trend in the automotive industry towards sustainability, which is pushing innovation in all engine types, including high-performance variants like the W16.

Manufacturers are responding to this demand by exploring various aftertreatment integration tactics. These include advanced catalytic converters, particulate filters, and innovative exhaust gas recirculation systems specifically designed for the unique configuration of W16 engines. The challenge lies in implementing these technologies without significantly compromising the engine's performance characteristics, which are crucial to its market appeal.

In conclusion, the market demand for clean W16 engines represents a specialized but growing segment within the automotive industry. It reflects a broader trend towards environmental responsibility in high-performance vehicles and presents both challenges and opportunities for manufacturers to innovate in emission management technologies.

W16 Aftertreatment Challenges

The W16 engine, renowned for its power and performance, faces significant challenges in meeting increasingly stringent emissions regulations. The primary hurdle lies in effectively managing the complex exhaust aftertreatment system required to reduce harmful emissions from this high-output engine.

One of the main challenges is the integration of a sufficiently large and efficient catalytic converter system. The W16's unique configuration and high exhaust flow rates necessitate a carefully designed aftertreatment package that can handle the increased thermal load and flow dynamics without compromising engine performance or causing excessive backpressure.

Temperature management presents another critical challenge. The W16 engine's high power output generates substantial exhaust heat, which must be carefully controlled to ensure optimal catalytic converter function and longevity. This requires advanced thermal management strategies and materials capable of withstanding extreme temperatures while maintaining catalytic efficiency.

Space constraints pose a significant obstacle in aftertreatment integration. The W16 engine's compact design leaves limited room for extensive exhaust treatment systems, necessitating innovative packaging solutions that maximize efficiency within a confined space. This challenge is further compounded by the need to maintain the vehicle's aerodynamic profile and weight distribution.

Particulate matter control is particularly demanding for W16 engines due to their high fuel consumption and combustion characteristics. Implementing effective particulate filters without severely impacting engine performance or requiring frequent regeneration cycles presents a complex engineering challenge.

NOx reduction in W16 engines is complicated by their typically rich-running nature, which is essential for power output but unfavorable for NOx control. Balancing performance requirements with effective NOx reduction technologies, such as selective catalytic reduction (SCR) systems, requires sophisticated engine management and aftertreatment strategies.

The durability and longevity of aftertreatment components under the extreme conditions generated by W16 engines present ongoing challenges. Ensuring that catalysts, sensors, and other critical components can withstand high temperatures, vibrations, and chemical stresses over extended periods is crucial for maintaining emissions compliance throughout the vehicle's lifecycle.

Lastly, calibration and control strategies for W16 engine aftertreatment systems are exceptionally complex. Optimizing the interplay between engine operation, emissions control systems, and performance demands requires advanced algorithms and real-time adaptive strategies to maintain compliance across various driving conditions while preserving the engine's characteristic power delivery.

One of the main challenges is the integration of a sufficiently large and efficient catalytic converter system. The W16's unique configuration and high exhaust flow rates necessitate a carefully designed aftertreatment package that can handle the increased thermal load and flow dynamics without compromising engine performance or causing excessive backpressure.

Temperature management presents another critical challenge. The W16 engine's high power output generates substantial exhaust heat, which must be carefully controlled to ensure optimal catalytic converter function and longevity. This requires advanced thermal management strategies and materials capable of withstanding extreme temperatures while maintaining catalytic efficiency.

Space constraints pose a significant obstacle in aftertreatment integration. The W16 engine's compact design leaves limited room for extensive exhaust treatment systems, necessitating innovative packaging solutions that maximize efficiency within a confined space. This challenge is further compounded by the need to maintain the vehicle's aerodynamic profile and weight distribution.

Particulate matter control is particularly demanding for W16 engines due to their high fuel consumption and combustion characteristics. Implementing effective particulate filters without severely impacting engine performance or requiring frequent regeneration cycles presents a complex engineering challenge.

NOx reduction in W16 engines is complicated by their typically rich-running nature, which is essential for power output but unfavorable for NOx control. Balancing performance requirements with effective NOx reduction technologies, such as selective catalytic reduction (SCR) systems, requires sophisticated engine management and aftertreatment strategies.

The durability and longevity of aftertreatment components under the extreme conditions generated by W16 engines present ongoing challenges. Ensuring that catalysts, sensors, and other critical components can withstand high temperatures, vibrations, and chemical stresses over extended periods is crucial for maintaining emissions compliance throughout the vehicle's lifecycle.

Lastly, calibration and control strategies for W16 engine aftertreatment systems are exceptionally complex. Optimizing the interplay between engine operation, emissions control systems, and performance demands requires advanced algorithms and real-time adaptive strategies to maintain compliance across various driving conditions while preserving the engine's characteristic power delivery.

Current W16 Aftertreatment Solutions

01 Exhaust gas recirculation (EGR) systems for W16 engines

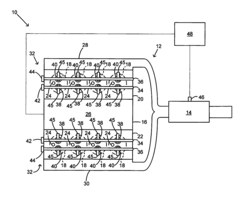

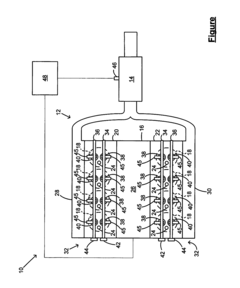

EGR systems are implemented in W16 engines to reduce emissions by recirculating a portion of the exhaust gas back into the engine cylinders. This process lowers combustion temperatures and reduces the formation of nitrogen oxides (NOx). Advanced EGR systems may include cooling mechanisms and precise control strategies to optimize emission reduction while maintaining engine performance.- Exhaust gas recirculation (EGR) systems for W16 engines: EGR systems are implemented in W16 engines to reduce emissions by recirculating a portion of the exhaust gas back into the engine cylinders. This process lowers combustion temperatures and reduces the formation of nitrogen oxides (NOx). Advanced EGR systems may include cooling mechanisms and precise control strategies to optimize emission reduction while maintaining engine performance.

- Catalytic converters and aftertreatment systems: Specialized catalytic converters and aftertreatment systems are designed for W16 engines to effectively reduce harmful emissions. These systems may include multiple stages of catalysts, particulate filters, and selective catalytic reduction (SCR) technology to target various pollutants such as carbon monoxide, hydrocarbons, and particulate matter.

- Engine management and control strategies: Advanced engine management systems and control strategies are employed in W16 engines to optimize combustion processes and minimize emissions. These may include precise fuel injection timing, variable valve timing, and adaptive algorithms that continuously adjust engine parameters based on operating conditions and emission sensor feedback.

- Turbocharging and supercharging technologies: W16 engines often incorporate advanced turbocharging or supercharging technologies to improve power output and efficiency while managing emissions. These forced induction systems may feature variable geometry turbines, electric compressors, or multi-stage configurations to optimize air intake across different engine speeds and loads.

- Lightweight materials and design optimization: The use of lightweight materials and optimized engine designs in W16 engines contributes to improved fuel efficiency and reduced emissions. This may include the application of advanced alloys, composite materials, and innovative manufacturing techniques to reduce engine weight and friction, as well as optimized combustion chamber designs for more complete fuel burning.

02 Catalytic converters and aftertreatment systems

Specialized catalytic converters and aftertreatment systems are designed for W16 engines to effectively reduce harmful emissions. These systems may include multiple stages of catalysts, particulate filters, and selective catalytic reduction (SCR) technology to target various pollutants such as carbon monoxide, hydrocarbons, and particulate matter.Expand Specific Solutions03 Advanced fuel injection and combustion control

W16 engines utilize sophisticated fuel injection systems and combustion control strategies to optimize fuel efficiency and reduce emissions. This may include direct injection technology, variable valve timing, and advanced engine management systems that precisely control fuel delivery and ignition timing based on various operating conditions.Expand Specific Solutions04 Turbocharging and supercharging technologies

Forced induction systems, such as turbochargers and superchargers, are employed in W16 engines to improve power output and efficiency while potentially reducing emissions. These systems may incorporate advanced features like variable geometry turbochargers or electric compressors to optimize performance across different engine speeds and loads.Expand Specific Solutions05 Lightweight materials and design optimization

The use of lightweight materials and optimized engine designs in W16 engines contributes to improved fuel efficiency and reduced emissions. This may include the use of advanced alloys, composite materials, and innovative manufacturing techniques to reduce engine weight while maintaining structural integrity and performance.Expand Specific Solutions

Key W16 Engine Manufacturers

The W16 Engine Emissions Management market is in a mature stage, with established players like Caterpillar, Cummins, and Volkswagen leading the way. The market size is substantial, driven by stringent emissions regulations and the need for cleaner engine technologies. Technological maturity is high, with companies like Bosch and Cummins Emission Solutions offering advanced aftertreatment systems. However, there's ongoing innovation in integration tactics, as evidenced by research from institutions like Tongji University and Tianjin University. Major automotive manufacturers such as GM, Porsche, and Scania are actively developing proprietary solutions, while suppliers like BASF and Afton Chemical contribute specialized components and additives to enhance aftertreatment performance.

Cummins, Inc.

Technical Solution: Cummins has developed an integrated aftertreatment system for W16 engines that combines Selective Catalytic Reduction (SCR) and Diesel Particulate Filter (DPF) technologies. Their system utilizes a close-coupled SCR catalyst positioned near the engine to optimize NOx reduction at low temperatures. The DPF is designed with advanced regeneration strategies to minimize fuel consumption during particulate matter removal. Cummins' solution also incorporates a sophisticated urea dosing system with predictive controls to ensure optimal NOx conversion efficiency across various operating conditions[1][3]. The company has implemented advanced thermal management techniques to maintain ideal catalyst temperatures, improving overall system performance and durability[5].

Strengths: Comprehensive integration of SCR and DPF technologies, advanced thermal management, and predictive urea dosing control. Weaknesses: Potential complexity in system maintenance and higher initial costs compared to simpler aftertreatment solutions.

GM Global Technology Operations LLC

Technical Solution: GM has engineered a sophisticated aftertreatment system for W16 engines, emphasizing integration with powertrain control strategies. Their solution incorporates a close-coupled SCR catalyst combined with a downstream SCR-on-filter system, maximizing NOx reduction efficiency while minimizing system footprint. GM's approach includes advanced exhaust gas thermal management, utilizing waste heat recovery systems to maintain optimal catalyst temperatures[10]. The company has implemented a predictive urea dosing strategy that leverages vehicle-to-infrastructure (V2I) communication to anticipate driving conditions and optimize AdBlue injection. GM's aftertreatment package also features an innovative particulate sensor-based control system for real-time DPF monitoring and regeneration management, ensuring optimal filtration efficiency and fuel economy[11].

Strengths: Integrated powertrain and aftertreatment control strategies, advanced thermal management, and V2I-enabled predictive urea dosing. Weaknesses: Potential dependency on V2I infrastructure availability for optimal performance in all regions.

Innovative W16 Emission Reduction Technologies

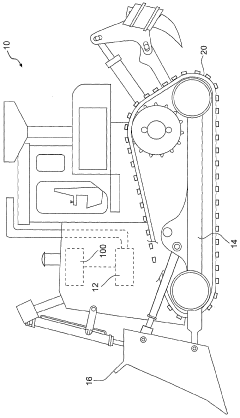

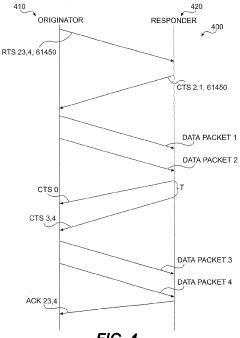

Valvetrain control strategies for exhaust aftertreatment devices

PatentInactiveUS20100071656A1

Innovation

- The engine operates in different valvetrain modes to control the temperature of the exhaust aftertreatment components by selectively actuating the valvetrain assembly between full cylinder and cylinder deactivation modes, adjusting valve timing, and using cam phasers to optimize exhaust gas temperature.

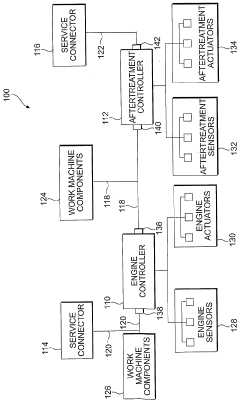

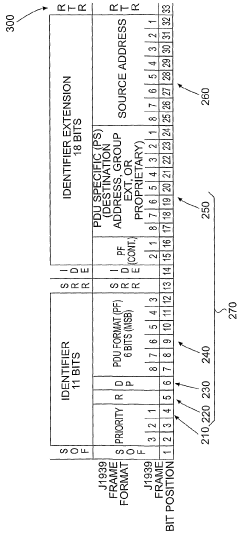

Integrated regeneration and engine controls

PatentWO2006135501A1

Innovation

- Integrating engine and aftertreatment controllers using a common data link protocol to enable bidirectional data flow, allowing for the exchange of multiple signals over a single connection, thereby reducing the number of physical wires needed and enhancing communication between the controllers.

Environmental Regulations Impact

Environmental regulations have a profound impact on W16 engine emissions management and aftertreatment integration tactics. The increasingly stringent emission standards set by regulatory bodies worldwide are driving the development of advanced aftertreatment systems and integration strategies for high-performance engines like the W16.

In recent years, major automotive markets have implemented progressively tighter emission limits. The European Union's Euro 6d standard, the United States' Tier 3 regulations, and China's China 6 standards have all pushed manufacturers to adopt more sophisticated emission control technologies. These regulations typically focus on reducing nitrogen oxides (NOx), particulate matter (PM), carbon monoxide (CO), and hydrocarbon (HC) emissions.

For W16 engines, which are known for their high power output and fuel consumption, meeting these stringent standards presents a significant challenge. Manufacturers must balance performance expectations with environmental compliance, leading to the development of innovative aftertreatment integration tactics.

One of the key impacts of environmental regulations on W16 engine emissions management is the necessity for more complex and efficient aftertreatment systems. This often involves the integration of multiple technologies, such as selective catalytic reduction (SCR), diesel particulate filters (DPF), and oxidation catalysts. The packaging and thermal management of these systems become critical factors in engine design and vehicle integration.

Moreover, the regulations have spurred advancements in engine control strategies. Real-time monitoring and adjustment of engine parameters, coupled with predictive algorithms for aftertreatment system performance, have become essential in maintaining compliance across various driving conditions. This has led to increased investment in sensor technologies and sophisticated engine management software.

The impact of environmental regulations extends beyond the technical aspects of engine design. Manufacturers must also consider the economic implications of compliance, including increased production costs and potential market restrictions for non-compliant vehicles. This has accelerated research into alternative powertrain technologies, such as hybridization, which can complement W16 engines and help meet emission targets.

As regulations continue to evolve, the future of W16 engines and their emissions management strategies remains uncertain. Manufacturers are exploring innovative solutions, including advanced materials for catalysts, improved thermal management techniques, and integration of artificial intelligence in engine control systems. The ongoing challenge is to preserve the performance characteristics that define W16 engines while adhering to increasingly strict environmental standards.

In recent years, major automotive markets have implemented progressively tighter emission limits. The European Union's Euro 6d standard, the United States' Tier 3 regulations, and China's China 6 standards have all pushed manufacturers to adopt more sophisticated emission control technologies. These regulations typically focus on reducing nitrogen oxides (NOx), particulate matter (PM), carbon monoxide (CO), and hydrocarbon (HC) emissions.

For W16 engines, which are known for their high power output and fuel consumption, meeting these stringent standards presents a significant challenge. Manufacturers must balance performance expectations with environmental compliance, leading to the development of innovative aftertreatment integration tactics.

One of the key impacts of environmental regulations on W16 engine emissions management is the necessity for more complex and efficient aftertreatment systems. This often involves the integration of multiple technologies, such as selective catalytic reduction (SCR), diesel particulate filters (DPF), and oxidation catalysts. The packaging and thermal management of these systems become critical factors in engine design and vehicle integration.

Moreover, the regulations have spurred advancements in engine control strategies. Real-time monitoring and adjustment of engine parameters, coupled with predictive algorithms for aftertreatment system performance, have become essential in maintaining compliance across various driving conditions. This has led to increased investment in sensor technologies and sophisticated engine management software.

The impact of environmental regulations extends beyond the technical aspects of engine design. Manufacturers must also consider the economic implications of compliance, including increased production costs and potential market restrictions for non-compliant vehicles. This has accelerated research into alternative powertrain technologies, such as hybridization, which can complement W16 engines and help meet emission targets.

As regulations continue to evolve, the future of W16 engines and their emissions management strategies remains uncertain. Manufacturers are exploring innovative solutions, including advanced materials for catalysts, improved thermal management techniques, and integration of artificial intelligence in engine control systems. The ongoing challenge is to preserve the performance characteristics that define W16 engines while adhering to increasingly strict environmental standards.

W16 Aftertreatment Cost-Benefit Analysis

The cost-benefit analysis of W16 engine aftertreatment systems is crucial for evaluating the economic viability and environmental impact of emissions management strategies. This analysis considers both the direct costs associated with implementing advanced aftertreatment technologies and the long-term benefits derived from improved emissions control and regulatory compliance.

Initial investment costs for W16 aftertreatment systems are substantial, encompassing hardware components such as catalytic converters, diesel particulate filters (DPF), selective catalytic reduction (SCR) systems, and associated sensors and control units. These components can significantly increase the overall engine production costs, potentially impacting the final price of vehicles equipped with W16 engines.

Operational expenses must also be factored into the analysis, including the ongoing costs of consumables like diesel exhaust fluid (DEF) for SCR systems and the increased fuel consumption due to the backpressure created by aftertreatment devices. Additionally, maintenance costs for cleaning or replacing filters and catalysts contribute to the total cost of ownership.

On the benefits side, effective aftertreatment systems enable W16 engines to meet stringent emissions regulations, allowing manufacturers to sell their products in markets with strict environmental standards. This compliance opens up new market opportunities and helps avoid potential fines or sales restrictions in regulated regions.

Improved emissions control also contributes to better air quality and reduced environmental impact, which can enhance brand reputation and appeal to environmentally conscious consumers. This intangible benefit may translate into increased sales and market share for manufacturers committed to sustainable practices.

Long-term cost savings can be realized through the optimization of engine performance and fuel efficiency. Advanced aftertreatment systems, when properly integrated, can allow engines to operate at more efficient combustion settings, potentially offsetting some of the initial costs through reduced fuel consumption over the vehicle's lifetime.

The analysis must also consider the potential for future regulatory changes and technological advancements. Investing in robust aftertreatment systems now may provide a competitive advantage and reduce the need for costly retrofits or redesigns in the future as emissions standards continue to evolve.

Ultimately, the cost-benefit analysis of W16 aftertreatment integration must balance the immediate financial implications against the long-term strategic benefits. While the upfront costs are significant, the potential for sustained market access, regulatory compliance, and environmental stewardship presents a compelling case for investment in advanced emissions management technologies.

Initial investment costs for W16 aftertreatment systems are substantial, encompassing hardware components such as catalytic converters, diesel particulate filters (DPF), selective catalytic reduction (SCR) systems, and associated sensors and control units. These components can significantly increase the overall engine production costs, potentially impacting the final price of vehicles equipped with W16 engines.

Operational expenses must also be factored into the analysis, including the ongoing costs of consumables like diesel exhaust fluid (DEF) for SCR systems and the increased fuel consumption due to the backpressure created by aftertreatment devices. Additionally, maintenance costs for cleaning or replacing filters and catalysts contribute to the total cost of ownership.

On the benefits side, effective aftertreatment systems enable W16 engines to meet stringent emissions regulations, allowing manufacturers to sell their products in markets with strict environmental standards. This compliance opens up new market opportunities and helps avoid potential fines or sales restrictions in regulated regions.

Improved emissions control also contributes to better air quality and reduced environmental impact, which can enhance brand reputation and appeal to environmentally conscious consumers. This intangible benefit may translate into increased sales and market share for manufacturers committed to sustainable practices.

Long-term cost savings can be realized through the optimization of engine performance and fuel efficiency. Advanced aftertreatment systems, when properly integrated, can allow engines to operate at more efficient combustion settings, potentially offsetting some of the initial costs through reduced fuel consumption over the vehicle's lifetime.

The analysis must also consider the potential for future regulatory changes and technological advancements. Investing in robust aftertreatment systems now may provide a competitive advantage and reduce the need for costly retrofits or redesigns in the future as emissions standards continue to evolve.

Ultimately, the cost-benefit analysis of W16 aftertreatment integration must balance the immediate financial implications against the long-term strategic benefits. While the upfront costs are significant, the potential for sustained market access, regulatory compliance, and environmental stewardship presents a compelling case for investment in advanced emissions management technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!