W16 Engine Cooling Strategy: Heat Load Metrics And Solutions

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

W16 Engine Cooling Background and Objectives

The W16 engine represents a pinnacle of automotive engineering, combining power, performance, and complexity in a unique configuration. This 16-cylinder powerplant, typically arranged in a W formation, has been the centerpiece of some of the world's most exclusive and high-performance vehicles. The development of the W16 engine has been driven by the pursuit of extreme power output while maintaining a relatively compact design compared to traditional V12 or V16 layouts.

The evolution of the W16 engine can be traced back to the late 1990s, with Volkswagen Group spearheading its development. The primary goal was to create an engine that could deliver unprecedented power levels for ultra-luxury and hypercar applications. This ambitious project aimed to push the boundaries of internal combustion engine technology, showcasing engineering prowess and setting new benchmarks in automotive performance.

As engine technology progressed, so did the challenges associated with managing the immense heat generated by these powerful powerplants. The W16 engine, with its high cylinder count and compact design, presents unique cooling challenges that require innovative solutions. The dense packaging of cylinders results in concentrated heat generation, necessitating advanced cooling strategies to maintain optimal operating temperatures and ensure longevity.

The objectives of W16 engine cooling strategies are multifaceted. Primarily, they aim to efficiently dissipate the enormous heat generated during combustion and mechanical operation. This is crucial not only for maintaining engine performance but also for ensuring reliability and longevity. Additionally, effective cooling strategies must address the challenge of maintaining uniform temperature distribution across all cylinders, preventing hot spots that could lead to premature wear or failure.

Another key objective is to optimize the engine's thermal efficiency. By precisely controlling temperatures throughout the engine, engineers can maximize power output while minimizing fuel consumption and emissions. This aligns with broader industry trends towards improved efficiency and reduced environmental impact, even in high-performance applications.

The development of heat load metrics for W16 engines is essential for quantifying and analyzing the thermal challenges faced by these complex powerplants. These metrics provide a framework for assessing cooling system performance, identifying areas of improvement, and guiding the development of innovative cooling solutions. By accurately measuring and predicting heat loads under various operating conditions, engineers can design more effective and efficient cooling systems tailored to the unique demands of W16 engines.

The evolution of the W16 engine can be traced back to the late 1990s, with Volkswagen Group spearheading its development. The primary goal was to create an engine that could deliver unprecedented power levels for ultra-luxury and hypercar applications. This ambitious project aimed to push the boundaries of internal combustion engine technology, showcasing engineering prowess and setting new benchmarks in automotive performance.

As engine technology progressed, so did the challenges associated with managing the immense heat generated by these powerful powerplants. The W16 engine, with its high cylinder count and compact design, presents unique cooling challenges that require innovative solutions. The dense packaging of cylinders results in concentrated heat generation, necessitating advanced cooling strategies to maintain optimal operating temperatures and ensure longevity.

The objectives of W16 engine cooling strategies are multifaceted. Primarily, they aim to efficiently dissipate the enormous heat generated during combustion and mechanical operation. This is crucial not only for maintaining engine performance but also for ensuring reliability and longevity. Additionally, effective cooling strategies must address the challenge of maintaining uniform temperature distribution across all cylinders, preventing hot spots that could lead to premature wear or failure.

Another key objective is to optimize the engine's thermal efficiency. By precisely controlling temperatures throughout the engine, engineers can maximize power output while minimizing fuel consumption and emissions. This aligns with broader industry trends towards improved efficiency and reduced environmental impact, even in high-performance applications.

The development of heat load metrics for W16 engines is essential for quantifying and analyzing the thermal challenges faced by these complex powerplants. These metrics provide a framework for assessing cooling system performance, identifying areas of improvement, and guiding the development of innovative cooling solutions. By accurately measuring and predicting heat loads under various operating conditions, engineers can design more effective and efficient cooling systems tailored to the unique demands of W16 engines.

Market Analysis for High-Performance Engines

The high-performance engine market has experienced significant growth in recent years, driven by increasing demand for luxury and sports vehicles. This segment is characterized by engines that deliver exceptional power output, typically exceeding 300 horsepower, and often featuring advanced technologies such as turbocharging, direct injection, and variable valve timing.

The global market for high-performance engines is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to remain strong through 2025. This growth is fueled by several factors, including rising disposable incomes in emerging markets, technological advancements in engine design, and a growing enthusiasm for performance vehicles among younger consumers.

Geographically, North America and Europe remain the largest markets for high-performance engines, with the United States and Germany leading in terms of both production and consumption. However, Asia-Pacific, particularly China and India, is emerging as a rapidly growing market, driven by increasing urbanization and a burgeoning middle class with a taste for luxury vehicles.

The market is segmented by engine type, with V8 and V12 configurations dominating the high-end spectrum. However, there is a growing trend towards smaller, more efficient engines that still deliver high performance, such as turbocharged four and six-cylinder units. This shift is partly driven by stringent emissions regulations and a growing focus on fuel efficiency, even in the performance segment.

Key players in the high-performance engine market include established automotive manufacturers like Mercedes-AMG, BMW M, and Ferrari, as well as specialized engine developers such as Cosworth and Ilmor. These companies are continuously innovating to improve power output, reduce emissions, and enhance overall engine efficiency.

The W16 engine, as used in the Bugatti Chiron, represents the pinnacle of high-performance engine technology. While its market share is limited due to its extreme nature, it serves as a halo product that drives innovation throughout the industry. The cooling strategies developed for such engines often trickle down to more mainstream high-performance applications.

Looking ahead, the high-performance engine market faces both opportunities and challenges. The push towards electrification is reshaping the automotive landscape, with hybrid powertrains becoming increasingly common in the performance segment. This trend is likely to continue, with high-performance combustion engines being complemented or eventually replaced by electric motors in many applications.

The global market for high-performance engines is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to remain strong through 2025. This growth is fueled by several factors, including rising disposable incomes in emerging markets, technological advancements in engine design, and a growing enthusiasm for performance vehicles among younger consumers.

Geographically, North America and Europe remain the largest markets for high-performance engines, with the United States and Germany leading in terms of both production and consumption. However, Asia-Pacific, particularly China and India, is emerging as a rapidly growing market, driven by increasing urbanization and a burgeoning middle class with a taste for luxury vehicles.

The market is segmented by engine type, with V8 and V12 configurations dominating the high-end spectrum. However, there is a growing trend towards smaller, more efficient engines that still deliver high performance, such as turbocharged four and six-cylinder units. This shift is partly driven by stringent emissions regulations and a growing focus on fuel efficiency, even in the performance segment.

Key players in the high-performance engine market include established automotive manufacturers like Mercedes-AMG, BMW M, and Ferrari, as well as specialized engine developers such as Cosworth and Ilmor. These companies are continuously innovating to improve power output, reduce emissions, and enhance overall engine efficiency.

The W16 engine, as used in the Bugatti Chiron, represents the pinnacle of high-performance engine technology. While its market share is limited due to its extreme nature, it serves as a halo product that drives innovation throughout the industry. The cooling strategies developed for such engines often trickle down to more mainstream high-performance applications.

Looking ahead, the high-performance engine market faces both opportunities and challenges. The push towards electrification is reshaping the automotive landscape, with hybrid powertrains becoming increasingly common in the performance segment. This trend is likely to continue, with high-performance combustion engines being complemented or eventually replaced by electric motors in many applications.

Current Cooling Challenges in W16 Engines

The W16 engine, renowned for its power and complexity, faces significant cooling challenges due to its unique design and high-performance characteristics. One of the primary issues is the increased heat generation resulting from the engine's compact layout and high cylinder count. With 16 cylinders arranged in a W configuration, the engine produces a substantial amount of heat that must be efficiently dissipated to maintain optimal performance and prevent damage.

The dense packaging of components within the W16 engine creates limited space for traditional cooling systems, exacerbating the challenge of heat management. This constraint necessitates innovative cooling strategies that can effectively operate within the confined engine bay. The proximity of cylinders to one another also leads to heat concentration in certain areas, requiring targeted cooling solutions to address potential hotspots.

Another significant challenge is the varying heat loads across different engine components. The central cylinders, being surrounded by other heat-generating elements, tend to experience higher temperatures compared to the outer cylinders. This uneven heat distribution demands a sophisticated cooling system capable of providing balanced thermal management across the entire engine block.

The high-performance nature of W16 engines further compounds cooling difficulties. These engines often operate at high RPMs and under extreme conditions, generating intense heat loads that fluctuate rapidly. Conventional cooling methods may struggle to respond quickly enough to these dynamic thermal changes, potentially leading to localized overheating or thermal stress on engine components.

Moreover, the increased number of moving parts in a W16 engine results in higher friction levels, contributing to additional heat generation. This excess heat must be efficiently removed to maintain engine efficiency and prevent premature wear of components. The cooling system must also contend with the heat produced by auxiliary systems such as turbochargers or superchargers, which are common in high-performance W16 configurations.

The challenge of maintaining optimal oil temperatures in W16 engines is particularly critical. With more cylinders and bearings to lubricate, the oil system must cope with increased thermal loads while ensuring proper viscosity and protection across a wide range of operating conditions. Inadequate oil cooling can lead to reduced lubrication effectiveness, accelerated wear, and potential engine failure.

Addressing these cooling challenges requires a multifaceted approach that combines advanced materials, precision engineering, and innovative cooling technologies. Engineers must develop solutions that not only manage heat effectively but also integrate seamlessly with the engine's design without compromising performance or reliability. As W16 engines continue to push the boundaries of automotive engineering, overcoming these cooling challenges remains a critical focus for manufacturers and researchers in the pursuit of enhanced performance and durability.

The dense packaging of components within the W16 engine creates limited space for traditional cooling systems, exacerbating the challenge of heat management. This constraint necessitates innovative cooling strategies that can effectively operate within the confined engine bay. The proximity of cylinders to one another also leads to heat concentration in certain areas, requiring targeted cooling solutions to address potential hotspots.

Another significant challenge is the varying heat loads across different engine components. The central cylinders, being surrounded by other heat-generating elements, tend to experience higher temperatures compared to the outer cylinders. This uneven heat distribution demands a sophisticated cooling system capable of providing balanced thermal management across the entire engine block.

The high-performance nature of W16 engines further compounds cooling difficulties. These engines often operate at high RPMs and under extreme conditions, generating intense heat loads that fluctuate rapidly. Conventional cooling methods may struggle to respond quickly enough to these dynamic thermal changes, potentially leading to localized overheating or thermal stress on engine components.

Moreover, the increased number of moving parts in a W16 engine results in higher friction levels, contributing to additional heat generation. This excess heat must be efficiently removed to maintain engine efficiency and prevent premature wear of components. The cooling system must also contend with the heat produced by auxiliary systems such as turbochargers or superchargers, which are common in high-performance W16 configurations.

The challenge of maintaining optimal oil temperatures in W16 engines is particularly critical. With more cylinders and bearings to lubricate, the oil system must cope with increased thermal loads while ensuring proper viscosity and protection across a wide range of operating conditions. Inadequate oil cooling can lead to reduced lubrication effectiveness, accelerated wear, and potential engine failure.

Addressing these cooling challenges requires a multifaceted approach that combines advanced materials, precision engineering, and innovative cooling technologies. Engineers must develop solutions that not only manage heat effectively but also integrate seamlessly with the engine's design without compromising performance or reliability. As W16 engines continue to push the boundaries of automotive engineering, overcoming these cooling challenges remains a critical focus for manufacturers and researchers in the pursuit of enhanced performance and durability.

Existing W16 Cooling Solutions

01 Cooling system optimization for W16 engines

Advanced cooling systems are developed to manage the high heat load of W16 engines. These systems may include improved radiator designs, enhanced coolant circulation, and strategic placement of cooling components to efficiently dissipate heat generated by the engine's multiple cylinders.- Cooling system optimization for W16 engines: Advanced cooling systems are developed to manage the high heat load of W16 engines. These systems may include improved radiator designs, enhanced coolant circulation, and strategic placement of cooling components to efficiently dissipate heat generated by the engine's multiple cylinders.

- Thermal management strategies: Various thermal management strategies are employed to control the heat load in W16 engines. These may include variable coolant flow rates, intelligent temperature sensors, and adaptive cooling algorithms to optimize engine performance and efficiency while managing heat generation.

- Heat exchanger innovations: Specialized heat exchangers are designed to handle the increased heat load of W16 engines. These may incorporate advanced materials, improved fin designs, and optimized flow patterns to enhance heat transfer and maintain optimal operating temperatures.

- Lubrication system enhancements: Improved lubrication systems are developed to address the heat load challenges in W16 engines. These enhancements may include oil cooling techniques, advanced oil formulations, and strategic oil routing to critical engine components to reduce friction and manage heat generation.

- Electronic control and monitoring: Advanced electronic control systems are implemented to monitor and manage the heat load in W16 engines. These systems may utilize real-time temperature sensors, predictive algorithms, and adaptive control strategies to optimize engine performance and prevent overheating.

02 Thermal management strategies

Various thermal management strategies are employed to control the heat load in W16 engines. These may include variable coolant flow rates, intelligent temperature sensors, and adaptive cooling algorithms to optimize engine performance and efficiency while managing heat generation.Expand Specific Solutions03 Heat exchanger innovations

Specialized heat exchangers are designed to handle the unique heat load characteristics of W16 engines. These may incorporate advanced materials, improved fin designs, and optimized flow patterns to enhance heat transfer and maintain optimal operating temperatures.Expand Specific Solutions04 Exhaust system heat management

Innovative exhaust system designs are developed to efficiently manage and utilize the heat generated by W16 engines. These may include heat-resistant materials, strategic routing of exhaust components, and integration with heat recovery systems to improve overall engine efficiency.Expand Specific Solutions05 Electronic control systems for heat load management

Advanced electronic control systems are implemented to monitor and regulate the heat load in W16 engines. These systems may use real-time data from multiple sensors to adjust engine parameters, cooling system operation, and other factors to optimize performance and manage heat generation effectively.Expand Specific Solutions

Key Players in W16 Engine Manufacturing

The W16 Engine Cooling Strategy market is in a mature stage, with established players competing to optimize heat load management solutions. The global market size for advanced engine cooling systems is substantial, driven by increasing demand for high-performance vehicles and stringent emissions regulations. Technologically, the field is evolving rapidly, with major automotive manufacturers like Ford, Toyota, and General Motors investing heavily in research and development. Companies such as Valeo Thermal Systems and Robert Bosch GmbH are at the forefront of innovation, developing sophisticated cooling strategies that integrate thermal management, energy recovery, and emissions control. The competitive landscape is characterized by a mix of traditional automakers and specialized thermal management suppliers, all striving to enhance engine efficiency and performance through advanced cooling technologies.

Robert Bosch GmbH

Technical Solution: Bosch has engineered a comprehensive cooling solution for W16 engines that focuses on maximizing thermal efficiency and minimizing heat load. Their approach integrates advanced sensor technology with intelligent cooling management systems. Bosch's solution employs a network of temperature and pressure sensors throughout the engine to provide real-time thermal data[2]. This data is processed by a sophisticated engine control unit that dynamically adjusts coolant flow rates and cooling fan speeds. The system also incorporates split cooling circuits, allowing for independent temperature control of the cylinder head and engine block[4]. Furthermore, Bosch has developed specialized high-performance electric water pumps that offer precise control over coolant flow, improving overall system efficiency[6].

Strengths: High precision in thermal management, adaptability to various driving conditions, and potential for improved engine longevity. Weaknesses: Increased system complexity may result in higher initial costs and require specialized maintenance.

Toyota Motor Corp.

Technical Solution: Toyota has developed an innovative cooling strategy for W16 engines that emphasizes both efficiency and environmental sustainability. Their approach combines advanced materials science with intelligent thermal management systems. Toyota's solution utilizes nano-engineered coolant additives that significantly enhance heat transfer capabilities[7]. The system also incorporates a hybrid cooling approach, combining traditional liquid cooling with thermoelectric cooling elements strategically placed at high-heat zones[9]. Toyota has also implemented an advanced heat recovery system that captures waste heat and converts it into usable energy, improving overall engine efficiency[11]. Additionally, their cooling strategy includes adaptive radiator louvers that automatically adjust to optimize aerodynamics and cooling performance based on driving conditions.

Strengths: Enhanced cooling efficiency, improved fuel economy through waste heat recovery, and eco-friendly approach. Weaknesses: Higher initial costs due to advanced technologies and potential complexity in servicing the system.

Core Innovations in Heat Load Management

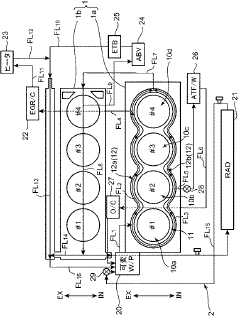

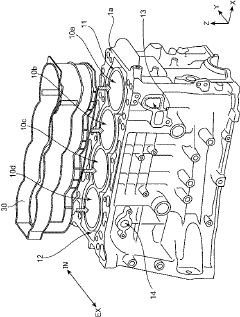

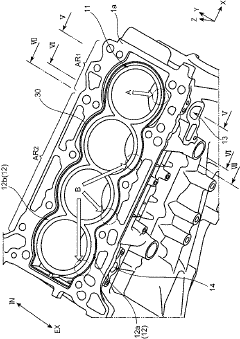

Cooling structure for engine

PatentActiveJP2019015284A

Innovation

- A cooling structure with a water jacket spacer that adjusts the gap between the water jacket and cylinder bore wall, incorporating introduction and discharge portions, and parallel intake and exhaust side water jackets to manage coolant flow and temperature uniformity.

Environmental Impact of W16 Engine Cooling

The environmental impact of W16 engine cooling is a critical consideration in the development and implementation of cooling strategies for high-performance engines. The W16 engine, known for its exceptional power output and complex design, presents unique challenges in terms of heat management and environmental sustainability.

One of the primary environmental concerns associated with W16 engine cooling is the increased energy consumption required to maintain optimal operating temperatures. The sophisticated cooling systems employed in these engines often demand significant power, which can lead to higher fuel consumption and, consequently, increased greenhouse gas emissions. This energy-intensive cooling process contributes to the overall carbon footprint of vehicles equipped with W16 engines.

Water consumption is another environmental factor to consider. Many cooling systems rely on liquid coolants, and the production, transportation, and disposal of these fluids can have ecological implications. The potential for coolant leaks also poses risks to soil and water ecosystems, necessitating careful handling and disposal protocols.

The materials used in W16 engine cooling systems also have environmental ramifications. Advanced heat-resistant alloys and specialized cooling components often require energy-intensive manufacturing processes and may involve the use of rare or environmentally sensitive materials. The lifecycle impact of these components, from production to eventual recycling or disposal, must be carefully evaluated.

Noise pollution is an additional environmental concern related to W16 engine cooling. High-performance cooling systems, particularly those employing powerful fans or pumps, can contribute to increased noise levels. This acoustic impact may have adverse effects on urban environments and wildlife habitats in areas where these engines operate.

As environmental regulations become increasingly stringent, manufacturers are compelled to innovate in cooling system design. This has led to the development of more efficient heat exchangers, advanced thermal management software, and the exploration of alternative cooling methods. Some promising approaches include the use of phase-change materials, thermoelectric cooling, and intelligent cooling systems that optimize performance based on real-time operating conditions.

The pursuit of improved cooling efficiency in W16 engines has also driven research into aerodynamic design and heat dissipation techniques. These advancements not only enhance engine performance but can also contribute to reduced environmental impact through improved overall vehicle efficiency.

In conclusion, while W16 engines represent the pinnacle of automotive engineering, their cooling systems present significant environmental challenges. Addressing these issues requires a holistic approach that considers energy efficiency, material selection, noise reduction, and innovative cooling technologies. As the automotive industry continues to evolve, balancing the performance requirements of W16 engines with environmental sustainability will remain a key focus for engineers and manufacturers alike.

One of the primary environmental concerns associated with W16 engine cooling is the increased energy consumption required to maintain optimal operating temperatures. The sophisticated cooling systems employed in these engines often demand significant power, which can lead to higher fuel consumption and, consequently, increased greenhouse gas emissions. This energy-intensive cooling process contributes to the overall carbon footprint of vehicles equipped with W16 engines.

Water consumption is another environmental factor to consider. Many cooling systems rely on liquid coolants, and the production, transportation, and disposal of these fluids can have ecological implications. The potential for coolant leaks also poses risks to soil and water ecosystems, necessitating careful handling and disposal protocols.

The materials used in W16 engine cooling systems also have environmental ramifications. Advanced heat-resistant alloys and specialized cooling components often require energy-intensive manufacturing processes and may involve the use of rare or environmentally sensitive materials. The lifecycle impact of these components, from production to eventual recycling or disposal, must be carefully evaluated.

Noise pollution is an additional environmental concern related to W16 engine cooling. High-performance cooling systems, particularly those employing powerful fans or pumps, can contribute to increased noise levels. This acoustic impact may have adverse effects on urban environments and wildlife habitats in areas where these engines operate.

As environmental regulations become increasingly stringent, manufacturers are compelled to innovate in cooling system design. This has led to the development of more efficient heat exchangers, advanced thermal management software, and the exploration of alternative cooling methods. Some promising approaches include the use of phase-change materials, thermoelectric cooling, and intelligent cooling systems that optimize performance based on real-time operating conditions.

The pursuit of improved cooling efficiency in W16 engines has also driven research into aerodynamic design and heat dissipation techniques. These advancements not only enhance engine performance but can also contribute to reduced environmental impact through improved overall vehicle efficiency.

In conclusion, while W16 engines represent the pinnacle of automotive engineering, their cooling systems present significant environmental challenges. Addressing these issues requires a holistic approach that considers energy efficiency, material selection, noise reduction, and innovative cooling technologies. As the automotive industry continues to evolve, balancing the performance requirements of W16 engines with environmental sustainability will remain a key focus for engineers and manufacturers alike.

Thermal Efficiency Optimization Techniques

Thermal efficiency optimization techniques play a crucial role in enhancing the performance and reducing the environmental impact of W16 engines. These techniques focus on maximizing the conversion of fuel energy into useful mechanical work while minimizing heat losses. One of the primary approaches involves improving combustion efficiency through advanced fuel injection systems and optimized combustion chamber designs. By ensuring a more complete and controlled burn of the fuel-air mixture, engineers can extract more energy from each combustion cycle.

Another key area of thermal efficiency optimization is the reduction of friction losses within the engine. This can be achieved through the use of advanced lubricants, low-friction coatings on engine components, and improved bearing designs. By minimizing the energy lost to friction, more of the engine's output can be directed towards useful work.

Heat recovery systems are also gaining prominence in thermal efficiency optimization. These systems capture waste heat from the exhaust gases and coolant, converting it into usable energy. Technologies such as turbocompounding and thermoelectric generators can harness this otherwise lost energy, improving overall engine efficiency.

Advanced materials and manufacturing techniques contribute significantly to thermal efficiency optimization. The use of lightweight, high-strength materials in engine construction allows for higher operating temperatures and pressures, leading to improved thermodynamic efficiency. Additionally, precision manufacturing techniques enable tighter tolerances and better sealing, reducing energy losses through gaps and improving overall engine performance.

Intelligent thermal management systems are becoming increasingly sophisticated in W16 engines. These systems use advanced sensors and control algorithms to optimize coolant flow and temperature distribution throughout the engine. By maintaining ideal operating temperatures for different engine components, thermal efficiency can be maximized across various operating conditions.

Finally, the integration of hybrid technologies and electrification is opening new avenues for thermal efficiency optimization in W16 engines. By combining internal combustion with electric propulsion, engineers can operate the engine in its most efficient range more frequently, while using electric power to supplement performance when needed. This synergy between traditional and electric powertrains represents a promising frontier in the quest for ever-higher thermal efficiencies in high-performance engines.

Another key area of thermal efficiency optimization is the reduction of friction losses within the engine. This can be achieved through the use of advanced lubricants, low-friction coatings on engine components, and improved bearing designs. By minimizing the energy lost to friction, more of the engine's output can be directed towards useful work.

Heat recovery systems are also gaining prominence in thermal efficiency optimization. These systems capture waste heat from the exhaust gases and coolant, converting it into usable energy. Technologies such as turbocompounding and thermoelectric generators can harness this otherwise lost energy, improving overall engine efficiency.

Advanced materials and manufacturing techniques contribute significantly to thermal efficiency optimization. The use of lightweight, high-strength materials in engine construction allows for higher operating temperatures and pressures, leading to improved thermodynamic efficiency. Additionally, precision manufacturing techniques enable tighter tolerances and better sealing, reducing energy losses through gaps and improving overall engine performance.

Intelligent thermal management systems are becoming increasingly sophisticated in W16 engines. These systems use advanced sensors and control algorithms to optimize coolant flow and temperature distribution throughout the engine. By maintaining ideal operating temperatures for different engine components, thermal efficiency can be maximized across various operating conditions.

Finally, the integration of hybrid technologies and electrification is opening new avenues for thermal efficiency optimization in W16 engines. By combining internal combustion with electric propulsion, engineers can operate the engine in its most efficient range more frequently, while using electric power to supplement performance when needed. This synergy between traditional and electric powertrains represents a promising frontier in the quest for ever-higher thermal efficiencies in high-performance engines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!