W16 Engine Packaging Constraints: Managing Space And Weight Tradeoffs

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

W16 Engine Evolution

The W16 engine has undergone significant evolution since its inception, driven by the need to balance power output with packaging constraints. Initially developed by Volkswagen Group in the late 1990s, the W16 engine was conceived as a solution to create a compact, high-performance powerplant for luxury and sports vehicles.

The first-generation W16 engine, introduced in the Bugatti Veyron in 2005, was a marvel of engineering. It combined two narrow-angle V8 engines in a "W" configuration, resulting in a 8.0-liter displacement producing 1,001 horsepower. This design allowed for a shorter overall engine length compared to traditional V16 layouts, addressing the critical issue of space management in high-performance vehicles.

As the automotive industry progressed, so did the W16 engine. The second-generation W16, featured in the Bugatti Chiron from 2016, maintained the same basic architecture but incorporated significant improvements. Engineers focused on enhancing power output while simultaneously addressing weight concerns. The result was an engine capable of producing 1,479 horsepower, a substantial increase over its predecessor.

Throughout its evolution, managing space and weight tradeoffs has been a constant challenge for W16 engine designers. The compact "W" configuration allowed for better weight distribution and a lower center of gravity, crucial factors in vehicle dynamics. However, the complexity of the engine layout presented cooling challenges, requiring innovative solutions in thermal management.

Recent iterations of the W16 engine have seen further refinements in materials and manufacturing processes. The use of lightweight alloys and advanced casting techniques has helped reduce the engine's overall weight without compromising structural integrity. Additionally, improvements in fuel injection systems and turbocharger technology have enhanced efficiency and power output, allowing engineers to extract more performance from the same basic engine architecture.

The latest developments in W16 engine technology have focused on hybridization. By integrating electric motors, engineers are exploring ways to supplement the W16's power output while potentially reducing fuel consumption and emissions. This hybrid approach represents a new frontier in managing the space and weight tradeoffs inherent in high-performance engine design, potentially extending the lifespan of the W16 configuration in an increasingly electrified automotive landscape.

The first-generation W16 engine, introduced in the Bugatti Veyron in 2005, was a marvel of engineering. It combined two narrow-angle V8 engines in a "W" configuration, resulting in a 8.0-liter displacement producing 1,001 horsepower. This design allowed for a shorter overall engine length compared to traditional V16 layouts, addressing the critical issue of space management in high-performance vehicles.

As the automotive industry progressed, so did the W16 engine. The second-generation W16, featured in the Bugatti Chiron from 2016, maintained the same basic architecture but incorporated significant improvements. Engineers focused on enhancing power output while simultaneously addressing weight concerns. The result was an engine capable of producing 1,479 horsepower, a substantial increase over its predecessor.

Throughout its evolution, managing space and weight tradeoffs has been a constant challenge for W16 engine designers. The compact "W" configuration allowed for better weight distribution and a lower center of gravity, crucial factors in vehicle dynamics. However, the complexity of the engine layout presented cooling challenges, requiring innovative solutions in thermal management.

Recent iterations of the W16 engine have seen further refinements in materials and manufacturing processes. The use of lightweight alloys and advanced casting techniques has helped reduce the engine's overall weight without compromising structural integrity. Additionally, improvements in fuel injection systems and turbocharger technology have enhanced efficiency and power output, allowing engineers to extract more performance from the same basic engine architecture.

The latest developments in W16 engine technology have focused on hybridization. By integrating electric motors, engineers are exploring ways to supplement the W16's power output while potentially reducing fuel consumption and emissions. This hybrid approach represents a new frontier in managing the space and weight tradeoffs inherent in high-performance engine design, potentially extending the lifespan of the W16 configuration in an increasingly electrified automotive landscape.

Market Demand Analysis

The market demand for W16 engines, particularly in the context of packaging constraints and space-weight tradeoffs, is primarily driven by the ultra-luxury and high-performance automotive sectors. These engines are typically found in exclusive hypercars and supercars, where their unique configuration and power output serve as key differentiators in a highly competitive market.

The global hypercar market, where W16 engines are most prevalent, has been experiencing steady growth. This growth is fueled by increasing disposable incomes among ultra-high-net-worth individuals and a growing appetite for exclusive, high-performance vehicles. The market for vehicles equipped with W16 engines, while niche, commands significant premium pricing and contributes substantially to brand prestige.

Consumer demand in this segment is characterized by a desire for cutting-edge technology, uncompromising performance, and exclusivity. Buyers of W16-equipped vehicles are often collectors or enthusiasts who value the engineering prowess and rarity of these powerplants. The complex packaging requirements of W16 engines contribute to their perceived value, as they represent a pinnacle of automotive engineering achievement.

However, the market for W16 engines faces challenges from evolving regulatory landscapes and shifting consumer preferences. Stringent emissions regulations in key markets are pushing manufacturers to explore more efficient powertrain options. This has led to increased interest in hybrid and electric powertrains, even in the ultra-luxury segment.

Despite these challenges, there remains a dedicated market for W16 engines, particularly among purist enthusiasts and collectors who value the unique characteristics of these powerplants. The ability to manage space and weight tradeoffs effectively in W16 engine packaging is crucial for maintaining market appeal. Manufacturers who can innovate in this area, reducing engine size and weight while maintaining or improving performance, are likely to see continued demand.

The market also shows potential for expansion into adjacent luxury segments, such as high-end sports sedans or grand tourers, provided that packaging constraints can be effectively managed. This could open up new revenue streams for manufacturers and broaden the appeal of W16 technology.

In conclusion, while the market for W16 engines remains specialized, there is sustained demand driven by exclusivity, performance, and engineering prestige. The ability to address packaging constraints effectively will be a key factor in maintaining and potentially expanding this market in the face of technological and regulatory changes.

The global hypercar market, where W16 engines are most prevalent, has been experiencing steady growth. This growth is fueled by increasing disposable incomes among ultra-high-net-worth individuals and a growing appetite for exclusive, high-performance vehicles. The market for vehicles equipped with W16 engines, while niche, commands significant premium pricing and contributes substantially to brand prestige.

Consumer demand in this segment is characterized by a desire for cutting-edge technology, uncompromising performance, and exclusivity. Buyers of W16-equipped vehicles are often collectors or enthusiasts who value the engineering prowess and rarity of these powerplants. The complex packaging requirements of W16 engines contribute to their perceived value, as they represent a pinnacle of automotive engineering achievement.

However, the market for W16 engines faces challenges from evolving regulatory landscapes and shifting consumer preferences. Stringent emissions regulations in key markets are pushing manufacturers to explore more efficient powertrain options. This has led to increased interest in hybrid and electric powertrains, even in the ultra-luxury segment.

Despite these challenges, there remains a dedicated market for W16 engines, particularly among purist enthusiasts and collectors who value the unique characteristics of these powerplants. The ability to manage space and weight tradeoffs effectively in W16 engine packaging is crucial for maintaining market appeal. Manufacturers who can innovate in this area, reducing engine size and weight while maintaining or improving performance, are likely to see continued demand.

The market also shows potential for expansion into adjacent luxury segments, such as high-end sports sedans or grand tourers, provided that packaging constraints can be effectively managed. This could open up new revenue streams for manufacturers and broaden the appeal of W16 technology.

In conclusion, while the market for W16 engines remains specialized, there is sustained demand driven by exclusivity, performance, and engineering prestige. The ability to address packaging constraints effectively will be a key factor in maintaining and potentially expanding this market in the face of technological and regulatory changes.

Technical Challenges

The development of W16 engines presents significant technical challenges, primarily centered around packaging constraints and the delicate balance between space utilization and weight management. One of the foremost issues is the engine's physical size, which is considerably larger than conventional V8 or V12 configurations. This increased size necessitates extensive modifications to the vehicle's chassis and body structure to accommodate the engine, often resulting in compromises in interior space or aerodynamic design.

Weight distribution poses another critical challenge. The W16 engine's substantial mass, typically exceeding 400 kg, creates difficulties in achieving optimal front-to-rear weight balance. This imbalance can negatively impact vehicle handling, stability, and overall performance, requiring innovative solutions in chassis design and weight reduction strategies for other components to compensate.

Thermal management is a complex issue due to the engine's compact design and high power output. The close proximity of cylinders and limited space for cooling systems make heat dissipation a significant engineering challenge. Overcoming this requires advanced cooling technologies and materials to prevent overheating and maintain optimal performance under various operating conditions.

Fuel efficiency and emissions control present additional hurdles. The W16 engine's large displacement and high power output inherently lead to increased fuel consumption and emissions. Meeting increasingly stringent environmental regulations while maintaining the engine's performance characteristics demands sophisticated fuel injection systems, advanced exhaust gas treatment technologies, and potentially hybrid integration.

Vibration and noise control are also major concerns. The W16 configuration, with its unique firing order and cylinder arrangement, can generate complex vibration patterns. Mitigating these vibrations to ensure passenger comfort and structural integrity requires advanced engine mounting systems and noise, vibration, and harshness (NVH) control measures.

Manufacturing complexity and cost present significant challenges in the production of W16 engines. The intricate design, tight tolerances, and specialized components demand highly skilled labor and advanced manufacturing processes, contributing to increased production costs and limited scalability.

Lastly, the integration of modern technologies such as direct injection, variable valve timing, and turbocharging within the confined space of a W16 engine layout presents substantial engineering challenges. Balancing these advanced systems with the spatial constraints requires innovative design solutions and often leads to compromises in other areas of engine performance or efficiency.

Weight distribution poses another critical challenge. The W16 engine's substantial mass, typically exceeding 400 kg, creates difficulties in achieving optimal front-to-rear weight balance. This imbalance can negatively impact vehicle handling, stability, and overall performance, requiring innovative solutions in chassis design and weight reduction strategies for other components to compensate.

Thermal management is a complex issue due to the engine's compact design and high power output. The close proximity of cylinders and limited space for cooling systems make heat dissipation a significant engineering challenge. Overcoming this requires advanced cooling technologies and materials to prevent overheating and maintain optimal performance under various operating conditions.

Fuel efficiency and emissions control present additional hurdles. The W16 engine's large displacement and high power output inherently lead to increased fuel consumption and emissions. Meeting increasingly stringent environmental regulations while maintaining the engine's performance characteristics demands sophisticated fuel injection systems, advanced exhaust gas treatment technologies, and potentially hybrid integration.

Vibration and noise control are also major concerns. The W16 configuration, with its unique firing order and cylinder arrangement, can generate complex vibration patterns. Mitigating these vibrations to ensure passenger comfort and structural integrity requires advanced engine mounting systems and noise, vibration, and harshness (NVH) control measures.

Manufacturing complexity and cost present significant challenges in the production of W16 engines. The intricate design, tight tolerances, and specialized components demand highly skilled labor and advanced manufacturing processes, contributing to increased production costs and limited scalability.

Lastly, the integration of modern technologies such as direct injection, variable valve timing, and turbocharging within the confined space of a W16 engine layout presents substantial engineering challenges. Balancing these advanced systems with the spatial constraints requires innovative design solutions and often leads to compromises in other areas of engine performance or efficiency.

Current Packaging Solutions

01 Compact design for W16 engine

W16 engines are designed to be compact, allowing for efficient use of space in the engine compartment. This configuration helps reduce the overall length of the engine, making it suitable for high-performance vehicles where space is at a premium. The compact design also contributes to improved weight distribution and vehicle balance.- Compact design for W16 engine: W16 engines are designed to be compact, allowing for efficient use of space in the engine compartment. This configuration helps reduce the overall length of the engine, making it suitable for high-performance vehicles where space is at a premium. The compact design also contributes to improved weight distribution and vehicle balance.

- Weight reduction techniques: Various methods are employed to reduce the weight of W16 engines, including the use of lightweight materials such as aluminum alloys and carbon fiber composites. Advanced manufacturing techniques and optimized component designs further contribute to weight reduction while maintaining structural integrity and performance.

- Engine layout optimization: The W16 engine layout is optimized to balance power output, weight distribution, and space efficiency. This includes careful positioning of components, integration of auxiliary systems, and innovative cooling solutions to manage heat dissipation within the confined space of the engine compartment.

- Integration with vehicle chassis: W16 engines are designed to integrate seamlessly with the vehicle chassis, often serving as a structural component. This integration helps to optimize space utilization, improve rigidity, and enhance overall vehicle dynamics. Advanced mounting systems are employed to manage vibrations and ensure smooth operation.

- Cooling and lubrication systems: Specialized cooling and lubrication systems are developed for W16 engines to manage heat and ensure efficient operation within the confined space. These systems are designed to be compact yet effective, utilizing advanced materials and flow optimization techniques to maintain optimal engine performance and longevity.

02 Weight reduction techniques

Various methods are employed to reduce the weight of W16 engines, including the use of lightweight materials such as aluminum alloys and composite materials for engine components. Advanced manufacturing techniques and optimized designs help minimize weight while maintaining structural integrity and performance.Expand Specific Solutions03 Engine mounting and integration

Specialized mounting systems and integration techniques are used to efficiently install W16 engines in vehicles. These methods focus on optimizing space utilization, reducing vibration, and ensuring proper weight distribution. The integration process may involve custom-designed subframes or engine mounts to accommodate the unique configuration of the W16 engine.Expand Specific Solutions04 Cooling system optimization

W16 engines require efficient cooling systems to manage heat generation in a compact space. Innovative cooling solutions, such as advanced radiator designs, multiple heat exchangers, and optimized coolant flow paths, are implemented to ensure proper temperature control without significantly increasing engine size or weight.Expand Specific Solutions05 Modular design approach

Some W16 engines utilize a modular design approach, allowing for easier manufacturing, maintenance, and potential customization. This approach can involve separate cylinder banks or modular subsystems that can be assembled or replaced independently, potentially reducing overall engine weight and simplifying production processes.Expand Specific Solutions

Key Manufacturers

The W16 engine packaging constraints market is in a mature stage, with established players competing to optimize space and weight tradeoffs. The global market for high-performance engines is substantial, driven by luxury and sports car segments. Technologically, W16 engines are highly advanced, with companies like Volkswagen Group (Bugatti) leading innovation. Other key players such as BMW, Mercedes-Benz, and Ferrari are also investing in compact, powerful engine designs. The challenge lies in balancing power output with increasingly stringent emissions regulations, pushing manufacturers to explore hybrid and electric alternatives alongside traditional combustion engine improvements.

Bayerische Motoren Werke AG

Technical Solution: BMW has tackled W16 engine packaging constraints through innovative engineering solutions. Their approach focuses on modular design and advanced manufacturing techniques. BMW utilizes a compact W16 configuration with four banks of four cylinders, arranged in a W shape to minimize the engine's overall length[5]. The company has implemented a high-pressure direct fuel injection system and variable valve timing to optimize performance within the space constraints[6]. To manage weight, BMW employs lightweight materials such as magnesium alloys for the engine block and aluminum for various components[7]. The engine's cooling system is integrated into the design, with carefully placed water jackets and oil coolers to maintain optimal operating temperatures in the confined space[8].

Strengths: Compact design allowing for better vehicle packaging, excellent power output for its size, and efficient use of lightweight materials. Weaknesses: Increased complexity in manufacturing and maintenance, potentially higher production costs.

Ford Global Technologies LLC

Technical Solution: Ford has addressed W16 engine packaging constraints through innovative engineering and design approaches. Their solution focuses on modularity and scalability to optimize space utilization. Ford's W16 engine design incorporates a compact cylinder arrangement with four banks of four cylinders, utilizing a shared crankcase to reduce overall length[13]. The company has implemented advanced variable valve timing and lift systems to enhance performance within the space constraints[14]. To manage weight, Ford uses a mix of aluminum alloys and composite materials in engine construction[15]. The cooling system is designed with precision, featuring targeted coolant channels and an integrated exhaust manifold to improve thermal efficiency in the confined space[16].

Strengths: Modular design allows for easier manufacturing and maintenance, good balance of performance and efficiency, and effective use of lightweight materials. Weaknesses: Potential challenges in achieving the highest power outputs compared to some competitors, and complexity in thermal management.

Core Patents Review

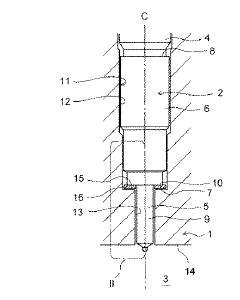

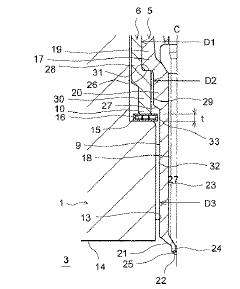

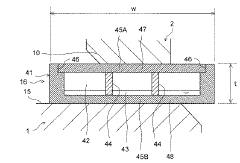

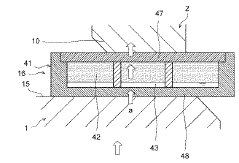

Packing and attachment structure

PatentActiveJP2019120246A

Innovation

- A packing structure with a closed cavity containing a heat transfer medium, such as water or alcohol, is installed between the cylinder head and the fuel injection valve, featuring a reinforcing member to maintain thermal contact and prevent reverse heat flow, thereby suppressing dew condensation.

Emissions Regulations

Emissions regulations play a crucial role in shaping the development and design of high-performance engines, including the W16 configuration. These regulations have become increasingly stringent over the years, posing significant challenges for manufacturers in managing space and weight tradeoffs while maintaining compliance.

The primary focus of emissions regulations is to reduce harmful pollutants such as carbon dioxide (CO2), nitrogen oxides (NOx), and particulate matter. For W16 engines, which are typically used in high-performance vehicles, meeting these standards while preserving power output and efficiency is particularly challenging. Manufacturers must implement advanced technologies and strategies to achieve compliance without compromising the engine's performance characteristics.

One of the key approaches to meeting emissions regulations is the integration of sophisticated exhaust aftertreatment systems. These systems, including catalytic converters, particulate filters, and selective catalytic reduction (SCR) units, require additional space within the engine compartment. For W16 engines, which already face packaging constraints due to their complex configuration, accommodating these components presents a significant design challenge.

The need for improved fuel efficiency to meet CO2 emissions targets also impacts the packaging of W16 engines. Technologies such as direct injection, variable valve timing, and advanced turbocharging systems are often employed to enhance efficiency. However, these additions can increase the overall complexity and space requirements of the engine, further exacerbating packaging constraints.

Weight reduction is another critical factor in meeting emissions regulations, as lighter vehicles generally produce fewer emissions. This necessitates the use of lightweight materials and innovative design solutions in W16 engines. However, the inherent complexity and size of these engines make significant weight reductions challenging, requiring careful balance between performance and compliance.

Thermal management is also a crucial consideration in emissions control. Efficient cooling systems are essential to maintain optimal operating temperatures and reduce emissions. For W16 engines, integrating these systems within the limited available space while ensuring adequate cooling for all cylinders presents a unique engineering challenge.

As emissions regulations continue to evolve, manufacturers must anticipate future standards and design W16 engines with adaptability in mind. This may involve incorporating modular components or leaving space for potential upgrades, further complicating the packaging puzzle. The ongoing shift towards electrification and hybrid powertrains also influences the design of W16 engines, as manufacturers explore ways to integrate electric components to meet stricter emissions targets.

In conclusion, emissions regulations significantly impact the packaging constraints of W16 engines, necessitating innovative solutions to balance performance, compliance, and spatial efficiency. As regulations become more stringent, the challenge of managing space and weight tradeoffs in these high-performance engines will continue to drive technological advancements and creative engineering approaches.

The primary focus of emissions regulations is to reduce harmful pollutants such as carbon dioxide (CO2), nitrogen oxides (NOx), and particulate matter. For W16 engines, which are typically used in high-performance vehicles, meeting these standards while preserving power output and efficiency is particularly challenging. Manufacturers must implement advanced technologies and strategies to achieve compliance without compromising the engine's performance characteristics.

One of the key approaches to meeting emissions regulations is the integration of sophisticated exhaust aftertreatment systems. These systems, including catalytic converters, particulate filters, and selective catalytic reduction (SCR) units, require additional space within the engine compartment. For W16 engines, which already face packaging constraints due to their complex configuration, accommodating these components presents a significant design challenge.

The need for improved fuel efficiency to meet CO2 emissions targets also impacts the packaging of W16 engines. Technologies such as direct injection, variable valve timing, and advanced turbocharging systems are often employed to enhance efficiency. However, these additions can increase the overall complexity and space requirements of the engine, further exacerbating packaging constraints.

Weight reduction is another critical factor in meeting emissions regulations, as lighter vehicles generally produce fewer emissions. This necessitates the use of lightweight materials and innovative design solutions in W16 engines. However, the inherent complexity and size of these engines make significant weight reductions challenging, requiring careful balance between performance and compliance.

Thermal management is also a crucial consideration in emissions control. Efficient cooling systems are essential to maintain optimal operating temperatures and reduce emissions. For W16 engines, integrating these systems within the limited available space while ensuring adequate cooling for all cylinders presents a unique engineering challenge.

As emissions regulations continue to evolve, manufacturers must anticipate future standards and design W16 engines with adaptability in mind. This may involve incorporating modular components or leaving space for potential upgrades, further complicating the packaging puzzle. The ongoing shift towards electrification and hybrid powertrains also influences the design of W16 engines, as manufacturers explore ways to integrate electric components to meet stricter emissions targets.

In conclusion, emissions regulations significantly impact the packaging constraints of W16 engines, necessitating innovative solutions to balance performance, compliance, and spatial efficiency. As regulations become more stringent, the challenge of managing space and weight tradeoffs in these high-performance engines will continue to drive technological advancements and creative engineering approaches.

Material Innovations

Material innovations play a crucial role in addressing the packaging constraints of W16 engines, offering solutions to manage space and weight tradeoffs effectively. Advanced composite materials, such as carbon fiber reinforced polymers (CFRP), have revolutionized engine design by providing exceptional strength-to-weight ratios. These materials allow for the creation of lighter yet robust engine components, reducing overall engine weight without compromising structural integrity.

Nano-engineered materials represent another frontier in material science, offering unprecedented opportunities for engine optimization. By manipulating materials at the nanoscale, engineers can enhance thermal properties, improve wear resistance, and reduce friction within engine components. This leads to more efficient heat dissipation and reduced energy losses, allowing for more compact engine designs without sacrificing performance.

High-temperature ceramics have emerged as a game-changer in engine material technology. These materials can withstand extreme temperatures and pressures, making them ideal for use in critical engine components such as turbine blades and combustion chambers. Their superior heat resistance allows for higher operating temperatures, potentially increasing engine efficiency and power output while maintaining a compact form factor.

Additive manufacturing techniques, particularly 3D printing of metals and ceramics, have opened new avenues for creating complex, lightweight structures that were previously impossible to manufacture. This technology enables the production of intricate cooling channels and optimized geometries that maximize strength while minimizing material usage, directly addressing the space and weight constraints of W16 engines.

Smart materials and shape memory alloys offer dynamic solutions to packaging challenges. These materials can change their properties or shape in response to external stimuli such as temperature or electrical current. In W16 engines, such materials could be used to create adaptive components that optimize performance under varying operating conditions, potentially allowing for more compact designs that can adapt to different power requirements.

Hybrid material systems, combining the strengths of different materials, are increasingly being explored for engine applications. For instance, metal matrix composites (MMCs) offer the lightweight properties of composites with the durability and heat resistance of metals. These hybrid materials can be tailored to meet specific performance requirements while addressing the space and weight constraints inherent in W16 engine design.

As research in material science continues to advance, the development of novel coatings and surface treatments offers additional avenues for optimizing engine components. These innovations can enhance wear resistance, reduce friction, and improve thermal management, all of which contribute to more efficient and compact engine designs. The ongoing exploration of two-dimensional materials like graphene also holds promise for future breakthroughs in engine material technology.

Nano-engineered materials represent another frontier in material science, offering unprecedented opportunities for engine optimization. By manipulating materials at the nanoscale, engineers can enhance thermal properties, improve wear resistance, and reduce friction within engine components. This leads to more efficient heat dissipation and reduced energy losses, allowing for more compact engine designs without sacrificing performance.

High-temperature ceramics have emerged as a game-changer in engine material technology. These materials can withstand extreme temperatures and pressures, making them ideal for use in critical engine components such as turbine blades and combustion chambers. Their superior heat resistance allows for higher operating temperatures, potentially increasing engine efficiency and power output while maintaining a compact form factor.

Additive manufacturing techniques, particularly 3D printing of metals and ceramics, have opened new avenues for creating complex, lightweight structures that were previously impossible to manufacture. This technology enables the production of intricate cooling channels and optimized geometries that maximize strength while minimizing material usage, directly addressing the space and weight constraints of W16 engines.

Smart materials and shape memory alloys offer dynamic solutions to packaging challenges. These materials can change their properties or shape in response to external stimuli such as temperature or electrical current. In W16 engines, such materials could be used to create adaptive components that optimize performance under varying operating conditions, potentially allowing for more compact designs that can adapt to different power requirements.

Hybrid material systems, combining the strengths of different materials, are increasingly being explored for engine applications. For instance, metal matrix composites (MMCs) offer the lightweight properties of composites with the durability and heat resistance of metals. These hybrid materials can be tailored to meet specific performance requirements while addressing the space and weight constraints inherent in W16 engine design.

As research in material science continues to advance, the development of novel coatings and surface treatments offers additional avenues for optimizing engine components. These innovations can enhance wear resistance, reduce friction, and improve thermal management, all of which contribute to more efficient and compact engine designs. The ongoing exploration of two-dimensional materials like graphene also holds promise for future breakthroughs in engine material technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!