How To Evaluate Fuel Efficiency Of W16 Powertrains In WRTE Cycles

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

W16 Powertrain Evolution

The W16 powertrain has undergone significant evolution since its inception, marking a unique trajectory in the automotive industry. Initially conceptualized in the early 20th century, the W16 engine configuration remained largely theoretical until its practical implementation in high-performance vehicles in the late 1990s and early 2000s.

The development of the W16 powertrain can be traced through several key stages. In its early phase, the focus was on proving the viability of the complex engine layout, which essentially combines two V8 engines in a W configuration. This period was characterized by extensive computer modeling and prototype testing to overcome challenges related to balance, vibration, and thermal management.

As the concept matured, the emphasis shifted towards performance optimization. Engineers worked on refining the combustion process, improving fuel injection systems, and enhancing turbocharging technologies to extract maximum power from the massive 8.0-liter displacement typical of W16 engines. This stage saw the introduction of advanced materials and manufacturing techniques to manage the immense heat and pressure generated by these powerplants.

The next evolutionary step focused on efficiency improvements, driven by increasing environmental concerns and regulatory pressures. This phase witnessed the integration of technologies such as direct fuel injection, variable valve timing, and cylinder deactivation systems. These advancements aimed to improve fuel economy and reduce emissions without compromising the extraordinary performance that W16 engines are known for.

Recent developments in W16 powertrain technology have centered on hybridization. Engineers have been exploring ways to combine the W16 engine with electric motors, creating hybrid powertrains that can deliver even more impressive performance figures while meeting stringent emissions standards. This represents a critical juncture in the W16's evolution, as it adapts to the automotive industry's shift towards electrification.

Throughout its evolution, the W16 powertrain has consistently pushed the boundaries of automotive engineering. Its development has driven advancements in areas such as thermal management, lubrication systems, and engine control units. The challenges posed by this complex engine configuration have spurred innovations that have benefited the broader field of powertrain engineering.

Looking ahead, the future of W16 powertrain evolution is likely to involve further refinements in hybrid technology, potentially leading to plug-in hybrid variants. There may also be explorations into alternative fuels and advanced combustion techniques to further enhance efficiency and reduce environmental impact. As automotive technology continues to advance, the W16 powertrain serves as a testament to the industry's capacity for innovation and the enduring appeal of high-performance engineering.

The development of the W16 powertrain can be traced through several key stages. In its early phase, the focus was on proving the viability of the complex engine layout, which essentially combines two V8 engines in a W configuration. This period was characterized by extensive computer modeling and prototype testing to overcome challenges related to balance, vibration, and thermal management.

As the concept matured, the emphasis shifted towards performance optimization. Engineers worked on refining the combustion process, improving fuel injection systems, and enhancing turbocharging technologies to extract maximum power from the massive 8.0-liter displacement typical of W16 engines. This stage saw the introduction of advanced materials and manufacturing techniques to manage the immense heat and pressure generated by these powerplants.

The next evolutionary step focused on efficiency improvements, driven by increasing environmental concerns and regulatory pressures. This phase witnessed the integration of technologies such as direct fuel injection, variable valve timing, and cylinder deactivation systems. These advancements aimed to improve fuel economy and reduce emissions without compromising the extraordinary performance that W16 engines are known for.

Recent developments in W16 powertrain technology have centered on hybridization. Engineers have been exploring ways to combine the W16 engine with electric motors, creating hybrid powertrains that can deliver even more impressive performance figures while meeting stringent emissions standards. This represents a critical juncture in the W16's evolution, as it adapts to the automotive industry's shift towards electrification.

Throughout its evolution, the W16 powertrain has consistently pushed the boundaries of automotive engineering. Its development has driven advancements in areas such as thermal management, lubrication systems, and engine control units. The challenges posed by this complex engine configuration have spurred innovations that have benefited the broader field of powertrain engineering.

Looking ahead, the future of W16 powertrain evolution is likely to involve further refinements in hybrid technology, potentially leading to plug-in hybrid variants. There may also be explorations into alternative fuels and advanced combustion techniques to further enhance efficiency and reduce environmental impact. As automotive technology continues to advance, the W16 powertrain serves as a testament to the industry's capacity for innovation and the enduring appeal of high-performance engineering.

WRTE Cycle Market Demand

The market demand for evaluating fuel efficiency of W16 powertrains in WRTE (World Reference Test Engine) cycles has been steadily growing in recent years. This demand is primarily driven by the automotive industry's increasing focus on environmental sustainability and regulatory compliance. As governments worldwide implement stricter emissions standards and fuel economy regulations, manufacturers of high-performance vehicles equipped with W16 engines are under pressure to demonstrate improved fuel efficiency.

The WRTE cycle, designed to simulate real-world driving conditions, has become a crucial tool for assessing engine performance and fuel consumption. For W16 powertrains, which are typically found in ultra-luxury and high-performance vehicles, the need for accurate fuel efficiency evaluation is particularly significant. These engines, known for their power output, face challenges in meeting increasingly stringent environmental standards while maintaining their performance characteristics.

Market analysis indicates that the demand for WRTE cycle evaluations of W16 powertrains is concentrated in specific segments of the automotive industry. Luxury car manufacturers, supercar producers, and racing teams are the primary stakeholders interested in this specialized testing. The market size for this specific evaluation is relatively small but highly valuable, given the premium nature of vehicles equipped with W16 engines.

Recent trends show an increasing interest from emerging markets, particularly in Asia and the Middle East, where there is a growing appetite for high-performance vehicles. This geographical expansion of demand is expected to drive further growth in the WRTE cycle evaluation market for W16 powertrains.

The automotive testing and certification industry has responded to this demand by developing specialized facilities and expertise in WRTE cycle evaluations for high-performance engines. These services are not only crucial for regulatory compliance but also serve as valuable marketing tools for manufacturers to showcase the efficiency improvements of their W16 powertrains.

Furthermore, the demand for these evaluations extends beyond just the automotive manufacturers. Suppliers of engine components, fuel systems, and engine management software also require WRTE cycle data to optimize their products for W16 applications. This has created a secondary market for WRTE cycle evaluation services and data analysis.

Looking ahead, the market demand for fuel efficiency evaluations of W16 powertrains in WRTE cycles is expected to evolve. As the automotive industry transitions towards electrification, there may be a shift in focus towards hybrid W16 powertrains, potentially expanding the scope and complexity of WRTE cycle evaluations. This evolution is likely to drive innovation in testing methodologies and create new opportunities in the market for specialized evaluation services.

The WRTE cycle, designed to simulate real-world driving conditions, has become a crucial tool for assessing engine performance and fuel consumption. For W16 powertrains, which are typically found in ultra-luxury and high-performance vehicles, the need for accurate fuel efficiency evaluation is particularly significant. These engines, known for their power output, face challenges in meeting increasingly stringent environmental standards while maintaining their performance characteristics.

Market analysis indicates that the demand for WRTE cycle evaluations of W16 powertrains is concentrated in specific segments of the automotive industry. Luxury car manufacturers, supercar producers, and racing teams are the primary stakeholders interested in this specialized testing. The market size for this specific evaluation is relatively small but highly valuable, given the premium nature of vehicles equipped with W16 engines.

Recent trends show an increasing interest from emerging markets, particularly in Asia and the Middle East, where there is a growing appetite for high-performance vehicles. This geographical expansion of demand is expected to drive further growth in the WRTE cycle evaluation market for W16 powertrains.

The automotive testing and certification industry has responded to this demand by developing specialized facilities and expertise in WRTE cycle evaluations for high-performance engines. These services are not only crucial for regulatory compliance but also serve as valuable marketing tools for manufacturers to showcase the efficiency improvements of their W16 powertrains.

Furthermore, the demand for these evaluations extends beyond just the automotive manufacturers. Suppliers of engine components, fuel systems, and engine management software also require WRTE cycle data to optimize their products for W16 applications. This has created a secondary market for WRTE cycle evaluation services and data analysis.

Looking ahead, the market demand for fuel efficiency evaluations of W16 powertrains in WRTE cycles is expected to evolve. As the automotive industry transitions towards electrification, there may be a shift in focus towards hybrid W16 powertrains, potentially expanding the scope and complexity of WRTE cycle evaluations. This evolution is likely to drive innovation in testing methodologies and create new opportunities in the market for specialized evaluation services.

W16 Efficiency Challenges

The W16 engine, a marvel of automotive engineering, presents unique challenges in evaluating its fuel efficiency within the context of WRTE (World-harmonized Real-world Test Emissions) cycles. These challenges stem from the engine's complex design, massive power output, and limited real-world application.

One of the primary difficulties lies in the sheer size and power of the W16 engine. Typically found in ultra-luxury and high-performance vehicles, these powertrains are designed for extreme performance rather than fuel efficiency. This focus on power often results in fuel consumption rates that are significantly higher than conventional engines, making it challenging to assess their efficiency using standard metrics.

The WRTE cycles, designed to simulate real-world driving conditions, may not adequately capture the typical usage patterns of vehicles equipped with W16 engines. These vehicles are often driven in specific conditions - high-speed autobahns, race tracks, or as collector's items with limited mileage. As a result, the standardized WRTE cycles may not provide an accurate representation of the engine's real-world efficiency.

Another challenge is the limited production and availability of W16-equipped vehicles. With only a handful of models featuring this powertrain, gathering comprehensive data for efficiency evaluation becomes problematic. The scarcity of these engines in the market makes it difficult to conduct large-scale studies or obtain statistically significant results.

The complexity of the W16 engine's design also poses challenges in efficiency evaluation. With its unique configuration of four banks of four cylinders, the engine's thermal management, fuel delivery, and exhaust systems are highly sophisticated. These intricate systems can behave differently under various operating conditions, making it challenging to develop standardized testing procedures that accurately reflect the engine's efficiency across all scenarios.

Moreover, the advanced technologies often incorporated in W16 engines, such as variable valve timing, multi-stage turbocharging, and advanced engine management systems, add layers of complexity to efficiency evaluations. These technologies can significantly alter the engine's behavior and efficiency depending on driving conditions, further complicating the assessment process.

Lastly, the environmental impact and regulatory compliance of W16 engines present additional challenges. As emissions regulations become increasingly stringent worldwide, evaluating the efficiency of these high-performance engines within the context of environmental standards adds another dimension to the assessment process. Balancing performance with regulatory compliance while accurately measuring efficiency becomes a complex task for engineers and researchers.

One of the primary difficulties lies in the sheer size and power of the W16 engine. Typically found in ultra-luxury and high-performance vehicles, these powertrains are designed for extreme performance rather than fuel efficiency. This focus on power often results in fuel consumption rates that are significantly higher than conventional engines, making it challenging to assess their efficiency using standard metrics.

The WRTE cycles, designed to simulate real-world driving conditions, may not adequately capture the typical usage patterns of vehicles equipped with W16 engines. These vehicles are often driven in specific conditions - high-speed autobahns, race tracks, or as collector's items with limited mileage. As a result, the standardized WRTE cycles may not provide an accurate representation of the engine's real-world efficiency.

Another challenge is the limited production and availability of W16-equipped vehicles. With only a handful of models featuring this powertrain, gathering comprehensive data for efficiency evaluation becomes problematic. The scarcity of these engines in the market makes it difficult to conduct large-scale studies or obtain statistically significant results.

The complexity of the W16 engine's design also poses challenges in efficiency evaluation. With its unique configuration of four banks of four cylinders, the engine's thermal management, fuel delivery, and exhaust systems are highly sophisticated. These intricate systems can behave differently under various operating conditions, making it challenging to develop standardized testing procedures that accurately reflect the engine's efficiency across all scenarios.

Moreover, the advanced technologies often incorporated in W16 engines, such as variable valve timing, multi-stage turbocharging, and advanced engine management systems, add layers of complexity to efficiency evaluations. These technologies can significantly alter the engine's behavior and efficiency depending on driving conditions, further complicating the assessment process.

Lastly, the environmental impact and regulatory compliance of W16 engines present additional challenges. As emissions regulations become increasingly stringent worldwide, evaluating the efficiency of these high-performance engines within the context of environmental standards adds another dimension to the assessment process. Balancing performance with regulatory compliance while accurately measuring efficiency becomes a complex task for engineers and researchers.

WRTE Test Methodologies

01 Engine management systems for W16 powertrains

Advanced engine management systems are employed in W16 powertrains to optimize fuel efficiency. These systems utilize sophisticated algorithms and sensors to control fuel injection, ignition timing, and air-fuel mixture, resulting in improved combustion efficiency and reduced fuel consumption.- Engine management systems for W16 powertrains: Advanced engine management systems are employed in W16 powertrains to optimize fuel efficiency. These systems utilize sophisticated algorithms and sensors to control fuel injection, ignition timing, and air-fuel mixture, resulting in improved combustion efficiency and reduced fuel consumption.

- Hybrid technology integration with W16 powertrains: Incorporating hybrid technology into W16 powertrains can significantly enhance fuel efficiency. This involves combining the W16 engine with electric motors and advanced battery systems, allowing for regenerative braking, electric-only operation at low speeds, and optimized power distribution between the combustion engine and electric motors.

- Aerodynamic improvements for W16-powered vehicles: Enhancing the aerodynamics of vehicles equipped with W16 powertrains can lead to improved fuel efficiency. This includes optimizing body design, implementing active aerodynamic elements, and reducing overall drag coefficient to minimize energy loss during high-speed operation.

- Lightweight materials and construction techniques: Utilizing lightweight materials and advanced construction techniques in W16-powered vehicles can significantly improve fuel efficiency. This involves the use of carbon fiber composites, aluminum alloys, and other high-strength, low-weight materials in the vehicle's chassis, body panels, and powertrain components to reduce overall vehicle weight.

- Transmission and drivetrain optimization: Optimizing the transmission and drivetrain systems for W16 powertrains can lead to improved fuel efficiency. This includes developing advanced multi-speed transmissions, implementing intelligent gear-shifting algorithms, and reducing friction losses in the drivetrain components to maximize power transfer and minimize energy waste.

02 Hybrid powertrain integration with W16 engines

Integrating hybrid technology with W16 powertrains can significantly enhance fuel efficiency. This approach combines the power of the W16 engine with electric motors, allowing for regenerative braking, electric-only operation at low speeds, and optimized power distribution between the combustion engine and electric motors.Expand Specific Solutions03 Aerodynamic improvements for W16-powered vehicles

Enhancing the aerodynamics of vehicles equipped with W16 powertrains can lead to improved fuel efficiency. This includes optimizing body shapes, implementing active aerodynamic elements, and reducing overall drag to minimize energy loss during high-speed operation.Expand Specific Solutions04 Lightweight materials and construction techniques

Utilizing lightweight materials and advanced construction techniques in W16-powered vehicles can significantly reduce overall weight, leading to improved fuel efficiency. This includes the use of carbon fiber composites, aluminum alloys, and innovative chassis designs to optimize the power-to-weight ratio.Expand Specific Solutions05 Advanced transmission systems for W16 powertrains

Implementing sophisticated transmission systems tailored for W16 powertrains can enhance fuel efficiency. This includes multi-speed automatic transmissions, dual-clutch transmissions, and continuously variable transmissions (CVTs) designed to optimize gear ratios and power delivery across various driving conditions.Expand Specific Solutions

W16 Manufacturers Analysis

The evaluation of W16 powertrains' fuel efficiency in WRTE cycles represents a niche area within the automotive industry, currently in its early development stage. The market size for this specific technology is relatively small, primarily driven by high-performance and luxury vehicle manufacturers. The technical maturity is still evolving, with companies like Jaguar Land Rover Ltd. and Volkswagen AG leading research efforts. Cummins, Inc. and FPT Motorenforschung AG are also contributing to advancements in powertrain efficiency, though not specifically for W16 engines. As environmental regulations tighten, there's growing interest in improving fuel efficiency even for high-performance engines, potentially expanding this market segment in the future.

Cummins, Inc.

Technical Solution: Cummins has developed advanced fuel efficiency evaluation techniques for their engines, including W16 powertrains, in World Random Transient Engine (WRTE) cycles. Their approach involves sophisticated engine mapping and real-time data acquisition systems to capture fuel consumption across various operating conditions. Cummins utilizes a combination of dynamometer testing and advanced simulation tools to replicate WRTE cycles accurately. They have implemented machine learning algorithms to analyze vast amounts of test data, enabling more precise predictions of fuel efficiency in real-world scenarios[1]. Additionally, Cummins has integrated thermal management systems and waste heat recovery technologies to further optimize fuel efficiency during WRTE cycles[3].

Strengths: Extensive experience in engine testing, advanced data analytics capabilities, and integrated approach to efficiency optimization. Weaknesses: Potential limitations in simulating all real-world conditions, and high costs associated with comprehensive testing procedures.

GM Global Technology Operations LLC

Technical Solution: GM's approach to evaluating fuel efficiency of W16 powertrains in WRTE cycles involves a comprehensive suite of testing and simulation tools. They utilize advanced powertrain dynamometers capable of replicating complex WRTE cycle conditions with high fidelity. GM has developed proprietary software that integrates vehicle dynamics, powertrain performance, and environmental factors to create highly accurate virtual testing environments. Their method includes real-time fuel flow measurement systems and exhaust gas analysis to provide precise fuel consumption data throughout the WRTE cycle[2]. GM also employs artificial intelligence and machine learning algorithms to optimize test parameters and predict long-term fuel efficiency trends based on accumulated data from multiple WRTE cycle tests[4].

Strengths: Cutting-edge simulation technology, extensive resources for physical testing, and advanced data analytics capabilities. Weaknesses: Potential over-reliance on simulations, which may not capture all real-world variables affecting fuel efficiency.

W16 Efficiency Innovations

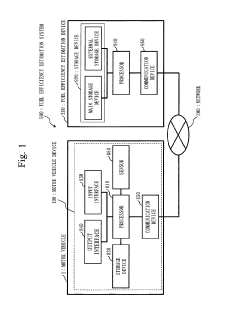

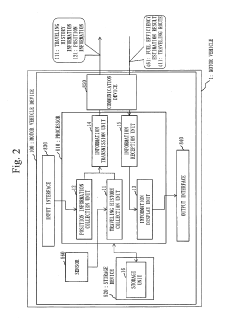

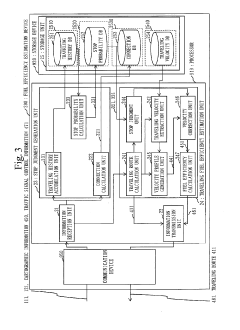

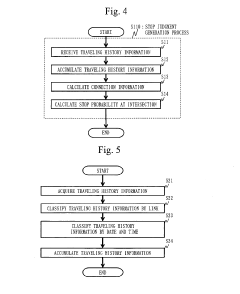

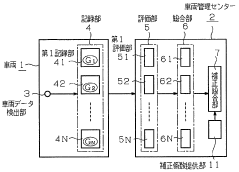

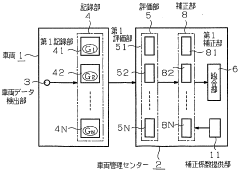

Fuel efficiency estimation system, fuel efficiency estimation method, and computer readable medium

PatentInactiveUS20190210610A1

Innovation

- A fuel efficiency estimation system that generates a velocity profile, judges stop probabilities at intersections based on traveling history and traffic signal connections, and corrects the profile for intersection stops, thereby improving the accuracy of fuel efficiency calculations.

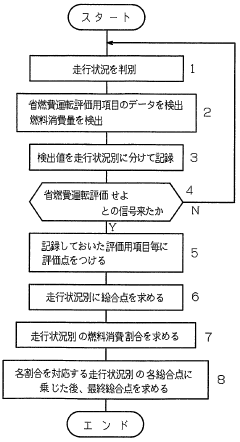

System and method for evaluating fuel saving operation

PatentWO2003095821A1

Innovation

- A device and method that classify vehicle data into specific driving conditions (e.g., high-speed driving, general road driving, idling) and apply correction coefficients based on fuel consumption ratios or time/mileage ratios for each condition to adjust evaluation scores, ensuring a more accurate reflection of fuel-saving driving practices.

Emissions Regulations

Emissions regulations play a crucial role in shaping the development and evaluation of fuel efficiency in W16 powertrains, particularly within the context of WRTE (World-harmonized Real Transient Engine) cycles. These regulations are designed to limit harmful emissions from vehicles and promote the development of more environmentally friendly technologies.

The European Union has been at the forefront of implementing stringent emissions standards through its Euro emissions regulations. The current Euro 6 standard, introduced in 2014, sets strict limits on various pollutants, including carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter (PM). These standards have a direct impact on the design and optimization of W16 powertrains, as manufacturers must balance performance with compliance.

In the United States, the Environmental Protection Agency (EPA) and the California Air Resources Board (CARB) establish emissions regulations. The EPA's Tier 3 standards, phased in from 2017 to 2025, require significant reductions in emissions of NOx and non-methane organic gases (NMOG). These regulations influence the development of W16 powertrains, pushing manufacturers to implement advanced technologies such as improved catalytic converters and exhaust gas recirculation systems.

China, another major automotive market, has implemented the China 6 emissions standard, which is comparable to Euro 6 in terms of stringency. This global alignment of emissions regulations creates a more unified approach to evaluating fuel efficiency and emissions performance of W16 powertrains across different markets.

The WRTE cycle, developed as part of the Worldwide Harmonized Heavy Duty Certification (WHDC) procedure, aims to provide a standardized method for measuring emissions and fuel consumption under real-world conditions. This cycle is particularly relevant for evaluating W16 powertrains, as it simulates a wide range of operating conditions, including urban, rural, and highway driving.

To comply with these regulations, manufacturers must employ advanced testing methodologies and equipment. This includes the use of portable emissions measurement systems (PEMS) to conduct real-world emissions testing, ensuring that W16 powertrains meet the required standards not just in laboratory conditions but also during actual on-road use.

The ongoing tightening of emissions regulations worldwide continues to drive innovation in W16 powertrain technology. Manufacturers are increasingly focusing on hybridization and electrification strategies to complement the W16 engine, aiming to reduce overall emissions while maintaining performance characteristics. This trend is likely to shape the future development and evaluation of W16 powertrains in WRTE cycles, as the industry moves towards more sustainable propulsion solutions.

The European Union has been at the forefront of implementing stringent emissions standards through its Euro emissions regulations. The current Euro 6 standard, introduced in 2014, sets strict limits on various pollutants, including carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter (PM). These standards have a direct impact on the design and optimization of W16 powertrains, as manufacturers must balance performance with compliance.

In the United States, the Environmental Protection Agency (EPA) and the California Air Resources Board (CARB) establish emissions regulations. The EPA's Tier 3 standards, phased in from 2017 to 2025, require significant reductions in emissions of NOx and non-methane organic gases (NMOG). These regulations influence the development of W16 powertrains, pushing manufacturers to implement advanced technologies such as improved catalytic converters and exhaust gas recirculation systems.

China, another major automotive market, has implemented the China 6 emissions standard, which is comparable to Euro 6 in terms of stringency. This global alignment of emissions regulations creates a more unified approach to evaluating fuel efficiency and emissions performance of W16 powertrains across different markets.

The WRTE cycle, developed as part of the Worldwide Harmonized Heavy Duty Certification (WHDC) procedure, aims to provide a standardized method for measuring emissions and fuel consumption under real-world conditions. This cycle is particularly relevant for evaluating W16 powertrains, as it simulates a wide range of operating conditions, including urban, rural, and highway driving.

To comply with these regulations, manufacturers must employ advanced testing methodologies and equipment. This includes the use of portable emissions measurement systems (PEMS) to conduct real-world emissions testing, ensuring that W16 powertrains meet the required standards not just in laboratory conditions but also during actual on-road use.

The ongoing tightening of emissions regulations worldwide continues to drive innovation in W16 powertrain technology. Manufacturers are increasingly focusing on hybridization and electrification strategies to complement the W16 engine, aiming to reduce overall emissions while maintaining performance characteristics. This trend is likely to shape the future development and evaluation of W16 powertrains in WRTE cycles, as the industry moves towards more sustainable propulsion solutions.

Comparative Benchmarking

Comparative benchmarking is a crucial step in evaluating the fuel efficiency of W16 powertrains in WRTE cycles. This process involves systematically comparing the performance of different W16 engines against established industry standards and competing powertrains. The primary focus is on fuel consumption metrics under various World Reference Test Environment (WRTE) cycle conditions.

To conduct an effective comparative benchmarking, it is essential to identify a representative set of W16 powertrains from different manufacturers. This selection should include both high-performance and efficiency-oriented variants to provide a comprehensive overview of the technology landscape. The chosen powertrains should be tested under identical WRTE cycle conditions to ensure fair and accurate comparisons.

Key performance indicators (KPIs) for fuel efficiency evaluation typically include fuel consumption rates (measured in liters per 100 kilometers or miles per gallon), CO2 emissions, and energy conversion efficiency. These metrics should be measured across various WRTE cycle segments, such as urban driving, highway cruising, and mixed-use scenarios. Additionally, power output and torque characteristics should be recorded to contextualize the efficiency data.

The benchmarking process should also consider the impact of different technologies employed in W16 powertrains, such as direct fuel injection, variable valve timing, and turbocharging. By analyzing how these technologies contribute to fuel efficiency in WRTE cycles, researchers can identify best practices and areas for improvement.

To ensure the reliability of the benchmarking results, it is crucial to employ standardized testing protocols and equipment. This includes using calibrated dynamometers, precise fuel flow meters, and advanced emissions analysis tools. The testing environment should be carefully controlled to minimize external factors that could influence the results.

Data collected from the comparative benchmarking should be analyzed using statistical methods to identify trends, correlations, and outliers. This analysis can reveal insights into the relative strengths and weaknesses of different W16 powertrains in terms of fuel efficiency across various WRTE cycle conditions. Visual representations, such as scatter plots and radar charts, can be used to effectively communicate these findings.

Finally, the benchmarking results should be contextualized within the broader automotive industry landscape. This involves comparing the fuel efficiency of W16 powertrains to other engine configurations, such as V8 or V12 engines, as well as alternative powertrain technologies like hybrid and electric systems. This comprehensive approach provides a holistic view of W16 powertrain performance and helps identify areas where further development may be necessary to remain competitive in terms of fuel efficiency.

To conduct an effective comparative benchmarking, it is essential to identify a representative set of W16 powertrains from different manufacturers. This selection should include both high-performance and efficiency-oriented variants to provide a comprehensive overview of the technology landscape. The chosen powertrains should be tested under identical WRTE cycle conditions to ensure fair and accurate comparisons.

Key performance indicators (KPIs) for fuel efficiency evaluation typically include fuel consumption rates (measured in liters per 100 kilometers or miles per gallon), CO2 emissions, and energy conversion efficiency. These metrics should be measured across various WRTE cycle segments, such as urban driving, highway cruising, and mixed-use scenarios. Additionally, power output and torque characteristics should be recorded to contextualize the efficiency data.

The benchmarking process should also consider the impact of different technologies employed in W16 powertrains, such as direct fuel injection, variable valve timing, and turbocharging. By analyzing how these technologies contribute to fuel efficiency in WRTE cycles, researchers can identify best practices and areas for improvement.

To ensure the reliability of the benchmarking results, it is crucial to employ standardized testing protocols and equipment. This includes using calibrated dynamometers, precise fuel flow meters, and advanced emissions analysis tools. The testing environment should be carefully controlled to minimize external factors that could influence the results.

Data collected from the comparative benchmarking should be analyzed using statistical methods to identify trends, correlations, and outliers. This analysis can reveal insights into the relative strengths and weaknesses of different W16 powertrains in terms of fuel efficiency across various WRTE cycle conditions. Visual representations, such as scatter plots and radar charts, can be used to effectively communicate these findings.

Finally, the benchmarking results should be contextualized within the broader automotive industry landscape. This involves comparing the fuel efficiency of W16 powertrains to other engine configurations, such as V8 or V12 engines, as well as alternative powertrain technologies like hybrid and electric systems. This comprehensive approach provides a holistic view of W16 powertrain performance and helps identify areas where further development may be necessary to remain competitive in terms of fuel efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!