How To Test W16 Cylinder Head Thermal Fatigue Resistance

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

W16 Thermal Fatigue Background and Objectives

The W16 engine, a marvel of automotive engineering, represents the pinnacle of high-performance powerplants. Developed primarily for ultra-luxury and hypercar applications, the W16 configuration combines two V8 engines in a unique arrangement, resulting in a compact yet incredibly powerful motor. The cylinder head, a critical component of this engine, faces extreme thermal and mechanical stresses during operation.

Thermal fatigue resistance in W16 cylinder heads is of paramount importance due to the engine's high output and operating temperatures. As the engine cycles through extreme temperature variations, the cylinder head material undergoes repeated expansion and contraction. This thermal cycling can lead to the formation and propagation of cracks, potentially resulting in catastrophic failure if not properly addressed.

The objective of testing W16 cylinder head thermal fatigue resistance is to ensure the longevity and reliability of these high-performance engines under the most demanding conditions. By subjecting the cylinder heads to rigorous thermal cycling tests, engineers aim to simulate real-world operating conditions and identify potential weaknesses in the design or materials used.

Historical development of thermal fatigue testing for cylinder heads has evolved alongside advancements in engine technology. Early methods relied on simplified thermal shock tests, but as engines became more powerful and complex, testing procedures have become increasingly sophisticated. Modern techniques incorporate advanced computer simulations, thermal imaging, and precise control of temperature cycles to accurately replicate the stresses experienced in actual engine operation.

The current technological landscape for thermal fatigue testing of W16 cylinder heads involves a combination of experimental and computational methods. Physical testing typically utilizes specialized rigs that can rapidly heat and cool the cylinder head while applying mechanical loads to simulate combustion pressures. Concurrently, finite element analysis (FEA) and computational fluid dynamics (CFD) simulations provide valuable insights into thermal distribution and stress concentrations within the complex geometry of the W16 cylinder head.

As we look towards the future, the goals for thermal fatigue testing of W16 cylinder heads are focused on developing even more accurate prediction models, reducing testing time without compromising reliability, and exploring new materials and manufacturing techniques that can further enhance thermal fatigue resistance. The ultimate aim is to push the boundaries of engine performance while ensuring uncompromised durability and safety in these extraordinary powerplants.

Thermal fatigue resistance in W16 cylinder heads is of paramount importance due to the engine's high output and operating temperatures. As the engine cycles through extreme temperature variations, the cylinder head material undergoes repeated expansion and contraction. This thermal cycling can lead to the formation and propagation of cracks, potentially resulting in catastrophic failure if not properly addressed.

The objective of testing W16 cylinder head thermal fatigue resistance is to ensure the longevity and reliability of these high-performance engines under the most demanding conditions. By subjecting the cylinder heads to rigorous thermal cycling tests, engineers aim to simulate real-world operating conditions and identify potential weaknesses in the design or materials used.

Historical development of thermal fatigue testing for cylinder heads has evolved alongside advancements in engine technology. Early methods relied on simplified thermal shock tests, but as engines became more powerful and complex, testing procedures have become increasingly sophisticated. Modern techniques incorporate advanced computer simulations, thermal imaging, and precise control of temperature cycles to accurately replicate the stresses experienced in actual engine operation.

The current technological landscape for thermal fatigue testing of W16 cylinder heads involves a combination of experimental and computational methods. Physical testing typically utilizes specialized rigs that can rapidly heat and cool the cylinder head while applying mechanical loads to simulate combustion pressures. Concurrently, finite element analysis (FEA) and computational fluid dynamics (CFD) simulations provide valuable insights into thermal distribution and stress concentrations within the complex geometry of the W16 cylinder head.

As we look towards the future, the goals for thermal fatigue testing of W16 cylinder heads are focused on developing even more accurate prediction models, reducing testing time without compromising reliability, and exploring new materials and manufacturing techniques that can further enhance thermal fatigue resistance. The ultimate aim is to push the boundaries of engine performance while ensuring uncompromised durability and safety in these extraordinary powerplants.

Market Demand for W16 Engine Durability

The market demand for W16 engine durability, particularly in relation to cylinder head thermal fatigue resistance, is driven by the high-performance automotive sector and the pursuit of engineering excellence. W16 engines, primarily associated with luxury and hypercar manufacturers, represent the pinnacle of internal combustion engine technology. The demand for these engines stems from a niche but influential market segment that values extreme performance, exclusivity, and technological innovation.

In the hypercar market, where W16 engines are most prevalent, there is a constant push for higher power outputs and improved reliability. This creates a significant demand for enhanced durability in all engine components, especially the cylinder heads which are subjected to extreme thermal stresses. The ability of a W16 engine to withstand thermal fatigue is crucial for maintaining performance consistency and longevity, factors highly valued by both manufacturers and end-users in this premium segment.

The market for W16 engines, while limited in volume, exerts a disproportionate influence on automotive engineering and brand prestige. Manufacturers investing in W16 technology do so not only for direct sales but also for the halo effect it creates for their brand. This drives a demand for continuous improvement in engine durability, as any reliability issues can have severe repercussions on brand reputation and customer confidence.

From a technical perspective, the demand for improved thermal fatigue resistance in W16 cylinder heads is fueled by the extreme operating conditions these engines face. With power outputs often exceeding 1000 horsepower, the thermal loads on cylinder heads are immense. The market expects these engines to perform flawlessly not just on the road, but also in high-stress scenarios like track days and endurance runs. This creates a need for advanced materials and designs that can withstand repeated thermal cycling without failure.

The demand also extends to the testing and validation processes for these engines. There is a growing market for sophisticated testing equipment and methodologies that can accurately simulate the extreme conditions W16 engines encounter. This includes advanced thermal imaging systems, high-precision sensors, and data analysis tools capable of predicting long-term fatigue behavior.

Furthermore, the push towards more sustainable and efficient high-performance engines is influencing the demand for W16 durability. As environmental regulations tighten, even in the hypercar segment, there's an increasing need for engines that can maintain high performance while meeting stringent emissions standards. This translates to a demand for cylinder heads that can withstand higher combustion pressures and temperatures, further emphasizing the importance of thermal fatigue resistance.

In the hypercar market, where W16 engines are most prevalent, there is a constant push for higher power outputs and improved reliability. This creates a significant demand for enhanced durability in all engine components, especially the cylinder heads which are subjected to extreme thermal stresses. The ability of a W16 engine to withstand thermal fatigue is crucial for maintaining performance consistency and longevity, factors highly valued by both manufacturers and end-users in this premium segment.

The market for W16 engines, while limited in volume, exerts a disproportionate influence on automotive engineering and brand prestige. Manufacturers investing in W16 technology do so not only for direct sales but also for the halo effect it creates for their brand. This drives a demand for continuous improvement in engine durability, as any reliability issues can have severe repercussions on brand reputation and customer confidence.

From a technical perspective, the demand for improved thermal fatigue resistance in W16 cylinder heads is fueled by the extreme operating conditions these engines face. With power outputs often exceeding 1000 horsepower, the thermal loads on cylinder heads are immense. The market expects these engines to perform flawlessly not just on the road, but also in high-stress scenarios like track days and endurance runs. This creates a need for advanced materials and designs that can withstand repeated thermal cycling without failure.

The demand also extends to the testing and validation processes for these engines. There is a growing market for sophisticated testing equipment and methodologies that can accurately simulate the extreme conditions W16 engines encounter. This includes advanced thermal imaging systems, high-precision sensors, and data analysis tools capable of predicting long-term fatigue behavior.

Furthermore, the push towards more sustainable and efficient high-performance engines is influencing the demand for W16 durability. As environmental regulations tighten, even in the hypercar segment, there's an increasing need for engines that can maintain high performance while meeting stringent emissions standards. This translates to a demand for cylinder heads that can withstand higher combustion pressures and temperatures, further emphasizing the importance of thermal fatigue resistance.

Current Challenges in Cylinder Head Testing

Testing the thermal fatigue resistance of W16 cylinder heads presents several significant challenges in the current automotive engineering landscape. The complexity of W16 engines, with their unique configuration and high-performance requirements, demands sophisticated testing methodologies that push the boundaries of conventional approaches.

One of the primary challenges lies in accurately simulating the extreme thermal conditions experienced by W16 cylinder heads during operation. These components are subjected to rapid and severe temperature fluctuations, with combustion temperatures reaching over 2000°C and cooling cycles bringing temperatures down to near-ambient levels. Replicating these thermal cycles in a controlled laboratory environment while maintaining precision and repeatability is a formidable task.

The intricate geometry of W16 cylinder heads further complicates the testing process. With multiple combustion chambers and complex cooling passages, ensuring uniform heat distribution and identifying potential weak points for thermal fatigue becomes increasingly difficult. Traditional testing methods may not adequately capture the nuanced thermal behavior of these advanced designs, necessitating the development of more sophisticated thermal imaging and sensor technologies.

Another significant challenge is the time-intensive nature of thermal fatigue testing. Accelerated life cycle tests must be carefully designed to compress years of operational wear into manageable testing periods without compromising the validity of results. Balancing the need for rapid testing with the requirement for accurate, long-term fatigue predictions remains a persistent challenge for engineers and researchers.

The materials used in W16 cylinder heads also present unique testing challenges. Advanced alloys and composites designed to withstand extreme temperatures and pressures may exhibit different fatigue characteristics compared to conventional materials. Developing appropriate testing protocols that account for these material properties and their long-term behavior under thermal stress is crucial for accurate assessment.

Furthermore, the integration of cooling systems and their impact on thermal fatigue resistance adds another layer of complexity to the testing process. Evaluating the effectiveness of cooling strategies and their interaction with the cylinder head structure requires sophisticated multi-physics simulations and advanced testing rigs that can simultaneously assess thermal, mechanical, and fluid dynamics aspects.

Lastly, the high cost and limited availability of W16 engines and components pose practical challenges for extensive testing. Researchers and engineers must often rely on a limited number of test specimens, making it essential to maximize the data extracted from each test while ensuring the reliability and reproducibility of results.

One of the primary challenges lies in accurately simulating the extreme thermal conditions experienced by W16 cylinder heads during operation. These components are subjected to rapid and severe temperature fluctuations, with combustion temperatures reaching over 2000°C and cooling cycles bringing temperatures down to near-ambient levels. Replicating these thermal cycles in a controlled laboratory environment while maintaining precision and repeatability is a formidable task.

The intricate geometry of W16 cylinder heads further complicates the testing process. With multiple combustion chambers and complex cooling passages, ensuring uniform heat distribution and identifying potential weak points for thermal fatigue becomes increasingly difficult. Traditional testing methods may not adequately capture the nuanced thermal behavior of these advanced designs, necessitating the development of more sophisticated thermal imaging and sensor technologies.

Another significant challenge is the time-intensive nature of thermal fatigue testing. Accelerated life cycle tests must be carefully designed to compress years of operational wear into manageable testing periods without compromising the validity of results. Balancing the need for rapid testing with the requirement for accurate, long-term fatigue predictions remains a persistent challenge for engineers and researchers.

The materials used in W16 cylinder heads also present unique testing challenges. Advanced alloys and composites designed to withstand extreme temperatures and pressures may exhibit different fatigue characteristics compared to conventional materials. Developing appropriate testing protocols that account for these material properties and their long-term behavior under thermal stress is crucial for accurate assessment.

Furthermore, the integration of cooling systems and their impact on thermal fatigue resistance adds another layer of complexity to the testing process. Evaluating the effectiveness of cooling strategies and their interaction with the cylinder head structure requires sophisticated multi-physics simulations and advanced testing rigs that can simultaneously assess thermal, mechanical, and fluid dynamics aspects.

Lastly, the high cost and limited availability of W16 engines and components pose practical challenges for extensive testing. Researchers and engineers must often rely on a limited number of test specimens, making it essential to maximize the data extracted from each test while ensuring the reliability and reproducibility of results.

Existing W16 Thermal Fatigue Test Protocols

01 Material selection for improved thermal fatigue resistance

Selecting appropriate materials for W16 cylinder heads can significantly enhance thermal fatigue resistance. High-strength alloys, such as aluminum alloys with silicon and copper, or cast iron with specific compositions, can withstand repeated thermal cycles better than conventional materials. These materials offer improved heat dissipation and structural integrity under high-temperature conditions.- Material selection for improved thermal fatigue resistance: Selecting appropriate materials for W16 cylinder heads can significantly improve thermal fatigue resistance. High-strength alloys, such as aluminum-silicon alloys with improved thermal conductivity and strength, are often used. These materials can better withstand the cyclic thermal stresses experienced during engine operation, reducing the risk of cracking and failure.

- Cooling system design optimization: Optimizing the cooling system design is crucial for enhancing thermal fatigue resistance in W16 cylinder heads. This includes improving coolant flow paths, implementing advanced cooling techniques such as precision cooling, and enhancing heat dissipation through strategic placement of cooling channels. Efficient cooling helps maintain more uniform temperatures across the cylinder head, reducing thermal stress concentrations.

- Structural design improvements: Enhancing the structural design of W16 cylinder heads can significantly improve thermal fatigue resistance. This involves optimizing the geometry of critical areas, such as valve bridges and combustion chamber walls, to better distribute thermal stresses. Finite element analysis and advanced simulation techniques are often used to identify and mitigate potential weak points in the design.

- Surface treatment and coatings: Applying specialized surface treatments and coatings can enhance the thermal fatigue resistance of W16 cylinder heads. These treatments may include shot peening, laser shock peening, or the application of thermal barrier coatings. Such processes can improve surface properties, reduce stress concentrations, and provide additional protection against thermal cycling effects.

- Advanced manufacturing techniques: Utilizing advanced manufacturing techniques can contribute to improved thermal fatigue resistance in W16 cylinder heads. These may include precision casting methods, additive manufacturing, or hybrid manufacturing processes that combine multiple techniques. Such advanced methods allow for more complex internal geometries, better control of material properties, and improved overall quality of the cylinder head.

02 Cooling system design optimization

Optimizing the cooling system design for W16 cylinder heads can greatly improve thermal fatigue resistance. This includes enhancing coolant flow paths, implementing advanced cooling techniques such as precision cooling, and integrating efficient heat exchangers. A well-designed cooling system helps maintain more uniform temperatures across the cylinder head, reducing thermal stress and fatigue.Expand Specific Solutions03 Surface treatment and coatings

Applying specialized surface treatments and coatings to W16 cylinder heads can enhance their thermal fatigue resistance. Techniques such as thermal barrier coatings, nitriding, or shot peening can improve the surface properties of the cylinder head, making it more resistant to thermal cycling and reducing the likelihood of crack initiation and propagation.Expand Specific Solutions04 Structural design improvements

Enhancing the structural design of W16 cylinder heads can significantly improve their thermal fatigue resistance. This includes optimizing the thickness distribution, reinforcing critical areas, and implementing advanced design features such as variable cross-sections or ribbed structures. These improvements help distribute thermal stresses more evenly and reduce localized hot spots.Expand Specific Solutions05 Advanced manufacturing techniques

Utilizing advanced manufacturing techniques can enhance the thermal fatigue resistance of W16 cylinder heads. Methods such as 3D printing, precision casting, or advanced machining processes can produce cylinder heads with more complex internal geometries, improved cooling channels, and better overall structural integrity, leading to enhanced thermal fatigue resistance.Expand Specific Solutions

Key Players in Engine Testing Industry

The thermal fatigue resistance testing of W16 cylinder heads is a niche area within the broader automotive and engine manufacturing industry. This sector is in a mature stage of development, with established players and well-defined testing methodologies. The market size for this specific testing is relatively small but crucial for high-performance engine manufacturers. Technologically, the field is moderately mature, with ongoing refinements in testing procedures and equipment. Key players in this space include Mercedes-Benz Group AG, known for their advanced engine technologies, and AVL List GmbH, a leader in powertrain engineering and testing solutions. Other significant contributors are Ford Global Technologies LLC and Toyota Motor Corp., who have extensive experience in engine development and testing. These companies are likely at the forefront of W16 cylinder head thermal fatigue resistance testing, continually improving methodologies to enhance engine performance and durability.

AVL List GmbH

Technical Solution: AVL List GmbH has developed advanced thermal fatigue testing methods for W16 cylinder heads. Their approach involves a combination of experimental and simulation techniques. They use thermal imaging cameras to capture real-time temperature distributions during engine operation[1]. This data is then fed into finite element analysis (FEA) models to simulate thermal stress and strain cycles. AVL's proprietary software allows for accelerated thermal cycling tests, simulating thousands of engine start-stop cycles in a fraction of the time[2]. They also employ strain gauges strategically placed on critical areas of the cylinder head to measure deformation under thermal load[3]. The company has developed specialized test rigs that can apply both mechanical and thermal loads simultaneously, closely mimicking real-world conditions.

Strengths: Comprehensive approach combining experimental and simulation techniques; Accelerated testing capabilities; Ability to simulate real-world conditions accurately. Weaknesses: High cost of specialized equipment; Requires significant expertise to interpret complex data.

Mercedes-Benz Group AG

Technical Solution: Mercedes-Benz Group AG has implemented a rigorous thermal fatigue resistance testing protocol for W16 cylinder heads. Their method involves a multi-stage approach, starting with computer-aided engineering (CAE) simulations to identify potential weak points[4]. They then use a combination of thermocouples and infrared cameras to map temperature distributions during engine operation. Mercedes-Benz employs a unique "thermal shock" test, where the cylinder head is rapidly heated and cooled using specialized fluid circulation systems[5]. This test can simulate thousands of thermal cycles in a compressed timeframe. Additionally, they use acoustic emission sensors to detect micro-crack initiation and propagation during thermal cycling[6]. The company also conducts long-term durability tests on complete engines, running them for extended periods under varying load conditions to validate the cylinder head's thermal fatigue resistance.

Strengths: Comprehensive testing approach from simulation to real-world validation; Advanced crack detection techniques; Extensive experience with high-performance engines. Weaknesses: Time-consuming and resource-intensive testing process; May not fully replicate all real-world conditions.

Core Innovations in Thermal Fatigue Analysis

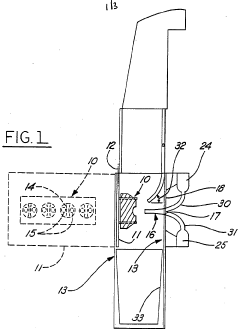

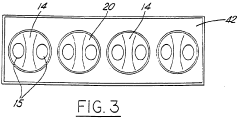

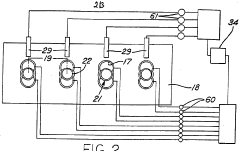

CYLINDER HEAD THERMAL LOADING AND VISUALIZATION TEST SYSTEM

PatentActiveTR201721711A3

Innovation

- The system allows for real-time observation of fatigue, temperature distribution, and material deformation in cylinder heads under thermal loads.

- The test system enables monitoring of crack formation and progression resulting from fatigue damage in cylinder heads.

- The system provides a comprehensive approach to testing thermal loading effects on both the entire cylinder head and its individual components.

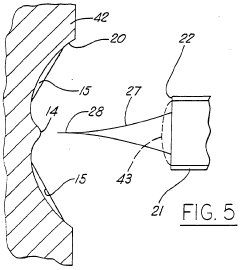

Accelerated thermal fatigue testing of engine combustion chambers

PatentInactiveGB2332747B

Innovation

- A method involving direct torch flame heating of selected areas on the cylinder head to a critical temperature, followed by rapid quenching, repeatedly until a crack is induced, using a controlled apparatus with torches and quenching nozzles to accelerate thermal fatigue testing.

Environmental Impact of W16 Engine Testing

The environmental impact of W16 engine testing, particularly in relation to thermal fatigue resistance of cylinder heads, is a critical consideration in the automotive industry. Testing procedures for W16 engines, known for their high performance and complex design, can have significant environmental implications. The primary environmental concerns stem from energy consumption, emissions, and resource utilization during the testing process.

Energy consumption during W16 engine testing is substantial, given the need for prolonged high-temperature and high-pressure conditions to simulate thermal fatigue. This energy-intensive process contributes to increased carbon emissions, especially if the power source is not from renewable energy. The use of specialized testing equipment, such as thermal cycling chambers and hydraulic systems, further amplifies the energy demand.

Emissions from W16 engine testing are another major environmental factor. During thermal fatigue resistance tests, the engine may produce exhaust gases containing various pollutants, including carbon monoxide, nitrogen oxides, and particulate matter. While modern testing facilities are equipped with advanced emission control systems, the cumulative effect of repeated tests can still have a notable impact on local air quality.

Water consumption is a significant concern in thermal fatigue testing of W16 cylinder heads. Cooling systems used to regulate temperature during cycling tests can require substantial amounts of water, potentially straining local water resources. Additionally, the disposal of coolants and other fluids used in the testing process necessitates careful management to prevent water pollution.

The materials used in W16 cylinder head testing also have environmental implications. Specialized alloys and coatings used in prototype cylinder heads may contain rare or toxic elements. The production and disposal of these materials can lead to resource depletion and potential environmental contamination if not properly managed.

Noise pollution is another environmental aspect of W16 engine testing. The high-performance nature of these engines can result in significant noise levels during operation, potentially affecting the surrounding ecosystem and local communities if testing facilities are not adequately soundproofed.

To mitigate these environmental impacts, automotive companies are increasingly adopting more sustainable testing practices. These include the use of advanced simulation technologies to reduce the need for physical testing, implementation of closed-loop cooling systems to minimize water consumption, and investment in renewable energy sources to power testing facilities. Additionally, the development of more efficient testing protocols helps in reducing the overall environmental footprint of W16 engine testing processes.

Energy consumption during W16 engine testing is substantial, given the need for prolonged high-temperature and high-pressure conditions to simulate thermal fatigue. This energy-intensive process contributes to increased carbon emissions, especially if the power source is not from renewable energy. The use of specialized testing equipment, such as thermal cycling chambers and hydraulic systems, further amplifies the energy demand.

Emissions from W16 engine testing are another major environmental factor. During thermal fatigue resistance tests, the engine may produce exhaust gases containing various pollutants, including carbon monoxide, nitrogen oxides, and particulate matter. While modern testing facilities are equipped with advanced emission control systems, the cumulative effect of repeated tests can still have a notable impact on local air quality.

Water consumption is a significant concern in thermal fatigue testing of W16 cylinder heads. Cooling systems used to regulate temperature during cycling tests can require substantial amounts of water, potentially straining local water resources. Additionally, the disposal of coolants and other fluids used in the testing process necessitates careful management to prevent water pollution.

The materials used in W16 cylinder head testing also have environmental implications. Specialized alloys and coatings used in prototype cylinder heads may contain rare or toxic elements. The production and disposal of these materials can lead to resource depletion and potential environmental contamination if not properly managed.

Noise pollution is another environmental aspect of W16 engine testing. The high-performance nature of these engines can result in significant noise levels during operation, potentially affecting the surrounding ecosystem and local communities if testing facilities are not adequately soundproofed.

To mitigate these environmental impacts, automotive companies are increasingly adopting more sustainable testing practices. These include the use of advanced simulation technologies to reduce the need for physical testing, implementation of closed-loop cooling systems to minimize water consumption, and investment in renewable energy sources to power testing facilities. Additionally, the development of more efficient testing protocols helps in reducing the overall environmental footprint of W16 engine testing processes.

Cost-Benefit Analysis of Testing Methods

When evaluating the cost-benefit analysis of testing methods for W16 cylinder head thermal fatigue resistance, several factors must be considered. The primary testing methods include finite element analysis (FEA), physical bench testing, and on-engine testing. Each method presents distinct advantages and drawbacks in terms of cost, accuracy, and time efficiency.

FEA offers a cost-effective initial approach, allowing engineers to simulate thermal stress and fatigue without physical prototypes. This method significantly reduces material costs and testing time. However, the accuracy of FEA results heavily depends on the quality of input data and model complexity. While less expensive than physical testing, high-fidelity FEA simulations require substantial computational resources and skilled personnel, potentially increasing overall costs.

Physical bench testing provides more accurate results than FEA but at a higher cost. This method involves subjecting actual cylinder head prototypes to thermal cycling in controlled environments. While it offers reliable data on material behavior and fatigue resistance, the expenses associated with prototype production, specialized equipment, and extended testing periods can be substantial. However, the insights gained from physical testing often justify the investment, particularly for high-performance engines like the W16.

On-engine testing represents the most comprehensive and expensive method. It involves integrating the cylinder head into a complete engine assembly and subjecting it to real-world operating conditions. This approach provides the most accurate assessment of thermal fatigue resistance but incurs significant costs in terms of engine build, fuel consumption, and facility usage. The extended duration required for accumulating sufficient test hours further increases expenses.

A balanced approach often yields the best cost-benefit ratio. Starting with FEA to optimize designs and identify potential issues can significantly reduce the number of physical prototypes required. Follow-up bench testing on refined designs can validate FEA results and provide crucial data on actual material behavior. Finally, limited on-engine testing can confirm real-world performance and durability.

The cost-benefit analysis should also consider the potential risks and costs associated with inadequate testing. For a high-performance engine like the W16, thermal fatigue failures could lead to catastrophic engine damage, warranty claims, and reputational damage. In this context, the investment in comprehensive testing methods may be justified by the mitigation of these risks and the assurance of product reliability and performance.

FEA offers a cost-effective initial approach, allowing engineers to simulate thermal stress and fatigue without physical prototypes. This method significantly reduces material costs and testing time. However, the accuracy of FEA results heavily depends on the quality of input data and model complexity. While less expensive than physical testing, high-fidelity FEA simulations require substantial computational resources and skilled personnel, potentially increasing overall costs.

Physical bench testing provides more accurate results than FEA but at a higher cost. This method involves subjecting actual cylinder head prototypes to thermal cycling in controlled environments. While it offers reliable data on material behavior and fatigue resistance, the expenses associated with prototype production, specialized equipment, and extended testing periods can be substantial. However, the insights gained from physical testing often justify the investment, particularly for high-performance engines like the W16.

On-engine testing represents the most comprehensive and expensive method. It involves integrating the cylinder head into a complete engine assembly and subjecting it to real-world operating conditions. This approach provides the most accurate assessment of thermal fatigue resistance but incurs significant costs in terms of engine build, fuel consumption, and facility usage. The extended duration required for accumulating sufficient test hours further increases expenses.

A balanced approach often yields the best cost-benefit ratio. Starting with FEA to optimize designs and identify potential issues can significantly reduce the number of physical prototypes required. Follow-up bench testing on refined designs can validate FEA results and provide crucial data on actual material behavior. Finally, limited on-engine testing can confirm real-world performance and durability.

The cost-benefit analysis should also consider the potential risks and costs associated with inadequate testing. For a high-performance engine like the W16, thermal fatigue failures could lead to catastrophic engine damage, warranty claims, and reputational damage. In this context, the investment in comprehensive testing methods may be justified by the mitigation of these risks and the assurance of product reliability and performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!