W16 Engine Balance And Vibration Mitigation Techniques

AUG 21, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

W16 Engine Evolution

The W16 engine, a marvel of automotive engineering, has undergone significant evolution since its inception. This unique configuration, featuring 16 cylinders arranged in a W formation, represents the pinnacle of internal combustion engine design. The journey of the W16 engine began in the late 1990s when Volkswagen Group initiated its development for high-performance applications.

The first notable milestone in W16 engine evolution came with the introduction of the Bugatti Veyron in 2005. This groundbreaking supercar showcased a quad-turbocharged 8.0-liter W16 engine, producing an astounding 1,001 horsepower. The Veyron's engine marked a new era in automotive performance, setting multiple speed records and redefining the boundaries of what was possible in a production car.

As the W16 engine matured, engineers focused on refining its balance and vibration characteristics. The inherent challenge of managing the forces generated by 16 cylinders firing in rapid succession necessitated innovative solutions. Advanced computer modeling and simulation techniques played a crucial role in optimizing the engine's layout and firing order to minimize vibrations and enhance overall smoothness.

The next significant leap in W16 engine development came with the Bugatti Chiron, unveiled in 2016. This iteration of the W16 engine saw improvements in power output, efficiency, and refinement. Engineers implemented enhanced turbocharging systems, redesigned combustion chambers, and advanced materials to achieve a power output of 1,479 horsepower while maintaining exceptional drivability and reliability.

Throughout its evolution, the W16 engine has consistently pushed the boundaries of automotive technology. Advancements in engine management systems, fuel injection technology, and thermal management have all contributed to the engine's ongoing development. These improvements have not only increased power output but also enhanced fuel efficiency and reduced emissions, addressing the growing demand for more environmentally conscious high-performance vehicles.

The latest iterations of the W16 engine have seen further refinements in balance and vibration mitigation techniques. Engineers have employed sophisticated active engine mounts, advanced crankshaft designs, and precision-engineered counterweights to minimize unwanted vibrations and ensure a smooth power delivery across the entire rev range. These advancements have resulted in a driving experience that combines raw power with refined comfort, a hallmark of modern W16-powered vehicles.

As the automotive industry shifts towards electrification, the future of the W16 engine remains a topic of discussion. While its days may be numbered in the face of stringent emissions regulations, the technological advancements made in its development continue to influence the design of high-performance powertrains across the industry.

The first notable milestone in W16 engine evolution came with the introduction of the Bugatti Veyron in 2005. This groundbreaking supercar showcased a quad-turbocharged 8.0-liter W16 engine, producing an astounding 1,001 horsepower. The Veyron's engine marked a new era in automotive performance, setting multiple speed records and redefining the boundaries of what was possible in a production car.

As the W16 engine matured, engineers focused on refining its balance and vibration characteristics. The inherent challenge of managing the forces generated by 16 cylinders firing in rapid succession necessitated innovative solutions. Advanced computer modeling and simulation techniques played a crucial role in optimizing the engine's layout and firing order to minimize vibrations and enhance overall smoothness.

The next significant leap in W16 engine development came with the Bugatti Chiron, unveiled in 2016. This iteration of the W16 engine saw improvements in power output, efficiency, and refinement. Engineers implemented enhanced turbocharging systems, redesigned combustion chambers, and advanced materials to achieve a power output of 1,479 horsepower while maintaining exceptional drivability and reliability.

Throughout its evolution, the W16 engine has consistently pushed the boundaries of automotive technology. Advancements in engine management systems, fuel injection technology, and thermal management have all contributed to the engine's ongoing development. These improvements have not only increased power output but also enhanced fuel efficiency and reduced emissions, addressing the growing demand for more environmentally conscious high-performance vehicles.

The latest iterations of the W16 engine have seen further refinements in balance and vibration mitigation techniques. Engineers have employed sophisticated active engine mounts, advanced crankshaft designs, and precision-engineered counterweights to minimize unwanted vibrations and ensure a smooth power delivery across the entire rev range. These advancements have resulted in a driving experience that combines raw power with refined comfort, a hallmark of modern W16-powered vehicles.

As the automotive industry shifts towards electrification, the future of the W16 engine remains a topic of discussion. While its days may be numbered in the face of stringent emissions regulations, the technological advancements made in its development continue to influence the design of high-performance powertrains across the industry.

Market for High-Performance Engines

The market for high-performance engines, particularly those incorporating W16 configurations, represents a niche yet lucrative segment within the automotive industry. This market is primarily driven by luxury and hypercar manufacturers seeking to push the boundaries of power, speed, and engineering excellence. The demand for such engines is closely tied to the ultra-high-net-worth individual (UHNWI) population, which has shown steady growth over the past decade.

Bugatti, a pioneer in W16 engine technology, has been at the forefront of this market. Their Chiron and its variants, powered by an 8.0-liter quad-turbocharged W16 engine, have set new standards for performance and exclusivity. The limited production runs of these vehicles, typically numbering in the hundreds, underscore the exclusivity and high demand within this market segment.

The market for high-performance engines extends beyond just W16 configurations. V12 and V8 engines, produced by manufacturers such as Ferrari, Lamborghini, and McLaren, also cater to this segment. These engines, while not as rare as W16s, still command significant market share in the high-performance sector.

Environmental regulations and the shift towards electrification present both challenges and opportunities for the high-performance engine market. While there is increasing pressure to reduce emissions, manufacturers are responding with innovative technologies such as hybrid powertrains and advanced materials to maintain performance while improving efficiency.

The aftermarket and tuning sector also plays a significant role in the high-performance engine market. Companies specializing in engine modifications and performance upgrades cater to enthusiasts seeking to enhance the power and characteristics of their vehicles, further expanding the market's reach.

Geographically, the market for high-performance engines shows strong presence in regions with high concentrations of wealth, including North America, Western Europe, the Middle East, and parts of Asia. Emerging markets, particularly in Asia and the Middle East, have shown increasing demand for ultra-luxury and high-performance vehicles, driving growth in this sector.

The racing and motorsport industry continues to be a key driver of innovation in high-performance engine technology. Advancements in areas such as materials science, combustion efficiency, and vibration mitigation often find their way from the racetrack to road-going vehicles, further enhancing the appeal and capabilities of high-performance engines in the consumer market.

Bugatti, a pioneer in W16 engine technology, has been at the forefront of this market. Their Chiron and its variants, powered by an 8.0-liter quad-turbocharged W16 engine, have set new standards for performance and exclusivity. The limited production runs of these vehicles, typically numbering in the hundreds, underscore the exclusivity and high demand within this market segment.

The market for high-performance engines extends beyond just W16 configurations. V12 and V8 engines, produced by manufacturers such as Ferrari, Lamborghini, and McLaren, also cater to this segment. These engines, while not as rare as W16s, still command significant market share in the high-performance sector.

Environmental regulations and the shift towards electrification present both challenges and opportunities for the high-performance engine market. While there is increasing pressure to reduce emissions, manufacturers are responding with innovative technologies such as hybrid powertrains and advanced materials to maintain performance while improving efficiency.

The aftermarket and tuning sector also plays a significant role in the high-performance engine market. Companies specializing in engine modifications and performance upgrades cater to enthusiasts seeking to enhance the power and characteristics of their vehicles, further expanding the market's reach.

Geographically, the market for high-performance engines shows strong presence in regions with high concentrations of wealth, including North America, Western Europe, the Middle East, and parts of Asia. Emerging markets, particularly in Asia and the Middle East, have shown increasing demand for ultra-luxury and high-performance vehicles, driving growth in this sector.

The racing and motorsport industry continues to be a key driver of innovation in high-performance engine technology. Advancements in areas such as materials science, combustion efficiency, and vibration mitigation often find their way from the racetrack to road-going vehicles, further enhancing the appeal and capabilities of high-performance engines in the consumer market.

W16 Balance Challenges

The W16 engine, a marvel of automotive engineering, presents unique challenges in terms of balance and vibration control. This complex powerplant, essentially two V8 engines joined at the crankshaft, generates significant forces that must be carefully managed to ensure smooth operation and longevity.

One of the primary balance challenges in W16 engines stems from the sheer number of cylinders and their arrangement. With 16 cylinders firing in rapid succession, the engine produces a multitude of reciprocating and rotating forces that can lead to severe vibrations if not properly addressed. The W configuration, while compact, introduces asymmetrical mass distribution that further complicates the balancing act.

The crankshaft design in W16 engines is particularly critical. Unlike simpler inline or V-configuration engines, the W16's crankshaft must accommodate four banks of cylinders, each with different firing orders and force vectors. This complex geometry can lead to torsional vibrations and bending moments that stress the crankshaft and surrounding components.

Another significant challenge is the management of secondary forces. While primary forces can be relatively easily balanced through counterweights on the crankshaft, secondary forces—which occur at twice the engine speed—are more difficult to neutralize in a W16 configuration. These forces can lead to high-frequency vibrations that are particularly noticeable at higher engine speeds.

The engine's firing order also plays a crucial role in balance and vibration control. Engineers must carefully sequence the cylinder firing to distribute power pulses evenly and minimize vibration. However, optimizing for balance can sometimes conflict with goals for performance or exhaust note, requiring careful trade-offs.

Heat management presents another balance-related challenge. The compact nature of the W16 layout means that some cylinders are more centrally located and may run hotter than others. This thermal imbalance can lead to uneven expansion and contraction, potentially affecting engine balance and introducing additional vibration sources.

Addressing these challenges requires a multifaceted approach. Advanced computer modeling and simulation are essential for predicting and mitigating balance issues before physical prototypes are built. Precision manufacturing techniques are crucial to ensure that all components meet exacting tolerances, as even minor imbalances can be magnified in such a high-performance engine.

One of the primary balance challenges in W16 engines stems from the sheer number of cylinders and their arrangement. With 16 cylinders firing in rapid succession, the engine produces a multitude of reciprocating and rotating forces that can lead to severe vibrations if not properly addressed. The W configuration, while compact, introduces asymmetrical mass distribution that further complicates the balancing act.

The crankshaft design in W16 engines is particularly critical. Unlike simpler inline or V-configuration engines, the W16's crankshaft must accommodate four banks of cylinders, each with different firing orders and force vectors. This complex geometry can lead to torsional vibrations and bending moments that stress the crankshaft and surrounding components.

Another significant challenge is the management of secondary forces. While primary forces can be relatively easily balanced through counterweights on the crankshaft, secondary forces—which occur at twice the engine speed—are more difficult to neutralize in a W16 configuration. These forces can lead to high-frequency vibrations that are particularly noticeable at higher engine speeds.

The engine's firing order also plays a crucial role in balance and vibration control. Engineers must carefully sequence the cylinder firing to distribute power pulses evenly and minimize vibration. However, optimizing for balance can sometimes conflict with goals for performance or exhaust note, requiring careful trade-offs.

Heat management presents another balance-related challenge. The compact nature of the W16 layout means that some cylinders are more centrally located and may run hotter than others. This thermal imbalance can lead to uneven expansion and contraction, potentially affecting engine balance and introducing additional vibration sources.

Addressing these challenges requires a multifaceted approach. Advanced computer modeling and simulation are essential for predicting and mitigating balance issues before physical prototypes are built. Precision manufacturing techniques are crucial to ensure that all components meet exacting tolerances, as even minor imbalances can be magnified in such a high-performance engine.

Current Balance Solutions

01 Balancing mechanisms for W16 engines

Various balancing mechanisms are employed in W16 engines to reduce vibration and improve overall engine performance. These mechanisms may include counterweights, balance shafts, and specialized crankshaft designs to offset the inherent imbalances caused by the W16 configuration. Such systems help distribute forces more evenly throughout the engine, resulting in smoother operation and reduced wear on components.- Balancing mechanisms for W16 engines: Various balancing mechanisms are employed in W16 engines to reduce vibration and improve overall engine performance. These mechanisms may include counterweights, balance shafts, and specialized crankshaft designs that help distribute the forces generated by the pistons and minimize engine vibration.

- Vibration dampening systems: W16 engines often incorporate advanced vibration dampening systems to minimize the transmission of engine vibrations to the vehicle chassis and passenger compartment. These systems may include engine mounts with specific damping characteristics, isolation materials, and active vibration control technologies.

- Crankshaft design optimization: The design of the crankshaft plays a crucial role in managing balance and vibration in W16 engines. Optimized crankshaft configurations, including specific firing orders and journal arrangements, help distribute forces more evenly and reduce overall engine vibration.

- Electronic control systems for vibration management: Advanced electronic control systems are implemented in W16 engines to monitor and manage engine balance and vibration in real-time. These systems may adjust engine parameters, such as ignition timing and fuel injection, to optimize performance and minimize vibration across various operating conditions.

- Innovative cylinder arrangement and firing sequence: W16 engines often feature unique cylinder arrangements and firing sequences designed to inherently improve engine balance and reduce vibration. These configurations may involve specific angles between cylinder banks and carefully planned firing orders to distribute forces more evenly throughout the engine's operation.

02 Vibration dampening systems

W16 engines often incorporate advanced vibration dampening systems to minimize unwanted oscillations and improve ride comfort. These systems may include engine mounts with variable stiffness, active vibration control modules, and specialized materials designed to absorb and dissipate vibrational energy. By effectively managing vibrations, these systems contribute to enhanced engine longevity and improved overall vehicle performance.Expand Specific Solutions03 Crankshaft design optimization

Optimizing crankshaft design is crucial for achieving proper balance and reducing vibration in W16 engines. This may involve careful consideration of crankpin arrangements, journal sizes, and counterweight placement. Advanced computer modeling and analysis techniques are often employed to fine-tune crankshaft designs, ensuring optimal balance and minimizing torsional vibrations throughout the engine's operating range.Expand Specific Solutions04 Electronic control systems for vibration management

Modern W16 engines often utilize sophisticated electronic control systems to manage engine balance and vibration. These systems may employ sensors to monitor engine vibrations in real-time and adjust various parameters such as ignition timing, fuel injection, and valve timing to minimize unwanted oscillations. By continuously optimizing engine operation, these control systems help maintain smooth performance across different operating conditions.Expand Specific Solutions05 Innovative cylinder arrangement and firing order

W16 engines may incorporate innovative cylinder arrangements and firing orders to achieve better balance and reduce vibration. This can include specific configurations of the cylinder banks, optimized firing sequences, and carefully designed intake and exhaust systems. By strategically arranging the cylinders and timing their firing, engineers can minimize the inherent imbalances associated with the W16 layout, resulting in smoother engine operation and reduced vibration.Expand Specific Solutions

Key W16 Engine Manufacturers

The W16 engine balance and vibration mitigation techniques market is in a mature stage, with established players continuously refining their technologies. The global market size for high-performance engines is substantial, driven by demand in luxury and sports car segments. Technologically, W16 engines are highly advanced, with companies like Volkswagen Group (through Bugatti) leading innovation. Toyota, Honda, and Nissan have made significant strides in engine balancing technologies, while Boeing and Mitsubishi Heavy Industries contribute expertise from aerospace applications. European manufacturers such as Peugeot and Ferrari are also key players, focusing on performance optimization and vibration reduction in high-output engines.

Toyota Motor Corp.

Technical Solution: Toyota's W16 engine balance and vibration mitigation techniques focus on advanced materials and precision manufacturing. They employ a hybrid structure combining aluminum and reinforced plastics to create a lightweight yet rigid engine block[1]. Toyota utilizes a proprietary vibration modeling software to optimize component design and placement for minimal vibration[3]. The company has developed an innovative "floating" cylinder liner system that reduces friction and absorbs vibrations between the pistons and engine block[5]. Toyota also implements an active thermal management system that maintains consistent operating temperatures across all cylinders, reducing thermal expansion-related vibrations[7]. Additionally, they use a computer-controlled balancing system during engine assembly to ensure near-perfect balance of rotating components[9].

Strengths: High-precision manufacturing and innovative materials lead to excellent vibration control. Weaknesses: Potentially higher production costs due to advanced technologies and materials used.

Honda Motor Co., Ltd.

Technical Solution: Honda's W16 engine balance and vibration mitigation strategy focuses on lightweight materials and innovative design. They use a combination of aluminum and magnesium alloys in the engine block and components to reduce overall mass while maintaining structural rigidity[1]. Honda employs a unique "split-pin" crankshaft design that allows for optimal firing intervals and reduced vibration[3]. The company has developed an advanced active engine mount system that uses hydraulic fluid and electronic controls to adapt to different driving conditions and engine loads[5]. Honda also implements a multi-layer sound insulation system within the engine bay to further reduce vibration transmission to the vehicle cabin[7].

Strengths: Excellent balance between performance and refinement, with emphasis on weight reduction. Weaknesses: Potential higher costs associated with advanced materials and manufacturing processes.

Innovative Vibration Damping

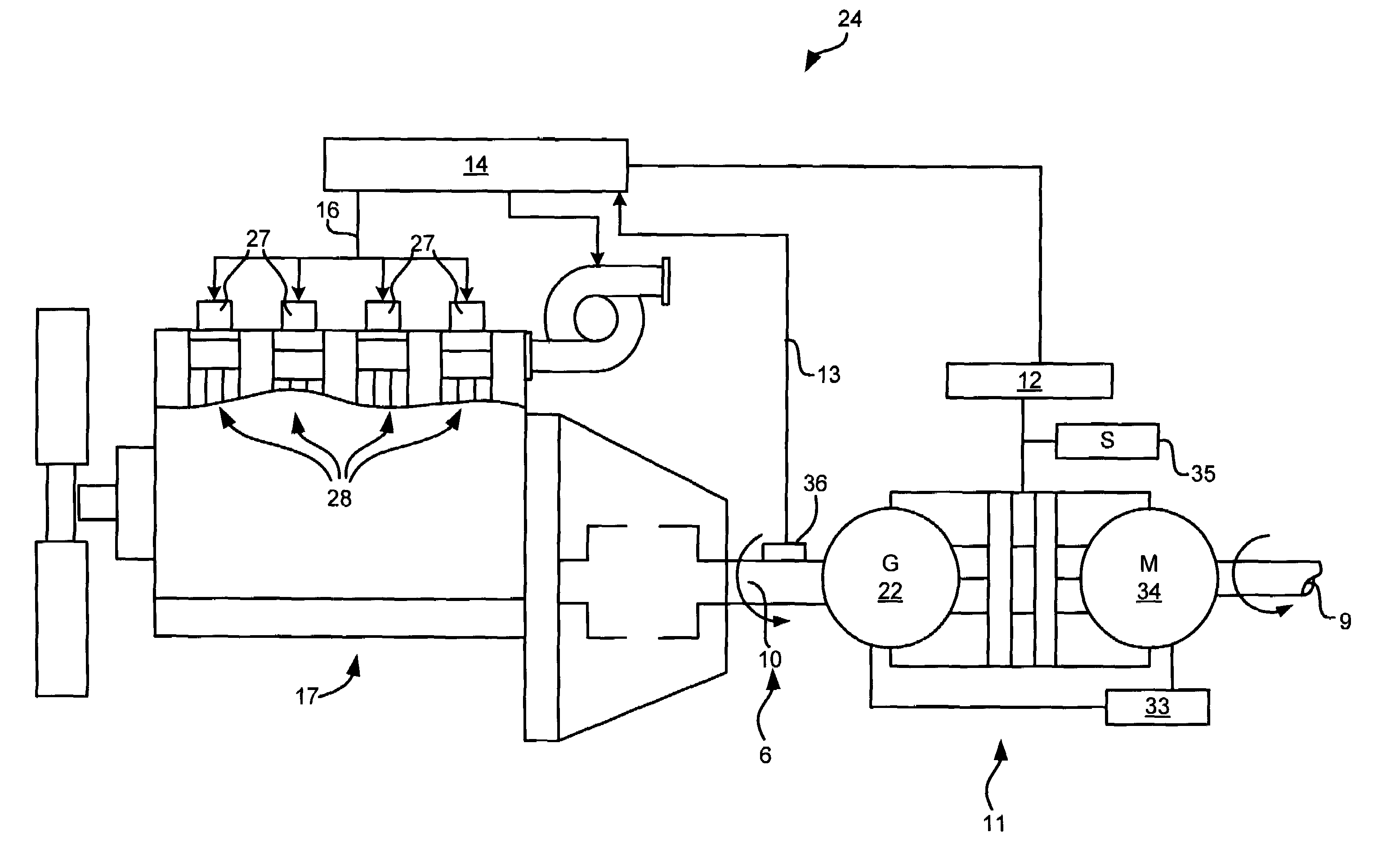

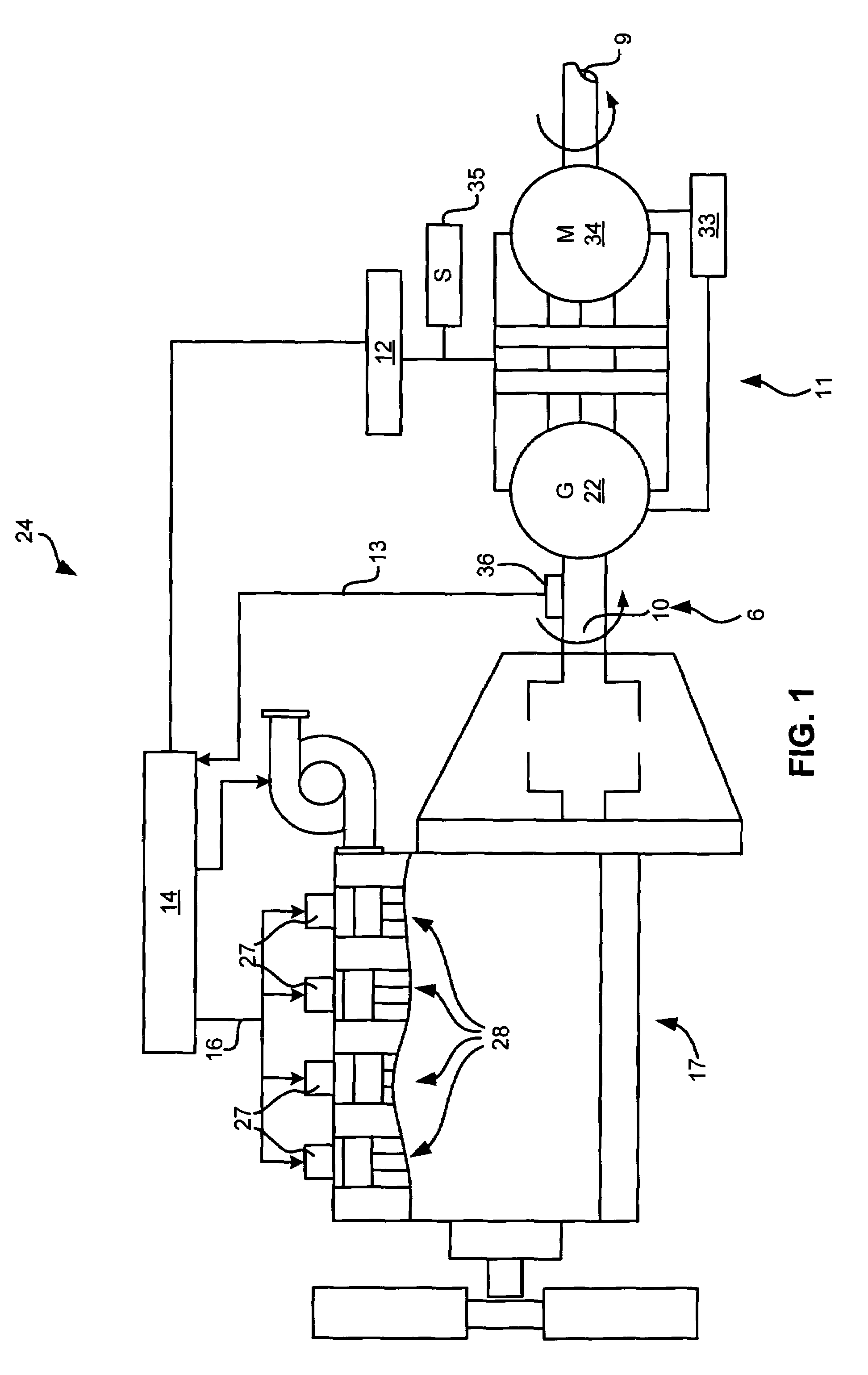

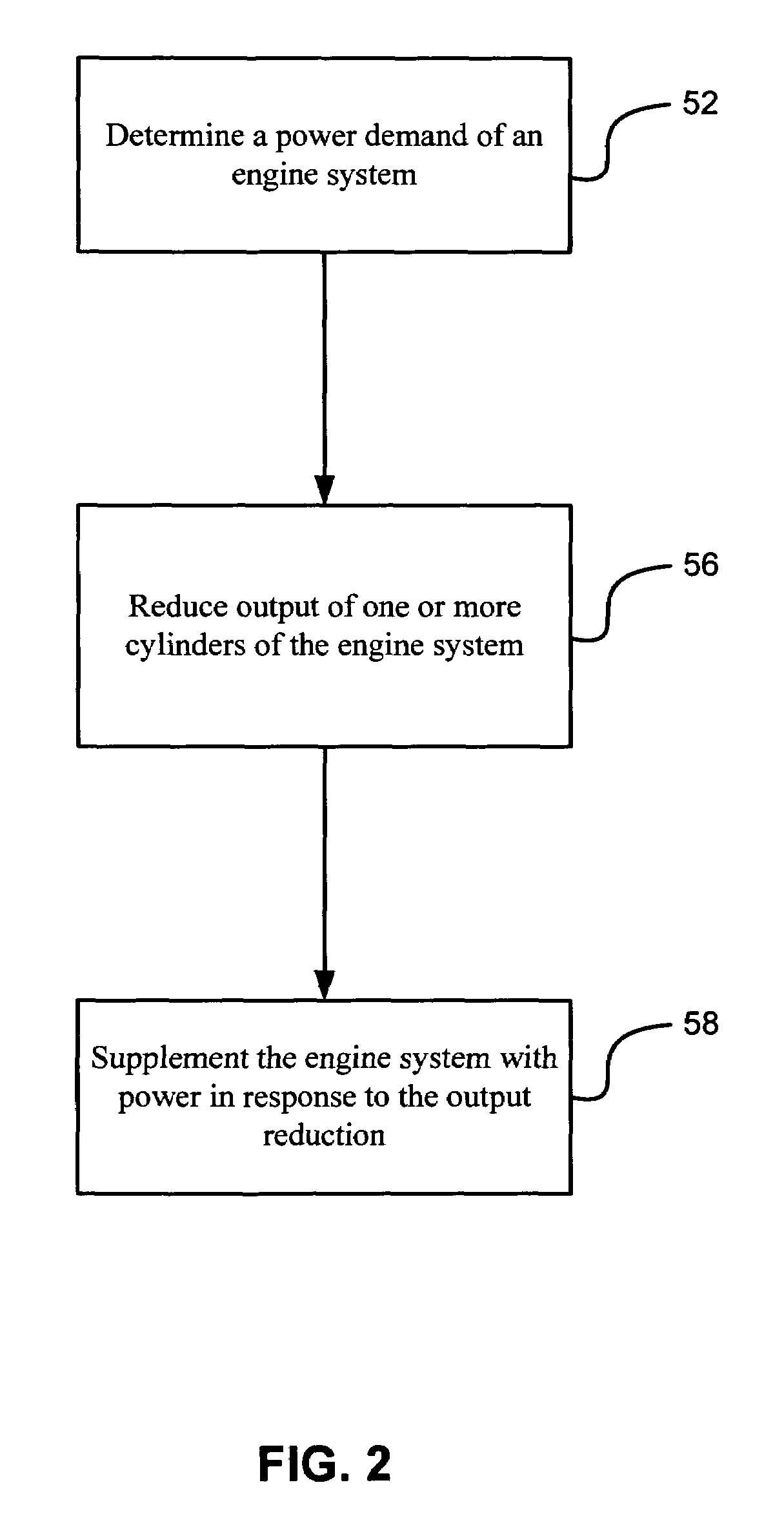

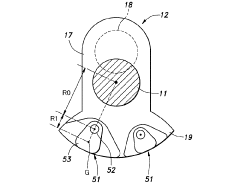

System and method for balancing an engine during cylinder cutout

PatentActiveUS7377250B1

Innovation

- A control system that reduces the output of one or more engine cylinders without reducing the output of the remaining cylinders, using an electric motor to supplement power and balance torsional loads, thereby reducing noise and vibration.

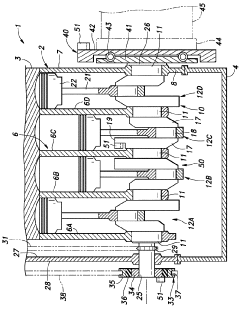

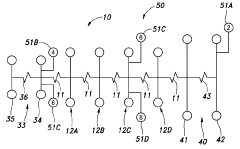

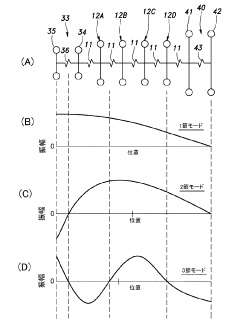

Vibration reducing device of internal combustion engine

PatentInactiveJP2019015316A

Innovation

- A vibration reducing device for internal combustion engines that includes centrifugal pendulum dampers positioned at specific antinodes corresponding to the one-node, two-node, and three-node modes of torsional vibration, with multiple dampers placed at strategic points along the crankshaft to suppress resonance and natural vibrations.

Emissions Regulations Impact

The impact of emissions regulations on W16 engine balance and vibration mitigation techniques is significant and multifaceted. As governments worldwide implement increasingly stringent emissions standards, manufacturers of high-performance engines like the W16 are compelled to adapt their designs and technologies to meet these requirements while maintaining optimal performance and minimizing vibrations.

One of the primary challenges posed by emissions regulations is the need for more efficient combustion processes. This often leads to higher combustion pressures and temperatures, which can exacerbate engine vibrations. To counteract these effects, engineers must develop more sophisticated balance shaft systems and engine mounts capable of absorbing and dissipating increased vibrational energy.

The introduction of exhaust gas recirculation (EGR) systems, mandated by many emissions regulations, can also impact engine balance. EGR systems alter the composition of the intake charge, potentially affecting combustion characteristics and, consequently, engine vibration patterns. This necessitates the development of more advanced engine management systems that can dynamically adjust ignition timing and fuel injection to maintain smooth operation across various operating conditions.

Emissions regulations have also driven the adoption of lightweight materials in engine construction. While beneficial for fuel efficiency, these materials may have different resonant frequencies compared to traditional engine components, requiring engineers to recalibrate their vibration mitigation strategies. This often involves the use of advanced computer modeling and simulation techniques to predict and address potential vibration issues before physical prototypes are built.

The push for cleaner emissions has led to the widespread implementation of particulate filters and catalytic converters in exhaust systems. These components can create additional back pressure, potentially altering the engine's operating characteristics and vibration profile. As a result, engineers must consider the entire powertrain system when designing vibration mitigation solutions, ensuring that emissions control devices do not compromise the engine's balance and smoothness.

Furthermore, the trend towards engine downsizing and turbocharging, driven in part by emissions regulations, presents new challenges for vibration control in high-performance engines like the W16. The increased power density of these engines can lead to higher stress on components and more intense vibrations, necessitating innovative approaches to engine mounting and internal balancing mechanisms.

In conclusion, emissions regulations have significantly influenced the development of balance and vibration mitigation techniques for W16 engines. Manufacturers must continually innovate to meet these regulatory challenges while maintaining the exceptional performance and refinement expected from these powerplants. This ongoing process drives advancements in materials science, computational modeling, and mechatronic systems, ultimately benefiting the broader field of engine design and vibration control.

One of the primary challenges posed by emissions regulations is the need for more efficient combustion processes. This often leads to higher combustion pressures and temperatures, which can exacerbate engine vibrations. To counteract these effects, engineers must develop more sophisticated balance shaft systems and engine mounts capable of absorbing and dissipating increased vibrational energy.

The introduction of exhaust gas recirculation (EGR) systems, mandated by many emissions regulations, can also impact engine balance. EGR systems alter the composition of the intake charge, potentially affecting combustion characteristics and, consequently, engine vibration patterns. This necessitates the development of more advanced engine management systems that can dynamically adjust ignition timing and fuel injection to maintain smooth operation across various operating conditions.

Emissions regulations have also driven the adoption of lightweight materials in engine construction. While beneficial for fuel efficiency, these materials may have different resonant frequencies compared to traditional engine components, requiring engineers to recalibrate their vibration mitigation strategies. This often involves the use of advanced computer modeling and simulation techniques to predict and address potential vibration issues before physical prototypes are built.

The push for cleaner emissions has led to the widespread implementation of particulate filters and catalytic converters in exhaust systems. These components can create additional back pressure, potentially altering the engine's operating characteristics and vibration profile. As a result, engineers must consider the entire powertrain system when designing vibration mitigation solutions, ensuring that emissions control devices do not compromise the engine's balance and smoothness.

Furthermore, the trend towards engine downsizing and turbocharging, driven in part by emissions regulations, presents new challenges for vibration control in high-performance engines like the W16. The increased power density of these engines can lead to higher stress on components and more intense vibrations, necessitating innovative approaches to engine mounting and internal balancing mechanisms.

In conclusion, emissions regulations have significantly influenced the development of balance and vibration mitigation techniques for W16 engines. Manufacturers must continually innovate to meet these regulatory challenges while maintaining the exceptional performance and refinement expected from these powerplants. This ongoing process drives advancements in materials science, computational modeling, and mechatronic systems, ultimately benefiting the broader field of engine design and vibration control.

NVH Optimization Strategies

NVH (Noise, Vibration, and Harshness) optimization is crucial for W16 engine performance and user comfort. Advanced strategies focus on minimizing vibrations and noise while maintaining power output. Active engine mounts play a significant role in isolating engine vibrations from the vehicle chassis. These mounts use sensors and actuators to counteract engine movements in real-time, significantly reducing transmitted vibrations.

Acoustic optimization techniques are employed to reduce noise propagation. This includes the use of sound-absorbing materials in strategic locations and the design of exhaust systems with multiple resonators and mufflers. Advanced computational fluid dynamics (CFD) simulations are utilized to optimize exhaust flow and minimize turbulence-induced noise.

Balancing shafts are integral to W16 engine NVH optimization. These counter-rotating shafts are precisely engineered to cancel out second-order vibrations inherent in the W16 configuration. The placement and mass of these shafts are critical for effective vibration cancellation without compromising engine performance.

Crankshaft design plays a crucial role in vibration mitigation. Advanced materials and manufacturing techniques allow for lighter, stiffer crankshafts that reduce flexing and associated vibrations. Torsional vibration dampers are often incorporated to absorb crankshaft oscillations, particularly at critical engine speeds.

Engine control strategies also contribute significantly to NVH optimization. Sophisticated engine management systems use adaptive algorithms to adjust ignition timing and fuel injection patterns, minimizing combustion-induced vibrations across the engine's operating range. These systems can also implement cylinder deactivation strategies during partial load conditions, further reducing vibrations and improving fuel efficiency.

Structural optimization of the engine block and surrounding components is another key aspect. Finite Element Analysis (FEA) is used to identify and reinforce areas prone to resonance or excessive vibration. This may involve the use of ribbing, material thickness variations, or the strategic placement of damping materials.

Lastly, advanced lubricants play a role in NVH optimization by reducing friction between moving parts, thereby minimizing vibration-inducing forces. These specially formulated oils maintain their viscosity characteristics under extreme conditions, ensuring consistent performance across the engine's operating range.

Acoustic optimization techniques are employed to reduce noise propagation. This includes the use of sound-absorbing materials in strategic locations and the design of exhaust systems with multiple resonators and mufflers. Advanced computational fluid dynamics (CFD) simulations are utilized to optimize exhaust flow and minimize turbulence-induced noise.

Balancing shafts are integral to W16 engine NVH optimization. These counter-rotating shafts are precisely engineered to cancel out second-order vibrations inherent in the W16 configuration. The placement and mass of these shafts are critical for effective vibration cancellation without compromising engine performance.

Crankshaft design plays a crucial role in vibration mitigation. Advanced materials and manufacturing techniques allow for lighter, stiffer crankshafts that reduce flexing and associated vibrations. Torsional vibration dampers are often incorporated to absorb crankshaft oscillations, particularly at critical engine speeds.

Engine control strategies also contribute significantly to NVH optimization. Sophisticated engine management systems use adaptive algorithms to adjust ignition timing and fuel injection patterns, minimizing combustion-induced vibrations across the engine's operating range. These systems can also implement cylinder deactivation strategies during partial load conditions, further reducing vibrations and improving fuel efficiency.

Structural optimization of the engine block and surrounding components is another key aspect. Finite Element Analysis (FEA) is used to identify and reinforce areas prone to resonance or excessive vibration. This may involve the use of ribbing, material thickness variations, or the strategic placement of damping materials.

Lastly, advanced lubricants play a role in NVH optimization by reducing friction between moving parts, thereby minimizing vibration-inducing forces. These specially formulated oils maintain their viscosity characteristics under extreme conditions, ensuring consistent performance across the engine's operating range.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!