W16 Engine Hybridization: Integration Strategies And Challenges

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

W16 Hybrid Evolution

The W16 engine, a marvel of automotive engineering, has undergone significant evolution since its inception. Initially developed as a high-performance powerplant for luxury and sports vehicles, the W16 has faced increasing pressure to adapt to modern environmental and efficiency standards. This has led to the exploration of hybridization as a means to enhance its performance while reducing its environmental impact.

The hybridization journey of the W16 engine began with preliminary studies in the early 2010s, as automakers sought ways to comply with stricter emissions regulations without sacrificing the power and prestige associated with large-displacement engines. The first conceptual designs for a W16 hybrid system emerged around 2015, focusing on integrating electric motors to supplement the combustion engine's output.

By 2018, prototype W16 hybrid powertrains were undergoing rigorous testing. These early systems typically employed a parallel hybrid configuration, where an electric motor was coupled to the transmission, allowing for both electric-only operation at low speeds and power boosting during high-performance driving. This approach presented significant challenges in terms of packaging and thermal management, given the already complex nature of the W16 engine.

The evolution continued with the development of more advanced hybrid systems around 2020. These newer iterations explored the potential of integrating multiple electric motors, with some designs placing motors directly on the axles to provide all-wheel drive capability and improved torque vectoring. This marked a shift towards a more holistic approach to hybridization, where the electric components were not merely add-ons but integral parts of the powertrain architecture.

Recent years have seen a focus on optimizing the integration of battery systems and power electronics. The unique layout of the W16 engine has necessitated innovative solutions for battery placement and cooling. Engineers have experimented with various configurations, including distributed battery packs and advanced thermal management systems that leverage the engine's existing cooling infrastructure.

As of 2023, the latest W16 hybrid concepts are pushing the boundaries of electrification. Some designs are exploring the possibility of using the electric motors not just for supplementary power, but as the primary drive units, with the W16 engine serving as a range extender or high-performance boost option. This represents a paradigm shift in the role of the combustion engine within the hybrid powertrain.

The evolution of W16 hybridization reflects broader trends in the automotive industry towards electrification and sustainable performance. It demonstrates the ongoing efforts to preserve the legacy of iconic engines while adapting to the demands of a changing automotive landscape.

The hybridization journey of the W16 engine began with preliminary studies in the early 2010s, as automakers sought ways to comply with stricter emissions regulations without sacrificing the power and prestige associated with large-displacement engines. The first conceptual designs for a W16 hybrid system emerged around 2015, focusing on integrating electric motors to supplement the combustion engine's output.

By 2018, prototype W16 hybrid powertrains were undergoing rigorous testing. These early systems typically employed a parallel hybrid configuration, where an electric motor was coupled to the transmission, allowing for both electric-only operation at low speeds and power boosting during high-performance driving. This approach presented significant challenges in terms of packaging and thermal management, given the already complex nature of the W16 engine.

The evolution continued with the development of more advanced hybrid systems around 2020. These newer iterations explored the potential of integrating multiple electric motors, with some designs placing motors directly on the axles to provide all-wheel drive capability and improved torque vectoring. This marked a shift towards a more holistic approach to hybridization, where the electric components were not merely add-ons but integral parts of the powertrain architecture.

Recent years have seen a focus on optimizing the integration of battery systems and power electronics. The unique layout of the W16 engine has necessitated innovative solutions for battery placement and cooling. Engineers have experimented with various configurations, including distributed battery packs and advanced thermal management systems that leverage the engine's existing cooling infrastructure.

As of 2023, the latest W16 hybrid concepts are pushing the boundaries of electrification. Some designs are exploring the possibility of using the electric motors not just for supplementary power, but as the primary drive units, with the W16 engine serving as a range extender or high-performance boost option. This represents a paradigm shift in the role of the combustion engine within the hybrid powertrain.

The evolution of W16 hybridization reflects broader trends in the automotive industry towards electrification and sustainable performance. It demonstrates the ongoing efforts to preserve the legacy of iconic engines while adapting to the demands of a changing automotive landscape.

Market for Hybrid Supercars

The market for hybrid supercars has experienced significant growth in recent years, driven by increasing environmental concerns, stricter emissions regulations, and a growing demand for high-performance vehicles with improved fuel efficiency. This segment represents a unique intersection of luxury, performance, and sustainability, appealing to affluent consumers who seek cutting-edge technology and eco-friendly options without compromising on power and prestige.

Major automotive manufacturers and boutique supercar brands have recognized the potential of this market, leading to a surge in hybrid supercar offerings. Companies like Ferrari, McLaren, Porsche, and Koenigsegg have introduced hybrid models that combine powerful internal combustion engines with electric motors, delivering exceptional performance while reducing fuel consumption and emissions.

The global hybrid supercar market is expected to continue its upward trajectory, with projections indicating substantial growth over the next decade. This expansion is fueled by advancements in hybrid powertrain technology, lightweight materials, and energy storage systems, which are enabling manufacturers to create increasingly efficient and powerful vehicles.

Consumer demand for hybrid supercars is particularly strong in regions with stringent emissions regulations and high environmental awareness, such as Europe and parts of North America. Additionally, emerging markets in Asia, particularly China, are showing increased interest in these high-end, technologically advanced vehicles.

The integration of W16 engines into hybrid powertrains represents a significant technological challenge and opportunity within this market. While W16 engines are known for their immense power output, their complexity and fuel consumption have traditionally limited their application. Hybridization offers a pathway to maintain the performance characteristics of W16 engines while addressing efficiency and emissions concerns.

However, the market for W16 hybrid supercars remains niche due to the extreme engineering requirements and high production costs associated with these powertrains. Only a handful of manufacturers, most notably Bugatti, have the expertise and resources to develop such systems. The potential market for W16 hybrid supercars is likely to remain limited to ultra-high-net-worth individuals and collectors who value exclusivity and cutting-edge technology.

Despite the challenges, the development of W16 hybrid powertrains could drive innovation in the broader hybrid supercar market, potentially leading to advancements in power density, thermal management, and energy recovery systems that could benefit a wider range of hybrid vehicle applications.

Major automotive manufacturers and boutique supercar brands have recognized the potential of this market, leading to a surge in hybrid supercar offerings. Companies like Ferrari, McLaren, Porsche, and Koenigsegg have introduced hybrid models that combine powerful internal combustion engines with electric motors, delivering exceptional performance while reducing fuel consumption and emissions.

The global hybrid supercar market is expected to continue its upward trajectory, with projections indicating substantial growth over the next decade. This expansion is fueled by advancements in hybrid powertrain technology, lightweight materials, and energy storage systems, which are enabling manufacturers to create increasingly efficient and powerful vehicles.

Consumer demand for hybrid supercars is particularly strong in regions with stringent emissions regulations and high environmental awareness, such as Europe and parts of North America. Additionally, emerging markets in Asia, particularly China, are showing increased interest in these high-end, technologically advanced vehicles.

The integration of W16 engines into hybrid powertrains represents a significant technological challenge and opportunity within this market. While W16 engines are known for their immense power output, their complexity and fuel consumption have traditionally limited their application. Hybridization offers a pathway to maintain the performance characteristics of W16 engines while addressing efficiency and emissions concerns.

However, the market for W16 hybrid supercars remains niche due to the extreme engineering requirements and high production costs associated with these powertrains. Only a handful of manufacturers, most notably Bugatti, have the expertise and resources to develop such systems. The potential market for W16 hybrid supercars is likely to remain limited to ultra-high-net-worth individuals and collectors who value exclusivity and cutting-edge technology.

Despite the challenges, the development of W16 hybrid powertrains could drive innovation in the broader hybrid supercar market, potentially leading to advancements in power density, thermal management, and energy recovery systems that could benefit a wider range of hybrid vehicle applications.

W16 Hybridization Challenges

The hybridization of W16 engines presents several significant challenges that must be addressed for successful integration. One of the primary obstacles is the complexity of the powertrain system. W16 engines are already intricate machines, and adding hybrid components further complicates the design and engineering process. This increased complexity can lead to potential reliability issues and higher maintenance costs.

Space constraints pose another major challenge. W16 engines are typically large and occupy a substantial portion of the vehicle's engine bay. Integrating hybrid components such as electric motors, batteries, and power electronics requires careful packaging and may necessitate redesigning the vehicle's architecture to accommodate these additional elements without compromising performance or safety.

Thermal management is a critical concern in W16 hybridization. The combination of a powerful combustion engine and electric components generates significant heat. Developing an efficient cooling system that can handle the thermal loads from both power sources while maintaining optimal operating temperatures is essential for performance and longevity.

Weight distribution is another key challenge. The addition of hybrid components, particularly battery packs, can significantly alter the vehicle's weight balance. Engineers must carefully consider the placement of these components to maintain proper weight distribution and preserve the vehicle's handling characteristics.

Power management and control systems present complex integration challenges. Coordinating the operation of the W16 engine with electric motors requires sophisticated control algorithms to optimize performance, efficiency, and emissions. Developing a seamless power delivery system that effectively blends combustion and electric power sources is crucial for a satisfying driving experience.

Emissions compliance is an increasingly important factor in engine development. While hybridization can potentially reduce emissions, integrating this technology with a high-performance W16 engine while meeting stringent environmental regulations requires advanced engineering solutions and careful calibration.

Cost considerations also play a significant role in W16 hybridization. The development and production costs associated with integrating hybrid technology into an already expensive engine platform can be substantial. Balancing performance gains with economic viability is a delicate challenge that manufacturers must navigate.

Lastly, maintaining the character and appeal of W16-powered vehicles while incorporating hybrid technology is a unique challenge. These engines are often chosen for their distinctive sound and power delivery characteristics. Preserving these qualities while embracing electrification requires innovative engineering approaches to ensure that the hybrid W16 retains its appeal to enthusiasts and customers.

Space constraints pose another major challenge. W16 engines are typically large and occupy a substantial portion of the vehicle's engine bay. Integrating hybrid components such as electric motors, batteries, and power electronics requires careful packaging and may necessitate redesigning the vehicle's architecture to accommodate these additional elements without compromising performance or safety.

Thermal management is a critical concern in W16 hybridization. The combination of a powerful combustion engine and electric components generates significant heat. Developing an efficient cooling system that can handle the thermal loads from both power sources while maintaining optimal operating temperatures is essential for performance and longevity.

Weight distribution is another key challenge. The addition of hybrid components, particularly battery packs, can significantly alter the vehicle's weight balance. Engineers must carefully consider the placement of these components to maintain proper weight distribution and preserve the vehicle's handling characteristics.

Power management and control systems present complex integration challenges. Coordinating the operation of the W16 engine with electric motors requires sophisticated control algorithms to optimize performance, efficiency, and emissions. Developing a seamless power delivery system that effectively blends combustion and electric power sources is crucial for a satisfying driving experience.

Emissions compliance is an increasingly important factor in engine development. While hybridization can potentially reduce emissions, integrating this technology with a high-performance W16 engine while meeting stringent environmental regulations requires advanced engineering solutions and careful calibration.

Cost considerations also play a significant role in W16 hybridization. The development and production costs associated with integrating hybrid technology into an already expensive engine platform can be substantial. Balancing performance gains with economic viability is a delicate challenge that manufacturers must navigate.

Lastly, maintaining the character and appeal of W16-powered vehicles while incorporating hybrid technology is a unique challenge. These engines are often chosen for their distinctive sound and power delivery characteristics. Preserving these qualities while embracing electrification requires innovative engineering approaches to ensure that the hybrid W16 retains its appeal to enthusiasts and customers.

W16 Hybrid Integration

01 Hybrid powertrain integration for W16 engines

Integration of hybrid technology into W16 engines, combining the power of internal combustion with electric motors. This hybridization aims to improve fuel efficiency, reduce emissions, and enhance overall performance. The system may include regenerative braking, electric assist, and pure electric driving modes.- Hybrid powertrain integration for W16 engines: Integration of hybrid technology with W16 engines to improve fuel efficiency and performance. This involves combining the W16 internal combustion engine with electric motors, batteries, and power management systems to create a hybrid powertrain. The hybrid system can provide additional power during acceleration and allow for electric-only operation at low speeds.

- Energy recovery systems for W16 hybrid engines: Development of energy recovery systems specifically designed for W16 hybrid engines. These systems capture and store energy typically lost during braking or deceleration, converting it into electrical energy for later use. This may include regenerative braking systems and kinetic energy recovery systems (KERS) adapted for the unique configuration of W16 engines.

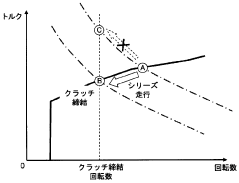

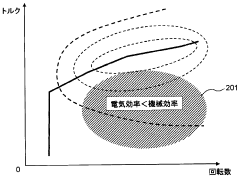

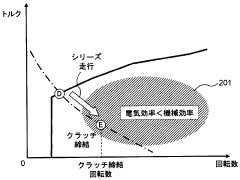

- Control strategies for W16 hybrid powertrains: Advanced control strategies and algorithms for managing power distribution between the W16 engine and electric components in hybrid configurations. These strategies optimize performance, fuel efficiency, and emissions by intelligently controlling the interaction between the internal combustion engine and electric motors based on driving conditions and power demands.

- Thermal management in W16 hybrid systems: Innovative thermal management solutions for W16 hybrid engines to address the increased heat generation from both the internal combustion engine and electric components. This includes advanced cooling systems, heat exchangers, and thermal regulation strategies to maintain optimal operating temperatures for all powertrain components, ensuring reliability and efficiency.

- Lightweight materials and designs for W16 hybrid engines: Application of lightweight materials and innovative designs to offset the additional weight of hybrid components in W16 engines. This involves the use of advanced alloys, composites, and optimized structural designs to reduce overall vehicle weight while maintaining the strength and durability required for high-performance applications.

02 Energy recovery and storage systems for W16 hybrid engines

Development of advanced energy recovery and storage systems specifically designed for W16 hybrid engines. These systems may include high-capacity batteries, supercapacitors, or other energy storage devices to capture and reuse energy during vehicle operation, improving overall efficiency.Expand Specific Solutions03 Control strategies for W16 hybrid powertrains

Implementation of sophisticated control strategies to optimize the performance of W16 hybrid powertrains. These strategies may involve advanced algorithms for power distribution between the internal combustion engine and electric motors, as well as adaptive systems that learn from driving patterns to maximize efficiency.Expand Specific Solutions04 Thermal management in W16 hybrid engines

Development of innovative thermal management solutions for W16 hybrid engines. These systems aim to efficiently manage heat generated by both the internal combustion engine and electric components, ensuring optimal performance and longevity of the hybrid powertrain.Expand Specific Solutions05 Lightweight materials and design for W16 hybrid engines

Utilization of advanced lightweight materials and design techniques to optimize the weight and packaging of W16 hybrid engines. This approach aims to offset the additional weight of hybrid components while maintaining or improving performance and efficiency.Expand Specific Solutions

Key W16 Hybrid Developers

The W16 engine hybridization market is in an early growth stage, characterized by increasing interest in high-performance hybrid powertrains. While the market size remains relatively small, it is expected to expand as luxury and sports car manufacturers explore electrification options. The technology is still evolving, with varying levels of maturity among key players. Companies like Volkswagen Group (through Bugatti) have pioneered W16 engines, while BMW, Robert Bosch, and ZF Friedrichshafen are advancing hybrid technologies. Chinese automakers like BYD and Geely are also investing in hybrid powertrains, potentially bringing new approaches to W16 hybridization. Overall, the field is marked by ongoing research and development, with full integration challenges still being addressed by industry leaders.

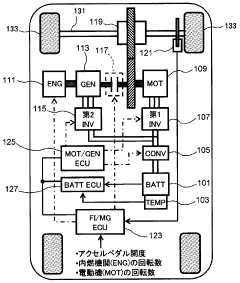

Robert Bosch GmbH

Technical Solution: Bosch's approach to W16 engine hybridization centers on their eAxle technology, which integrates the electric motor, power electronics, and transmission into a compact unit. For W16 applications, Bosch has developed a high-performance version of the eAxle capable of delivering up to 300 kW of power[2]. Their system employs advanced 800-volt technology, enabling faster charging and improved efficiency. Bosch's solution includes intelligent power distribution algorithms that optimize the balance between electric and combustion power sources, maximizing performance while minimizing fuel consumption. They have also developed specialized cooling systems to manage the high heat output of both the W16 engine and the electric components[4].

Strengths: Highly integrated system reduces overall weight and complexity. Advanced 800-volt technology improves efficiency and charging speed. Weaknesses: May require significant modifications to existing W16 engine designs for integration.

Bayerische Motoren Werke AG

Technical Solution: BMW's approach to W16 engine hybridization focuses on integrating electric motors with their high-performance combustion engines. They employ a modular hybrid system that can be adapted to various engine configurations, including the W16. The system utilizes a compact electric motor positioned between the engine and transmission, allowing for power boosting and energy recuperation[1]. BMW's strategy involves advanced power electronics and battery management systems to optimize the interaction between the combustion engine and electric components. They have developed a sophisticated thermal management system to maintain optimal operating temperatures for both the W16 engine and the hybrid components, crucial for maintaining performance and efficiency[3].

Strengths: Modular design allows for flexible integration across different engine types. Advanced thermal management enhances overall system efficiency. Weaknesses: The added complexity of the hybrid system may increase maintenance requirements and costs.

Core W16 Hybrid Patents

Hybrid vehicle and method for controlling same

PatentWO2011074482A1

Innovation

- The hybrid vehicle employs an internal combustion engine, a generator, an electric motor, and a power transmission connecting/disconnecting unit controlled by an ECU to match the rotation speed and output of the internal combustion engine with the required output, ensuring smooth transition by operating on the best fuel efficiency line or equal output line, and engaging the power transmission only when the speeds match.

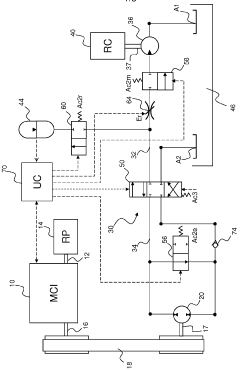

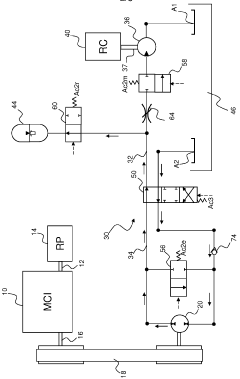

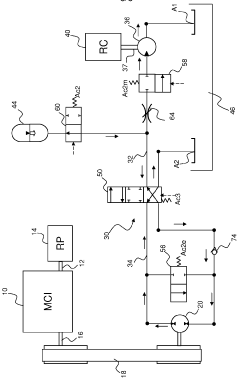

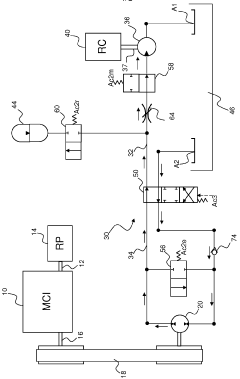

Light hydraulic hybridization and power take-off drive on an industrial engine

PatentWO2011117493A1

Innovation

- A light hybrid motorization device combining an internal combustion engine with a pump/motor unit, a hydraulic circuit, a high-pressure accumulator, and a low-pressure reservoir, featuring a main hydraulic distributor, hydraulic clutch distributor, pressure regulator, and a computer for controlling the device's operational states to manage torque and speed independently of the engine's rotation.

Emissions Regulations Impact

The impact of emissions regulations on W16 engine hybridization is significant and multifaceted. As global environmental concerns intensify, governments worldwide are implementing increasingly stringent emissions standards for vehicles. These regulations are driving the automotive industry towards cleaner and more efficient powertrain solutions, including the hybridization of high-performance engines like the W16.

One of the primary challenges faced by W16 engines in meeting emissions regulations is their inherently high fuel consumption and CO2 emissions. The complex design and large displacement of these engines, while providing exceptional power output, also result in substantial environmental impact. Hybridization offers a potential solution to this problem by integrating electric propulsion systems, which can significantly reduce overall emissions and improve fuel efficiency.

The integration of hybrid technology into W16 engines presents both opportunities and challenges. On the positive side, hybrid systems can provide instant torque at low speeds, reducing the need for the W16 engine to operate in less efficient ranges. This can lead to lower emissions during urban driving and improved overall fuel economy. Additionally, regenerative braking systems can capture and store energy that would otherwise be lost, further enhancing efficiency.

However, the implementation of hybrid technology in W16 engines also faces several hurdles. The added weight of batteries and electric motors can potentially offset some of the efficiency gains, particularly in high-performance applications where power-to-weight ratio is crucial. Engineers must carefully balance the hybrid system's components to maintain the vehicle's performance characteristics while meeting emissions targets.

Furthermore, the complexity of integrating hybrid systems with W16 engines poses significant technical challenges. The sophisticated engine management systems required to seamlessly blend combustion and electric power must be developed and fine-tuned to ensure optimal performance and emissions compliance across various driving conditions.

The emissions regulations also impact the design and materials used in W16 hybrid powertrains. Advanced catalytic converters, particulate filters, and other exhaust after-treatment systems must be incorporated to meet stringent emissions standards. This may require redesigning certain aspects of the engine and exhaust system, potentially affecting the iconic sound and character associated with W16 engines.

As regulations continue to evolve, manufacturers developing W16 hybrid systems must anticipate future standards and design their powertrains with adaptability in mind. This forward-thinking approach is essential to ensure that vehicles equipped with W16 hybrid engines remain compliant and competitive in the market for years to come.

One of the primary challenges faced by W16 engines in meeting emissions regulations is their inherently high fuel consumption and CO2 emissions. The complex design and large displacement of these engines, while providing exceptional power output, also result in substantial environmental impact. Hybridization offers a potential solution to this problem by integrating electric propulsion systems, which can significantly reduce overall emissions and improve fuel efficiency.

The integration of hybrid technology into W16 engines presents both opportunities and challenges. On the positive side, hybrid systems can provide instant torque at low speeds, reducing the need for the W16 engine to operate in less efficient ranges. This can lead to lower emissions during urban driving and improved overall fuel economy. Additionally, regenerative braking systems can capture and store energy that would otherwise be lost, further enhancing efficiency.

However, the implementation of hybrid technology in W16 engines also faces several hurdles. The added weight of batteries and electric motors can potentially offset some of the efficiency gains, particularly in high-performance applications where power-to-weight ratio is crucial. Engineers must carefully balance the hybrid system's components to maintain the vehicle's performance characteristics while meeting emissions targets.

Furthermore, the complexity of integrating hybrid systems with W16 engines poses significant technical challenges. The sophisticated engine management systems required to seamlessly blend combustion and electric power must be developed and fine-tuned to ensure optimal performance and emissions compliance across various driving conditions.

The emissions regulations also impact the design and materials used in W16 hybrid powertrains. Advanced catalytic converters, particulate filters, and other exhaust after-treatment systems must be incorporated to meet stringent emissions standards. This may require redesigning certain aspects of the engine and exhaust system, potentially affecting the iconic sound and character associated with W16 engines.

As regulations continue to evolve, manufacturers developing W16 hybrid systems must anticipate future standards and design their powertrains with adaptability in mind. This forward-thinking approach is essential to ensure that vehicles equipped with W16 hybrid engines remain compliant and competitive in the market for years to come.

Performance vs Efficiency

The hybridization of W16 engines presents a complex interplay between performance and efficiency. Traditional W16 engines are renowned for their exceptional power output and smooth operation, making them a preferred choice for high-performance luxury vehicles. However, these engines typically suffer from poor fuel efficiency and high emissions, which are increasingly problematic in today's environmentally conscious automotive landscape.

Hybridization offers a potential solution to this dilemma by combining the raw power of the W16 engine with the efficiency benefits of electric propulsion. In terms of performance, hybrid W16 systems can potentially deliver even greater power outputs than their conventional counterparts. The electric motors can provide instant torque, filling in the power gaps at lower RPMs where internal combustion engines are less efficient. This results in improved acceleration and overall responsiveness.

Moreover, the integration of electric motors allows for more flexible power distribution, enabling advanced torque vectoring systems that can enhance handling and stability. This is particularly beneficial for large, heavy vehicles that typically employ W16 engines, as it can mitigate some of the inherent challenges associated with their size and weight.

On the efficiency front, hybridization offers several advantages. The electric motors can take over propulsion duties during low-speed urban driving, significantly reducing fuel consumption and emissions in stop-and-go traffic. Regenerative braking systems can recapture energy typically lost during deceleration, further improving overall efficiency. Additionally, the hybrid system allows for engine downsizing or cylinder deactivation strategies, where part of the W16 engine can be shut off during cruising, with the electric motors providing supplementary power as needed.

However, the integration of hybrid technology into W16 engines is not without challenges. The additional weight of batteries and electric motors can offset some of the efficiency gains, particularly in high-performance applications where weight is a critical factor. Balancing the power distribution between the combustion engine and electric motors to optimize both performance and efficiency requires sophisticated control systems and careful calibration.

Furthermore, the complexity of packaging a hybrid system alongside an already large W16 engine presents significant engineering challenges. Heat management becomes more critical, as both the combustion engine and electric components generate substantial thermal loads that must be efficiently dissipated.

In conclusion, while hybridization of W16 engines offers promising avenues for improving both performance and efficiency, it requires careful engineering to balance these often-competing objectives. The ultimate success of such systems will depend on innovative integration strategies that can maximize the strengths of both combustion and electric technologies while minimizing their respective drawbacks.

Hybridization offers a potential solution to this dilemma by combining the raw power of the W16 engine with the efficiency benefits of electric propulsion. In terms of performance, hybrid W16 systems can potentially deliver even greater power outputs than their conventional counterparts. The electric motors can provide instant torque, filling in the power gaps at lower RPMs where internal combustion engines are less efficient. This results in improved acceleration and overall responsiveness.

Moreover, the integration of electric motors allows for more flexible power distribution, enabling advanced torque vectoring systems that can enhance handling and stability. This is particularly beneficial for large, heavy vehicles that typically employ W16 engines, as it can mitigate some of the inherent challenges associated with their size and weight.

On the efficiency front, hybridization offers several advantages. The electric motors can take over propulsion duties during low-speed urban driving, significantly reducing fuel consumption and emissions in stop-and-go traffic. Regenerative braking systems can recapture energy typically lost during deceleration, further improving overall efficiency. Additionally, the hybrid system allows for engine downsizing or cylinder deactivation strategies, where part of the W16 engine can be shut off during cruising, with the electric motors providing supplementary power as needed.

However, the integration of hybrid technology into W16 engines is not without challenges. The additional weight of batteries and electric motors can offset some of the efficiency gains, particularly in high-performance applications where weight is a critical factor. Balancing the power distribution between the combustion engine and electric motors to optimize both performance and efficiency requires sophisticated control systems and careful calibration.

Furthermore, the complexity of packaging a hybrid system alongside an already large W16 engine presents significant engineering challenges. Heat management becomes more critical, as both the combustion engine and electric components generate substantial thermal loads that must be efficiently dissipated.

In conclusion, while hybridization of W16 engines offers promising avenues for improving both performance and efficiency, it requires careful engineering to balance these often-competing objectives. The ultimate success of such systems will depend on innovative integration strategies that can maximize the strengths of both combustion and electric technologies while minimizing their respective drawbacks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!