W16 Engine Lubrication System Design For High RPM Operation

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

W16 Engine Lubrication Background and Objectives

The W16 engine represents a pinnacle of automotive engineering, combining power, performance, and complexity in a single powerplant. The lubrication system for such an engine, especially when designed for high RPM operation, is a critical component that demands meticulous attention to detail and innovative solutions. The background of W16 engine lubrication stems from the need to manage the intense heat and friction generated by 16 cylinders operating at extreme speeds.

Historically, the development of W16 engines can be traced back to the early 20th century, with notable implementations in aviation and later in high-performance automobiles. The lubrication challenges faced by these engines have evolved alongside advancements in materials science, fluid dynamics, and precision manufacturing techniques. As engine speeds have increased, so too has the complexity of lubrication systems required to maintain optimal performance and longevity.

The primary objective of a W16 engine lubrication system for high RPM operation is to ensure consistent and adequate oil supply to all critical components under extreme conditions. This includes maintaining proper oil pressure, managing oil temperature, and minimizing oil aeration and foaming. Additionally, the system must be capable of rapid oil circulation to keep pace with the engine's high-speed operation while also providing effective scavenging to prevent oil accumulation in the crankcase.

Another crucial goal is to minimize parasitic losses associated with the lubrication system. As engine speeds increase, the power required to drive the oil pump and overcome fluid friction becomes significant. Therefore, designing an efficient lubrication system that doesn't excessively tax the engine's output is paramount. This often involves the use of variable-displacement oil pumps, advanced oil formulations, and optimized oil passage geometries.

Durability and reliability are also key objectives in W16 engine lubrication system design. The system must be capable of withstanding prolonged high-speed operation without failure, which necessitates careful consideration of materials, sealing technologies, and filtration methods. Furthermore, the lubrication system should contribute to the overall engine's thermal management, aiding in heat dissipation from critical components such as pistons, cylinder walls, and bearings.

In the context of modern automotive engineering, the lubrication system must also address environmental concerns and regulatory requirements. This includes developing systems that minimize oil consumption, reduce emissions related to oil burning, and potentially incorporate oil quality monitoring to optimize service intervals. The integration of advanced sensors and control systems to dynamically adjust lubrication parameters based on engine load and speed is becoming increasingly important in achieving these objectives.

Historically, the development of W16 engines can be traced back to the early 20th century, with notable implementations in aviation and later in high-performance automobiles. The lubrication challenges faced by these engines have evolved alongside advancements in materials science, fluid dynamics, and precision manufacturing techniques. As engine speeds have increased, so too has the complexity of lubrication systems required to maintain optimal performance and longevity.

The primary objective of a W16 engine lubrication system for high RPM operation is to ensure consistent and adequate oil supply to all critical components under extreme conditions. This includes maintaining proper oil pressure, managing oil temperature, and minimizing oil aeration and foaming. Additionally, the system must be capable of rapid oil circulation to keep pace with the engine's high-speed operation while also providing effective scavenging to prevent oil accumulation in the crankcase.

Another crucial goal is to minimize parasitic losses associated with the lubrication system. As engine speeds increase, the power required to drive the oil pump and overcome fluid friction becomes significant. Therefore, designing an efficient lubrication system that doesn't excessively tax the engine's output is paramount. This often involves the use of variable-displacement oil pumps, advanced oil formulations, and optimized oil passage geometries.

Durability and reliability are also key objectives in W16 engine lubrication system design. The system must be capable of withstanding prolonged high-speed operation without failure, which necessitates careful consideration of materials, sealing technologies, and filtration methods. Furthermore, the lubrication system should contribute to the overall engine's thermal management, aiding in heat dissipation from critical components such as pistons, cylinder walls, and bearings.

In the context of modern automotive engineering, the lubrication system must also address environmental concerns and regulatory requirements. This includes developing systems that minimize oil consumption, reduce emissions related to oil burning, and potentially incorporate oil quality monitoring to optimize service intervals. The integration of advanced sensors and control systems to dynamically adjust lubrication parameters based on engine load and speed is becoming increasingly important in achieving these objectives.

High-Performance Engine Market Analysis

The high-performance engine market has experienced significant growth in recent years, driven by increasing demand for luxury sports cars, racing vehicles, and high-end automotive applications. This market segment is characterized by a focus on power, efficiency, and cutting-edge technology, with W16 engines representing the pinnacle of performance and engineering prowess.

The global high-performance engine market was valued at approximately $28 billion in 2020 and is projected to reach $36 billion by 2025, growing at a CAGR of 5.2% during the forecast period. This growth is primarily fueled by rising disposable incomes, a growing passion for motorsports, and technological advancements in engine design and materials.

Within this market, W16 engines occupy a niche but highly prestigious position. These engines are primarily used in ultra-luxury and hypercar segments, with Bugatti being the most prominent manufacturer. The demand for W16 engines, while limited in volume, commands premium pricing and drives significant research and development investments.

The market for high-performance engines, including W16 configurations, is geographically concentrated in regions with strong automotive industries and high consumer purchasing power. Europe, particularly Germany and Italy, leads in terms of production and technological innovation. North America follows closely, with a strong presence in the racing and muscle car segments. Emerging markets in Asia, especially China, are showing increasing interest in high-performance vehicles, presenting new growth opportunities.

Key trends shaping the high-performance engine market include the push for improved fuel efficiency without compromising power, the integration of hybrid and electric technologies, and the use of advanced materials to reduce weight and enhance durability. For W16 engines specifically, there is a growing focus on optimizing lubrication systems to handle extreme RPM ranges, as evidenced by the need for specialized designs in high-speed operations.

Challenges facing the high-performance engine market include stringent emissions regulations, the shift towards electrification, and the high costs associated with research and development. However, these challenges also drive innovation, pushing manufacturers to develop more efficient and technologically advanced engines.

The competitive landscape is dominated by established automotive giants and specialized high-performance engine manufacturers. Key players include Volkswagen Group (parent company of Bugatti), Ferrari, McLaren, and Koenigsegg, among others. These companies continually invest in R&D to maintain their competitive edge and meet the evolving demands of discerning customers.

The global high-performance engine market was valued at approximately $28 billion in 2020 and is projected to reach $36 billion by 2025, growing at a CAGR of 5.2% during the forecast period. This growth is primarily fueled by rising disposable incomes, a growing passion for motorsports, and technological advancements in engine design and materials.

Within this market, W16 engines occupy a niche but highly prestigious position. These engines are primarily used in ultra-luxury and hypercar segments, with Bugatti being the most prominent manufacturer. The demand for W16 engines, while limited in volume, commands premium pricing and drives significant research and development investments.

The market for high-performance engines, including W16 configurations, is geographically concentrated in regions with strong automotive industries and high consumer purchasing power. Europe, particularly Germany and Italy, leads in terms of production and technological innovation. North America follows closely, with a strong presence in the racing and muscle car segments. Emerging markets in Asia, especially China, are showing increasing interest in high-performance vehicles, presenting new growth opportunities.

Key trends shaping the high-performance engine market include the push for improved fuel efficiency without compromising power, the integration of hybrid and electric technologies, and the use of advanced materials to reduce weight and enhance durability. For W16 engines specifically, there is a growing focus on optimizing lubrication systems to handle extreme RPM ranges, as evidenced by the need for specialized designs in high-speed operations.

Challenges facing the high-performance engine market include stringent emissions regulations, the shift towards electrification, and the high costs associated with research and development. However, these challenges also drive innovation, pushing manufacturers to develop more efficient and technologically advanced engines.

The competitive landscape is dominated by established automotive giants and specialized high-performance engine manufacturers. Key players include Volkswagen Group (parent company of Bugatti), Ferrari, McLaren, and Koenigsegg, among others. These companies continually invest in R&D to maintain their competitive edge and meet the evolving demands of discerning customers.

Current Challenges in High-RPM Lubrication

High-RPM operation in W16 engines presents significant challenges for lubrication systems, pushing the boundaries of conventional designs. The primary issue stems from the extreme centrifugal forces generated at high rotational speeds, which can cause oil to be flung away from critical components, leading to inadequate lubrication and potential engine failure.

One of the key challenges is maintaining proper oil pressure and distribution throughout the engine. As RPM increases, the oil pump must work harder to overcome the centrifugal forces and ensure that oil reaches all necessary parts. This often requires redesigning the oil pump and its drive system to handle higher pressures and flow rates without cavitation or excessive power consumption.

Another critical concern is oil aeration and foaming. At high RPMs, the rapid movement of engine components can introduce air into the oil, reducing its lubricating properties and potentially causing bearing damage. Developing effective air separation systems and selecting appropriate oil formulations that resist foaming become crucial in addressing this issue.

Heat management presents a significant challenge in high-RPM lubrication systems. The increased friction and mechanical work generate substantial heat, which must be efficiently removed to prevent oil degradation and maintain its viscosity. This often necessitates the implementation of advanced oil cooling systems and the use of high-performance synthetic oils capable of withstanding extreme temperatures.

Oil return and scavenging systems face particular difficulties in high-RPM operations. The strong centrifugal forces can prevent oil from properly draining back to the sump, leading to oil starvation in critical areas. Designing effective scavenge pumps and strategically placing return passages becomes essential to ensure proper oil circulation and prevent oil accumulation in undesired areas.

Bearing design and lubrication present unique challenges in W16 engines operating at high RPMs. The extreme speeds can lead to oil film breakdown and metal-to-metal contact, potentially causing catastrophic failure. Developing bearings with optimized clearances, surface treatments, and materials that can maintain a stable oil film under these conditions is crucial.

Furthermore, the complexity of the W16 engine layout adds to the lubrication challenges. Ensuring uniform oil distribution across all cylinders and moving parts requires intricate oil passage designs and careful consideration of flow dynamics. This complexity often leads to increased manufacturing costs and potential reliability issues if not properly addressed.

Lastly, the development of advanced sealing technologies becomes critical in high-RPM W16 engines. Traditional seals may struggle to contain oil under the extreme pressures and temperatures generated, leading to leaks and potential engine damage. Innovating new sealing materials and designs that can withstand these harsh conditions while maintaining effectiveness is an ongoing challenge in the field.

One of the key challenges is maintaining proper oil pressure and distribution throughout the engine. As RPM increases, the oil pump must work harder to overcome the centrifugal forces and ensure that oil reaches all necessary parts. This often requires redesigning the oil pump and its drive system to handle higher pressures and flow rates without cavitation or excessive power consumption.

Another critical concern is oil aeration and foaming. At high RPMs, the rapid movement of engine components can introduce air into the oil, reducing its lubricating properties and potentially causing bearing damage. Developing effective air separation systems and selecting appropriate oil formulations that resist foaming become crucial in addressing this issue.

Heat management presents a significant challenge in high-RPM lubrication systems. The increased friction and mechanical work generate substantial heat, which must be efficiently removed to prevent oil degradation and maintain its viscosity. This often necessitates the implementation of advanced oil cooling systems and the use of high-performance synthetic oils capable of withstanding extreme temperatures.

Oil return and scavenging systems face particular difficulties in high-RPM operations. The strong centrifugal forces can prevent oil from properly draining back to the sump, leading to oil starvation in critical areas. Designing effective scavenge pumps and strategically placing return passages becomes essential to ensure proper oil circulation and prevent oil accumulation in undesired areas.

Bearing design and lubrication present unique challenges in W16 engines operating at high RPMs. The extreme speeds can lead to oil film breakdown and metal-to-metal contact, potentially causing catastrophic failure. Developing bearings with optimized clearances, surface treatments, and materials that can maintain a stable oil film under these conditions is crucial.

Furthermore, the complexity of the W16 engine layout adds to the lubrication challenges. Ensuring uniform oil distribution across all cylinders and moving parts requires intricate oil passage designs and careful consideration of flow dynamics. This complexity often leads to increased manufacturing costs and potential reliability issues if not properly addressed.

Lastly, the development of advanced sealing technologies becomes critical in high-RPM W16 engines. Traditional seals may struggle to contain oil under the extreme pressures and temperatures generated, leading to leaks and potential engine damage. Innovating new sealing materials and designs that can withstand these harsh conditions while maintaining effectiveness is an ongoing challenge in the field.

Existing High-RPM Lubrication Solutions

01 High-pressure oil supply system for high RPM operation

A high-pressure oil supply system is crucial for W16 engines operating at high RPMs. This system ensures adequate lubrication to critical components under extreme conditions, preventing wear and maintaining engine performance. It may include specialized pumps, pressure regulators, and oil passages designed to withstand high-speed operation.- High-pressure oil supply system for high RPM operation: A high-pressure oil supply system is crucial for W16 engines operating at high RPMs. This system ensures adequate lubrication to critical components under extreme conditions. It typically includes high-capacity oil pumps, pressure regulators, and efficient oil passages to maintain consistent oil flow and pressure throughout the engine, even at maximum engine speeds.

- Advanced oil cooling mechanisms for high-performance engines: W16 engines operating at high RPMs generate significant heat, necessitating advanced oil cooling mechanisms. These may include larger oil coolers, multiple cooling circuits, or innovative heat exchanger designs. Effective oil cooling helps maintain optimal oil viscosity and prevents oil degradation, ensuring proper lubrication and engine protection during high-speed operation.

- Optimized oil distribution and scavenging systems: Efficient oil distribution and scavenging systems are essential for W16 engines at high RPMs. These systems ensure that oil reaches all critical components quickly and is effectively removed from the crankcase to prevent oil starvation or foaming. Advanced designs may include multiple scavenge pumps, strategically placed oil galleries, and optimized oil return pathways.

- Specialized lubricants for high-performance W16 engines: High-performance W16 engines operating at extreme RPMs require specialized lubricants. These oils are formulated to maintain their viscosity and protective properties under high temperatures and shear forces. They may contain advanced additives to reduce friction, improve heat dissipation, and protect against wear in high-stress conditions.

- Electronic monitoring and control of lubrication systems: Advanced electronic monitoring and control systems are implemented in W16 engines to optimize lubrication at high RPMs. These systems may include oil pressure and temperature sensors, adaptive oil pump control, and real-time adjustment of oil flow based on engine load and speed. This ensures optimal lubrication under varying operating conditions and helps prevent potential lubrication-related failures.

02 Advanced oil cooling mechanisms for high-performance engines

Efficient oil cooling is essential for W16 engines during high RPM operation. Advanced cooling mechanisms, such as oil-to-water heat exchangers or dedicated oil radiators, help maintain optimal oil temperature and viscosity. This ensures proper lubrication and prevents oil degradation under extreme operating conditions.Expand Specific Solutions03 Optimized oil flow distribution for multi-bank engines

W16 engines require carefully designed oil flow distribution systems to ensure all cylinders and components receive adequate lubrication at high RPMs. This may involve specialized oil galleries, flow control valves, and strategically placed oil jets to target critical areas such as cylinder walls, pistons, and valve trains.Expand Specific Solutions04 Adaptive lubrication control systems for varying engine loads

Adaptive lubrication control systems are implemented to optimize oil delivery based on engine load and RPM. These systems may use sensors and electronic control units to adjust oil pressure, flow rates, and distribution in real-time, ensuring optimal lubrication across all operating conditions of the W16 engine.Expand Specific Solutions05 High-performance oil filtration and contamination management

Advanced oil filtration and contamination management systems are crucial for maintaining oil quality during high RPM operation of W16 engines. These may include high-flow oil filters, centrifugal oil cleaners, or magnetic particle collectors to remove debris and contaminants, ensuring clean oil circulation and prolonging engine life.Expand Specific Solutions

Key Players in High-Performance Engine Industry

The W16 engine lubrication system design for high RPM operation is in a competitive and evolving landscape. The industry is in a mature stage, with established players like Nissan, Honda, and Toyota leading in automotive engine technology. However, there's ongoing innovation in high-performance engines, particularly for luxury and racing applications. The market size is significant, driven by demand for high-performance vehicles and motorsports. Technologically, companies like Mercedes-Benz, Rolls-Royce, and Caterpillar are at the forefront, leveraging their extensive R&D capabilities. Specialized firms such as The Lubrizol Corp. and Hans Jensen Lubricators A/S contribute expertise in lubrication technology, crucial for high RPM operations.

Nissan Motor Co., Ltd.

Technical Solution: Nissan has developed a high-performance lubrication system suitable for W16 engines operating at high RPMs. Their system utilizes a hybrid dry sump configuration with multiple oil reservoirs to ensure consistent oil supply under various driving conditions[1]. Nissan's design incorporates a two-stage oil pump system: a high-volume, low-pressure stage for general circulation, and a high-pressure stage for critical components like bearings and valve train[3]. The system features advanced oil passage geometry optimized through computational fluid dynamics to minimize pressure drops and ensure efficient oil delivery at high engine speeds. Nissan has also implemented an innovative oil-air separator system to reduce oil foaming and maintain lubricant quality under extreme conditions[5]. Additionally, their technology includes an intelligent oil cooling system that adjusts based on engine load and ambient conditions to maintain optimal oil temperature.

Strengths: Versatile oil management for various driving conditions, efficient oil delivery at high RPMs, and intelligent thermal management. Weaknesses: Multi-stage pump system may increase complexity and potential points of failure.

Honda Motor Co., Ltd.

Technical Solution: Honda has engineered an advanced lubrication system applicable to W16 engines for high RPM operation. Their system employs a fully integrated dry sump design with multiple scavenge pumps strategically placed to ensure consistent oil supply under high G-forces[2]. Honda's technology incorporates a variable-displacement main oil pump that adjusts output based on engine speed and load, optimizing efficiency across the RPM range. The system features precision-machined oil galleries with specialized coatings to reduce friction and improve oil flow dynamics[4]. Honda has also developed an innovative air-oil separation system to minimize oil aeration at high engine speeds. Additionally, their lubrication technology includes active thermal management, using oil as a medium for targeted cooling of critical engine components[6].

Strengths: Excellent oil management under high G-forces, efficient oil pump design, and advanced thermal management. Weaknesses: Potential for increased system weight and complexity compared to simpler lubrication systems.

Innovative Lubrication Technologies for W16 Engines

Method of lubricating an internal combustion engine

PatentWO2015106083A1

Innovation

- A lubricating composition for compression-ignition internal combustion engines with a maximum laden mass over 2,700 kg, comprising an oil of lubricating viscosity, 1.5 wt % to 10 wt % ashless dispersant, 300 TBN or higher alkaline earth metal sulphonate detergent, 80 TBN or lower alkaline earth metal sulphonate detergent, and minimal phenolic-based detergent, optimized to reduce soot, deposits, and wear while maintaining cleanliness.

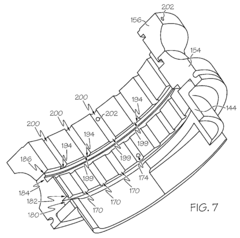

System for supplying oil from an oil source to a bearing assembly

PatentActiveEP2031261A3

Innovation

- A system with a forward and aft ring configuration, featuring axial and radial channels, annular wells, and dams, which allows for even circumferential distribution of lubricant to the cage rails and bearings, eliminating the need for anti-rotation pins and ensuring consistent lubrication regardless of ring orientation.

Thermal Management in High-RPM W16 Engines

Thermal management is a critical aspect of high-RPM W16 engine design, particularly in the context of lubrication system optimization. As these engines operate at extreme speeds, the heat generated can significantly impact performance, reliability, and longevity. Effective thermal management strategies are essential to maintain optimal oil temperatures and ensure proper lubrication throughout the engine.

One of the primary challenges in thermal management for high-RPM W16 engines is the rapid heat generation due to increased friction and combustion rates. The oil temperature can quickly rise to levels that compromise its lubricating properties, leading to increased wear and potential engine failure. To address this, advanced cooling systems are employed, often incorporating oil-to-water heat exchangers to efficiently dissipate heat from the lubricating oil.

The design of oil passages and galleries plays a crucial role in thermal management. Engineers must carefully optimize these pathways to ensure adequate oil flow to all critical components while minimizing heat buildup. This often involves the use of computational fluid dynamics (CFD) simulations to analyze oil flow patterns and identify potential hotspots within the engine.

Material selection is another key consideration in thermal management. High-performance alloys with superior heat dissipation properties are often used for engine components that are subjected to extreme temperatures. Additionally, thermal barrier coatings may be applied to certain surfaces to reduce heat transfer to the oil and maintain more consistent temperatures throughout the engine.

Advanced oil formulations also contribute significantly to thermal management in high-RPM W16 engines. Synthetic oils with high thermal stability and low volatility are typically used to withstand the extreme conditions. These oils maintain their viscosity and lubricating properties even at elevated temperatures, ensuring consistent protection across a wide operating range.

Innovative cooling techniques, such as piston cooling jets and targeted oil sprays, are often implemented to address localized heat buildup in critical areas. These systems direct precise streams of cooled oil to high-stress components, effectively managing temperatures in the most demanding regions of the engine.

Monitoring and control systems play a vital role in maintaining optimal thermal conditions. Advanced sensors and electronic control units continuously monitor oil temperatures and adjust cooling parameters in real-time. This dynamic approach to thermal management ensures that the engine operates within its ideal temperature range, maximizing performance and reliability even under the most demanding conditions.

One of the primary challenges in thermal management for high-RPM W16 engines is the rapid heat generation due to increased friction and combustion rates. The oil temperature can quickly rise to levels that compromise its lubricating properties, leading to increased wear and potential engine failure. To address this, advanced cooling systems are employed, often incorporating oil-to-water heat exchangers to efficiently dissipate heat from the lubricating oil.

The design of oil passages and galleries plays a crucial role in thermal management. Engineers must carefully optimize these pathways to ensure adequate oil flow to all critical components while minimizing heat buildup. This often involves the use of computational fluid dynamics (CFD) simulations to analyze oil flow patterns and identify potential hotspots within the engine.

Material selection is another key consideration in thermal management. High-performance alloys with superior heat dissipation properties are often used for engine components that are subjected to extreme temperatures. Additionally, thermal barrier coatings may be applied to certain surfaces to reduce heat transfer to the oil and maintain more consistent temperatures throughout the engine.

Advanced oil formulations also contribute significantly to thermal management in high-RPM W16 engines. Synthetic oils with high thermal stability and low volatility are typically used to withstand the extreme conditions. These oils maintain their viscosity and lubricating properties even at elevated temperatures, ensuring consistent protection across a wide operating range.

Innovative cooling techniques, such as piston cooling jets and targeted oil sprays, are often implemented to address localized heat buildup in critical areas. These systems direct precise streams of cooled oil to high-stress components, effectively managing temperatures in the most demanding regions of the engine.

Monitoring and control systems play a vital role in maintaining optimal thermal conditions. Advanced sensors and electronic control units continuously monitor oil temperatures and adjust cooling parameters in real-time. This dynamic approach to thermal management ensures that the engine operates within its ideal temperature range, maximizing performance and reliability even under the most demanding conditions.

Environmental Impact of High-Performance Lubricants

The environmental impact of high-performance lubricants used in W16 engine lubrication systems for high RPM operation is a critical consideration in the automotive industry. These specialized lubricants are designed to withstand extreme temperatures and pressures, providing optimal protection for engine components under demanding conditions. However, their production, use, and disposal can have significant environmental implications.

The manufacturing process of high-performance lubricants often involves the use of synthetic base oils and advanced additive packages. These components require energy-intensive production methods and may involve the use of potentially harmful chemicals. The extraction and refinement of raw materials for these lubricants can lead to habitat disruption, soil contamination, and greenhouse gas emissions.

During engine operation, high-performance lubricants may experience increased volatility and oil consumption compared to conventional lubricants. This can result in higher emissions of particulate matter and volatile organic compounds (VOCs), contributing to air pollution and potential health hazards. Additionally, the increased oil consumption may necessitate more frequent oil changes, leading to a larger volume of waste oil requiring proper disposal or recycling.

The disposal of used high-performance lubricants presents another environmental challenge. If not handled properly, these oils can contaminate soil and water sources, posing risks to ecosystems and human health. The presence of advanced additives in these lubricants may also complicate recycling processes, potentially reducing the efficiency of oil reclamation efforts.

However, it is important to note that high-performance lubricants can also offer environmental benefits. Their enhanced protection and longevity can extend engine life, reducing the need for premature replacements and the associated environmental impacts of manufacturing new engines. Furthermore, their improved efficiency can lead to reduced fuel consumption and lower overall emissions over the lifespan of the engine.

Efforts are being made to develop more environmentally friendly high-performance lubricants. These include the use of bio-based materials, biodegradable additives, and improved formulations that reduce oil consumption and emissions. Research is also focused on enhancing the recyclability of these lubricants and developing more efficient recycling processes.

As environmental regulations become increasingly stringent, manufacturers of high-performance lubricants are investing in sustainable practices and technologies. This includes optimizing production processes to reduce energy consumption and waste, as well as developing lubricants that meet both performance requirements and environmental standards.

The manufacturing process of high-performance lubricants often involves the use of synthetic base oils and advanced additive packages. These components require energy-intensive production methods and may involve the use of potentially harmful chemicals. The extraction and refinement of raw materials for these lubricants can lead to habitat disruption, soil contamination, and greenhouse gas emissions.

During engine operation, high-performance lubricants may experience increased volatility and oil consumption compared to conventional lubricants. This can result in higher emissions of particulate matter and volatile organic compounds (VOCs), contributing to air pollution and potential health hazards. Additionally, the increased oil consumption may necessitate more frequent oil changes, leading to a larger volume of waste oil requiring proper disposal or recycling.

The disposal of used high-performance lubricants presents another environmental challenge. If not handled properly, these oils can contaminate soil and water sources, posing risks to ecosystems and human health. The presence of advanced additives in these lubricants may also complicate recycling processes, potentially reducing the efficiency of oil reclamation efforts.

However, it is important to note that high-performance lubricants can also offer environmental benefits. Their enhanced protection and longevity can extend engine life, reducing the need for premature replacements and the associated environmental impacts of manufacturing new engines. Furthermore, their improved efficiency can lead to reduced fuel consumption and lower overall emissions over the lifespan of the engine.

Efforts are being made to develop more environmentally friendly high-performance lubricants. These include the use of bio-based materials, biodegradable additives, and improved formulations that reduce oil consumption and emissions. Research is also focused on enhancing the recyclability of these lubricants and developing more efficient recycling processes.

As environmental regulations become increasingly stringent, manufacturers of high-performance lubricants are investing in sustainable practices and technologies. This includes optimizing production processes to reduce energy consumption and waste, as well as developing lubricants that meet both performance requirements and environmental standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!