How ToDesign W16 Turbine/Turbo Layout For Optimal Boosting

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

W16 Turbo Evolution

The W16 engine configuration, featuring 16 cylinders arranged in a W shape, has undergone significant evolution in its turbocharging systems to achieve optimal boosting. This progression has been driven by the need for increased power output, improved efficiency, and enhanced performance characteristics.

In the early stages of W16 turbo development, engineers primarily focused on single turbocharger setups. These initial designs utilized large, single turbochargers to provide boost across the entire engine. While effective in increasing overall power, this approach often resulted in noticeable turbo lag and less-than-ideal low-end torque characteristics.

As technology advanced, dual-turbocharger configurations became more prevalent. This setup typically involved using two smaller turbochargers, each responsible for boosting half of the engine's cylinders. The dual-turbo layout offered improved responsiveness and more balanced power delivery across the rev range, addressing some of the shortcomings of single-turbo designs.

The next significant step in W16 turbo evolution came with the introduction of quad-turbocharger systems. This configuration employs four smaller turbochargers, often arranged with two turbos per bank of cylinders. The quad-turbo layout further reduced turbo lag and allowed for more precise boost control, resulting in smoother power delivery and improved overall engine efficiency.

Recent advancements have seen the integration of electric turbochargers into W16 engines. These e-turbos utilize electric motors to spool up the compressor wheels almost instantaneously, virtually eliminating turbo lag. When combined with traditional exhaust-driven turbochargers, this hybrid setup offers the best of both worlds: immediate low-end response and substantial high-end power.

Another area of innovation in W16 turbo evolution has been the development of variable geometry turbochargers (VGTs). These sophisticated units feature adjustable vanes that can alter the flow of exhaust gases, allowing for optimized boost pressure across a wider range of engine speeds and load conditions.

The most recent trend in W16 turbo design focuses on holistic system integration. This approach considers the turbocharging system as part of a larger, interconnected powertrain. Advanced engine management systems, coupled with sophisticated sensors and actuators, enable real-time adjustment of boost pressure, fuel injection, and valve timing to maximize performance and efficiency under varying driving conditions.

As environmental concerns gain prominence, future W16 turbo evolution is likely to emphasize not only performance but also emissions reduction and fuel efficiency. This may lead to the development of even more advanced hybrid turbocharging systems, potentially incorporating technologies such as turbo compound systems or exhaust energy recovery mechanisms to further optimize engine output and efficiency.

In the early stages of W16 turbo development, engineers primarily focused on single turbocharger setups. These initial designs utilized large, single turbochargers to provide boost across the entire engine. While effective in increasing overall power, this approach often resulted in noticeable turbo lag and less-than-ideal low-end torque characteristics.

As technology advanced, dual-turbocharger configurations became more prevalent. This setup typically involved using two smaller turbochargers, each responsible for boosting half of the engine's cylinders. The dual-turbo layout offered improved responsiveness and more balanced power delivery across the rev range, addressing some of the shortcomings of single-turbo designs.

The next significant step in W16 turbo evolution came with the introduction of quad-turbocharger systems. This configuration employs four smaller turbochargers, often arranged with two turbos per bank of cylinders. The quad-turbo layout further reduced turbo lag and allowed for more precise boost control, resulting in smoother power delivery and improved overall engine efficiency.

Recent advancements have seen the integration of electric turbochargers into W16 engines. These e-turbos utilize electric motors to spool up the compressor wheels almost instantaneously, virtually eliminating turbo lag. When combined with traditional exhaust-driven turbochargers, this hybrid setup offers the best of both worlds: immediate low-end response and substantial high-end power.

Another area of innovation in W16 turbo evolution has been the development of variable geometry turbochargers (VGTs). These sophisticated units feature adjustable vanes that can alter the flow of exhaust gases, allowing for optimized boost pressure across a wider range of engine speeds and load conditions.

The most recent trend in W16 turbo design focuses on holistic system integration. This approach considers the turbocharging system as part of a larger, interconnected powertrain. Advanced engine management systems, coupled with sophisticated sensors and actuators, enable real-time adjustment of boost pressure, fuel injection, and valve timing to maximize performance and efficiency under varying driving conditions.

As environmental concerns gain prominence, future W16 turbo evolution is likely to emphasize not only performance but also emissions reduction and fuel efficiency. This may lead to the development of even more advanced hybrid turbocharging systems, potentially incorporating technologies such as turbo compound systems or exhaust energy recovery mechanisms to further optimize engine output and efficiency.

Market for High-Performance Engines

The market for high-performance engines has experienced significant growth in recent years, driven by increasing demand for luxury and sports vehicles. This segment caters to automotive enthusiasts, racing teams, and luxury car manufacturers seeking powerful and efficient engines. The W16 engine, particularly known for its use in Bugatti vehicles, represents the pinnacle of high-performance engine design.

Consumer preferences in this market are shifting towards engines that offer not only raw power but also improved fuel efficiency and reduced emissions. This trend is partly due to stricter environmental regulations and a growing awareness of sustainability issues among high-end consumers. As a result, manufacturers are investing heavily in technologies that can optimize engine performance while meeting these new demands.

The global high-performance engine market is expected to continue its growth trajectory. Key factors contributing to this growth include rising disposable incomes in emerging economies, technological advancements in engine design, and the expanding motorsports industry. Additionally, the increasing popularity of supercars and hypercars is creating new opportunities for advanced engine technologies like the W16.

Geographically, North America and Europe remain the largest markets for high-performance engines, with Asia-Pacific showing the fastest growth. Countries like China and India are emerging as significant markets due to their rapidly growing luxury car segments and motorsports industries.

In terms of market segmentation, high-performance engines are primarily used in sports cars, luxury vehicles, and racing cars. The W16 engine, being at the top end of this spectrum, caters to a niche but highly lucrative segment of ultra-luxury and hypercar manufacturers.

The competitive landscape of the high-performance engine market is dominated by established automotive giants and specialized engine manufacturers. These companies are continuously innovating to maintain their market position, with a focus on developing more powerful, efficient, and environmentally friendly engines.

Looking ahead, the market for high-performance engines is likely to be influenced by several factors. These include advancements in materials science, the integration of electric and hybrid technologies, and the development of more sophisticated turbocharging and supercharging systems. The challenge for manufacturers will be to balance the demand for extreme performance with the need for improved fuel efficiency and reduced emissions.

Consumer preferences in this market are shifting towards engines that offer not only raw power but also improved fuel efficiency and reduced emissions. This trend is partly due to stricter environmental regulations and a growing awareness of sustainability issues among high-end consumers. As a result, manufacturers are investing heavily in technologies that can optimize engine performance while meeting these new demands.

The global high-performance engine market is expected to continue its growth trajectory. Key factors contributing to this growth include rising disposable incomes in emerging economies, technological advancements in engine design, and the expanding motorsports industry. Additionally, the increasing popularity of supercars and hypercars is creating new opportunities for advanced engine technologies like the W16.

Geographically, North America and Europe remain the largest markets for high-performance engines, with Asia-Pacific showing the fastest growth. Countries like China and India are emerging as significant markets due to their rapidly growing luxury car segments and motorsports industries.

In terms of market segmentation, high-performance engines are primarily used in sports cars, luxury vehicles, and racing cars. The W16 engine, being at the top end of this spectrum, caters to a niche but highly lucrative segment of ultra-luxury and hypercar manufacturers.

The competitive landscape of the high-performance engine market is dominated by established automotive giants and specialized engine manufacturers. These companies are continuously innovating to maintain their market position, with a focus on developing more powerful, efficient, and environmentally friendly engines.

Looking ahead, the market for high-performance engines is likely to be influenced by several factors. These include advancements in materials science, the integration of electric and hybrid technologies, and the development of more sophisticated turbocharging and supercharging systems. The challenge for manufacturers will be to balance the demand for extreme performance with the need for improved fuel efficiency and reduced emissions.

W16 Turbo Design Challenges

The design of a W16 turbine/turbo layout for optimal boosting presents several significant challenges that engineers must overcome to achieve peak performance. One of the primary obstacles is the complex integration of multiple turbochargers within the limited engine bay space. The W16 configuration, with its four banks of four cylinders, requires careful placement of turbochargers to ensure efficient exhaust gas flow and minimal turbo lag.

Heat management is another critical challenge in W16 turbo design. With sixteen cylinders and multiple turbochargers generating substantial heat, engineers must develop innovative cooling solutions to prevent thermal stress and maintain optimal operating temperatures. This often involves intricate intercooler designs and advanced thermal management systems.

Balancing the airflow distribution among the cylinders is a complex task in W16 turbo layouts. Ensuring equal boost pressure and air delivery to all sixteen cylinders requires precise engineering of the intake manifold and boost control systems. Any imbalance can lead to uneven power delivery and reduced overall engine efficiency.

The timing and control of multiple turbochargers in a W16 configuration present another significant challenge. Coordinating the operation of two or more turbochargers to provide seamless power delivery across the entire RPM range requires sophisticated engine management systems and precise calibration.

Durability and reliability are paramount concerns in high-performance W16 turbo designs. The extreme pressures and temperatures generated by such a powerful engine configuration demand the use of advanced materials and manufacturing techniques to ensure long-term reliability under demanding conditions.

Emissions compliance is an increasingly important challenge in W16 turbo design. Engineers must balance the pursuit of maximum performance with the need to meet stringent emissions regulations, often requiring the integration of complex aftertreatment systems and precise engine tuning.

Packaging constraints pose a significant challenge in W16 turbo layouts. Fitting all necessary components, including turbochargers, intercoolers, and associated plumbing, within the confines of a vehicle's engine bay while maintaining proper weight distribution and center of gravity is a complex engineering task.

Optimizing the turbocharger size and configuration for a W16 engine is particularly challenging. Engineers must carefully select turbocharger specifications to provide the desired boost characteristics across the engine's operating range while minimizing turbo lag and maximizing efficiency.

Heat management is another critical challenge in W16 turbo design. With sixteen cylinders and multiple turbochargers generating substantial heat, engineers must develop innovative cooling solutions to prevent thermal stress and maintain optimal operating temperatures. This often involves intricate intercooler designs and advanced thermal management systems.

Balancing the airflow distribution among the cylinders is a complex task in W16 turbo layouts. Ensuring equal boost pressure and air delivery to all sixteen cylinders requires precise engineering of the intake manifold and boost control systems. Any imbalance can lead to uneven power delivery and reduced overall engine efficiency.

The timing and control of multiple turbochargers in a W16 configuration present another significant challenge. Coordinating the operation of two or more turbochargers to provide seamless power delivery across the entire RPM range requires sophisticated engine management systems and precise calibration.

Durability and reliability are paramount concerns in high-performance W16 turbo designs. The extreme pressures and temperatures generated by such a powerful engine configuration demand the use of advanced materials and manufacturing techniques to ensure long-term reliability under demanding conditions.

Emissions compliance is an increasingly important challenge in W16 turbo design. Engineers must balance the pursuit of maximum performance with the need to meet stringent emissions regulations, often requiring the integration of complex aftertreatment systems and precise engine tuning.

Packaging constraints pose a significant challenge in W16 turbo layouts. Fitting all necessary components, including turbochargers, intercoolers, and associated plumbing, within the confines of a vehicle's engine bay while maintaining proper weight distribution and center of gravity is a complex engineering task.

Optimizing the turbocharger size and configuration for a W16 engine is particularly challenging. Engineers must carefully select turbocharger specifications to provide the desired boost characteristics across the engine's operating range while minimizing turbo lag and maximizing efficiency.

Current W16 Turbo Configurations

01 Turbocharging systems for W16 engines

Turbocharging systems are employed to boost the performance of W16 engines. These systems utilize exhaust gases to drive turbines, which in turn compress intake air, increasing the engine's power output and efficiency. Advanced turbocharging configurations may include multiple turbochargers or variable geometry designs to optimize performance across different engine speeds.- Turbocharging systems for W16 engines: Turbocharging systems are employed to boost the performance of W16 engines. These systems utilize exhaust gases to drive turbines, which in turn compress intake air, increasing the engine's power output and efficiency. Advanced turbocharging configurations may include multiple turbochargers or variable geometry turbines to optimize performance across different engine speeds.

- Electronic control systems for engine boosting: Sophisticated electronic control systems are implemented to manage and optimize the boosting process in W16 engines. These systems monitor various engine parameters and adjust boost pressure, fuel injection, and ignition timing to maximize performance and efficiency while maintaining engine reliability. Advanced algorithms and sensors are used to ensure precise control under various operating conditions.

- Intercooling and charge air cooling: Intercooling and charge air cooling systems are integrated into W16 engine designs to enhance boosting efficiency. These systems cool the compressed air from the turbochargers or superchargers before it enters the engine, increasing air density and allowing for greater power output. Advanced heat exchanger designs and cooling strategies are employed to maximize the effectiveness of these systems.

- Variable valve timing for improved boosting: Variable valve timing mechanisms are utilized in W16 engines to optimize air flow and exhaust gas management, enhancing the boosting process. These systems allow for dynamic adjustment of valve timing and duration, improving engine breathing and turbocharger response across a wide range of operating conditions. Advanced camshaft designs and actuators enable precise control of valve events.

- Multi-stage boosting systems: Multi-stage boosting systems are implemented in W16 engines to achieve higher boost pressures and improved overall performance. These systems may combine different types of forced induction, such as turbochargers and superchargers, or use multiple turbochargers in series or parallel configurations. Advanced control strategies are employed to manage the interaction between different stages and optimize boost delivery across the engine's operating range.

02 Electronic control systems for engine boosting

Electronic control systems play a crucial role in managing and optimizing the boosting process in W16 engines. These systems monitor various engine parameters and adjust boost pressure, fuel injection, and other factors to maximize performance and efficiency while maintaining reliability. Advanced control algorithms may incorporate adaptive learning and predictive capabilities.Expand Specific Solutions03 Intercooling and charge air cooling

Intercooling and charge air cooling systems are essential components in boosted W16 engines. These systems help reduce the temperature of the compressed air from the turbocharger or supercharger, increasing air density and allowing for more efficient combustion. Advanced cooling designs may incorporate multiple stages or innovative heat exchanger technologies to maximize cooling efficiency.Expand Specific Solutions04 Variable valve timing for improved boosting

Variable valve timing systems are utilized in W16 engines to enhance boosting performance. By adjusting the timing and duration of valve openings, these systems can optimize airflow and exhaust gas scavenging across different engine speeds and load conditions. This technology works in conjunction with turbocharging or supercharging systems to improve overall engine efficiency and power output.Expand Specific Solutions05 Supercharging systems for W16 engines

Supercharging systems offer an alternative or complementary approach to turbocharging for boosting W16 engines. These mechanically driven compressors provide immediate boost response and can be designed to deliver consistent performance across a wide range of engine speeds. Advanced supercharger designs may incorporate variable drive ratios or bypass systems to optimize efficiency and power delivery.Expand Specific Solutions

W16 Engine Manufacturers

The W16 turbine/turbo layout optimization for boosting is in a mature stage of development, with significant market potential in the automotive and aerospace industries. The global turbocharger market size is projected to reach billions of dollars by 2025, driven by increasing demand for fuel-efficient vehicles. Key players like BorgWarner, Honeywell, and Garrett Motion are at the forefront of technological advancements, leveraging their extensive experience in turbocharging technologies. These companies, along with major automotive manufacturers such as Ford, Toyota, and Continental, are investing heavily in research and development to improve turbocharger efficiency and performance, indicating a highly competitive landscape with ongoing innovation in W16 turbine/turbo layouts.

BorgWarner, Inc.

Technical Solution: BorgWarner's W16 turbine/turbo layout design for optimal boosting focuses on their advanced dual-volute turbocharger technology. This innovative approach utilizes a divided turbine housing with two separate flow channels, allowing for better pulse separation and improved turbine efficiency[1]. The design incorporates variable turbine geometry (VTG) technology, which adjusts the turbine's aspect ratio to optimize performance across a wide range of engine speeds[2]. BorgWarner's system also features an electrically actuated wastegate for precise boost control and reduced turbo lag[3]. The company has implemented advanced aerodynamic modeling and computational fluid dynamics (CFD) simulations to optimize the turbine wheel design, resulting in improved flow characteristics and overall turbocharger efficiency[4].

Strengths: Dual-volute technology improves low-end torque and transient response. VTG allows for optimized performance across a broad operating range. Advanced aerodynamics enhance overall efficiency. Weaknesses: Complexity may lead to higher production costs. Potential reliability concerns due to more moving parts in VTG system.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell's approach to W16 turbine/turbo layout for optimal boosting centers on their TwoStage™ series turbocharging system. This design incorporates two turbochargers working in series: a smaller high-pressure turbo for quick response at low engine speeds, and a larger low-pressure turbo for maximum power at high engine speeds[1]. The system utilizes advanced materials such as titanium aluminide for turbine wheels, reducing inertia and improving transient response[2]. Honeywell's design also incorporates their proprietary aerodynamic blade design, optimized through extensive CFD analysis and real-world testing[3]. The company has implemented an electronic wastegate control system for precise boost management and improved fuel efficiency[4]. Additionally, Honeywell's turbo layout includes an integrated exhaust manifold design to reduce overall system weight and improve thermal efficiency[5].

Strengths: TwoStage™ system provides excellent low-end response and high-end power. Advanced materials improve durability and performance. Integrated exhaust manifold reduces weight and improves efficiency. Weaknesses: Complex system may increase manufacturing costs. Potential challenges in packaging due to the dual turbocharger setup.

Key Innovations in W16 Turbocharging

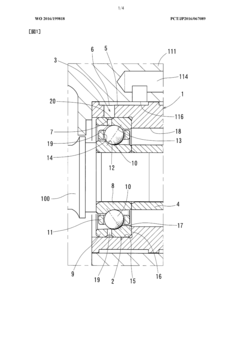

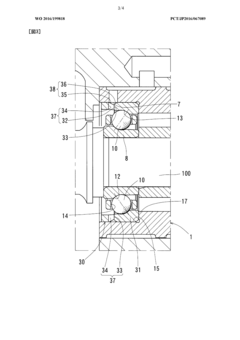

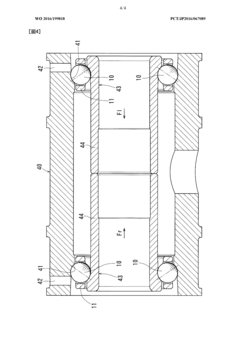

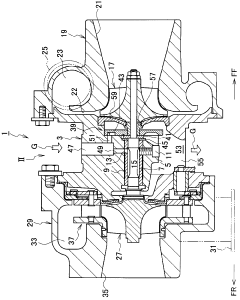

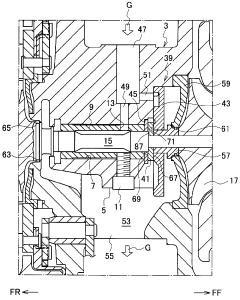

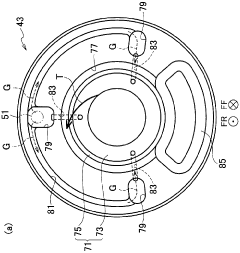

Bearing unit

PatentWO2016199818A1

Innovation

- A bearing unit design where the oil supply hole opens radially facing the rolling elements, allowing direct lubrication and simplifying the housing structure by eliminating the need for protrusions near the cage, with options including forming the oil supply hole in the outer ring or housing, and using a fixed ring to create a groove for phase shift during assembly.

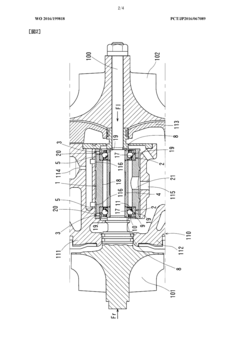

Thrust bearing structure and supercharger equipped with said thrust bearing structure

PatentWO2012147542A1

Innovation

- A thrust bearing structure utilizing a novel configuration with a thrust collar and thrust bearing, where one of the pads has a tapered portion and a land portion, and the lubricating oil's trajectory is determined by centrifugal force, enhancing the wedge effect to support axial thrust loads effectively.

Emissions Regulations Impact

The impact of emissions regulations on W16 turbine/turbo layout design for optimal boosting is significant and multifaceted. As governments worldwide implement increasingly stringent emissions standards, engine manufacturers must adapt their designs to meet these requirements while maintaining performance and efficiency.

Emissions regulations primarily focus on reducing harmful pollutants such as nitrogen oxides (NOx), carbon monoxide (CO), particulate matter (PM), and carbon dioxide (CO2). These regulations have led to the development of more advanced turbocharging systems, including the W16 configuration, to achieve better fuel efficiency and lower emissions.

The W16 turbine/turbo layout presents unique challenges and opportunities in meeting emissions standards. Its compact design allows for better packaging and weight distribution, which can contribute to overall vehicle efficiency. However, the complexity of the system requires careful optimization to ensure compliance with emissions regulations.

One key aspect of emissions-compliant W16 turbo designs is the integration of advanced exhaust gas recirculation (EGR) systems. EGR helps reduce NOx emissions by lowering combustion temperatures. In W16 configurations, engineers must carefully design the EGR system to ensure uniform distribution across all cylinders, which can be challenging due to the engine's complex layout.

Turbocharger efficiency plays a crucial role in meeting emissions targets. High-efficiency turbochargers can help reduce fuel consumption and CO2 emissions. For W16 engines, this often involves implementing variable geometry turbochargers (VGTs) or twin-scroll designs that can optimize boost across a wide range of engine speeds and loads.

Aftertreatment systems are another critical component in emissions compliance. W16 engines typically require sophisticated catalytic converters and particulate filters to meet stringent standards. The placement and sizing of these components must be carefully considered in the overall turbo layout design to ensure optimal performance and emissions reduction.

The pursuit of lower emissions has also led to the development of electrified turbocharging systems. These e-turbos can provide rapid boost response and improved low-end torque, potentially allowing for engine downsizing without sacrificing performance. In W16 applications, e-turbos could help address transient response issues and further optimize emissions control.

As emissions regulations continue to evolve, W16 turbine/turbo layout designs must remain adaptable. Future standards may require even more advanced technologies, such as integrated starter-generators or mild hybrid systems, to further reduce emissions. Engineers must consider these potential requirements when developing new W16 turbocharging solutions to ensure long-term compliance and competitiveness in the market.

Emissions regulations primarily focus on reducing harmful pollutants such as nitrogen oxides (NOx), carbon monoxide (CO), particulate matter (PM), and carbon dioxide (CO2). These regulations have led to the development of more advanced turbocharging systems, including the W16 configuration, to achieve better fuel efficiency and lower emissions.

The W16 turbine/turbo layout presents unique challenges and opportunities in meeting emissions standards. Its compact design allows for better packaging and weight distribution, which can contribute to overall vehicle efficiency. However, the complexity of the system requires careful optimization to ensure compliance with emissions regulations.

One key aspect of emissions-compliant W16 turbo designs is the integration of advanced exhaust gas recirculation (EGR) systems. EGR helps reduce NOx emissions by lowering combustion temperatures. In W16 configurations, engineers must carefully design the EGR system to ensure uniform distribution across all cylinders, which can be challenging due to the engine's complex layout.

Turbocharger efficiency plays a crucial role in meeting emissions targets. High-efficiency turbochargers can help reduce fuel consumption and CO2 emissions. For W16 engines, this often involves implementing variable geometry turbochargers (VGTs) or twin-scroll designs that can optimize boost across a wide range of engine speeds and loads.

Aftertreatment systems are another critical component in emissions compliance. W16 engines typically require sophisticated catalytic converters and particulate filters to meet stringent standards. The placement and sizing of these components must be carefully considered in the overall turbo layout design to ensure optimal performance and emissions reduction.

The pursuit of lower emissions has also led to the development of electrified turbocharging systems. These e-turbos can provide rapid boost response and improved low-end torque, potentially allowing for engine downsizing without sacrificing performance. In W16 applications, e-turbos could help address transient response issues and further optimize emissions control.

As emissions regulations continue to evolve, W16 turbine/turbo layout designs must remain adaptable. Future standards may require even more advanced technologies, such as integrated starter-generators or mild hybrid systems, to further reduce emissions. Engineers must consider these potential requirements when developing new W16 turbocharging solutions to ensure long-term compliance and competitiveness in the market.

Thermal Management Strategies

Thermal management is a critical aspect of designing a W16 turbine/turbo layout for optimal boosting. Effective thermal management strategies are essential to maintain engine efficiency, performance, and longevity. In a W16 engine configuration, the compact design and high power output create significant thermal challenges that must be addressed.

One key thermal management strategy is the implementation of advanced cooling systems. This includes both liquid and air cooling methods. Liquid cooling circuits can be designed to target specific high-temperature areas within the engine, such as cylinder heads and turbochargers. The use of high-performance coolants and precision-engineered cooling channels helps dissipate heat more effectively.

Intercooling plays a vital role in managing the temperature of compressed air from the turbochargers. Efficient intercooler designs, such as air-to-water systems, can significantly reduce intake air temperature, improving engine volumetric efficiency and reducing the risk of detonation. Placement of intercoolers is crucial, balancing the need for short air paths with adequate cooling capacity.

Heat shielding and insulation techniques are employed to protect sensitive components from excessive heat exposure. This includes the use of heat-resistant materials and coatings on exhaust manifolds, turbochargers, and nearby components. Strategic placement of heat shields can also help manage thermal radiation within the engine bay.

Oil cooling systems are another critical element of thermal management in a W16 turbo layout. Enhanced oil coolers and carefully designed oil circuits ensure proper lubrication and heat dissipation, particularly for high-stress components like turbocharger bearings and cylinder walls.

Advanced thermal management control systems can optimize cooling based on real-time engine conditions. These systems can adjust coolant flow rates, fan speeds, and even oil temperatures to maintain ideal operating conditions across various engine loads and ambient temperatures.

Exhaust gas management is also crucial for thermal control. Properly designed exhaust manifolds and turbocharger housings can help efficiently channel hot exhaust gases away from sensitive areas while maximizing energy extraction for the turbochargers.

Lastly, aerodynamic considerations in the overall engine bay design can significantly impact thermal management. Careful airflow management, including the use of ducting and venting, can help direct cool air to critical components and efficiently remove hot air from the engine compartment.

One key thermal management strategy is the implementation of advanced cooling systems. This includes both liquid and air cooling methods. Liquid cooling circuits can be designed to target specific high-temperature areas within the engine, such as cylinder heads and turbochargers. The use of high-performance coolants and precision-engineered cooling channels helps dissipate heat more effectively.

Intercooling plays a vital role in managing the temperature of compressed air from the turbochargers. Efficient intercooler designs, such as air-to-water systems, can significantly reduce intake air temperature, improving engine volumetric efficiency and reducing the risk of detonation. Placement of intercoolers is crucial, balancing the need for short air paths with adequate cooling capacity.

Heat shielding and insulation techniques are employed to protect sensitive components from excessive heat exposure. This includes the use of heat-resistant materials and coatings on exhaust manifolds, turbochargers, and nearby components. Strategic placement of heat shields can also help manage thermal radiation within the engine bay.

Oil cooling systems are another critical element of thermal management in a W16 turbo layout. Enhanced oil coolers and carefully designed oil circuits ensure proper lubrication and heat dissipation, particularly for high-stress components like turbocharger bearings and cylinder walls.

Advanced thermal management control systems can optimize cooling based on real-time engine conditions. These systems can adjust coolant flow rates, fan speeds, and even oil temperatures to maintain ideal operating conditions across various engine loads and ambient temperatures.

Exhaust gas management is also crucial for thermal control. Properly designed exhaust manifolds and turbocharger housings can help efficiently channel hot exhaust gases away from sensitive areas while maximizing energy extraction for the turbochargers.

Lastly, aerodynamic considerations in the overall engine bay design can significantly impact thermal management. Careful airflow management, including the use of ducting and venting, can help direct cool air to critical components and efficiently remove hot air from the engine compartment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!