W16 Engine Noise Control: Measurement And NVH Solutions

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

W16 Engine NVH Background and Objectives

The W16 engine, a marvel of automotive engineering, represents the pinnacle of internal combustion technology. Developed primarily for high-performance luxury vehicles, this 16-cylinder powerplant has become synonymous with unparalleled power and prestige. However, with great power comes significant challenges, particularly in the realm of Noise, Vibration, and Harshness (NVH) control.

The evolution of W16 engine technology has been driven by the relentless pursuit of performance coupled with the increasing demand for refined driving experiences. As regulatory pressures mount for quieter and more environmentally friendly vehicles, the need for advanced NVH solutions has become paramount. The primary objective in W16 engine NVH control is to mitigate the inherent noise and vibration issues associated with such a complex and powerful engine configuration.

Historically, W16 engines have been characterized by their distinctive sound profile, which, while appealing to enthusiasts, can be problematic from a comfort and regulatory standpoint. The unique arrangement of cylinders in a W configuration presents specific challenges in terms of vibration harmonics and noise propagation. These issues are further compounded by the high-performance nature of vehicles typically equipped with W16 engines, where lightweight construction and aerodynamic designs can exacerbate NVH concerns.

The technical goals for W16 engine NVH control are multifaceted. They include reducing overall noise levels to meet increasingly stringent regulatory standards, minimizing vibration transmission to the vehicle cabin, and enhancing the perceived quality of the engine sound. Additionally, there is a focus on maintaining the engine's performance characteristics while implementing NVH solutions, as any significant increase in weight or reduction in power output would be unacceptable in the ultra-luxury market segment.

Recent technological advancements have opened new avenues for NVH control in W16 engines. These include the development of advanced materials for engine mounts and acoustic insulation, the implementation of active noise control systems, and the use of sophisticated computer modeling for optimizing engine design and exhaust systems. The integration of these technologies aims to create a harmonious balance between the raw power of the W16 engine and the refined experience expected in luxury vehicles.

As the automotive industry continues to evolve, with a growing emphasis on electrification and sustainability, the future of W16 engines and their NVH control strategies remains a subject of intense research and development. The challenge lies in preserving the unique character of these extraordinary powerplants while meeting the ever-increasing demands for quieter, more efficient, and environmentally responsible vehicles.

The evolution of W16 engine technology has been driven by the relentless pursuit of performance coupled with the increasing demand for refined driving experiences. As regulatory pressures mount for quieter and more environmentally friendly vehicles, the need for advanced NVH solutions has become paramount. The primary objective in W16 engine NVH control is to mitigate the inherent noise and vibration issues associated with such a complex and powerful engine configuration.

Historically, W16 engines have been characterized by their distinctive sound profile, which, while appealing to enthusiasts, can be problematic from a comfort and regulatory standpoint. The unique arrangement of cylinders in a W configuration presents specific challenges in terms of vibration harmonics and noise propagation. These issues are further compounded by the high-performance nature of vehicles typically equipped with W16 engines, where lightweight construction and aerodynamic designs can exacerbate NVH concerns.

The technical goals for W16 engine NVH control are multifaceted. They include reducing overall noise levels to meet increasingly stringent regulatory standards, minimizing vibration transmission to the vehicle cabin, and enhancing the perceived quality of the engine sound. Additionally, there is a focus on maintaining the engine's performance characteristics while implementing NVH solutions, as any significant increase in weight or reduction in power output would be unacceptable in the ultra-luxury market segment.

Recent technological advancements have opened new avenues for NVH control in W16 engines. These include the development of advanced materials for engine mounts and acoustic insulation, the implementation of active noise control systems, and the use of sophisticated computer modeling for optimizing engine design and exhaust systems. The integration of these technologies aims to create a harmonious balance between the raw power of the W16 engine and the refined experience expected in luxury vehicles.

As the automotive industry continues to evolve, with a growing emphasis on electrification and sustainability, the future of W16 engines and their NVH control strategies remains a subject of intense research and development. The challenge lies in preserving the unique character of these extraordinary powerplants while meeting the ever-increasing demands for quieter, more efficient, and environmentally responsible vehicles.

Market Demand for Quiet High-Performance Engines

The market demand for quiet high-performance engines has been steadily increasing in recent years, driven by a combination of consumer preferences, regulatory pressures, and technological advancements. Luxury car manufacturers, in particular, have recognized the importance of noise control in enhancing the overall driving experience and perceived quality of their vehicles.

Consumers in the high-end automotive market are increasingly seeking vehicles that offer both exhilarating performance and refined comfort. This has led to a growing demand for engines that can deliver substantial power output while maintaining low noise levels. The W16 engine, known for its impressive power capabilities, has become a focal point for noise control efforts to meet these market expectations.

Regulatory bodies worldwide have been implementing stricter noise emission standards for vehicles, compelling manufacturers to invest in advanced noise control technologies. These regulations aim to reduce environmental noise pollution and improve the quality of life in urban areas. As a result, automakers are under pressure to develop quieter engines, even for their high-performance models.

The automotive industry has witnessed a shift towards electrification, with many manufacturers introducing hybrid and fully electric vehicles. This trend has raised the bar for noise control in internal combustion engines, as consumers have become accustomed to the quiet operation of electric powertrains. To remain competitive, manufacturers of high-performance combustion engines, including W16 engines, must prioritize noise reduction to meet evolving customer expectations.

Market research indicates that noise, vibration, and harshness (NVH) characteristics significantly influence purchasing decisions in the luxury car segment. Buyers are willing to pay a premium for vehicles that offer a quieter and more refined driving experience. This has created a substantial market opportunity for manufacturers who can effectively address engine noise issues in their high-performance offerings.

The demand for quiet high-performance engines extends beyond the automotive sector. Other industries, such as marine and aerospace, are also seeking advanced noise control solutions for their high-output engines. This cross-sector demand is driving innovation in NVH technologies and creating new market opportunities for companies specializing in engine noise control.

As the market for high-performance vehicles continues to grow globally, particularly in emerging economies, the demand for quiet yet powerful engines is expected to increase further. Manufacturers who can successfully balance performance and noise control in their W16 engines and other high-output powertrains are likely to gain a significant competitive advantage in this expanding market.

Consumers in the high-end automotive market are increasingly seeking vehicles that offer both exhilarating performance and refined comfort. This has led to a growing demand for engines that can deliver substantial power output while maintaining low noise levels. The W16 engine, known for its impressive power capabilities, has become a focal point for noise control efforts to meet these market expectations.

Regulatory bodies worldwide have been implementing stricter noise emission standards for vehicles, compelling manufacturers to invest in advanced noise control technologies. These regulations aim to reduce environmental noise pollution and improve the quality of life in urban areas. As a result, automakers are under pressure to develop quieter engines, even for their high-performance models.

The automotive industry has witnessed a shift towards electrification, with many manufacturers introducing hybrid and fully electric vehicles. This trend has raised the bar for noise control in internal combustion engines, as consumers have become accustomed to the quiet operation of electric powertrains. To remain competitive, manufacturers of high-performance combustion engines, including W16 engines, must prioritize noise reduction to meet evolving customer expectations.

Market research indicates that noise, vibration, and harshness (NVH) characteristics significantly influence purchasing decisions in the luxury car segment. Buyers are willing to pay a premium for vehicles that offer a quieter and more refined driving experience. This has created a substantial market opportunity for manufacturers who can effectively address engine noise issues in their high-performance offerings.

The demand for quiet high-performance engines extends beyond the automotive sector. Other industries, such as marine and aerospace, are also seeking advanced noise control solutions for their high-output engines. This cross-sector demand is driving innovation in NVH technologies and creating new market opportunities for companies specializing in engine noise control.

As the market for high-performance vehicles continues to grow globally, particularly in emerging economies, the demand for quiet yet powerful engines is expected to increase further. Manufacturers who can successfully balance performance and noise control in their W16 engines and other high-output powertrains are likely to gain a significant competitive advantage in this expanding market.

Current W16 NVH Challenges and Limitations

The W16 engine, renowned for its power and complexity, presents unique challenges in noise, vibration, and harshness (NVH) control. Current limitations in W16 NVH solutions stem from the engine's intricate design and high-performance nature. The sheer number of cylinders and moving parts contribute to a complex noise profile that is difficult to isolate and mitigate effectively.

One of the primary challenges is the management of combustion noise. With 16 cylinders firing in rapid succession, the W16 engine generates significant pressure waves that can result in both low-frequency rumble and high-frequency harmonics. Traditional sound dampening materials struggle to address this wide spectrum of noise frequencies simultaneously, necessitating a multi-faceted approach to NVH control.

Vibration management poses another significant hurdle. The W16's unique configuration, essentially combining two V8 engines, creates intricate vibration patterns that can propagate through the vehicle structure. Current isolation systems are often pushed to their limits, struggling to absorb and dissipate these complex vibrations without compromising the engine's performance or the vehicle's handling characteristics.

Heat management intersects with NVH concerns in W16 engines. The substantial heat generated by this powerful engine requires extensive cooling systems, which can introduce additional noise sources through fluid movement and fan operation. Balancing thermal efficiency with noise reduction remains a persistent challenge for engineers working on W16 powerplants.

The pursuit of lightweight construction in high-performance vehicles further complicates NVH solutions for W16 engines. Traditional noise-dampening materials often add significant weight, which is at odds with performance goals. This necessitates the development of advanced, lightweight materials that can provide effective sound insulation without compromising the vehicle's power-to-weight ratio.

Measurement and analysis of W16 engine noise present their own set of challenges. The complexity of the sound profile requires sophisticated acoustic measurement tools and analysis software capable of isolating and characterizing multiple noise sources simultaneously. Current limitations in real-time analysis and the ability to differentiate between closely related noise frequencies can hinder the development of targeted NVH solutions.

Moreover, the exclusivity and low production volumes of W16-equipped vehicles limit the resources available for extensive NVH research and development. This constraint often results in solutions that are highly customized but may lack the benefit of large-scale testing and refinement seen in more common engine configurations.

In conclusion, while significant progress has been made in W16 engine NVH control, substantial challenges remain. Overcoming these limitations will require innovative approaches to materials science, advanced signal processing techniques, and a holistic view of engine design that integrates NVH considerations from the earliest stages of development.

One of the primary challenges is the management of combustion noise. With 16 cylinders firing in rapid succession, the W16 engine generates significant pressure waves that can result in both low-frequency rumble and high-frequency harmonics. Traditional sound dampening materials struggle to address this wide spectrum of noise frequencies simultaneously, necessitating a multi-faceted approach to NVH control.

Vibration management poses another significant hurdle. The W16's unique configuration, essentially combining two V8 engines, creates intricate vibration patterns that can propagate through the vehicle structure. Current isolation systems are often pushed to their limits, struggling to absorb and dissipate these complex vibrations without compromising the engine's performance or the vehicle's handling characteristics.

Heat management intersects with NVH concerns in W16 engines. The substantial heat generated by this powerful engine requires extensive cooling systems, which can introduce additional noise sources through fluid movement and fan operation. Balancing thermal efficiency with noise reduction remains a persistent challenge for engineers working on W16 powerplants.

The pursuit of lightweight construction in high-performance vehicles further complicates NVH solutions for W16 engines. Traditional noise-dampening materials often add significant weight, which is at odds with performance goals. This necessitates the development of advanced, lightweight materials that can provide effective sound insulation without compromising the vehicle's power-to-weight ratio.

Measurement and analysis of W16 engine noise present their own set of challenges. The complexity of the sound profile requires sophisticated acoustic measurement tools and analysis software capable of isolating and characterizing multiple noise sources simultaneously. Current limitations in real-time analysis and the ability to differentiate between closely related noise frequencies can hinder the development of targeted NVH solutions.

Moreover, the exclusivity and low production volumes of W16-equipped vehicles limit the resources available for extensive NVH research and development. This constraint often results in solutions that are highly customized but may lack the benefit of large-scale testing and refinement seen in more common engine configurations.

In conclusion, while significant progress has been made in W16 engine NVH control, substantial challenges remain. Overcoming these limitations will require innovative approaches to materials science, advanced signal processing techniques, and a holistic view of engine design that integrates NVH considerations from the earliest stages of development.

Existing W16 Noise Measurement and Control Methods

01 Noise reduction systems for W16 engines

Various noise reduction systems are designed specifically for W16 engines to minimize engine noise. These systems may include advanced mufflers, sound-absorbing materials, and acoustic chambers that help to attenuate and dissipate sound waves generated by the engine. The goal is to reduce both internal and external noise levels while maintaining engine performance.- Noise reduction systems for W16 engines: Various noise reduction systems are employed in W16 engines to minimize engine noise. These systems may include sound-absorbing materials, acoustic barriers, and specialized exhaust systems designed to dampen and redirect sound waves. Advanced noise cancellation technologies may also be integrated to actively counteract engine noise.

- Engine design modifications for noise reduction: Structural modifications to the W16 engine design can help reduce noise. This may involve optimizing the engine block geometry, improving cylinder head design, and using advanced materials with better vibration-damping properties. Balancing mechanisms and precision manufacturing techniques are also employed to minimize mechanical noise sources.

- Electronic noise control systems: Electronic systems are implemented to monitor and control engine noise in W16 engines. These may include sensors to detect noise levels, microprocessors to analyze sound patterns, and actuators to adjust engine parameters in real-time. Active noise control algorithms can be used to generate anti-noise signals, effectively canceling out unwanted engine sounds.

- Exhaust system innovations for noise reduction: Specialized exhaust systems are developed for W16 engines to reduce noise emissions. These may include multi-chamber mufflers, resonators, and variable geometry exhaust components. Advanced materials and coatings are used in exhaust systems to absorb sound and reduce thermal expansion noise.

- Vibration isolation and damping techniques: Various vibration isolation and damping techniques are employed to reduce noise transmission from the W16 engine to the vehicle body and cabin. This includes the use of advanced engine mounts, isolation bushings, and damping materials strategically placed throughout the engine compartment and vehicle structure.

02 Active noise control for W16 engines

Active noise control systems are implemented in W16 engines to counteract unwanted engine noise. These systems use electronic sensors to detect engine noise patterns and generate anti-noise signals to cancel out the undesirable sounds. This technology can be particularly effective in reducing low-frequency engine noise and improving overall cabin comfort in vehicles equipped with W16 engines.Expand Specific Solutions03 Engine design modifications to reduce noise

Structural modifications and design improvements are made to W16 engines to minimize noise generation at the source. These may include optimizing engine block design, improving cylinder head geometry, and using advanced materials with better sound-damping properties. Such modifications aim to reduce mechanical noise and vibrations inherent to the W16 engine configuration.Expand Specific Solutions04 Exhaust system enhancements for noise reduction

Specialized exhaust systems are developed for W16 engines to reduce noise emissions. These systems may incorporate resonators, multiple mufflers, and variable valve technologies to control exhaust flow and sound. Advanced materials and designs are used to optimize sound attenuation while maintaining exhaust efficiency and engine performance.Expand Specific Solutions05 Vibration isolation and damping techniques

Various vibration isolation and damping techniques are employed to minimize noise transmission from W16 engines to the vehicle body and cabin. These may include advanced engine mounts, sound-absorbing materials, and structural reinforcements. The goal is to isolate engine vibrations and prevent them from amplifying or transmitting noise to other parts of the vehicle.Expand Specific Solutions

Key Players in W16 Engine and NVH Solutions

The W16 Engine Noise Control market is in a growth phase, driven by increasing demand for quieter and more refined high-performance vehicles. The market size is expanding as luxury automakers invest in advanced NVH solutions. Technologically, the field is rapidly evolving, with companies like Ford Global Technologies, GM Global Technology Operations, and Mercedes-Benz Group AG leading innovation. These firms are developing sophisticated measurement techniques and noise reduction technologies. Emerging players such as Tula Technology are introducing software-based solutions, while traditional automakers like Toyota, Nissan, and Hyundai are also making significant strides in engine noise control for their premium offerings.

GM Global Technology Operations LLC

Technical Solution: GM's approach to W16 engine noise control focuses on a multi-faceted strategy. They have developed an advanced Electronic Sound Quality (ESQ) system that uses predictive algorithms to anticipate engine noise based on throttle position, engine speed, and load[4]. This system works in conjunction with active noise cancellation technology to provide a more refined driving experience. GM has also invested in innovative engine design features, such as a rigid aluminum engine block with cast-in-place iron cylinder liners, which significantly reduces engine vibration and noise[5]. Furthermore, GM employs advanced computational fluid dynamics (CFD) simulations to optimize exhaust system design, minimizing noise without compromising performance[6].

Strengths: Proactive noise prediction and cancellation, innovative engine design for inherent noise reduction, and optimized exhaust systems. Weaknesses: High development costs and potential over-reliance on electronic systems for noise control.

Mercedes-Benz Group AG

Technical Solution: Mercedes-Benz has developed a sophisticated approach to W16 engine noise control, focusing on both active and passive measures. Their Active Noise Control (ANC) system utilizes advanced digital signal processing to create anti-noise waves, effectively canceling out low-frequency engine sounds[7]. This is complemented by their Acoustic Comfort package, which includes specially designed insulation materials and acoustic glass to further reduce noise transmission into the cabin. Mercedes has also implemented a unique engine mounting system that uses electro-hydraulic mounts to dynamically adjust stiffness based on engine vibration, significantly reducing structure-borne noise[8]. Additionally, they have developed a variable exhaust system that can alter the exhaust note based on driving mode, allowing for a more refined sound when desired[9].

Strengths: Comprehensive noise control strategy combining cutting-edge active and passive technologies, dynamic engine mounting system, and customizable exhaust notes. Weaknesses: High complexity and cost of implementation, potential for system failures due to the intricate nature of the technologies used.

Core Innovations in W16 NVH Reduction

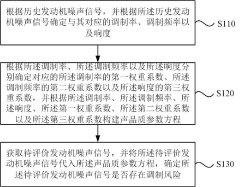

Engine sound quality evaluation method and device, electronic equipment and storage medium

PatentActiveCN117990378A

Innovation

- By determining the modulation rate, modulation frequency and loudness based on historical engine noise signals, calculating the corresponding weight coefficients, and constructing a sound quality parameter equation, it is possible to determine whether there is a modulation risk in the engine noise signal to be evaluated and optimize it.

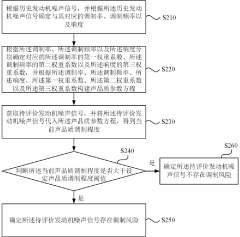

Engine operation power adjusting method and device and electronic equipment

PatentPendingCN117657034A

Innovation

- By obtaining the in-car sound pressure value of the target vehicle, and finding the maximum sound pressure value that is less than the in-car sound pressure value from the preset correspondence between the engine operating power and the sound pressure value, the engine operating power is adjusted to improve efficiency.

Environmental Regulations Impact on Engine NVH

Environmental regulations have become increasingly stringent in recent years, significantly impacting the development of engine noise, vibration, and harshness (NVH) solutions, particularly for high-performance engines like the W16. These regulations aim to reduce noise pollution and improve overall environmental quality, forcing manufacturers to adapt their engine designs and NVH control strategies.

One of the primary impacts of environmental regulations on engine NVH is the need for more advanced sound insulation and damping materials. As noise emission limits become stricter, engineers must develop innovative solutions to contain engine noise without compromising performance or adding excessive weight. This has led to the adoption of lightweight, high-performance acoustic materials and the integration of active noise control systems in many high-end vehicles.

The push for cleaner emissions has also indirectly affected engine NVH characteristics. The implementation of technologies such as turbocharging, direct injection, and exhaust gas recirculation (EGR) to meet emission standards can introduce new noise and vibration sources. For instance, turbochargers can generate high-frequency whistling sounds, while direct injection systems may produce a distinctive ticking noise. These challenges require engineers to develop targeted NVH solutions specific to these new technologies.

Furthermore, environmental regulations have accelerated the trend towards electrification and hybridization, which presents both challenges and opportunities for NVH control. While electric motors are generally quieter than internal combustion engines, they can produce high-frequency whines that require different mitigation strategies. In hybrid powertrains, the transition between electric and combustion modes must be carefully managed to maintain a consistent and pleasant sound profile.

The regulatory landscape has also prompted increased focus on exterior vehicle noise. Many countries have implemented pass-by noise regulations, which limit the sound levels produced by vehicles under specific driving conditions. This has led to the development of active exhaust systems and sophisticated engine sound management techniques to ensure compliance while maintaining the desired auditory character of high-performance engines like the W16.

As a result of these regulatory pressures, NVH engineering has become an increasingly critical aspect of engine development. Manufacturers must now consider NVH performance from the earliest stages of design, integrating advanced simulation tools and testing methodologies to predict and optimize noise and vibration characteristics. This proactive approach helps ensure compliance with current and future environmental regulations while maintaining the performance and emotional appeal expected from premium engines.

One of the primary impacts of environmental regulations on engine NVH is the need for more advanced sound insulation and damping materials. As noise emission limits become stricter, engineers must develop innovative solutions to contain engine noise without compromising performance or adding excessive weight. This has led to the adoption of lightweight, high-performance acoustic materials and the integration of active noise control systems in many high-end vehicles.

The push for cleaner emissions has also indirectly affected engine NVH characteristics. The implementation of technologies such as turbocharging, direct injection, and exhaust gas recirculation (EGR) to meet emission standards can introduce new noise and vibration sources. For instance, turbochargers can generate high-frequency whistling sounds, while direct injection systems may produce a distinctive ticking noise. These challenges require engineers to develop targeted NVH solutions specific to these new technologies.

Furthermore, environmental regulations have accelerated the trend towards electrification and hybridization, which presents both challenges and opportunities for NVH control. While electric motors are generally quieter than internal combustion engines, they can produce high-frequency whines that require different mitigation strategies. In hybrid powertrains, the transition between electric and combustion modes must be carefully managed to maintain a consistent and pleasant sound profile.

The regulatory landscape has also prompted increased focus on exterior vehicle noise. Many countries have implemented pass-by noise regulations, which limit the sound levels produced by vehicles under specific driving conditions. This has led to the development of active exhaust systems and sophisticated engine sound management techniques to ensure compliance while maintaining the desired auditory character of high-performance engines like the W16.

As a result of these regulatory pressures, NVH engineering has become an increasingly critical aspect of engine development. Manufacturers must now consider NVH performance from the earliest stages of design, integrating advanced simulation tools and testing methodologies to predict and optimize noise and vibration characteristics. This proactive approach helps ensure compliance with current and future environmental regulations while maintaining the performance and emotional appeal expected from premium engines.

Cost-Benefit Analysis of W16 NVH Solutions

The cost-benefit analysis of W16 NVH solutions is a critical aspect of implementing noise control measures for this high-performance engine. The W16 engine, known for its power and complexity, presents unique challenges in noise, vibration, and harshness (NVH) management. This analysis aims to evaluate the economic viability of various NVH solutions against their effectiveness in improving the overall driving experience and meeting regulatory requirements.

Initial costs associated with W16 NVH solutions can be substantial, encompassing research and development, materials, manufacturing processes, and integration into the vehicle design. Advanced sound-absorbing materials, active noise cancellation systems, and precision-engineered engine mounts are among the costlier components. However, these upfront investments must be weighed against long-term benefits and potential cost savings.

One significant benefit is the enhancement of brand perception and customer satisfaction. Luxury and high-performance vehicles equipped with W16 engines are expected to deliver a refined driving experience. Effective NVH solutions contribute to a perception of quality and engineering excellence, potentially increasing sales and customer loyalty. This can lead to improved market share and higher profit margins, offsetting the initial implementation costs.

Regulatory compliance is another crucial factor in the cost-benefit equation. Stringent noise emission standards in various markets necessitate effective NVH control. The cost of implementing these solutions should be compared to potential fines, sales restrictions, or the need for market-specific modifications if regulations are not met. In this context, proactive NVH management can be seen as a risk mitigation strategy with quantifiable financial benefits.

Fuel efficiency and performance optimization can also be indirect benefits of NVH solutions. Some noise reduction techniques, such as improved aerodynamics or engine efficiency measures, may contribute to better fuel economy or performance characteristics. These improvements can translate into cost savings for consumers and enhanced competitiveness in the market.

However, it's essential to consider potential trade-offs. Excessive focus on noise reduction might lead to increased vehicle weight, which could negatively impact performance and fuel efficiency. Therefore, a balanced approach is necessary, optimizing NVH solutions while maintaining the W16 engine's core performance attributes.

The longevity and durability of NVH solutions should also factor into the cost-benefit analysis. High-quality materials and well-engineered systems may have higher upfront costs but can offer extended service life and reduced maintenance needs. This can result in lower warranty claims and service costs over the vehicle's lifetime, improving the overall value proposition for both the manufacturer and the consumer.

In conclusion, while the implementation of advanced NVH solutions for W16 engines involves significant initial investments, the long-term benefits in terms of brand value, regulatory compliance, and customer satisfaction can justify these costs. A comprehensive cost-benefit analysis should consider both tangible and intangible factors to guide decision-making in NVH strategy for high-performance engines.

Initial costs associated with W16 NVH solutions can be substantial, encompassing research and development, materials, manufacturing processes, and integration into the vehicle design. Advanced sound-absorbing materials, active noise cancellation systems, and precision-engineered engine mounts are among the costlier components. However, these upfront investments must be weighed against long-term benefits and potential cost savings.

One significant benefit is the enhancement of brand perception and customer satisfaction. Luxury and high-performance vehicles equipped with W16 engines are expected to deliver a refined driving experience. Effective NVH solutions contribute to a perception of quality and engineering excellence, potentially increasing sales and customer loyalty. This can lead to improved market share and higher profit margins, offsetting the initial implementation costs.

Regulatory compliance is another crucial factor in the cost-benefit equation. Stringent noise emission standards in various markets necessitate effective NVH control. The cost of implementing these solutions should be compared to potential fines, sales restrictions, or the need for market-specific modifications if regulations are not met. In this context, proactive NVH management can be seen as a risk mitigation strategy with quantifiable financial benefits.

Fuel efficiency and performance optimization can also be indirect benefits of NVH solutions. Some noise reduction techniques, such as improved aerodynamics or engine efficiency measures, may contribute to better fuel economy or performance characteristics. These improvements can translate into cost savings for consumers and enhanced competitiveness in the market.

However, it's essential to consider potential trade-offs. Excessive focus on noise reduction might lead to increased vehicle weight, which could negatively impact performance and fuel efficiency. Therefore, a balanced approach is necessary, optimizing NVH solutions while maintaining the W16 engine's core performance attributes.

The longevity and durability of NVH solutions should also factor into the cost-benefit analysis. High-quality materials and well-engineered systems may have higher upfront costs but can offer extended service life and reduced maintenance needs. This can result in lower warranty claims and service costs over the vehicle's lifetime, improving the overall value proposition for both the manufacturer and the consumer.

In conclusion, while the implementation of advanced NVH solutions for W16 engines involves significant initial investments, the long-term benefits in terms of brand value, regulatory compliance, and customer satisfaction can justify these costs. A comprehensive cost-benefit analysis should consider both tangible and intangible factors to guide decision-making in NVH strategy for high-performance engines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!