How To Diagnose Common Failures In High-Output W16 Engines

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

W16 Engine Evolution

The W16 engine, a marvel of automotive engineering, has undergone significant evolution since its inception. This unique configuration, essentially combining two V8 engines, was first conceptualized in the early 20th century but only saw practical implementation in high-performance vehicles in recent decades.

The journey of the W16 engine began with theoretical designs in the 1920s, but it wasn't until the late 1990s that Volkswagen Group seriously pursued its development. The first modern W16 engine was unveiled in the Bentley Hunaudières concept car in 1999, showcasing the potential of this complex powerplant.

A major milestone in W16 evolution came with the introduction of the Bugatti Veyron in 2005. This hypercar featured a quad-turbocharged 8.0-liter W16 engine, producing an unprecedented 1,001 horsepower. The Veyron's engine represented a quantum leap in automotive technology, combining massive power output with daily drivability.

Subsequent iterations of the W16 engine saw continuous improvements in power, efficiency, and reliability. The Bugatti Chiron, introduced in 2016, featured an enhanced version of the W16, now producing 1,479 horsepower. This evolution demonstrated advancements in materials science, thermal management, and engine control systems.

The latest evolution, seen in the Bugatti Centodieci and Chiron Super Sport 300+, pushes the W16 to new heights with outputs exceeding 1,600 horsepower. These developments have been accompanied by improvements in cooling systems, fuel injection technology, and turbocharger design to manage the immense heat and pressure generated by such high-output engines.

Throughout its evolution, the W16 engine has faced and overcome numerous engineering challenges. These include managing thermal loads, reducing friction between components, and optimizing the complex valve timing required for such a large number of cylinders. Innovations in materials, such as the use of lightweight alloys and advanced coatings, have been crucial in addressing these challenges.

The diagnostic capabilities for W16 engines have also evolved alongside the engine itself. Modern W16 engines are equipped with sophisticated sensor arrays and onboard diagnostic systems, allowing for real-time monitoring of engine performance and early detection of potential issues. This evolution in diagnostics has been essential in maintaining the reliability and longevity of these complex powerplants.

As environmental concerns grow, the future evolution of the W16 engine faces new challenges. Recent developments have focused on improving fuel efficiency and reducing emissions while maintaining high performance. This has led to the exploration of hybrid technologies and more advanced engine management systems, potentially paving the way for a new generation of high-output, environmentally conscious W16 engines.

The journey of the W16 engine began with theoretical designs in the 1920s, but it wasn't until the late 1990s that Volkswagen Group seriously pursued its development. The first modern W16 engine was unveiled in the Bentley Hunaudières concept car in 1999, showcasing the potential of this complex powerplant.

A major milestone in W16 evolution came with the introduction of the Bugatti Veyron in 2005. This hypercar featured a quad-turbocharged 8.0-liter W16 engine, producing an unprecedented 1,001 horsepower. The Veyron's engine represented a quantum leap in automotive technology, combining massive power output with daily drivability.

Subsequent iterations of the W16 engine saw continuous improvements in power, efficiency, and reliability. The Bugatti Chiron, introduced in 2016, featured an enhanced version of the W16, now producing 1,479 horsepower. This evolution demonstrated advancements in materials science, thermal management, and engine control systems.

The latest evolution, seen in the Bugatti Centodieci and Chiron Super Sport 300+, pushes the W16 to new heights with outputs exceeding 1,600 horsepower. These developments have been accompanied by improvements in cooling systems, fuel injection technology, and turbocharger design to manage the immense heat and pressure generated by such high-output engines.

Throughout its evolution, the W16 engine has faced and overcome numerous engineering challenges. These include managing thermal loads, reducing friction between components, and optimizing the complex valve timing required for such a large number of cylinders. Innovations in materials, such as the use of lightweight alloys and advanced coatings, have been crucial in addressing these challenges.

The diagnostic capabilities for W16 engines have also evolved alongside the engine itself. Modern W16 engines are equipped with sophisticated sensor arrays and onboard diagnostic systems, allowing for real-time monitoring of engine performance and early detection of potential issues. This evolution in diagnostics has been essential in maintaining the reliability and longevity of these complex powerplants.

As environmental concerns grow, the future evolution of the W16 engine faces new challenges. Recent developments have focused on improving fuel efficiency and reducing emissions while maintaining high performance. This has led to the exploration of hybrid technologies and more advanced engine management systems, potentially paving the way for a new generation of high-output, environmentally conscious W16 engines.

Market for High-Output Engines

The market for high-output engines, particularly W16 configurations, represents a niche but highly lucrative segment within the automotive industry. These powerplants are primarily found in ultra-luxury and hypercar segments, catering to a discerning clientele that demands exceptional performance and exclusivity. The Bugatti Chiron, featuring a quad-turbocharged 8.0-liter W16 engine, stands as the pinnacle of this market, producing over 1,500 horsepower and achieving speeds in excess of 300 mph.

Despite their limited production numbers, high-output W16 engines have a significant impact on the broader automotive market. They serve as technological showcases, pushing the boundaries of internal combustion engine design and efficiency. Innovations developed for these engines often trickle down to more mainstream applications, benefiting the wider industry.

The market for vehicles equipped with high-output engines has shown resilience and growth, even in the face of increasing environmental regulations. Wealthy enthusiasts and collectors continue to seek out these engineering marvels, driving demand for ever-more powerful and refined powerplants. This sustained interest has encouraged manufacturers to invest in research and development, leading to advancements in materials science, thermal management, and powertrain control systems.

While exact market size figures for high-output W16 engines are challenging to quantify due to their exclusivity, the broader high-performance engine market is estimated to be worth several billion dollars annually. This includes not only complete vehicles but also aftermarket parts, specialized maintenance services, and related technologies.

The future of the high-output engine market faces both challenges and opportunities. Stricter emissions regulations and the shift towards electrification pose potential threats to traditional internal combustion engines. However, manufacturers are exploring hybrid technologies and alternative fuels to ensure the longevity of high-performance powerplants. Some are even developing all-electric hypercars that aim to match or exceed the performance of their combustion-powered counterparts.

As diagnostic technologies advance, the ability to quickly and accurately identify failures in complex engines like the W16 becomes increasingly critical. This creates a parallel market for sophisticated diagnostic tools and training programs, essential for maintaining these high-value assets. The demand for specialized technicians capable of servicing these engines also continues to grow, supporting a niche but highly skilled workforce within the automotive industry.

Despite their limited production numbers, high-output W16 engines have a significant impact on the broader automotive market. They serve as technological showcases, pushing the boundaries of internal combustion engine design and efficiency. Innovations developed for these engines often trickle down to more mainstream applications, benefiting the wider industry.

The market for vehicles equipped with high-output engines has shown resilience and growth, even in the face of increasing environmental regulations. Wealthy enthusiasts and collectors continue to seek out these engineering marvels, driving demand for ever-more powerful and refined powerplants. This sustained interest has encouraged manufacturers to invest in research and development, leading to advancements in materials science, thermal management, and powertrain control systems.

While exact market size figures for high-output W16 engines are challenging to quantify due to their exclusivity, the broader high-performance engine market is estimated to be worth several billion dollars annually. This includes not only complete vehicles but also aftermarket parts, specialized maintenance services, and related technologies.

The future of the high-output engine market faces both challenges and opportunities. Stricter emissions regulations and the shift towards electrification pose potential threats to traditional internal combustion engines. However, manufacturers are exploring hybrid technologies and alternative fuels to ensure the longevity of high-performance powerplants. Some are even developing all-electric hypercars that aim to match or exceed the performance of their combustion-powered counterparts.

As diagnostic technologies advance, the ability to quickly and accurately identify failures in complex engines like the W16 becomes increasingly critical. This creates a parallel market for sophisticated diagnostic tools and training programs, essential for maintaining these high-value assets. The demand for specialized technicians capable of servicing these engines also continues to grow, supporting a niche but highly skilled workforce within the automotive industry.

W16 Engine Challenges

The W16 engine, a marvel of automotive engineering, presents unique challenges in diagnosis and maintenance due to its complex design and high-performance nature. As a powerplant primarily used in ultra-luxury and high-performance vehicles, the W16 engine's intricate configuration demands specialized knowledge and advanced diagnostic techniques to identify and address common failures.

One of the primary challenges in diagnosing W16 engine issues stems from its unconventional layout. The W16 configuration, essentially two narrow-angle V8 engines joined at the crankshaft, creates a compact yet highly complex system. This design can make it difficult to access certain components, requiring specialized tools and procedures for even routine inspections. Technicians must be well-versed in the engine's architecture to navigate its intricate web of components effectively.

The high output of W16 engines, often exceeding 1,000 horsepower, puts tremendous stress on all engine components. This extreme performance envelope can lead to accelerated wear and potential failures that may not be common in less powerful engines. Diagnosing issues related to this high-stress environment requires a deep understanding of material limitations and the ability to detect early signs of component fatigue or failure.

Thermal management presents another significant challenge in W16 engines. With 16 cylinders generating immense heat in a relatively compact space, cooling system efficiency is critical. Diagnosing cooling-related issues requires careful analysis of temperature data from multiple sensors and an understanding of the engine's thermal dynamics. Failures in the cooling system can quickly lead to catastrophic engine damage, making accurate and timely diagnosis essential.

The complexity of the W16 engine's fuel and ignition systems also poses diagnostic challenges. With 16 cylinders to manage, the engine control unit (ECU) must precisely coordinate fuel injection and ignition timing. Any discrepancies in these systems can lead to performance issues, increased emissions, or engine damage. Diagnosing these problems often requires advanced electronic diagnostic tools and the ability to interpret complex data streams from the ECU.

Vibration analysis is particularly crucial and challenging in W16 engines. The unique configuration can create complex vibration patterns that are difficult to interpret. Technicians must be skilled in using advanced vibration analysis tools and techniques to distinguish between normal operational vibrations and those indicating potential failures.

Lastly, the rarity of W16 engines in the automotive market means that diagnostic information and repair procedures are often limited. Technicians may face challenges in accessing up-to-date technical information or specialized diagnostic equipment. This scarcity of resources necessitates a high level of expertise and problem-solving skills to effectively diagnose and address engine issues.

One of the primary challenges in diagnosing W16 engine issues stems from its unconventional layout. The W16 configuration, essentially two narrow-angle V8 engines joined at the crankshaft, creates a compact yet highly complex system. This design can make it difficult to access certain components, requiring specialized tools and procedures for even routine inspections. Technicians must be well-versed in the engine's architecture to navigate its intricate web of components effectively.

The high output of W16 engines, often exceeding 1,000 horsepower, puts tremendous stress on all engine components. This extreme performance envelope can lead to accelerated wear and potential failures that may not be common in less powerful engines. Diagnosing issues related to this high-stress environment requires a deep understanding of material limitations and the ability to detect early signs of component fatigue or failure.

Thermal management presents another significant challenge in W16 engines. With 16 cylinders generating immense heat in a relatively compact space, cooling system efficiency is critical. Diagnosing cooling-related issues requires careful analysis of temperature data from multiple sensors and an understanding of the engine's thermal dynamics. Failures in the cooling system can quickly lead to catastrophic engine damage, making accurate and timely diagnosis essential.

The complexity of the W16 engine's fuel and ignition systems also poses diagnostic challenges. With 16 cylinders to manage, the engine control unit (ECU) must precisely coordinate fuel injection and ignition timing. Any discrepancies in these systems can lead to performance issues, increased emissions, or engine damage. Diagnosing these problems often requires advanced electronic diagnostic tools and the ability to interpret complex data streams from the ECU.

Vibration analysis is particularly crucial and challenging in W16 engines. The unique configuration can create complex vibration patterns that are difficult to interpret. Technicians must be skilled in using advanced vibration analysis tools and techniques to distinguish between normal operational vibrations and those indicating potential failures.

Lastly, the rarity of W16 engines in the automotive market means that diagnostic information and repair procedures are often limited. Technicians may face challenges in accessing up-to-date technical information or specialized diagnostic equipment. This scarcity of resources necessitates a high level of expertise and problem-solving skills to effectively diagnose and address engine issues.

W16 Diagnostic Methods

01 Engine diagnostics and failure detection

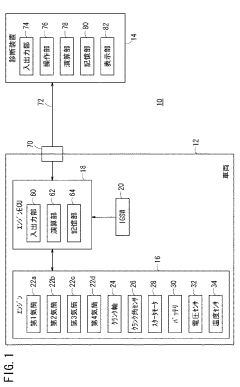

Advanced diagnostic systems are crucial for high-output W16 engines to detect and prevent failures. These systems use various sensors and algorithms to monitor engine performance, identify potential issues, and alert drivers or technicians to necessary maintenance or repairs. Early detection of problems can prevent catastrophic failures and extend engine life.- Engine monitoring and diagnostics: Advanced monitoring systems are crucial for high-output W16 engines to detect potential failures early. These systems use various sensors and data analysis techniques to continuously assess engine performance, identify anomalies, and predict potential issues before they lead to catastrophic failures.

- Thermal management and cooling systems: Effective thermal management is essential for preventing failures in high-output W16 engines. Advanced cooling systems, including innovative radiator designs and coolant circulation methods, are employed to maintain optimal operating temperatures and prevent overheating-related failures.

- Materials and manufacturing techniques: The use of advanced materials and manufacturing techniques is critical in producing reliable high-output W16 engines. This includes the development of heat-resistant alloys, precision machining processes, and innovative coating technologies to enhance durability and reduce wear in critical engine components.

- Lubrication system optimization: Optimized lubrication systems are crucial for preventing failures in high-output W16 engines. This involves developing advanced oil formulations, improving oil circulation and filtration systems, and implementing innovative oil cooling techniques to ensure proper lubrication under extreme operating conditions.

- Electronic control and failure prevention: Sophisticated electronic control systems play a vital role in preventing failures in high-output W16 engines. These systems include advanced engine management units, real-time performance optimization algorithms, and fail-safe mechanisms that can detect and respond to potential failure conditions before they escalate.

02 Thermal management and cooling systems

Effective thermal management is essential for high-output W16 engines to prevent overheating and related failures. Advanced cooling systems, including innovative radiator designs, coolant formulations, and heat dissipation techniques, are employed to maintain optimal operating temperatures under extreme performance conditions.Expand Specific Solutions03 Materials and manufacturing processes

The use of advanced materials and manufacturing processes is critical in producing reliable high-output W16 engines. This includes the development of heat-resistant alloys, precision machining techniques, and quality control measures to ensure component durability and reduce the risk of material failures under high stress and temperature conditions.Expand Specific Solutions04 Lubrication and oil management systems

Sophisticated lubrication and oil management systems are vital for preventing failures in high-output W16 engines. These systems ensure proper oil distribution, pressure regulation, and filtration to minimize wear on engine components and reduce the risk of oil-related failures, particularly under high-performance operating conditions.Expand Specific Solutions05 Electronic control and performance optimization

Advanced electronic control systems play a crucial role in optimizing the performance and reliability of high-output W16 engines. These systems manage fuel injection, ignition timing, and other critical parameters to ensure efficient operation and prevent failures due to suboptimal engine management or excessive stress on components.Expand Specific Solutions

W16 Manufacturers

The competitive landscape for diagnosing common failures in high-output W16 engines is characterized by a mature market with established players and advanced technologies. The market size is relatively niche due to the specialized nature of W16 engines, primarily used in high-performance luxury vehicles. Key players like Robert Bosch GmbH, Continental Automotive GmbH, and Delphi International Operations Luxembourg SARL lead in automotive diagnostics technology. These companies leverage their extensive experience in engine management systems and sensor technologies to develop sophisticated diagnostic tools. Luxury automakers such as Volkswagen Group (Bugatti) and BMW AG also contribute significantly to W16 engine diagnostics through their in-house expertise. The technology's maturity is evident in the integration of advanced sensors, real-time monitoring systems, and AI-driven predictive maintenance solutions offered by these industry leaders.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced diagnostic systems for high-output engines, including W16 configurations. Their approach combines real-time sensor data analysis with machine learning algorithms to detect and predict common failures. The system utilizes a network of sensors strategically placed throughout the engine to monitor key parameters such as temperature, pressure, and vibration[1]. This data is processed by a central control unit that employs pattern recognition to identify anomalies indicative of potential failures. Additionally, Bosch has implemented predictive maintenance capabilities, analyzing historical data and engine performance trends to forecast potential issues before they occur[3]. Their diagnostic software also includes a user-friendly interface for technicians, providing detailed error codes and step-by-step troubleshooting guides specific to W16 engines.

Strengths: Comprehensive sensor network, advanced data analytics, and predictive maintenance capabilities. Weaknesses: High implementation cost and complexity, potential for false positives in early stages of deployment.

Toyota Motor Corp.

Technical Solution: Toyota has developed a multi-faceted approach to diagnosing failures in high-output engines, which can be applied to W16 configurations. Their system incorporates advanced OBD-II (On-Board Diagnostics) technology with enhanced capabilities for monitoring complex engine layouts. Toyota's diagnostic strategy focuses on real-time performance analysis, utilizing a vast array of sensors to monitor critical engine parameters[2]. The system employs adaptive learning algorithms that continuously refine the diagnostic process based on accumulated data. Toyota has also integrated thermal imaging technology to detect hotspots and potential areas of failure in the engine block[4]. Their diagnostic software includes a comprehensive database of W16-specific fault codes and corresponding troubleshooting procedures, enabling quick and accurate identification of common failures.

Strengths: Adaptive learning algorithms, extensive fault code database, and integration of thermal imaging. Weaknesses: May require frequent updates to maintain accuracy, potentially less specialized for W16 engines compared to luxury sports car manufacturers.

Key W16 Failure Modes

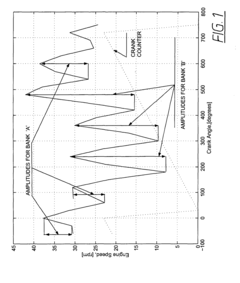

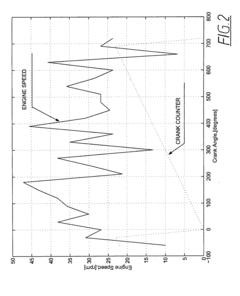

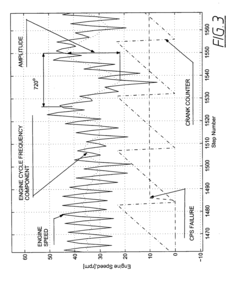

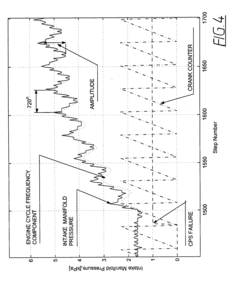

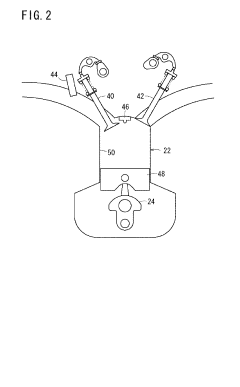

Method for detection failure in a cam profile switching system

PatentInactiveEP1580407A1

Innovation

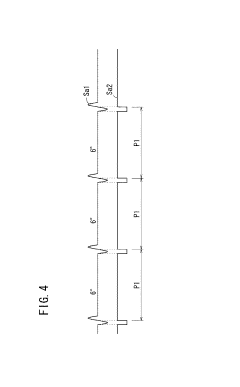

- A method that arranges specific ignition sequences and uses amplitude and phase analysis of low-frequency components in engine speed and intake manifold pressure signals to detect failures, independent of ignition and fuelling system issues, allowing for cylinder individual failure detection at both low and high speeds.

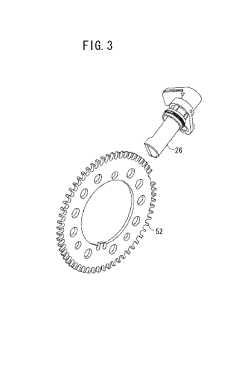

Method and device for diagnosis of failure in engine

PatentInactiveJP2012202241A

Innovation

- The method involves detecting the fluctuation value of the angular velocity of the crankshaft during engine operation to identify misfires and compression pressure abnormalities without disassembling the engine, using the vehicle ECU's logic for misfire determination to simplify the configuration and reduce man-hours.

W16 Emissions Compliance

Emissions compliance is a critical aspect of W16 engine development and operation, particularly for high-output variants. These powerful engines must meet increasingly stringent environmental regulations while maintaining their exceptional performance characteristics. The W16 engine, most notably used in Bugatti vehicles, faces unique challenges in emissions control due to its large displacement and high power output.

Current emissions standards for W16 engines are primarily governed by Euro 6 regulations in Europe and EPA Tier 3 standards in the United States. These regulations set strict limits on various pollutants, including carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter (PM). To meet these standards, W16 engines employ a combination of advanced technologies and strategies.

One key technology is the use of multiple catalytic converters. W16 engines typically feature four or more catalytic converters to effectively reduce harmful emissions. These converters are strategically placed to maximize their efficiency in converting pollutants into less harmful substances. Additionally, the engine management system plays a crucial role in optimizing combustion processes to minimize the formation of pollutants at the source.

Advanced fuel injection systems are another critical component of W16 emissions compliance. Direct fuel injection, coupled with precise electronic control, allows for more accurate fuel metering and improved combustion efficiency. This not only helps reduce emissions but also contributes to the engine's overall performance and fuel economy.

Exhaust gas recirculation (EGR) is widely employed in W16 engines to reduce NOx emissions. By recirculating a portion of the exhaust gases back into the combustion chamber, peak combustion temperatures are lowered, resulting in decreased NOx formation. However, implementing EGR in high-output engines requires careful calibration to maintain performance while achieving emissions targets.

Particulate filters have become increasingly important for W16 engines, especially in light of tightening regulations on particulate matter emissions. These filters trap soot particles from the exhaust stream, periodically regenerating to burn off accumulated particulates. Integrating effective particulate filtration without compromising the engine's performance characteristics presents a significant engineering challenge.

Looking ahead, future emissions compliance for W16 engines will likely require even more advanced technologies. This may include the integration of mild hybrid systems to further reduce emissions during low-load operations and improve overall efficiency. Additionally, ongoing research into advanced materials and coatings for catalytic converters and exhaust systems aims to enhance their effectiveness and durability under the extreme conditions generated by high-output W16 engines.

Current emissions standards for W16 engines are primarily governed by Euro 6 regulations in Europe and EPA Tier 3 standards in the United States. These regulations set strict limits on various pollutants, including carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter (PM). To meet these standards, W16 engines employ a combination of advanced technologies and strategies.

One key technology is the use of multiple catalytic converters. W16 engines typically feature four or more catalytic converters to effectively reduce harmful emissions. These converters are strategically placed to maximize their efficiency in converting pollutants into less harmful substances. Additionally, the engine management system plays a crucial role in optimizing combustion processes to minimize the formation of pollutants at the source.

Advanced fuel injection systems are another critical component of W16 emissions compliance. Direct fuel injection, coupled with precise electronic control, allows for more accurate fuel metering and improved combustion efficiency. This not only helps reduce emissions but also contributes to the engine's overall performance and fuel economy.

Exhaust gas recirculation (EGR) is widely employed in W16 engines to reduce NOx emissions. By recirculating a portion of the exhaust gases back into the combustion chamber, peak combustion temperatures are lowered, resulting in decreased NOx formation. However, implementing EGR in high-output engines requires careful calibration to maintain performance while achieving emissions targets.

Particulate filters have become increasingly important for W16 engines, especially in light of tightening regulations on particulate matter emissions. These filters trap soot particles from the exhaust stream, periodically regenerating to burn off accumulated particulates. Integrating effective particulate filtration without compromising the engine's performance characteristics presents a significant engineering challenge.

Looking ahead, future emissions compliance for W16 engines will likely require even more advanced technologies. This may include the integration of mild hybrid systems to further reduce emissions during low-load operations and improve overall efficiency. Additionally, ongoing research into advanced materials and coatings for catalytic converters and exhaust systems aims to enhance their effectiveness and durability under the extreme conditions generated by high-output W16 engines.

W16 Reliability Metrics

Reliability metrics for W16 engines are crucial indicators of performance and durability, providing valuable insights into the engine's overall health and potential failure points. These metrics encompass a wide range of parameters, including mean time between failures (MTBF), failure rates, and component-specific reliability data. For high-output W16 engines, such as those found in luxury and high-performance vehicles, reliability metrics are particularly important due to the complex nature of the engine design and the extreme conditions under which they operate.

One key reliability metric for W16 engines is the cylinder pressure curve analysis. This metric provides detailed information about combustion efficiency, valve timing, and potential issues with individual cylinders. By monitoring deviations in cylinder pressure curves across all 16 cylinders, engineers can identify early signs of component wear, valve leakage, or fuel injection problems. Another critical metric is oil analysis, which involves examining the engine oil for metal particles, contaminants, and viscosity changes. Regular oil analysis can reveal accelerated wear in specific engine components, allowing for proactive maintenance and preventing catastrophic failures.

Vibration analysis is another essential reliability metric for W16 engines. By measuring and analyzing vibration patterns across different engine speeds and loads, technicians can detect imbalances, misalignments, or bearing wear before they lead to more severe issues. Additionally, exhaust gas composition analysis serves as a valuable metric for assessing engine health. Deviations in exhaust gas composition can indicate problems with fuel mixture, catalytic converter efficiency, or valve sealing.

Temperature monitoring across various engine components is a crucial reliability metric for high-output W16 engines. This includes coolant temperature, oil temperature, and exhaust gas temperature at multiple points. Abnormal temperature readings can signal cooling system inefficiencies, oil circulation problems, or combustion irregularities. Furthermore, fuel consumption metrics provide insights into engine efficiency and potential issues with fuel delivery or combustion processes.

Electronic control unit (ECU) data logging is an increasingly important reliability metric for modern W16 engines. By analyzing ECU data, technicians can identify patterns in sensor readings, fuel injection timing, and ignition events that may indicate developing problems. This data-driven approach allows for more precise diagnostics and predictive maintenance strategies. Lastly, compression and leak-down tests remain fundamental reliability metrics, providing direct measurements of cylinder sealing integrity and valve function across all 16 cylinders.

One key reliability metric for W16 engines is the cylinder pressure curve analysis. This metric provides detailed information about combustion efficiency, valve timing, and potential issues with individual cylinders. By monitoring deviations in cylinder pressure curves across all 16 cylinders, engineers can identify early signs of component wear, valve leakage, or fuel injection problems. Another critical metric is oil analysis, which involves examining the engine oil for metal particles, contaminants, and viscosity changes. Regular oil analysis can reveal accelerated wear in specific engine components, allowing for proactive maintenance and preventing catastrophic failures.

Vibration analysis is another essential reliability metric for W16 engines. By measuring and analyzing vibration patterns across different engine speeds and loads, technicians can detect imbalances, misalignments, or bearing wear before they lead to more severe issues. Additionally, exhaust gas composition analysis serves as a valuable metric for assessing engine health. Deviations in exhaust gas composition can indicate problems with fuel mixture, catalytic converter efficiency, or valve sealing.

Temperature monitoring across various engine components is a crucial reliability metric for high-output W16 engines. This includes coolant temperature, oil temperature, and exhaust gas temperature at multiple points. Abnormal temperature readings can signal cooling system inefficiencies, oil circulation problems, or combustion irregularities. Furthermore, fuel consumption metrics provide insights into engine efficiency and potential issues with fuel delivery or combustion processes.

Electronic control unit (ECU) data logging is an increasingly important reliability metric for modern W16 engines. By analyzing ECU data, technicians can identify patterns in sensor readings, fuel injection timing, and ignition events that may indicate developing problems. This data-driven approach allows for more precise diagnostics and predictive maintenance strategies. Lastly, compression and leak-down tests remain fundamental reliability metrics, providing direct measurements of cylinder sealing integrity and valve function across all 16 cylinders.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!