W16 Engine Comparative Study: Turbocharging Strategies And Gains

AUG 21, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

W16 Engine Evolution

The W16 engine, a marvel of automotive engineering, has undergone significant evolution since its inception. This unique powerplant, characterized by its 16-cylinder configuration arranged in a W formation, has been primarily associated with high-performance luxury vehicles, most notably those produced by Bugatti.

The journey of the W16 engine began in the late 1990s when Volkswagen Group, under the leadership of Ferdinand Piëch, embarked on an ambitious project to create an engine that would redefine automotive performance. The concept was to essentially combine two narrow-angle VR8 engines on a common crankshaft, resulting in a compact yet incredibly powerful engine.

The first production W16 engine debuted in the Bugatti Veyron in 2005. This initial iteration displaced 8.0 liters and utilized four turbochargers to produce an astonishing 1,001 horsepower. The engine's design allowed for a relatively compact package, crucial for the Veyron's aerodynamic requirements and weight distribution.

As technology advanced, so did the W16 engine. The Bugatti Chiron, introduced in 2016, featured an evolved version of the W16. While still displacing 8.0 liters, significant improvements in turbocharging, fuel injection, and thermal management allowed this iteration to produce 1,479 horsepower, a substantial increase over its predecessor.

The evolution continued with the Chiron Super Sport 300+, which pushed the boundaries even further. This version of the W16 engine was tuned to deliver 1,578 horsepower, enabling the vehicle to break the 300 mph barrier in 2019, a testament to the engine's ongoing development and potential.

Throughout its evolution, the W16 engine has consistently pushed the boundaries of what's possible in automotive engineering. Advancements in materials science, particularly in the realm of lightweight alloys and heat-resistant components, have played a crucial role in the engine's development. These improvements have allowed for higher operating temperatures and pressures, contributing to increased power output and efficiency.

The turbocharging strategies employed in the W16 engine have also evolved significantly. From the initial quad-turbo setup in the Veyron to the more advanced systems in the Chiron, engineers have continually refined the turbocharging process to minimize lag and maximize power delivery across the entire rev range.

As environmental concerns have grown, recent iterations of the W16 engine have also focused on improving efficiency and reducing emissions, albeit within the context of ultra-high-performance applications. This has involved advancements in engine management systems, combustion optimization, and the integration of technologies such as cylinder deactivation.

The journey of the W16 engine began in the late 1990s when Volkswagen Group, under the leadership of Ferdinand Piëch, embarked on an ambitious project to create an engine that would redefine automotive performance. The concept was to essentially combine two narrow-angle VR8 engines on a common crankshaft, resulting in a compact yet incredibly powerful engine.

The first production W16 engine debuted in the Bugatti Veyron in 2005. This initial iteration displaced 8.0 liters and utilized four turbochargers to produce an astonishing 1,001 horsepower. The engine's design allowed for a relatively compact package, crucial for the Veyron's aerodynamic requirements and weight distribution.

As technology advanced, so did the W16 engine. The Bugatti Chiron, introduced in 2016, featured an evolved version of the W16. While still displacing 8.0 liters, significant improvements in turbocharging, fuel injection, and thermal management allowed this iteration to produce 1,479 horsepower, a substantial increase over its predecessor.

The evolution continued with the Chiron Super Sport 300+, which pushed the boundaries even further. This version of the W16 engine was tuned to deliver 1,578 horsepower, enabling the vehicle to break the 300 mph barrier in 2019, a testament to the engine's ongoing development and potential.

Throughout its evolution, the W16 engine has consistently pushed the boundaries of what's possible in automotive engineering. Advancements in materials science, particularly in the realm of lightweight alloys and heat-resistant components, have played a crucial role in the engine's development. These improvements have allowed for higher operating temperatures and pressures, contributing to increased power output and efficiency.

The turbocharging strategies employed in the W16 engine have also evolved significantly. From the initial quad-turbo setup in the Veyron to the more advanced systems in the Chiron, engineers have continually refined the turbocharging process to minimize lag and maximize power delivery across the entire rev range.

As environmental concerns have grown, recent iterations of the W16 engine have also focused on improving efficiency and reducing emissions, albeit within the context of ultra-high-performance applications. This has involved advancements in engine management systems, combustion optimization, and the integration of technologies such as cylinder deactivation.

Market Demand Analysis

The market demand for advanced turbocharging strategies in W16 engines has been steadily growing, driven by the automotive industry's pursuit of higher performance and efficiency. This demand is particularly strong in the high-end luxury and supercar segments, where W16 engines are predominantly used.

Manufacturers like Bugatti, known for their W16-powered hypercars, have been at the forefront of pushing the boundaries of engine performance. The market for these ultra-high-performance vehicles, while niche, has shown resilience and growth even in challenging economic times. This indicates a consistent demand for cutting-edge turbocharging technologies that can extract maximum power from W16 engines.

The global supercar market, which includes W16-powered vehicles, has been expanding. This growth is fueled by increasing wealth in emerging markets, particularly in Asia and the Middle East, where there is a strong appetite for exclusive, high-performance vehicles. The demand for advanced turbocharging strategies in W16 engines is closely tied to this market trend.

Environmental regulations and the push for improved fuel efficiency have also been significant drivers in the market for advanced turbocharging technologies. Even in the high-performance segment, there is growing pressure to reduce emissions and improve fuel economy without compromising power output. This has led to increased interest in sophisticated turbocharging strategies that can optimize engine performance across a wide range of operating conditions.

The motorsport industry has also played a crucial role in driving demand for advanced turbocharging technologies. Racing teams and manufacturers constantly seek ways to extract more power from their engines while staying within regulatory limits. Innovations developed for racing often trickle down to production vehicles, further stimulating market demand for advanced turbocharging solutions in W16 engines.

There is also a growing trend towards hybridization in the high-performance vehicle segment. This has created a new dimension in the market for turbocharging strategies, as manufacturers explore ways to integrate electric powertrains with turbocharged W16 engines to achieve even higher levels of performance and efficiency.

The aftermarket and tuning sector represents another significant area of demand for advanced turbocharging technologies. Enthusiasts and specialized tuning companies are constantly seeking ways to enhance the performance of W16 engines, creating a market for innovative turbocharging solutions that can be retrofitted or customized.

Manufacturers like Bugatti, known for their W16-powered hypercars, have been at the forefront of pushing the boundaries of engine performance. The market for these ultra-high-performance vehicles, while niche, has shown resilience and growth even in challenging economic times. This indicates a consistent demand for cutting-edge turbocharging technologies that can extract maximum power from W16 engines.

The global supercar market, which includes W16-powered vehicles, has been expanding. This growth is fueled by increasing wealth in emerging markets, particularly in Asia and the Middle East, where there is a strong appetite for exclusive, high-performance vehicles. The demand for advanced turbocharging strategies in W16 engines is closely tied to this market trend.

Environmental regulations and the push for improved fuel efficiency have also been significant drivers in the market for advanced turbocharging technologies. Even in the high-performance segment, there is growing pressure to reduce emissions and improve fuel economy without compromising power output. This has led to increased interest in sophisticated turbocharging strategies that can optimize engine performance across a wide range of operating conditions.

The motorsport industry has also played a crucial role in driving demand for advanced turbocharging technologies. Racing teams and manufacturers constantly seek ways to extract more power from their engines while staying within regulatory limits. Innovations developed for racing often trickle down to production vehicles, further stimulating market demand for advanced turbocharging solutions in W16 engines.

There is also a growing trend towards hybridization in the high-performance vehicle segment. This has created a new dimension in the market for turbocharging strategies, as manufacturers explore ways to integrate electric powertrains with turbocharged W16 engines to achieve even higher levels of performance and efficiency.

The aftermarket and tuning sector represents another significant area of demand for advanced turbocharging technologies. Enthusiasts and specialized tuning companies are constantly seeking ways to enhance the performance of W16 engines, creating a market for innovative turbocharging solutions that can be retrofitted or customized.

Turbocharging Challenges

Turbocharging, while offering significant performance gains for W16 engines, presents several notable challenges that engineers must address. One primary concern is the increased thermal load on engine components. The compressed air from turbochargers enters the combustion chamber at higher temperatures, potentially leading to pre-ignition or knocking. This necessitates advanced cooling systems and more robust materials for pistons, valves, and cylinder heads.

Another challenge lies in managing turbo lag, particularly in large displacement engines like the W16. The time delay between throttle input and power delivery can be more pronounced due to the increased inertia of larger turbines. Engineers must carefully balance turbocharger size and configuration to minimize this effect while maintaining desired power output.

Packaging constraints pose a significant hurdle in W16 engine designs. Integrating multiple turbochargers within the limited engine bay space requires intricate plumbing and innovative layout solutions. This complexity can lead to increased manufacturing costs and potential maintenance difficulties.

The control of boost pressure across a wide range of engine speeds and loads is crucial for optimal performance and reliability. Sophisticated engine management systems are required to regulate boost pressure, fuel injection, and ignition timing precisely. This becomes even more challenging when implementing variable geometry turbochargers or multi-stage turbocharging systems.

Durability and longevity of turbocharger components are critical concerns, especially in high-performance applications. The extreme temperatures and rotational speeds experienced by turbochargers in W16 engines demand advanced materials and precision engineering to ensure long-term reliability.

Emissions compliance presents an ongoing challenge for turbocharged W16 engines. While turbocharging can improve fuel efficiency, it can also lead to increased NOx emissions due to higher combustion temperatures. Engineers must implement advanced exhaust aftertreatment systems and fine-tune engine parameters to meet stringent emissions standards without compromising performance.

Lastly, the complexity of turbocharged W16 engines raises concerns about serviceability and maintenance costs. The intricate design and specialized components may require more frequent servicing and specialized expertise, potentially increasing the total cost of ownership for end-users.

Another challenge lies in managing turbo lag, particularly in large displacement engines like the W16. The time delay between throttle input and power delivery can be more pronounced due to the increased inertia of larger turbines. Engineers must carefully balance turbocharger size and configuration to minimize this effect while maintaining desired power output.

Packaging constraints pose a significant hurdle in W16 engine designs. Integrating multiple turbochargers within the limited engine bay space requires intricate plumbing and innovative layout solutions. This complexity can lead to increased manufacturing costs and potential maintenance difficulties.

The control of boost pressure across a wide range of engine speeds and loads is crucial for optimal performance and reliability. Sophisticated engine management systems are required to regulate boost pressure, fuel injection, and ignition timing precisely. This becomes even more challenging when implementing variable geometry turbochargers or multi-stage turbocharging systems.

Durability and longevity of turbocharger components are critical concerns, especially in high-performance applications. The extreme temperatures and rotational speeds experienced by turbochargers in W16 engines demand advanced materials and precision engineering to ensure long-term reliability.

Emissions compliance presents an ongoing challenge for turbocharged W16 engines. While turbocharging can improve fuel efficiency, it can also lead to increased NOx emissions due to higher combustion temperatures. Engineers must implement advanced exhaust aftertreatment systems and fine-tune engine parameters to meet stringent emissions standards without compromising performance.

Lastly, the complexity of turbocharged W16 engines raises concerns about serviceability and maintenance costs. The intricate design and specialized components may require more frequent servicing and specialized expertise, potentially increasing the total cost of ownership for end-users.

Current Turbo Solutions

01 Multi-stage turbocharging systems

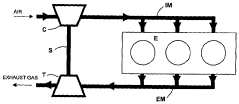

W16 engines can benefit from multi-stage turbocharging systems, which involve using multiple turbochargers in series or parallel configurations. This setup allows for improved boost pressure across a wider range of engine speeds, resulting in enhanced power output and efficiency. The system can be designed to optimize low-end torque and high-end power, addressing the unique requirements of a W16 engine.- Multi-stage turbocharging systems: W16 engines can benefit from multi-stage turbocharging systems, which involve using multiple turbochargers in series or parallel configurations. This setup allows for improved boost pressure across a wider range of engine speeds, resulting in enhanced power output and efficiency. The system can be designed to optimize low-end torque and high-end power, addressing the unique demands of a W16 engine.

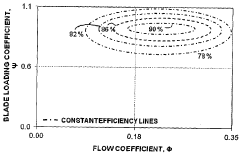

- Variable geometry turbochargers: Implementing variable geometry turbochargers in W16 engines can significantly improve turbocharging gains. These advanced turbochargers feature adjustable vanes or nozzles that can alter the flow of exhaust gases, allowing for optimized boost pressure across different engine speeds and load conditions. This technology helps reduce turbo lag and enhances overall engine performance and efficiency.

- Intercooling and charge air cooling: Effective intercooling and charge air cooling systems are crucial for maximizing turbocharging gains in W16 engines. These systems help lower the temperature of the compressed air from the turbochargers, increasing its density and allowing for more efficient combustion. Advanced cooling techniques, such as dual-stage intercoolers or water-to-air charge coolers, can further enhance the engine's power output and thermal efficiency.

- Electronic boost control and management: Sophisticated electronic boost control and management systems can optimize turbocharging performance in W16 engines. These systems use sensors and advanced algorithms to precisely regulate boost pressure, wastegate operation, and other turbocharging parameters. By continuously adjusting these factors based on engine load, speed, and environmental conditions, the engine can achieve improved power delivery, fuel efficiency, and emissions control.

- Integration with exhaust energy recovery systems: Combining turbocharging with exhaust energy recovery systems can further enhance the performance gains in W16 engines. Technologies such as electric turbocompounding or thermoelectric generators can harness waste heat from the exhaust gases to generate additional power or reduce parasitic losses. This integration helps improve overall engine efficiency and can provide supplementary power for auxiliary systems or hybrid powertrains.

02 Variable geometry turbochargers

Implementing variable geometry turbochargers in W16 engines can provide significant performance gains. These turbochargers feature adjustable vanes or nozzles that can alter the flow of exhaust gases, allowing for optimized boost pressure across different engine speeds and load conditions. This technology can help reduce turbo lag and improve overall engine responsiveness in W16 configurations.Expand Specific Solutions03 Advanced intercooling systems

Enhancing the intercooling systems for turbocharged W16 engines can lead to significant performance gains. Advanced intercooler designs, such as air-to-water intercoolers or multi-stage cooling systems, can more effectively reduce the temperature of the compressed air from the turbochargers. This results in increased air density, allowing for more efficient combustion and higher power output from the W16 engine.Expand Specific Solutions04 Electronic boost control

Implementing sophisticated electronic boost control systems can optimize the turbocharging performance of W16 engines. These systems can precisely regulate boost pressure based on various engine parameters and driving conditions. Advanced algorithms and sensors can be used to fine-tune the turbocharger operation, maximizing efficiency and power output while ensuring engine reliability and longevity.Expand Specific Solutions05 Integrated exhaust manifold design

Developing specialized exhaust manifold designs for turbocharged W16 engines can lead to improved turbocharging efficiency. Integrated exhaust manifolds that are optimized for the unique cylinder layout of a W16 engine can help maintain exhaust gas velocity and temperature, enhancing turbocharger response and overall engine performance. These designs may also contribute to reduced engine weight and improved packaging.Expand Specific Solutions

Key W16 Manufacturers

The W16 engine comparative study focusing on turbocharging strategies and gains reveals a competitive landscape in a mature yet evolving sector. Major players like BorgWarner, Ford Global Technologies, and GM Global Technology Operations are at the forefront of innovation, leveraging their extensive R&D capabilities. The market size for high-performance engines remains niche but significant, driven by luxury and sports car segments. Technological maturity varies, with companies like Siemens AG and Robert Bosch GmbH contributing advanced electronic control systems. Emerging players such as Bright Acceleration Technologies and Quest Engines are introducing novel approaches, potentially disrupting traditional turbocharging methods. The industry is in a phase of refinement, balancing performance gains with increasing environmental regulations.

BorgWarner, Inc.

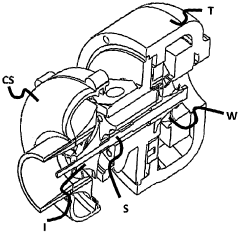

Technical Solution: BorgWarner has developed a cutting-edge turbocharging solution for W16 engines, focusing on their eTurbo™ technology. This electrically assisted turbocharger combines a traditional turbocharger with an electric motor-generator, allowing for rapid boost pressure build-up and improved transient response [2]. The eTurbo™ system can operate in three modes: assist, generate, and normal turbocharger mode, providing flexibility across various engine operating conditions. BorgWarner's solution also incorporates advanced aerodynamics in the compressor and turbine designs, optimized for the high airflow requirements of W16 engines [4]. The company has implemented a twin-scroll turbine housing design, which helps to minimize exhaust pulse interference and improve scavenging efficiency [6].

Strengths: Rapid boost response, improved low-end torque, and potential for energy recovery. Weaknesses: Increased system complexity and cost, potential reliability concerns with the electric components in high-performance applications.

Robert Bosch Corp.

Technical Solution: Robert Bosch Corp. has developed an innovative turbocharging strategy for W16 engines, focusing on a modular twin-turbo system with integrated exhaust manifolds. This approach allows for compact packaging and reduced thermal mass, improving overall engine efficiency. The system utilizes Bosch's latest-generation variable nozzle turbine (VNT) technology, providing precise boost control across the entire engine operating range [7]. Bosch has also implemented an advanced air-to-water intercooling system, strategically positioned to minimize charge air path length and optimize throttle response [9]. The company's turbocharging solution is complemented by a sophisticated engine management system that employs predictive algorithms to anticipate boost requirements based on driver input and vehicle dynamics [11].

Strengths: Compact design, excellent throttle response, and advanced boost control. Weaknesses: Potential heat management challenges due to integrated exhaust manifolds, and complexity in manufacturing and assembly.

Innovative Turbo Tech

A turbine wheel, a turbine and use thereof

PatentWO2012114058A1

Innovation

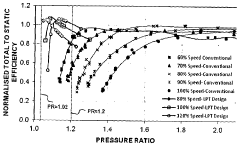

- A novel turbine wheel design with a specific area ratio of outlet to inlet area (A2/A1) less than approximately 0.4, combined with a shroud covering the wheel, and optimized exit relative flow angle between -41 degrees and -55 degrees, which allows for high performance at low pressure ratios by optimizing the geometry and flow conditions.

Increasing the fuel efficiency of four stroke engine by using turbocharger

PatentPendingIN202341044672A

Innovation

- The integration of a turbocharger system, where exhaust gases drive a turbine connected to a compressor, increasing air density and facilitating more efficient combustion, is enhanced by careful design and engineering considerations, including intercooling and advanced engine management systems to optimize performance and fuel efficiency.

Emissions Regulations

Emissions regulations play a crucial role in shaping the development and implementation of turbocharging strategies for W16 engines. As governments worldwide continue to tighten restrictions on vehicle emissions, manufacturers are compelled to innovate and optimize their engine designs to meet these stringent standards.

In the European Union, the Euro 6d emissions standard has set strict limits on nitrogen oxides (NOx) and particulate matter (PM) emissions. This has led to the widespread adoption of advanced turbocharging technologies in W16 engines, such as variable geometry turbochargers and multi-stage turbocharging systems. These innovations allow for more precise control over boost pressure and exhaust gas recirculation, resulting in improved fuel efficiency and reduced emissions.

The United States Environmental Protection Agency (EPA) has also implemented rigorous emissions standards through its Tier 3 program. These regulations have prompted W16 engine manufacturers to focus on reducing carbon dioxide (CO2) emissions while maintaining performance. As a result, turbocharging strategies have evolved to include electric compressors and e-turbo systems, which can provide instant boost and improve overall engine efficiency.

In China, the implementation of the China 6 emissions standard has further accelerated the development of advanced turbocharging technologies for W16 engines. Manufacturers are exploring innovative solutions such as twin-scroll turbochargers and integrated exhaust manifold designs to meet these stringent requirements while preserving the power output that W16 engines are known for.

The global push towards electrification has also influenced turbocharging strategies for W16 engines. Hybrid powertrains that combine electric motors with turbocharged W16 engines are becoming increasingly common, allowing manufacturers to meet emissions targets while still delivering exceptional performance. This trend has led to the development of more compact and efficient turbocharging systems that can seamlessly integrate with hybrid powertrains.

As emissions regulations continue to evolve, the future of W16 engine turbocharging strategies will likely focus on further reducing fuel consumption and emissions without compromising performance. This may include the integration of advanced materials, such as ceramic turbine wheels, to improve heat resistance and efficiency. Additionally, the use of artificial intelligence and machine learning algorithms to optimize turbocharger performance in real-time driving conditions is expected to gain traction in the coming years.

In the European Union, the Euro 6d emissions standard has set strict limits on nitrogen oxides (NOx) and particulate matter (PM) emissions. This has led to the widespread adoption of advanced turbocharging technologies in W16 engines, such as variable geometry turbochargers and multi-stage turbocharging systems. These innovations allow for more precise control over boost pressure and exhaust gas recirculation, resulting in improved fuel efficiency and reduced emissions.

The United States Environmental Protection Agency (EPA) has also implemented rigorous emissions standards through its Tier 3 program. These regulations have prompted W16 engine manufacturers to focus on reducing carbon dioxide (CO2) emissions while maintaining performance. As a result, turbocharging strategies have evolved to include electric compressors and e-turbo systems, which can provide instant boost and improve overall engine efficiency.

In China, the implementation of the China 6 emissions standard has further accelerated the development of advanced turbocharging technologies for W16 engines. Manufacturers are exploring innovative solutions such as twin-scroll turbochargers and integrated exhaust manifold designs to meet these stringent requirements while preserving the power output that W16 engines are known for.

The global push towards electrification has also influenced turbocharging strategies for W16 engines. Hybrid powertrains that combine electric motors with turbocharged W16 engines are becoming increasingly common, allowing manufacturers to meet emissions targets while still delivering exceptional performance. This trend has led to the development of more compact and efficient turbocharging systems that can seamlessly integrate with hybrid powertrains.

As emissions regulations continue to evolve, the future of W16 engine turbocharging strategies will likely focus on further reducing fuel consumption and emissions without compromising performance. This may include the integration of advanced materials, such as ceramic turbine wheels, to improve heat resistance and efficiency. Additionally, the use of artificial intelligence and machine learning algorithms to optimize turbocharger performance in real-time driving conditions is expected to gain traction in the coming years.

Performance Benchmarks

In the realm of W16 engine development, performance benchmarks serve as crucial indicators of technological advancement and competitive positioning. The W16 engine, particularly when enhanced with turbocharging strategies, represents the pinnacle of automotive engineering. To establish meaningful performance benchmarks, extensive testing and analysis are conducted across various parameters.

Acceleration metrics form a primary benchmark, with 0-60 mph and 0-100 mph times being standard measures. Top-tier W16 engines, such as those found in hypercars, typically achieve 0-60 mph times under 2.5 seconds, showcasing the immense power-to-weight ratios these engines can deliver. Quarter-mile times and trap speeds further illustrate the engine's performance capabilities, with some W16-powered vehicles completing the quarter-mile in less than 10 seconds.

Top speed serves as another critical benchmark, with modern W16 engines capable of propelling vehicles to speeds exceeding 260 mph (418 km/h) under controlled conditions. These figures not only demonstrate raw power but also highlight the effectiveness of aerodynamic design and turbocharging strategies in overcoming air resistance at extreme velocities.

Power output and torque curves provide detailed insights into engine performance across the RPM range. State-of-the-art W16 engines with advanced turbocharging systems can produce over 1,500 horsepower and 1,180 lb-ft (1,600 Nm) of torque. The shape of these curves, particularly the breadth of the torque plateau, indicates the engine's responsiveness and drivability in real-world conditions.

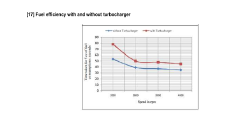

Fuel efficiency, while often secondary in high-performance applications, remains a relevant benchmark. Despite their immense power, modern W16 engines incorporate technologies to optimize fuel consumption, with some achieving surprisingly reasonable efficiency figures during highway cruising.

Emissions performance has become increasingly important, even for ultra-high-performance engines. Benchmarks in this area include CO2 emissions per kilometer and compliance with stringent emissions standards such as Euro 6 or equivalent regulations in other markets.

Durability and reliability metrics, though less publicized, are crucial benchmarks for manufacturers. These include engine longevity under high-stress conditions, maintenance intervals, and component wear rates. Such data, while often proprietary, informs both engineering decisions and consumer confidence in these extraordinary powerplants.

Acceleration metrics form a primary benchmark, with 0-60 mph and 0-100 mph times being standard measures. Top-tier W16 engines, such as those found in hypercars, typically achieve 0-60 mph times under 2.5 seconds, showcasing the immense power-to-weight ratios these engines can deliver. Quarter-mile times and trap speeds further illustrate the engine's performance capabilities, with some W16-powered vehicles completing the quarter-mile in less than 10 seconds.

Top speed serves as another critical benchmark, with modern W16 engines capable of propelling vehicles to speeds exceeding 260 mph (418 km/h) under controlled conditions. These figures not only demonstrate raw power but also highlight the effectiveness of aerodynamic design and turbocharging strategies in overcoming air resistance at extreme velocities.

Power output and torque curves provide detailed insights into engine performance across the RPM range. State-of-the-art W16 engines with advanced turbocharging systems can produce over 1,500 horsepower and 1,180 lb-ft (1,600 Nm) of torque. The shape of these curves, particularly the breadth of the torque plateau, indicates the engine's responsiveness and drivability in real-world conditions.

Fuel efficiency, while often secondary in high-performance applications, remains a relevant benchmark. Despite their immense power, modern W16 engines incorporate technologies to optimize fuel consumption, with some achieving surprisingly reasonable efficiency figures during highway cruising.

Emissions performance has become increasingly important, even for ultra-high-performance engines. Benchmarks in this area include CO2 emissions per kilometer and compliance with stringent emissions standards such as Euro 6 or equivalent regulations in other markets.

Durability and reliability metrics, though less publicized, are crucial benchmarks for manufacturers. These include engine longevity under high-stress conditions, maintenance intervals, and component wear rates. Such data, while often proprietary, informs both engineering decisions and consumer confidence in these extraordinary powerplants.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!