W16 Engine Durability Testing: Protocols And Acceptance Criteria

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

W16 Engine Background

The W16 engine represents a pinnacle of automotive engineering, combining power, precision, and prestige. Developed primarily for high-performance luxury vehicles, the W16 engine configuration emerged as a result of the relentless pursuit of power and efficiency in the automotive industry. This unique engine design consists of two narrow-angle V8 engines joined at a 90-degree angle, effectively creating a W shape when viewed from the front.

The origins of the W16 engine can be traced back to the late 1990s when Volkswagen Group, under the leadership of Ferdinand Piëch, began exploring new engine configurations to push the boundaries of automotive performance. The concept was first introduced in the Bentley Hunaudières concept car in 1999, showcasing the potential of this innovative engine design.

The W16 engine gained widespread recognition with its implementation in the Bugatti Veyron, launched in 2005. This groundbreaking supercar utilized a quad-turbocharged 8.0-liter W16 engine, producing an astounding 1,001 horsepower. The Veyron's success cemented the W16 engine's reputation as a symbol of ultimate performance and engineering excellence.

Over the years, the W16 engine has undergone continuous refinement and improvement. Subsequent iterations, such as those found in the Bugatti Chiron, have seen increases in power output and efficiency. The latest versions of the W16 engine are capable of producing over 1,500 horsepower, pushing the boundaries of what is possible in automotive engineering.

The complexity of the W16 engine design presents unique challenges in terms of durability testing. The intricate arrangement of cylinders, the high power output, and the extreme operating conditions necessitate rigorous testing protocols to ensure reliability and longevity. Durability testing for W16 engines must account for factors such as thermal management, oil circulation, and structural integrity under high-stress conditions.

As environmental concerns and regulations become increasingly stringent, the future of the W16 engine faces new challenges. Manufacturers are exploring ways to improve efficiency and reduce emissions while maintaining the exceptional performance characteristics that define the W16 engine. This includes the potential integration of hybrid technologies and advanced materials to optimize power delivery and fuel economy.

The W16 engine's legacy extends beyond its technical specifications, representing a pinnacle of engineering achievement and a testament to human ingenuity in automotive design. Its development and ongoing evolution continue to inspire innovation across the automotive industry, pushing the limits of what is possible in internal combustion engine technology.

The origins of the W16 engine can be traced back to the late 1990s when Volkswagen Group, under the leadership of Ferdinand Piëch, began exploring new engine configurations to push the boundaries of automotive performance. The concept was first introduced in the Bentley Hunaudières concept car in 1999, showcasing the potential of this innovative engine design.

The W16 engine gained widespread recognition with its implementation in the Bugatti Veyron, launched in 2005. This groundbreaking supercar utilized a quad-turbocharged 8.0-liter W16 engine, producing an astounding 1,001 horsepower. The Veyron's success cemented the W16 engine's reputation as a symbol of ultimate performance and engineering excellence.

Over the years, the W16 engine has undergone continuous refinement and improvement. Subsequent iterations, such as those found in the Bugatti Chiron, have seen increases in power output and efficiency. The latest versions of the W16 engine are capable of producing over 1,500 horsepower, pushing the boundaries of what is possible in automotive engineering.

The complexity of the W16 engine design presents unique challenges in terms of durability testing. The intricate arrangement of cylinders, the high power output, and the extreme operating conditions necessitate rigorous testing protocols to ensure reliability and longevity. Durability testing for W16 engines must account for factors such as thermal management, oil circulation, and structural integrity under high-stress conditions.

As environmental concerns and regulations become increasingly stringent, the future of the W16 engine faces new challenges. Manufacturers are exploring ways to improve efficiency and reduce emissions while maintaining the exceptional performance characteristics that define the W16 engine. This includes the potential integration of hybrid technologies and advanced materials to optimize power delivery and fuel economy.

The W16 engine's legacy extends beyond its technical specifications, representing a pinnacle of engineering achievement and a testament to human ingenuity in automotive design. Its development and ongoing evolution continue to inspire innovation across the automotive industry, pushing the limits of what is possible in internal combustion engine technology.

Market Analysis

The market for W16 engine durability testing protocols and acceptance criteria is driven by the luxury automotive sector, particularly manufacturers of high-performance supercars and hypercars. This niche market segment demands rigorous testing procedures to ensure the reliability and longevity of these complex powerplants under extreme conditions.

The global luxury car market, which includes vehicles equipped with W16 engines, has been experiencing steady growth. This growth is fueled by increasing disposable incomes in emerging economies, a rising number of high-net-worth individuals, and a growing appetite for exclusive, high-performance vehicles.

Demand for W16 engine durability testing is primarily concentrated in automotive manufacturing hubs such as Germany, Italy, and France, where many luxury and supercar brands are based. However, there is also growing interest from emerging markets like China and the Middle East, where domestic manufacturers are entering the high-performance vehicle segment.

The market for W16 engine testing equipment and services is relatively small but highly specialized. Key players in this market include automotive testing equipment manufacturers, specialized engineering firms, and the in-house testing facilities of luxury car manufacturers.

One of the main drivers for advanced durability testing protocols is the increasing focus on reliability and customer satisfaction in the ultra-luxury segment. Manufacturers are under pressure to deliver vehicles that not only offer exceptional performance but also maintain that performance over extended periods and under various operating conditions.

Environmental regulations and the push for improved fuel efficiency are also influencing the W16 engine durability testing market. Manufacturers must ensure that these high-output engines can meet stringent emissions standards while maintaining their performance characteristics over time.

The advent of digital twin technology and advanced simulation tools is reshaping the W16 engine testing landscape. These technologies allow for more comprehensive and cost-effective testing procedures, reducing the time and resources required for physical testing while improving the accuracy of durability predictions.

As the automotive industry moves towards electrification, the long-term market outlook for W16 engine durability testing may face challenges. However, in the near to medium term, the demand for these specialized testing services is expected to remain stable, driven by the ongoing production of limited-edition hypercars and the need to support existing W16-powered vehicles in the market.

The global luxury car market, which includes vehicles equipped with W16 engines, has been experiencing steady growth. This growth is fueled by increasing disposable incomes in emerging economies, a rising number of high-net-worth individuals, and a growing appetite for exclusive, high-performance vehicles.

Demand for W16 engine durability testing is primarily concentrated in automotive manufacturing hubs such as Germany, Italy, and France, where many luxury and supercar brands are based. However, there is also growing interest from emerging markets like China and the Middle East, where domestic manufacturers are entering the high-performance vehicle segment.

The market for W16 engine testing equipment and services is relatively small but highly specialized. Key players in this market include automotive testing equipment manufacturers, specialized engineering firms, and the in-house testing facilities of luxury car manufacturers.

One of the main drivers for advanced durability testing protocols is the increasing focus on reliability and customer satisfaction in the ultra-luxury segment. Manufacturers are under pressure to deliver vehicles that not only offer exceptional performance but also maintain that performance over extended periods and under various operating conditions.

Environmental regulations and the push for improved fuel efficiency are also influencing the W16 engine durability testing market. Manufacturers must ensure that these high-output engines can meet stringent emissions standards while maintaining their performance characteristics over time.

The advent of digital twin technology and advanced simulation tools is reshaping the W16 engine testing landscape. These technologies allow for more comprehensive and cost-effective testing procedures, reducing the time and resources required for physical testing while improving the accuracy of durability predictions.

As the automotive industry moves towards electrification, the long-term market outlook for W16 engine durability testing may face challenges. However, in the near to medium term, the demand for these specialized testing services is expected to remain stable, driven by the ongoing production of limited-edition hypercars and the need to support existing W16-powered vehicles in the market.

Technical Challenges

The durability testing of W16 engines presents several significant technical challenges that must be addressed to ensure reliable and accurate results. One of the primary difficulties lies in the complexity of the W16 engine design, which features 16 cylinders arranged in a W configuration. This unique layout creates intricate thermal management issues, as the heat distribution across the engine block is more complex than in conventional engine designs.

Another major challenge is the development of appropriate test protocols that can accurately simulate the extreme conditions these high-performance engines are likely to encounter during their operational lifetime. This includes replicating high-speed, high-load scenarios for extended periods, which puts immense stress on engine components and systems. Creating test cycles that balance between accelerated wear and realistic usage patterns is a delicate task that requires extensive expertise and data analysis.

The selection and implementation of suitable measurement and monitoring systems pose additional technical hurdles. Given the engine's complexity, a wide array of sensors and data acquisition systems must be employed to capture comprehensive performance metrics. These systems need to be both highly accurate and capable of withstanding the harsh testing environment, including high temperatures, vibrations, and potential electromagnetic interference.

Establishing meaningful acceptance criteria for W16 engine durability is another significant challenge. The criteria must be stringent enough to ensure the engine's reliability in real-world applications while also being achievable within reasonable development timeframes and costs. This requires a deep understanding of the engine's design limits, material properties, and failure modes, as well as the ability to correlate test results with actual field performance.

Furthermore, the testing of advanced materials and coatings used in W16 engines presents its own set of challenges. These materials, often employed to enhance performance and durability, may behave differently under extreme testing conditions compared to traditional engine materials. Developing appropriate test methodologies to evaluate their long-term performance and degradation characteristics is crucial but technically demanding.

Lastly, the integration of increasingly complex electronic control systems in modern W16 engines adds another layer of complexity to durability testing. These systems must be thoroughly evaluated not only for their hardware durability but also for the robustness of their software and control algorithms under various operating conditions. This necessitates the development of sophisticated test procedures that can assess both the mechanical and electronic aspects of engine durability in an integrated manner.

Another major challenge is the development of appropriate test protocols that can accurately simulate the extreme conditions these high-performance engines are likely to encounter during their operational lifetime. This includes replicating high-speed, high-load scenarios for extended periods, which puts immense stress on engine components and systems. Creating test cycles that balance between accelerated wear and realistic usage patterns is a delicate task that requires extensive expertise and data analysis.

The selection and implementation of suitable measurement and monitoring systems pose additional technical hurdles. Given the engine's complexity, a wide array of sensors and data acquisition systems must be employed to capture comprehensive performance metrics. These systems need to be both highly accurate and capable of withstanding the harsh testing environment, including high temperatures, vibrations, and potential electromagnetic interference.

Establishing meaningful acceptance criteria for W16 engine durability is another significant challenge. The criteria must be stringent enough to ensure the engine's reliability in real-world applications while also being achievable within reasonable development timeframes and costs. This requires a deep understanding of the engine's design limits, material properties, and failure modes, as well as the ability to correlate test results with actual field performance.

Furthermore, the testing of advanced materials and coatings used in W16 engines presents its own set of challenges. These materials, often employed to enhance performance and durability, may behave differently under extreme testing conditions compared to traditional engine materials. Developing appropriate test methodologies to evaluate their long-term performance and degradation characteristics is crucial but technically demanding.

Lastly, the integration of increasingly complex electronic control systems in modern W16 engines adds another layer of complexity to durability testing. These systems must be thoroughly evaluated not only for their hardware durability but also for the robustness of their software and control algorithms under various operating conditions. This necessitates the development of sophisticated test procedures that can assess both the mechanical and electronic aspects of engine durability in an integrated manner.

Current Testing Protocols

01 Improved cooling system design

Enhanced cooling systems are crucial for W16 engine durability. These designs may include advanced radiator configurations, optimized coolant flow paths, and efficient heat dissipation mechanisms. Improved cooling helps maintain optimal operating temperatures, reducing thermal stress on engine components and extending overall engine life.- Improved cooling systems for W16 engines: Enhanced cooling systems are crucial for improving the durability of W16 engines. These systems may include advanced radiators, optimized coolant flow, and innovative heat dissipation techniques to maintain optimal operating temperatures and prevent overheating, which can lead to premature wear and reduced engine lifespan.

- Advanced lubrication systems for W16 engines: Sophisticated lubrication systems play a vital role in enhancing W16 engine durability. These systems may incorporate high-performance oil pumps, improved oil filtration, and strategic oil distribution channels to ensure proper lubrication of all moving parts, reducing friction and wear throughout the engine.

- Reinforced engine components for W16 engines: Utilizing reinforced engine components can significantly improve the durability of W16 engines. This may include strengthened pistons, connecting rods, and crankshafts made from high-performance materials or featuring advanced designs to withstand the high stresses and temperatures associated with W16 engine operation.

- Advanced engine management systems for W16 engines: Sophisticated engine management systems can enhance the durability of W16 engines by optimizing performance and reducing stress on engine components. These systems may include advanced sensors, real-time monitoring, and adaptive control algorithms to ensure optimal fuel injection, ignition timing, and overall engine operation.

- Innovative materials and coatings for W16 engine components: The use of innovative materials and coatings can significantly improve the durability of W16 engine components. This may include ceramic coatings, diamond-like carbon (DLC) coatings, or advanced alloys that offer superior wear resistance, reduced friction, and improved heat dissipation properties.

02 Advanced lubrication techniques

Implementing sophisticated lubrication systems can significantly enhance W16 engine durability. These may involve high-performance oil formulations, precision oil delivery systems, and innovative oil filtration methods. Effective lubrication reduces friction, wear, and heat generation, contributing to increased engine longevity.Expand Specific Solutions03 Reinforced engine block and components

Utilizing high-strength materials and advanced manufacturing techniques for engine blocks and critical components can improve W16 engine durability. This may include reinforced cylinder walls, strengthened crankshafts, and more robust connecting rods. These enhancements help withstand the high stresses and pressures associated with W16 engine operation.Expand Specific Solutions04 Advanced combustion control systems

Implementing sophisticated combustion control systems can optimize fuel efficiency and reduce engine wear. This may involve precise fuel injection timing, advanced ignition systems, and intelligent engine management units. These technologies help maintain optimal combustion conditions, reducing stress on engine components and improving overall durability.Expand Specific Solutions05 Innovative materials and coatings

Incorporating advanced materials and surface treatments can enhance W16 engine durability. This may include the use of ceramic coatings, diamond-like carbon (DLC) coatings, or other wear-resistant materials for critical engine components. These innovations help reduce friction, improve heat dissipation, and increase resistance to wear and corrosion.Expand Specific Solutions

Key Industry Players

The W16 engine durability testing market is in a mature stage, with established protocols and acceptance criteria. The global automotive engine testing market size is estimated to be around $3-4 billion annually. Key players like AVL List GmbH, Toyota Motor Corp., and GM Global Technology Operations LLC have developed sophisticated testing capabilities. These companies, along with others like Scania CV AB and Ford Global Technologies LLC, have advanced the technology to a high level of maturity. The focus is now on refining methodologies for increased efficiency, reliability, and environmental performance, particularly for high-performance engines like the W16.

AVL List GmbH

Technical Solution: AVL List GmbH has developed a comprehensive W16 engine durability testing protocol that combines advanced simulation techniques with physical testing. Their approach utilizes a high-fidelity digital twin of the W16 engine, allowing for extensive virtual testing before physical prototypes are built. This method includes thermal cycling, vibration analysis, and accelerated wear simulations. AVL's protocol incorporates real-time monitoring systems that can detect minute changes in engine performance, enabling early identification of potential failure points. The company has also developed specialized test benches capable of replicating extreme operating conditions, including high-altitude performance and extreme temperature variations[1][3]. Their acceptance criteria are based on a statistical analysis of multiple test runs, ensuring a high confidence level in the engine's long-term reliability.

Strengths: Comprehensive digital twin technology reduces physical testing time and costs. Advanced monitoring systems provide early detection of potential issues. Weaknesses: High initial investment required for sophisticated testing equipment and software.

Toyota Motor Corp.

Technical Solution: Toyota Motor Corp. has implemented a rigorous W16 engine durability testing protocol that emphasizes long-term reliability and efficiency. Their approach combines extensive road testing with laboratory simulations, focusing on the unique challenges posed by the W16 configuration. Toyota's protocol includes a series of endurance tests that simulate various driving conditions, from stop-and-go city traffic to high-speed highway driving. They utilize advanced dynamometers capable of replicating real-world loads and environmental conditions. Toyota's testing also incorporates thermal imaging to identify hotspots and potential areas of stress within the engine[2]. Their acceptance criteria are particularly stringent, with a focus on maintaining performance and efficiency over extended periods. The company employs a "kaizen" approach, continuously refining their testing methods based on data collected from both laboratory tests and real-world performance[4].

Strengths: Extensive real-world testing combined with laboratory simulations provides comprehensive data. Continuous improvement philosophy ensures up-to-date testing methods. Weaknesses: Time-consuming process due to emphasis on long-term reliability testing.

Critical Test Parameters

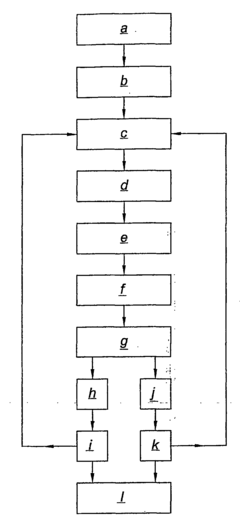

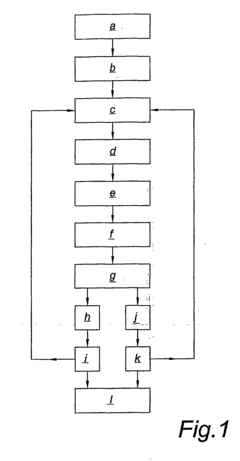

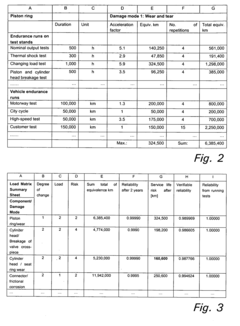

Method for ensuring the reliability of technical components

PatentInactiveEP1671093A1

Innovation

- A method involving selecting critical components and damage modes, defining reliability targets, assigning test procedures and durations, determining acceleration factors, and calculating equivalent test durations to verify and adjust the reliability of components, using a load matrix to optimize test programs and reduce unnecessary testing or extend test durations as needed.

Method for ensuring the reliability of technical components

PatentInactiveUS20070079651A1

Innovation

- A method involving the selection of critical components and damage modes, definition of reliability goals, allocation of test procedures and durations, determination of acceleration factors, and calculation of equivalent test durations to evaluate and adjust the test program to meet reliability and service life goals, using deterioration models for precise assessment.

Regulatory Compliance

Regulatory compliance is a critical aspect of W16 engine durability testing, ensuring that the engine meets all necessary standards and regulations before being approved for production and use. The protocols and acceptance criteria for W16 engine durability testing must align with various regulatory requirements set by different governing bodies worldwide.

In the United States, the Environmental Protection Agency (EPA) and the California Air Resources Board (CARB) play crucial roles in setting emissions standards for engines. W16 engines must comply with these regulations, which include limits on pollutants such as carbon monoxide, nitrogen oxides, and particulate matter. The durability testing protocols must demonstrate that the engine can maintain compliance with these emissions standards throughout its expected lifespan.

The European Union has its own set of regulations, including the Euro 6 emissions standard for passenger vehicles. W16 engines intended for use in the European market must adhere to these stringent requirements. Durability testing protocols should incorporate specific test cycles and measurement procedures outlined in EU regulations to ensure compliance.

Safety regulations also play a significant role in W16 engine durability testing. In the United States, the National Highway Traffic Safety Administration (NHTSA) sets safety standards for vehicles and their components, including engines. Durability testing protocols must address these safety requirements, ensuring that the engine maintains its structural integrity and performance characteristics over time.

International standards, such as those set by the International Organization for Standardization (ISO), provide guidelines for engine testing procedures and performance evaluation. W16 engine durability testing protocols should incorporate relevant ISO standards to ensure consistency and comparability of results across different testing facilities and regions.

Fuel efficiency regulations, such as the Corporate Average Fuel Economy (CAFE) standards in the United States, also impact W16 engine durability testing. The protocols must demonstrate that the engine can maintain its fuel efficiency performance over its expected lifespan, meeting or exceeding the required standards.

Acceptance criteria for W16 engine durability testing must be designed to ensure compliance with all applicable regulations. This includes setting specific performance thresholds for emissions, fuel efficiency, and safety-related parameters. The criteria should also account for any degradation in performance over time, ensuring that the engine remains compliant throughout its intended service life.

Documentation and reporting requirements are essential aspects of regulatory compliance in W16 engine durability testing. Detailed records of test procedures, results, and any modifications made during the testing process must be maintained to satisfy regulatory audits and certification processes.

In the United States, the Environmental Protection Agency (EPA) and the California Air Resources Board (CARB) play crucial roles in setting emissions standards for engines. W16 engines must comply with these regulations, which include limits on pollutants such as carbon monoxide, nitrogen oxides, and particulate matter. The durability testing protocols must demonstrate that the engine can maintain compliance with these emissions standards throughout its expected lifespan.

The European Union has its own set of regulations, including the Euro 6 emissions standard for passenger vehicles. W16 engines intended for use in the European market must adhere to these stringent requirements. Durability testing protocols should incorporate specific test cycles and measurement procedures outlined in EU regulations to ensure compliance.

Safety regulations also play a significant role in W16 engine durability testing. In the United States, the National Highway Traffic Safety Administration (NHTSA) sets safety standards for vehicles and their components, including engines. Durability testing protocols must address these safety requirements, ensuring that the engine maintains its structural integrity and performance characteristics over time.

International standards, such as those set by the International Organization for Standardization (ISO), provide guidelines for engine testing procedures and performance evaluation. W16 engine durability testing protocols should incorporate relevant ISO standards to ensure consistency and comparability of results across different testing facilities and regions.

Fuel efficiency regulations, such as the Corporate Average Fuel Economy (CAFE) standards in the United States, also impact W16 engine durability testing. The protocols must demonstrate that the engine can maintain its fuel efficiency performance over its expected lifespan, meeting or exceeding the required standards.

Acceptance criteria for W16 engine durability testing must be designed to ensure compliance with all applicable regulations. This includes setting specific performance thresholds for emissions, fuel efficiency, and safety-related parameters. The criteria should also account for any degradation in performance over time, ensuring that the engine remains compliant throughout its intended service life.

Documentation and reporting requirements are essential aspects of regulatory compliance in W16 engine durability testing. Detailed records of test procedures, results, and any modifications made during the testing process must be maintained to satisfy regulatory audits and certification processes.

Environmental Impact

The environmental impact of W16 engine durability testing is a critical aspect that must be carefully considered and managed throughout the testing process. These high-performance engines, typically used in luxury and sports vehicles, consume significant amounts of fuel and produce substantial emissions during extended durability tests. To mitigate these environmental concerns, testing protocols should incorporate stringent emission control measures and fuel efficiency monitoring.

One key consideration is the implementation of advanced exhaust aftertreatment systems during testing. These systems, including catalytic converters and particulate filters, help reduce harmful emissions such as nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter (PM). Regular monitoring and maintenance of these systems throughout the durability testing period ensure optimal performance and minimal environmental impact.

Fuel consumption is another crucial factor in assessing the environmental impact of W16 engine durability testing. Protocols should include precise fuel measurement techniques and analysis of fuel efficiency trends over the course of the testing period. This data not only provides valuable insights into engine performance but also helps in developing strategies to improve fuel economy and reduce overall carbon footprint.

The use of alternative fuels or fuel blends during certain phases of durability testing can further contribute to reducing environmental impact. For instance, incorporating biofuels or synthetic fuels in specific test cycles can help evaluate the engine's compatibility with more sustainable fuel options while potentially lowering greenhouse gas emissions.

Noise pollution is an often-overlooked aspect of engine testing that can have significant environmental consequences. W16 engines, known for their power output, can generate considerable noise levels. Implementing sound-dampening technologies in testing facilities and conducting tests within specified time frames can help minimize disturbance to surrounding ecosystems and communities.

Water consumption and management during testing procedures also warrant attention. Cooling systems for high-performance engines like the W16 require substantial amounts of water. Implementing closed-loop cooling systems and water recycling processes can significantly reduce water usage and minimize the environmental impact of testing operations.

Lastly, the disposal of waste materials generated during durability testing, such as used oil, coolants, and worn components, must adhere to strict environmental regulations. Establishing comprehensive recycling and proper disposal protocols ensures that these potentially harmful materials do not contaminate soil or water sources.

One key consideration is the implementation of advanced exhaust aftertreatment systems during testing. These systems, including catalytic converters and particulate filters, help reduce harmful emissions such as nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter (PM). Regular monitoring and maintenance of these systems throughout the durability testing period ensure optimal performance and minimal environmental impact.

Fuel consumption is another crucial factor in assessing the environmental impact of W16 engine durability testing. Protocols should include precise fuel measurement techniques and analysis of fuel efficiency trends over the course of the testing period. This data not only provides valuable insights into engine performance but also helps in developing strategies to improve fuel economy and reduce overall carbon footprint.

The use of alternative fuels or fuel blends during certain phases of durability testing can further contribute to reducing environmental impact. For instance, incorporating biofuels or synthetic fuels in specific test cycles can help evaluate the engine's compatibility with more sustainable fuel options while potentially lowering greenhouse gas emissions.

Noise pollution is an often-overlooked aspect of engine testing that can have significant environmental consequences. W16 engines, known for their power output, can generate considerable noise levels. Implementing sound-dampening technologies in testing facilities and conducting tests within specified time frames can help minimize disturbance to surrounding ecosystems and communities.

Water consumption and management during testing procedures also warrant attention. Cooling systems for high-performance engines like the W16 require substantial amounts of water. Implementing closed-loop cooling systems and water recycling processes can significantly reduce water usage and minimize the environmental impact of testing operations.

Lastly, the disposal of waste materials generated during durability testing, such as used oil, coolants, and worn components, must adhere to strict environmental regulations. Establishing comprehensive recycling and proper disposal protocols ensures that these potentially harmful materials do not contaminate soil or water sources.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!