How to Conduct Environmental Impact Studies for Lithium Nitride

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Nitride Environmental Assessment Background and Objectives

Lithium nitride (Li₃N) has emerged as a critical material in modern energy storage systems, particularly in advanced battery technologies. The historical development of lithium nitride applications can be traced back to the 1970s, when its ionic conductivity properties were first extensively studied. Over the past five decades, this compound has transitioned from a laboratory curiosity to a material of significant industrial importance, with applications expanding beyond energy storage to include hydrogen storage systems, semiconductor manufacturing, and specialized ceramic production.

The technological evolution of lithium nitride has accelerated dramatically in the past decade, driven primarily by the global push toward renewable energy solutions and electric mobility. This acceleration has created an urgent need for comprehensive environmental impact assessments that specifically address the unique properties and potential ecological footprint of lithium nitride throughout its lifecycle.

The primary objective of environmental impact studies for lithium nitride is to establish a scientific framework for evaluating its ecological interactions from extraction of raw materials through manufacturing, use, and eventual disposal or recycling. These studies aim to quantify both direct environmental effects, such as land use changes and water consumption during production, and indirect impacts, including energy requirements and greenhouse gas emissions associated with the compound's lifecycle.

A secondary but equally important goal is to develop standardized methodologies for lithium nitride environmental assessment that can be consistently applied across different geographical regions and regulatory frameworks. Current assessment protocols designed for conventional materials often fail to adequately capture the unique environmental considerations of advanced materials like lithium nitride, creating a significant gap in environmental governance.

Furthermore, these studies seek to identify potential environmental risks specific to lithium nitride, including its reactivity with atmospheric moisture and potential for nitrogen release under certain conditions. Understanding these risks is essential for developing appropriate mitigation strategies and safety protocols for industrial applications.

The technological trajectory suggests increasing adoption of lithium nitride in energy storage and other applications, making proactive environmental assessment crucial for sustainable development. By establishing comprehensive baseline data now, future technological innovations can be guided by environmental considerations from their inception rather than as an afterthought.

These environmental impact studies must also consider the full spectrum of ecosystem interactions, from potential effects on soil chemistry and microbial communities to broader impacts on biodiversity and ecosystem services. This holistic approach represents the current best practice in environmental assessment methodology and is particularly relevant for novel materials with limited historical environmental data.

The technological evolution of lithium nitride has accelerated dramatically in the past decade, driven primarily by the global push toward renewable energy solutions and electric mobility. This acceleration has created an urgent need for comprehensive environmental impact assessments that specifically address the unique properties and potential ecological footprint of lithium nitride throughout its lifecycle.

The primary objective of environmental impact studies for lithium nitride is to establish a scientific framework for evaluating its ecological interactions from extraction of raw materials through manufacturing, use, and eventual disposal or recycling. These studies aim to quantify both direct environmental effects, such as land use changes and water consumption during production, and indirect impacts, including energy requirements and greenhouse gas emissions associated with the compound's lifecycle.

A secondary but equally important goal is to develop standardized methodologies for lithium nitride environmental assessment that can be consistently applied across different geographical regions and regulatory frameworks. Current assessment protocols designed for conventional materials often fail to adequately capture the unique environmental considerations of advanced materials like lithium nitride, creating a significant gap in environmental governance.

Furthermore, these studies seek to identify potential environmental risks specific to lithium nitride, including its reactivity with atmospheric moisture and potential for nitrogen release under certain conditions. Understanding these risks is essential for developing appropriate mitigation strategies and safety protocols for industrial applications.

The technological trajectory suggests increasing adoption of lithium nitride in energy storage and other applications, making proactive environmental assessment crucial for sustainable development. By establishing comprehensive baseline data now, future technological innovations can be guided by environmental considerations from their inception rather than as an afterthought.

These environmental impact studies must also consider the full spectrum of ecosystem interactions, from potential effects on soil chemistry and microbial communities to broader impacts on biodiversity and ecosystem services. This holistic approach represents the current best practice in environmental assessment methodology and is particularly relevant for novel materials with limited historical environmental data.

Market Demand Analysis for Sustainable Lithium Nitride Production

The global market for sustainable lithium nitride production is experiencing significant growth driven by the increasing demand for advanced materials in energy storage, electronics, and sustainable manufacturing sectors. As lithium-based technologies continue to dominate the energy storage landscape, the need for environmentally responsible production methods has become paramount, creating a robust market for sustainable lithium nitride solutions.

Market research indicates that the energy storage sector represents the largest demand segment for lithium nitride, with applications in solid-state batteries showing particular promise. These next-generation batteries offer higher energy density, improved safety profiles, and longer lifespans compared to conventional lithium-ion technologies. The electric vehicle industry's exponential growth trajectory is creating substantial pull for these advanced battery technologies, with major automotive manufacturers investing heavily in solid-state battery research and development.

Beyond energy storage, lithium nitride's unique properties are driving demand in semiconductor manufacturing, where it serves as a specialized material for advanced electronic components. The compound's excellent thermal conductivity and electrical properties make it valuable for high-performance computing applications, contributing to market expansion in the technology sector.

The hydrogen storage market represents another emerging demand vector, as lithium nitride-based materials demonstrate promising capabilities for efficient hydrogen capture and release. This application aligns with the growing global hydrogen economy and presents significant long-term market potential as clean energy infrastructure continues to develop worldwide.

Regional analysis reveals that Asia-Pacific currently dominates the market demand for sustainable lithium nitride production, led by China, Japan, and South Korea's robust manufacturing ecosystems and aggressive clean energy transitions. North America and Europe follow closely, driven by stringent environmental regulations and substantial investments in green technology development.

Market forecasts suggest that demand for sustainably produced lithium nitride will grow at a compound annual rate exceeding the broader chemical manufacturing sector, reflecting the increasing premium placed on environmentally responsible production methods. This trend is reinforced by regulatory pressures in major markets, where environmental impact assessments are becoming mandatory components of industrial permitting processes.

Consumer-facing companies are increasingly incorporating environmental performance metrics into their supplier evaluation criteria, creating downstream pressure for sustainable production methods throughout the supply chain. This market dynamic is accelerating the adoption of cleaner production technologies and creating competitive advantages for early adopters of sustainable lithium nitride manufacturing processes.

Market research indicates that the energy storage sector represents the largest demand segment for lithium nitride, with applications in solid-state batteries showing particular promise. These next-generation batteries offer higher energy density, improved safety profiles, and longer lifespans compared to conventional lithium-ion technologies. The electric vehicle industry's exponential growth trajectory is creating substantial pull for these advanced battery technologies, with major automotive manufacturers investing heavily in solid-state battery research and development.

Beyond energy storage, lithium nitride's unique properties are driving demand in semiconductor manufacturing, where it serves as a specialized material for advanced electronic components. The compound's excellent thermal conductivity and electrical properties make it valuable for high-performance computing applications, contributing to market expansion in the technology sector.

The hydrogen storage market represents another emerging demand vector, as lithium nitride-based materials demonstrate promising capabilities for efficient hydrogen capture and release. This application aligns with the growing global hydrogen economy and presents significant long-term market potential as clean energy infrastructure continues to develop worldwide.

Regional analysis reveals that Asia-Pacific currently dominates the market demand for sustainable lithium nitride production, led by China, Japan, and South Korea's robust manufacturing ecosystems and aggressive clean energy transitions. North America and Europe follow closely, driven by stringent environmental regulations and substantial investments in green technology development.

Market forecasts suggest that demand for sustainably produced lithium nitride will grow at a compound annual rate exceeding the broader chemical manufacturing sector, reflecting the increasing premium placed on environmentally responsible production methods. This trend is reinforced by regulatory pressures in major markets, where environmental impact assessments are becoming mandatory components of industrial permitting processes.

Consumer-facing companies are increasingly incorporating environmental performance metrics into their supplier evaluation criteria, creating downstream pressure for sustainable production methods throughout the supply chain. This market dynamic is accelerating the adoption of cleaner production technologies and creating competitive advantages for early adopters of sustainable lithium nitride manufacturing processes.

Current Environmental Impact Assessment Methodologies and Challenges

Environmental impact assessment (EIA) for lithium nitride production and application currently employs several methodologies, each with distinct advantages and limitations. Life Cycle Assessment (LCA) stands as the predominant approach, systematically evaluating environmental impacts across the entire lifecycle of lithium nitride—from raw material extraction through manufacturing, use, and disposal. However, LCA methodologies often struggle with data gaps specific to lithium nitride, particularly regarding long-term environmental fate and transformation products.

Risk Assessment frameworks complement LCA by quantifying potential ecological and human health risks associated with lithium nitride exposure. These assessments typically involve hazard identification, dose-response assessment, exposure assessment, and risk characterization. The challenge lies in the limited toxicological data for lithium nitride across different environmental compartments and exposure pathways, creating significant uncertainty in risk calculations.

Material Flow Analysis (MFA) tracks lithium nitride through industrial systems and the environment, providing valuable insights into potential accumulation points and release pathways. However, MFA faces challenges in accounting for transformation products and capturing the dynamic nature of environmental systems where lithium nitride may be present.

Environmental monitoring represents another critical methodology, involving direct measurement of lithium nitride or its derivatives in environmental media. Current analytical techniques face sensitivity limitations when detecting lithium nitride at environmentally relevant concentrations, particularly in complex matrices like soil or sediment.

Ecological impact studies examine effects on specific ecosystems and species, but standardized protocols for lithium nitride ecotoxicity testing remain underdeveloped. This gap creates challenges in establishing regulatory thresholds and environmental quality standards.

Computational modeling approaches, including environmental fate models and ecosystem response simulations, offer predictive capabilities but require extensive validation with empirical data—which is currently insufficient for lithium nitride.

Cross-cutting challenges include methodological inconsistencies across different regulatory frameworks, limited baseline environmental data in regions where lithium nitride production occurs, and inadequate consideration of cumulative impacts when multiple industrial activities affect the same ecosystem. Additionally, there is insufficient integration of socioeconomic factors into environmental assessments, potentially overlooking important sustainability dimensions.

Emerging challenges involve accounting for climate change effects on environmental fate and transport of lithium nitride, as well as addressing potential nanoscale applications where traditional assessment frameworks may prove inadequate due to unique physicochemical properties and environmental behaviors.

Risk Assessment frameworks complement LCA by quantifying potential ecological and human health risks associated with lithium nitride exposure. These assessments typically involve hazard identification, dose-response assessment, exposure assessment, and risk characterization. The challenge lies in the limited toxicological data for lithium nitride across different environmental compartments and exposure pathways, creating significant uncertainty in risk calculations.

Material Flow Analysis (MFA) tracks lithium nitride through industrial systems and the environment, providing valuable insights into potential accumulation points and release pathways. However, MFA faces challenges in accounting for transformation products and capturing the dynamic nature of environmental systems where lithium nitride may be present.

Environmental monitoring represents another critical methodology, involving direct measurement of lithium nitride or its derivatives in environmental media. Current analytical techniques face sensitivity limitations when detecting lithium nitride at environmentally relevant concentrations, particularly in complex matrices like soil or sediment.

Ecological impact studies examine effects on specific ecosystems and species, but standardized protocols for lithium nitride ecotoxicity testing remain underdeveloped. This gap creates challenges in establishing regulatory thresholds and environmental quality standards.

Computational modeling approaches, including environmental fate models and ecosystem response simulations, offer predictive capabilities but require extensive validation with empirical data—which is currently insufficient for lithium nitride.

Cross-cutting challenges include methodological inconsistencies across different regulatory frameworks, limited baseline environmental data in regions where lithium nitride production occurs, and inadequate consideration of cumulative impacts when multiple industrial activities affect the same ecosystem. Additionally, there is insufficient integration of socioeconomic factors into environmental assessments, potentially overlooking important sustainability dimensions.

Emerging challenges involve accounting for climate change effects on environmental fate and transport of lithium nitride, as well as addressing potential nanoscale applications where traditional assessment frameworks may prove inadequate due to unique physicochemical properties and environmental behaviors.

Established Environmental Impact Assessment Protocols for Lithium Compounds

01 Environmental impact assessment of lithium nitride production

The production of lithium nitride has various environmental impacts that need to be assessed. These impacts include energy consumption, greenhouse gas emissions, and resource depletion. Environmental impact assessments help in identifying and mitigating these effects through sustainable manufacturing processes and proper waste management strategies. Comprehensive life cycle assessments can quantify the environmental footprint of lithium nitride throughout its production, use, and disposal phases.- Environmental impact assessment of lithium nitride production: The production of lithium nitride has various environmental impacts that need to be assessed. These impacts include energy consumption, greenhouse gas emissions, and resource depletion. Environmental impact assessments help in identifying and mitigating these impacts through sustainable production methods and lifecycle analysis. Proper assessment enables manufacturers to develop more environmentally friendly processes for lithium nitride production.

- Recycling and waste management of lithium nitride compounds: Recycling and proper waste management of lithium nitride compounds are essential to reduce environmental impact. This includes recovery processes for spent lithium nitride materials, treatment of waste products, and circular economy approaches. Effective recycling methods can significantly reduce the environmental footprint of lithium nitride by minimizing resource extraction and waste disposal issues.

- Ecological effects of lithium nitride in water systems: Lithium nitride can have significant impacts on aquatic ecosystems if released into water systems. These compounds may affect water quality, aquatic organisms, and overall ecosystem health. Understanding the behavior and transformation of lithium nitride in aquatic environments is crucial for preventing contamination and protecting water resources from potential toxic effects.

- Sustainable alternatives and green chemistry approaches: Research is focused on developing sustainable alternatives and green chemistry approaches for lithium nitride applications. This includes using environmentally friendly precursors, reducing toxic byproducts, and designing processes with lower environmental impacts. Green chemistry principles are being applied to create more sustainable lithium nitride compounds that maintain functionality while reducing ecological harm.

- Monitoring and regulatory compliance for lithium nitride: Environmental monitoring and regulatory compliance are essential aspects of managing lithium nitride's environmental impact. This includes implementing monitoring systems to track emissions and releases, adhering to environmental regulations, and reporting requirements. Proper monitoring helps in early detection of potential environmental issues and ensures compliance with increasingly stringent environmental protection standards.

02 Recycling and waste management of lithium nitride compounds

Recycling and proper waste management of lithium nitride compounds are essential to minimize environmental impact. These processes involve collection, separation, and treatment of lithium nitride waste to recover valuable materials and prevent environmental contamination. Advanced recycling technologies can help in reducing the demand for raw materials and decreasing the environmental footprint associated with lithium nitride disposal. Implementing effective waste management strategies is crucial for sustainable use of lithium-based materials.Expand Specific Solutions03 Water and soil contamination from lithium nitride

Lithium nitride can potentially contaminate water bodies and soil if not properly handled or disposed of. When exposed to moisture, lithium nitride can decompose to form ammonia and lithium hydroxide, which can alter the pH of water and soil. This contamination can affect aquatic ecosystems and agricultural productivity. Monitoring systems and containment measures are necessary to prevent leaching of lithium compounds into groundwater and surrounding environments.Expand Specific Solutions04 Energy efficiency in lithium nitride applications

Improving energy efficiency in lithium nitride applications can significantly reduce its environmental impact. This includes optimizing manufacturing processes, developing energy-efficient storage systems, and implementing sustainable energy sources for production. Energy-efficient applications of lithium nitride in batteries and other technologies can help in reducing overall carbon footprint. Research focuses on minimizing energy consumption throughout the lifecycle of lithium nitride-based products.Expand Specific Solutions05 Regulatory compliance and environmental standards for lithium compounds

Regulatory compliance and adherence to environmental standards are crucial for managing the environmental impact of lithium nitride. Various international and national regulations govern the production, use, and disposal of lithium compounds to protect human health and the environment. Companies working with lithium nitride must comply with these regulations, which may include emissions limits, waste disposal requirements, and reporting obligations. Environmental management systems help in ensuring compliance and continuous improvement in environmental performance.Expand Specific Solutions

Key Industry Players and Research Institutions in Lithium Nitride Field

The environmental impact studies for lithium nitride are evolving within an emerging market characterized by growing demand but limited technological maturity. Key players represent diverse sectors: academic institutions (Central South University, Huazhong University of Science & Technology), specialized research organizations (Chinese Research Academy of Environmental Sciences, Beijing Academy of Environmental Protection Sciences), and commercial entities (PolyPlus Battery, Tianqi Lithium, EVE Energy). The competitive landscape shows a concentration of expertise in China, with companies focusing on battery technologies and environmental assessment methodologies. While established battery manufacturers like SANYO and Proterial have relevant capabilities, specialized environmental assessment firms are developing proprietary methodologies to address the unique challenges of lithium nitride's environmental footprint throughout its lifecycle.

PolyPlus Battery Co., Inc.

Technical Solution: PolyPlus has developed a comprehensive Environmental Impact Assessment (EIA) methodology specifically for lithium nitride materials used in their protected lithium electrode technology. Their approach integrates life cycle assessment (LCA) with specific focus on water-lithium interactions, as lithium nitride is highly reactive with water. The company employs controlled laboratory environments with specialized containment systems to study degradation pathways and potential environmental releases. Their methodology includes multi-phase testing that examines lithium nitride behavior in various environmental conditions (soil, water, air) while monitoring reaction products and potential toxicity. PolyPlus has established proprietary protocols for quantifying environmental persistence and transformation products of lithium nitride compounds, providing crucial data for regulatory compliance and sustainable battery development.

Strengths: Specialized expertise in lithium chemistry and battery applications provides deep understanding of material behavior; proprietary containment systems allow for safe handling of reactive materials. Weaknesses: Focus primarily on battery applications may limit broader environmental assessment scope; as a smaller company, may have resource limitations compared to larger research institutions.

Chinese Research Academy of Environmental Sciences

Technical Solution: The Chinese Research Academy of Environmental Sciences has developed a comprehensive framework for lithium nitride environmental impact assessment that integrates multiple analytical approaches. Their methodology employs a three-tiered assessment system beginning with laboratory-scale reactivity studies, followed by mesocosm experiments simulating various environmental compartments, and culminating in field monitoring at lithium processing sites. The Academy has pioneered specialized analytical techniques for detecting trace lithium nitride transformation products in environmental matrices, including advanced mass spectrometry protocols capable of identifying previously unknown degradation compounds. Their research has established standardized protocols for evaluating lithium nitride's impacts on soil microbial communities, aquatic ecosystems, and air quality, with particular attention to the compound's hydrolysis behavior and ammonia generation potential. The Academy maintains China's most comprehensive database of lithium compound environmental fate data, supporting evidence-based regulatory decisions.

Strengths: Comprehensive research capabilities spanning laboratory to field studies; strong government backing providing substantial resources; established protocols that have been adopted nationally. Weaknesses: Research findings may be less accessible internationally due to language barriers; some methodologies may be specifically tailored to Chinese environmental conditions and regulatory frameworks.

Critical Research Findings on Lithium Nitride Ecological Interactions

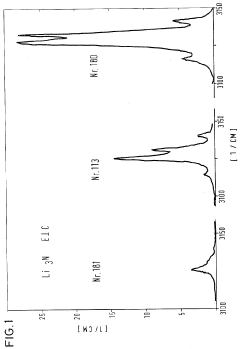

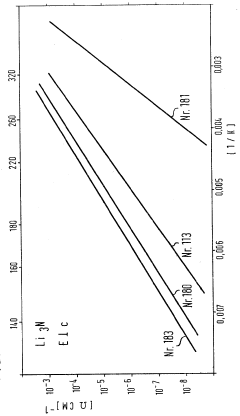

Lithium nitride of increased conductivity, method for its preparation, and its use

PatentInactiveUS4321163A

Innovation

- Doping lithium nitride with hydrogen to form nitrogen-hydrogen complex compounds, creating lithium vacancies that enhance ionic conductivity, and maintaining specific purity standards to improve stability, with hydrogen content optimized between 0.2 to 8 mole percent.

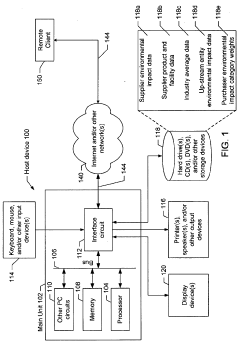

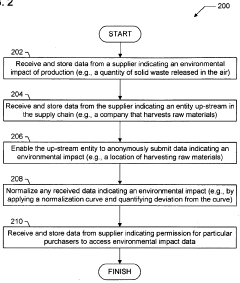

Method and apparatus for tracking and analyzing environmental impact of producing paper

PatentWO2010048175A1

Innovation

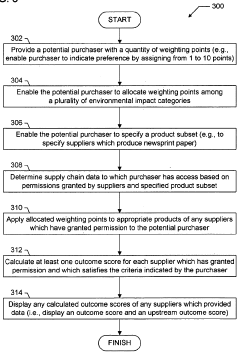

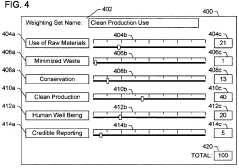

- An environmental impact data tracking system that allows suppliers to input data on their products, includes upstream entities' data anonymously, normalizes data for comparison, and enables purchasers to set custom weightings for environmental impact categories, generating outcome scores for suppliers based on their preferences.

Regulatory Compliance Framework for Lithium Compound Manufacturing

The regulatory landscape for lithium compound manufacturing, particularly for lithium nitride, is complex and multifaceted, spanning international, national, and local jurisdictions. Manufacturers must navigate a web of environmental regulations that govern the entire lifecycle of lithium compounds, from extraction to disposal.

At the international level, frameworks such as the Basel Convention on Hazardous Waste and the Strategic Approach to International Chemicals Management (SAICM) provide overarching guidelines for managing chemical substances. These frameworks emphasize the precautionary principle and require thorough environmental impact assessments before approval of new manufacturing processes.

In the United States, the Environmental Protection Agency (EPA) regulates lithium compound manufacturing under several statutes, including the Toxic Substances Control Act (TSCA), the Clean Air Act, and the Clean Water Act. The National Environmental Policy Act (NEPA) mandates environmental impact studies for major federal actions, which often includes permitting for large-scale lithium processing facilities.

European regulations are generally more stringent, with the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) framework requiring manufacturers to register chemical substances and provide comprehensive safety data. The Industrial Emissions Directive (IED) further imposes strict emission limits and mandates the use of Best Available Techniques (BAT).

Asian markets, particularly China and Japan, have developed their own regulatory frameworks that increasingly align with international standards while addressing region-specific concerns. China's recent environmental protection laws have significantly tightened controls on chemical manufacturing emissions.

Compliance requirements typically include obtaining permits for air emissions, wastewater discharges, and waste management. These permits often stipulate continuous monitoring and regular reporting of environmental parameters. For lithium nitride specifically, its reactive nature with water necessitates additional safety protocols and emergency response planning.

Environmental impact studies must address specific concerns related to lithium compounds, including potential groundwater contamination, air quality impacts from particulate matter, and ecological effects on sensitive species. The studies should incorporate baseline environmental data, predictive modeling of potential impacts, and proposed mitigation measures.

Emerging trends in regulatory compliance include increased focus on sustainability metrics, life-cycle assessment requirements, and extended producer responsibility. Many jurisdictions are also implementing green chemistry initiatives that encourage the development of less hazardous alternatives and more efficient manufacturing processes.

At the international level, frameworks such as the Basel Convention on Hazardous Waste and the Strategic Approach to International Chemicals Management (SAICM) provide overarching guidelines for managing chemical substances. These frameworks emphasize the precautionary principle and require thorough environmental impact assessments before approval of new manufacturing processes.

In the United States, the Environmental Protection Agency (EPA) regulates lithium compound manufacturing under several statutes, including the Toxic Substances Control Act (TSCA), the Clean Air Act, and the Clean Water Act. The National Environmental Policy Act (NEPA) mandates environmental impact studies for major federal actions, which often includes permitting for large-scale lithium processing facilities.

European regulations are generally more stringent, with the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) framework requiring manufacturers to register chemical substances and provide comprehensive safety data. The Industrial Emissions Directive (IED) further imposes strict emission limits and mandates the use of Best Available Techniques (BAT).

Asian markets, particularly China and Japan, have developed their own regulatory frameworks that increasingly align with international standards while addressing region-specific concerns. China's recent environmental protection laws have significantly tightened controls on chemical manufacturing emissions.

Compliance requirements typically include obtaining permits for air emissions, wastewater discharges, and waste management. These permits often stipulate continuous monitoring and regular reporting of environmental parameters. For lithium nitride specifically, its reactive nature with water necessitates additional safety protocols and emergency response planning.

Environmental impact studies must address specific concerns related to lithium compounds, including potential groundwater contamination, air quality impacts from particulate matter, and ecological effects on sensitive species. The studies should incorporate baseline environmental data, predictive modeling of potential impacts, and proposed mitigation measures.

Emerging trends in regulatory compliance include increased focus on sustainability metrics, life-cycle assessment requirements, and extended producer responsibility. Many jurisdictions are also implementing green chemistry initiatives that encourage the development of less hazardous alternatives and more efficient manufacturing processes.

Life Cycle Assessment Methodologies for Lithium Nitride Applications

Life Cycle Assessment (LCA) methodologies for lithium nitride applications require a comprehensive framework that evaluates environmental impacts across the entire value chain. These methodologies typically follow ISO 14040 and 14044 standards, which provide guidelines for conducting thorough environmental assessments of products and processes from raw material extraction to end-of-life disposal.

The LCA process for lithium nitride begins with a clear definition of scope and boundaries, identifying all relevant inputs, outputs, and processes involved in the material's lifecycle. This includes mining of lithium resources, synthesis of lithium nitride, application in various technologies, and eventual disposal or recycling. Goal definition is crucial at this stage to ensure the assessment addresses specific environmental concerns related to lithium nitride applications.

Inventory analysis constitutes the second phase, involving detailed data collection on energy consumption, resource utilization, emissions, and waste generation throughout the lifecycle. For lithium nitride, this includes quantifying energy requirements for synthesis processes, chemical inputs, transportation impacts, and operational parameters during application phases. Special attention must be paid to the high reactivity of lithium nitride with water, which presents unique handling and safety considerations affecting the inventory data.

Impact assessment methodologies for lithium nitride should incorporate multiple environmental indicators, including global warming potential, acidification, eutrophication, resource depletion, and toxicity metrics. The ReCiPe or IMPACT 2002+ frameworks are particularly suitable for lithium compounds due to their comprehensive coverage of impact categories relevant to chemical processing and energy-intensive materials.

Interpretation of LCA results requires sensitivity analysis to identify key environmental hotspots in the lithium nitride lifecycle. This often reveals that energy consumption during synthesis and potential environmental releases during disposal represent critical impact points. Uncertainty analysis using Monte Carlo simulations can strengthen the reliability of conclusions drawn from the assessment.

Comparative LCAs between lithium nitride and alternative materials for similar applications provide valuable insights for technology developers and policy makers. These comparisons should consider functional equivalence and performance characteristics to ensure fair assessment of environmental trade-offs between different material choices.

Emerging methodologies incorporating social and economic dimensions alongside environmental impacts (Life Cycle Sustainability Assessment) offer more holistic evaluation frameworks for lithium nitride applications, particularly important given the material's role in emerging energy technologies and potential socioeconomic implications of its supply chain.

The LCA process for lithium nitride begins with a clear definition of scope and boundaries, identifying all relevant inputs, outputs, and processes involved in the material's lifecycle. This includes mining of lithium resources, synthesis of lithium nitride, application in various technologies, and eventual disposal or recycling. Goal definition is crucial at this stage to ensure the assessment addresses specific environmental concerns related to lithium nitride applications.

Inventory analysis constitutes the second phase, involving detailed data collection on energy consumption, resource utilization, emissions, and waste generation throughout the lifecycle. For lithium nitride, this includes quantifying energy requirements for synthesis processes, chemical inputs, transportation impacts, and operational parameters during application phases. Special attention must be paid to the high reactivity of lithium nitride with water, which presents unique handling and safety considerations affecting the inventory data.

Impact assessment methodologies for lithium nitride should incorporate multiple environmental indicators, including global warming potential, acidification, eutrophication, resource depletion, and toxicity metrics. The ReCiPe or IMPACT 2002+ frameworks are particularly suitable for lithium compounds due to their comprehensive coverage of impact categories relevant to chemical processing and energy-intensive materials.

Interpretation of LCA results requires sensitivity analysis to identify key environmental hotspots in the lithium nitride lifecycle. This often reveals that energy consumption during synthesis and potential environmental releases during disposal represent critical impact points. Uncertainty analysis using Monte Carlo simulations can strengthen the reliability of conclusions drawn from the assessment.

Comparative LCAs between lithium nitride and alternative materials for similar applications provide valuable insights for technology developers and policy makers. These comparisons should consider functional equivalence and performance characteristics to ensure fair assessment of environmental trade-offs between different material choices.

Emerging methodologies incorporating social and economic dimensions alongside environmental impacts (Life Cycle Sustainability Assessment) offer more holistic evaluation frameworks for lithium nitride applications, particularly important given the material's role in emerging energy technologies and potential socioeconomic implications of its supply chain.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!