How to Safely Handle Lithium Nitride in Laboratory Settings

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Nitride Safety Background and Objectives

Lithium nitride (Li₃N) has emerged as a significant compound in various advanced technological applications, including hydrogen storage systems, battery technologies, and specialized ceramic materials. The historical development of lithium nitride research dates back to the early 20th century, but recent decades have witnessed accelerated interest due to its unique properties and potential applications in sustainable energy solutions.

The evolution of lithium nitride handling protocols has been shaped by several serious laboratory incidents in the 1980s and 1990s, which highlighted the compound's extreme reactivity with moisture and air. These incidents prompted the development of standardized safety procedures that continue to evolve as new applications for the material emerge. The technical trajectory shows a clear shift from basic characterization studies to application-focused research, particularly in energy storage domains.

Current safety challenges with lithium nitride stem from its classification as a highly reactive alkali metal compound that generates hazardous byproducts upon contact with water, including ammonia gas and corrosive lithium hydroxide. Additionally, its fine powder form presents dust explosion risks when exposed to air. The compound's sensitivity to environmental conditions necessitates specialized handling protocols that balance research accessibility with stringent safety measures.

The global research landscape shows concentrated expertise in lithium nitride handling, with leading centers in North America, Europe, and East Asia developing distinct approaches to safety management. Regional variations in regulatory frameworks have led to different emphasis points in safety protocols, though international standardization efforts are gradually harmonizing these practices.

Our technical objectives for this research include developing comprehensive, scalable safety protocols for lithium nitride handling that address the full lifecycle of the material in laboratory settings. This encompasses storage solutions, transfer methodologies, reaction vessel designs, and emergency response procedures specifically tailored to the compound's unique properties.

We aim to establish quantifiable safety metrics for lithium nitride operations, including acceptable exposure limits, optimal inert atmosphere parameters, and material compatibility guidelines. The ultimate goal is to enable broader research applications while minimizing risk through engineered controls rather than procedural limitations, thereby expanding the compound's utility in next-generation energy storage and materials science applications.

The evolution of lithium nitride handling protocols has been shaped by several serious laboratory incidents in the 1980s and 1990s, which highlighted the compound's extreme reactivity with moisture and air. These incidents prompted the development of standardized safety procedures that continue to evolve as new applications for the material emerge. The technical trajectory shows a clear shift from basic characterization studies to application-focused research, particularly in energy storage domains.

Current safety challenges with lithium nitride stem from its classification as a highly reactive alkali metal compound that generates hazardous byproducts upon contact with water, including ammonia gas and corrosive lithium hydroxide. Additionally, its fine powder form presents dust explosion risks when exposed to air. The compound's sensitivity to environmental conditions necessitates specialized handling protocols that balance research accessibility with stringent safety measures.

The global research landscape shows concentrated expertise in lithium nitride handling, with leading centers in North America, Europe, and East Asia developing distinct approaches to safety management. Regional variations in regulatory frameworks have led to different emphasis points in safety protocols, though international standardization efforts are gradually harmonizing these practices.

Our technical objectives for this research include developing comprehensive, scalable safety protocols for lithium nitride handling that address the full lifecycle of the material in laboratory settings. This encompasses storage solutions, transfer methodologies, reaction vessel designs, and emergency response procedures specifically tailored to the compound's unique properties.

We aim to establish quantifiable safety metrics for lithium nitride operations, including acceptable exposure limits, optimal inert atmosphere parameters, and material compatibility guidelines. The ultimate goal is to enable broader research applications while minimizing risk through engineered controls rather than procedural limitations, thereby expanding the compound's utility in next-generation energy storage and materials science applications.

Laboratory Demand Analysis for Lithium Nitride Handling

The demand for safe handling protocols for lithium nitride in laboratory settings has grown significantly in recent years, driven by its increasing applications in energy storage research, semiconductor manufacturing, and advanced materials development. Market analysis indicates that research institutions and industrial R&D laboratories constitute the primary demand sources, with an estimated annual growth rate of 7.8% in lithium nitride usage for experimental purposes across these sectors.

Academic research laboratories, particularly those focused on battery technology and energy storage solutions, represent approximately 45% of the current demand. These facilities require lithium nitride for investigating novel electrode materials and solid-state electrolytes, where its nitrogen-rich properties offer promising performance characteristics for next-generation energy storage devices.

Industrial research facilities account for roughly 38% of market demand, with semiconductor manufacturers and materials science companies leading adoption. These organizations utilize lithium nitride in thin-film deposition processes, specialized ceramic production, and as a precursor for nitride-based electronic components. The remaining demand comes from government research laboratories and specialized testing facilities.

Safety considerations significantly influence market dynamics, as lithium nitride's reactivity with moisture presents handling challenges that require specialized equipment and protocols. This has created a parallel market for safety equipment specifically designed for reactive nitride compounds, including moisture-controlled glove boxes, specialized storage containers, and monitoring systems.

Regional analysis reveals that North America and East Asia dominate the research demand landscape, collectively accounting for over 70% of global lithium nitride laboratory usage. European research institutions follow at approximately 22%, with emerging research hubs in other regions making up the remainder.

The demand pattern shows seasonal variations aligned with academic research cycles and industrial R&D budget allocations. Peak procurement periods typically occur during the first and third quarters of the fiscal year, corresponding to the initiation of new research projects and budget utilization deadlines respectively.

Cost sensitivity analysis indicates that while price remains a consideration, laboratories prioritize purity levels and reliable safety documentation over cost factors when sourcing lithium nitride. This has led suppliers to compete primarily on quality certifications and comprehensive safety data rather than price points alone.

Future demand projections suggest continued growth, particularly in emerging applications such as quantum computing materials, advanced ceramics for extreme environments, and specialized catalyst development. These expanding application areas are expected to drive demand for increasingly sophisticated handling protocols and safety systems tailored to specific research environments.

Academic research laboratories, particularly those focused on battery technology and energy storage solutions, represent approximately 45% of the current demand. These facilities require lithium nitride for investigating novel electrode materials and solid-state electrolytes, where its nitrogen-rich properties offer promising performance characteristics for next-generation energy storage devices.

Industrial research facilities account for roughly 38% of market demand, with semiconductor manufacturers and materials science companies leading adoption. These organizations utilize lithium nitride in thin-film deposition processes, specialized ceramic production, and as a precursor for nitride-based electronic components. The remaining demand comes from government research laboratories and specialized testing facilities.

Safety considerations significantly influence market dynamics, as lithium nitride's reactivity with moisture presents handling challenges that require specialized equipment and protocols. This has created a parallel market for safety equipment specifically designed for reactive nitride compounds, including moisture-controlled glove boxes, specialized storage containers, and monitoring systems.

Regional analysis reveals that North America and East Asia dominate the research demand landscape, collectively accounting for over 70% of global lithium nitride laboratory usage. European research institutions follow at approximately 22%, with emerging research hubs in other regions making up the remainder.

The demand pattern shows seasonal variations aligned with academic research cycles and industrial R&D budget allocations. Peak procurement periods typically occur during the first and third quarters of the fiscal year, corresponding to the initiation of new research projects and budget utilization deadlines respectively.

Cost sensitivity analysis indicates that while price remains a consideration, laboratories prioritize purity levels and reliable safety documentation over cost factors when sourcing lithium nitride. This has led suppliers to compete primarily on quality certifications and comprehensive safety data rather than price points alone.

Future demand projections suggest continued growth, particularly in emerging applications such as quantum computing materials, advanced ceramics for extreme environments, and specialized catalyst development. These expanding application areas are expected to drive demand for increasingly sophisticated handling protocols and safety systems tailored to specific research environments.

Current Challenges in Lithium Nitride Laboratory Management

The safe handling of lithium nitride (Li₃N) in laboratory settings presents several significant challenges due to its highly reactive nature. One of the primary concerns is its extreme sensitivity to moisture, as lithium nitride reacts vigorously with water to produce ammonia gas and lithium hydroxide. This reaction can be exothermic and potentially hazardous, especially when larger quantities are involved, creating risks of fire or explosion in inadequately controlled environments.

Atmospheric exposure represents another major challenge, as lithium nitride readily reacts with oxygen and carbon dioxide in air. These reactions not only compromise sample purity but also generate potentially harmful byproducts. The degradation of lithium nitride upon exposure necessitates specialized containment systems, which many laboratories find difficult to implement or maintain properly.

Personnel safety issues are particularly concerning, as lithium nitride can cause severe chemical burns upon contact with skin or mucous membranes. The ammonia released during hydrolysis reactions can cause respiratory irritation and, at higher concentrations, serious respiratory damage. Many laboratories report inadequate personal protective equipment specifically designed for handling this compound.

Storage stability presents ongoing difficulties, with lithium nitride requiring storage under completely inert conditions, typically in argon or nitrogen atmospheres. The compound's tendency to degrade over time, even under seemingly appropriate storage conditions, creates challenges for long-term research projects and reproducibility of experiments.

Analytical challenges further complicate work with lithium nitride, as its high reactivity makes standard characterization techniques difficult to apply without sample degradation. Researchers often struggle to obtain accurate compositional and structural data, limiting the advancement of fundamental understanding of this material's properties.

Waste disposal represents a significant environmental and safety concern. The reactive nature of lithium nitride waste requires specialized neutralization procedures before disposal, yet standardized protocols remain inconsistently implemented across research institutions. Many laboratories lack proper facilities for safe deactivation of lithium nitride waste.

Regulatory compliance adds another layer of complexity, with varying requirements across different jurisdictions regarding the storage, handling, and disposal of reactive nitrides. Many laboratories report difficulties in navigating these regulations, particularly when international collaborations are involved.

Training deficiencies compound these challenges, as many researchers receive insufficient specialized training in handling air-sensitive and water-reactive materials like lithium nitride. This knowledge gap increases the risk of accidents and compromises both safety and research quality.

Atmospheric exposure represents another major challenge, as lithium nitride readily reacts with oxygen and carbon dioxide in air. These reactions not only compromise sample purity but also generate potentially harmful byproducts. The degradation of lithium nitride upon exposure necessitates specialized containment systems, which many laboratories find difficult to implement or maintain properly.

Personnel safety issues are particularly concerning, as lithium nitride can cause severe chemical burns upon contact with skin or mucous membranes. The ammonia released during hydrolysis reactions can cause respiratory irritation and, at higher concentrations, serious respiratory damage. Many laboratories report inadequate personal protective equipment specifically designed for handling this compound.

Storage stability presents ongoing difficulties, with lithium nitride requiring storage under completely inert conditions, typically in argon or nitrogen atmospheres. The compound's tendency to degrade over time, even under seemingly appropriate storage conditions, creates challenges for long-term research projects and reproducibility of experiments.

Analytical challenges further complicate work with lithium nitride, as its high reactivity makes standard characterization techniques difficult to apply without sample degradation. Researchers often struggle to obtain accurate compositional and structural data, limiting the advancement of fundamental understanding of this material's properties.

Waste disposal represents a significant environmental and safety concern. The reactive nature of lithium nitride waste requires specialized neutralization procedures before disposal, yet standardized protocols remain inconsistently implemented across research institutions. Many laboratories lack proper facilities for safe deactivation of lithium nitride waste.

Regulatory compliance adds another layer of complexity, with varying requirements across different jurisdictions regarding the storage, handling, and disposal of reactive nitrides. Many laboratories report difficulties in navigating these regulations, particularly when international collaborations are involved.

Training deficiencies compound these challenges, as many researchers receive insufficient specialized training in handling air-sensitive and water-reactive materials like lithium nitride. This knowledge gap increases the risk of accidents and compromises both safety and research quality.

Established Safety Protocols for Reactive Nitrogen Compounds

01 Handling and storage safety protocols

Lithium nitride requires specific handling and storage protocols due to its reactivity with moisture and air. Safety measures include storing in dry, inert environments, using appropriate personal protective equipment, and implementing proper ventilation systems. These protocols help prevent accidents and ensure safe handling of lithium nitride in laboratory and industrial settings.- Handling and storage safety measures for lithium nitride: Lithium nitride requires specific handling and storage protocols due to its reactivity with moisture and air. Safety measures include storing in inert atmospheres, using appropriate containment vessels, and implementing proper ventilation systems. Personnel should be equipped with suitable protective equipment when handling this compound to prevent exposure risks. Regular safety training and emergency response procedures are essential for facilities working with lithium nitride.

- Fire and explosion hazards of lithium nitride: Lithium nitride presents significant fire and explosion hazards due to its reactivity with water, which produces flammable hydrogen gas and ammonia. The compound can ignite spontaneously when exposed to moisture or under certain conditions. Fire suppression systems specifically designed for metal fires must be implemented in areas where lithium nitride is handled or stored. Special fire extinguishing agents that do not contain water should be used in case of lithium nitride fires.

- Toxicological properties and health effects: Lithium nitride can cause severe irritation and burns upon contact with skin, eyes, or mucous membranes due to its caustic nature and the formation of alkaline products when it reacts with moisture. Inhalation of lithium nitride dust or fumes can lead to respiratory tract irritation and potential lung damage. Chronic exposure may affect the central nervous system and kidney function. Medical surveillance programs are recommended for workers regularly exposed to lithium nitride.

- Safe manufacturing processes and stabilization techniques: Advanced manufacturing processes have been developed to enhance the safety of lithium nitride production. These include controlled atmosphere synthesis, stabilization with protective coatings or additives, and modified reaction pathways that reduce hazardous intermediates. Microencapsulation techniques can be employed to create safer forms of lithium nitride for handling and transportation. Process automation helps minimize human exposure during manufacturing operations.

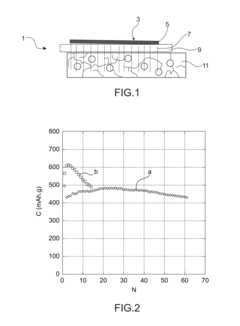

- Safety considerations in battery applications: When used in battery systems, lithium nitride requires specific safety measures to prevent thermal runaway and other hazardous events. These include incorporating safety vents, thermal management systems, and electronic protection circuits. Battery designs utilizing lithium nitride should include physical barriers to prevent moisture ingress and containment systems to mitigate risks in case of cell failure. Testing protocols have been established to evaluate the safety performance of lithium nitride-containing batteries under various abuse conditions.

02 Fire and explosion hazard mitigation

Lithium nitride presents fire and explosion hazards due to its reactivity. Mitigation strategies include using fire suppression systems specifically designed for metal fires, avoiding water-based extinguishers which can react violently with lithium compounds, maintaining controlled environments, and implementing emergency response procedures. These measures are essential for preventing and managing potential fire incidents involving lithium nitride.Expand Specific Solutions03 Protective coatings and stabilization techniques

Various protective coatings and stabilization techniques have been developed to enhance the safety of lithium nitride. These include encapsulation methods, surface passivation treatments, and composite formations that reduce reactivity with environmental elements. Such techniques improve stability during handling and storage while maintaining the functional properties of lithium nitride for various applications.Expand Specific Solutions04 Safety in battery applications

When used in battery applications, lithium nitride requires specific safety considerations. These include thermal management systems to prevent overheating, structural designs that contain potential failures, monitoring systems for early detection of safety issues, and isolation mechanisms to prevent cascading failures. These safety features are crucial for the development of stable and reliable lithium-based energy storage systems.Expand Specific Solutions05 Environmental and health impact management

Managing the environmental and health impacts of lithium nitride involves implementing proper disposal procedures, containment systems to prevent environmental release, exposure monitoring for workers, and medical response protocols for accidental exposure. These management strategies help minimize risks to human health and the environment while enabling the continued use of lithium nitride in various technological applications.Expand Specific Solutions

Leading Research Institutions and Chemical Safety Organizations

The lithium nitride laboratory safety landscape is evolving within a growing market driven by advanced battery technologies. Currently in the early commercialization phase, this field is experiencing increased attention due to lithium's critical role in energy storage applications. Companies like PolyPlus Battery, with their protected lithium electrode technology, and Tianqi Lithium Corp are leading technical innovation, while established players such as LG Energy Solution and Samsung SDI bring manufacturing expertise. Research institutions including Dalian Institute of Chemical Physics and China Petroleum University Beijing contribute fundamental knowledge. The market is characterized by specialized safety protocols development and growing collaboration between academic and industrial sectors to address the unique challenges of handling reactive lithium compounds.

PolyPlus Battery Co., Inc.

Technical Solution: PolyPlus has developed comprehensive safety protocols for handling lithium nitride in their advanced battery research laboratories. Their approach includes specialized glove box systems with controlled atmosphere environments (< 1 ppm oxygen and moisture) where lithium nitride is exclusively handled. The company employs a multi-layered safety strategy including: (1) specialized training programs for all personnel working with reactive lithium compounds, (2) custom-designed storage containers with moisture-resistant seals and inert gas purging capabilities, (3) automated monitoring systems that continuously track environmental conditions and provide early warning of potential hazards, and (4) proprietary neutralization procedures for safe disposal of lithium nitride waste. Their protocol includes specific emergency response procedures for different exposure scenarios and incorporates regular safety drills to ensure preparedness.

Strengths: Industry-leading expertise in handling reactive lithium compounds with proven safety record in battery research applications. Their integrated monitoring systems provide real-time hazard detection. Weaknesses: Their protocols are highly specialized for battery manufacturing environments and may require significant adaptation for general laboratory settings. The systems require substantial initial investment in specialized equipment.

Tianqi Lithium Corp.

Technical Solution: Tianqi Lithium has developed specialized handling protocols for lithium nitride and other reactive lithium compounds throughout their production and research facilities. Their approach centers on a comprehensive risk assessment framework that identifies specific hazards associated with each handling step. Key components include: (1) specialized containment systems with multiple redundant barriers to prevent moisture and oxygen exposure, (2) advanced environmental monitoring systems that continuously track temperature, humidity, and gas composition in handling areas, (3) detailed standard operating procedures with specific emergency response protocols for different incident scenarios, and (4) specialized training programs that include hands-on practice with simulated emergency situations. Tianqi's protocol incorporates regular safety drills and scenario-based training to ensure personnel readiness. Their approach also includes detailed documentation requirements and regular process audits to verify compliance with established safety procedures.

Strengths: Comprehensive risk assessment approach that addresses specific hazards at each handling stage. Their training program with simulated emergencies ensures practical preparedness. Weaknesses: Their protocols are primarily designed for large-scale industrial operations and may require significant adaptation for laboratory settings. Implementation requires substantial organizational commitment to safety culture development.

Critical Safety Innovations for Lithium Nitride Handling

Assembly consisting of a current collector and a silicon electrode

PatentInactiveUS20140377650A1

Innovation

- A current collector-electrode assembly is developed with an elastic polymer layer connecting the silicon electrode and current collector, which absorbs deformations and maintains the interface integrity, using a combination of thermoplastic, thermosetting, and elastomeric polymers, along with carbon nanotubes for electrical connection and flexibility.

Regulatory Compliance for Hazardous Chemical Handling

Regulatory compliance for handling lithium nitride in laboratory settings is governed by multiple international, national, and local frameworks that address hazardous chemical management. The Occupational Safety and Health Administration (OSHA) in the United States establishes the primary regulatory foundation through its Hazard Communication Standard (29 CFR 1910.1200) and Laboratory Standard (29 CFR 1910.1450), which mandate comprehensive hazard assessment, proper labeling, and employee training for all hazardous substances including reactive compounds like lithium nitride.

The Environmental Protection Agency (EPA) further regulates lithium nitride handling under the Resource Conservation and Recovery Act (RCRA) and the Toxic Substances Control Act (TSCA), particularly concerning waste disposal and environmental release prevention. These regulations require detailed documentation of chemical inventories, waste generation, and disposal procedures specific to water-reactive compounds.

European laboratories must comply with the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation and the Classification, Labeling and Packaging (CLP) regulation, which mandate extensive safety data sheets and appropriate hazard pictograms for lithium nitride. The European Chemical Agency (ECHA) classification of lithium nitride as a water-reactive substance necessitates specific storage and handling protocols.

International Air Transport Association (IATA) and Department of Transportation (DOT) regulations govern the transportation of lithium nitride, classifying it as a Class 4.3 dangerous good (substances which, in contact with water, emit flammable gases). This classification requires specialized packaging, labeling, and documentation during transport between facilities.

Local fire codes and building regulations impose additional requirements for storage quantities, containment systems, and emergency response planning. Many jurisdictions mandate regular inspections and certifications for facilities handling water-reactive materials like lithium nitride.

Compliance documentation requirements include maintaining current Safety Data Sheets (SDS), chemical hygiene plans, training records, and incident reports. Laboratories must implement regular compliance audits and keep records of all safety inspections and corrective actions taken.

Penalties for non-compliance can be severe, ranging from substantial fines to facility closure and potential criminal liability in cases of negligence leading to injury or environmental damage. OSHA violations related to hazardous chemical handling can result in penalties exceeding $13,000 per violation, with willful violations reaching up to $136,532 (as of 2023).

Staying current with evolving regulations requires establishing a systematic approach to regulatory monitoring, including subscription to relevant regulatory updates and participation in professional organizations focused on laboratory safety and chemical management.

The Environmental Protection Agency (EPA) further regulates lithium nitride handling under the Resource Conservation and Recovery Act (RCRA) and the Toxic Substances Control Act (TSCA), particularly concerning waste disposal and environmental release prevention. These regulations require detailed documentation of chemical inventories, waste generation, and disposal procedures specific to water-reactive compounds.

European laboratories must comply with the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation and the Classification, Labeling and Packaging (CLP) regulation, which mandate extensive safety data sheets and appropriate hazard pictograms for lithium nitride. The European Chemical Agency (ECHA) classification of lithium nitride as a water-reactive substance necessitates specific storage and handling protocols.

International Air Transport Association (IATA) and Department of Transportation (DOT) regulations govern the transportation of lithium nitride, classifying it as a Class 4.3 dangerous good (substances which, in contact with water, emit flammable gases). This classification requires specialized packaging, labeling, and documentation during transport between facilities.

Local fire codes and building regulations impose additional requirements for storage quantities, containment systems, and emergency response planning. Many jurisdictions mandate regular inspections and certifications for facilities handling water-reactive materials like lithium nitride.

Compliance documentation requirements include maintaining current Safety Data Sheets (SDS), chemical hygiene plans, training records, and incident reports. Laboratories must implement regular compliance audits and keep records of all safety inspections and corrective actions taken.

Penalties for non-compliance can be severe, ranging from substantial fines to facility closure and potential criminal liability in cases of negligence leading to injury or environmental damage. OSHA violations related to hazardous chemical handling can result in penalties exceeding $13,000 per violation, with willful violations reaching up to $136,532 (as of 2023).

Staying current with evolving regulations requires establishing a systematic approach to regulatory monitoring, including subscription to relevant regulatory updates and participation in professional organizations focused on laboratory safety and chemical management.

Emergency Response Procedures for Lithium Compound Incidents

Emergency response procedures for lithium compound incidents, particularly those involving lithium nitride, require meticulous planning and execution due to the compound's high reactivity with water and potential for generating toxic ammonia gas. Laboratory personnel must be trained to recognize the distinct hazard signs of lithium nitride incidents, including smoke, fire, or the characteristic ammonia odor.

Immediate response to a lithium nitride spill or fire should begin with alerting all laboratory occupants and activating the emergency response system. Small incidents may be manageable with appropriate fire extinguishers (Class D for metal fires), while larger incidents necessitate evacuation and professional emergency response teams. Under no circumstances should water be applied to lithium nitride fires, as this will exacerbate the situation by producing hydrogen gas and potentially causing explosions.

Personal protective equipment for emergency responders must include respiratory protection with appropriate filters for ammonia, chemical-resistant gloves, face shields, and fire-resistant clothing. First aid procedures should be clearly established for various exposure scenarios, including skin contact, eye exposure, inhalation of ammonia gas, or ingestion, with immediate medical attention being paramount in all cases.

Containment strategies for lithium nitride spills involve using dry inert materials such as sand, vermiculite, or specialized absorbents designed for reactive metals. The contaminated area should be isolated and ventilated while preventing the introduction of moisture. Cleanup operations must be conducted by trained personnel using non-sparking tools and appropriate containment vessels.

Post-incident procedures are equally critical and should include thorough documentation of the incident, assessment of response effectiveness, investigation of root causes, and implementation of corrective actions to prevent recurrence. Equipment and facilities must be inspected for damage before resuming operations, and all contaminated materials must be properly disposed of according to hazardous waste regulations.

Regular emergency drills specific to lithium compound incidents should be conducted to ensure all laboratory personnel are familiar with response protocols. These drills should simulate various scenarios, including spills of different magnitudes, fires, and personnel exposure situations, to build confidence and competence in emergency response procedures.

Coordination with local emergency services is essential, ensuring they are aware of the presence of lithium compounds in the facility and understand the specific hazards and response requirements. This may include providing specialized training or information sessions for first responders who might be called to the facility during an emergency.

Immediate response to a lithium nitride spill or fire should begin with alerting all laboratory occupants and activating the emergency response system. Small incidents may be manageable with appropriate fire extinguishers (Class D for metal fires), while larger incidents necessitate evacuation and professional emergency response teams. Under no circumstances should water be applied to lithium nitride fires, as this will exacerbate the situation by producing hydrogen gas and potentially causing explosions.

Personal protective equipment for emergency responders must include respiratory protection with appropriate filters for ammonia, chemical-resistant gloves, face shields, and fire-resistant clothing. First aid procedures should be clearly established for various exposure scenarios, including skin contact, eye exposure, inhalation of ammonia gas, or ingestion, with immediate medical attention being paramount in all cases.

Containment strategies for lithium nitride spills involve using dry inert materials such as sand, vermiculite, or specialized absorbents designed for reactive metals. The contaminated area should be isolated and ventilated while preventing the introduction of moisture. Cleanup operations must be conducted by trained personnel using non-sparking tools and appropriate containment vessels.

Post-incident procedures are equally critical and should include thorough documentation of the incident, assessment of response effectiveness, investigation of root causes, and implementation of corrective actions to prevent recurrence. Equipment and facilities must be inspected for damage before resuming operations, and all contaminated materials must be properly disposed of according to hazardous waste regulations.

Regular emergency drills specific to lithium compound incidents should be conducted to ensure all laboratory personnel are familiar with response protocols. These drills should simulate various scenarios, including spills of different magnitudes, fires, and personnel exposure situations, to build confidence and competence in emergency response procedures.

Coordination with local emergency services is essential, ensuring they are aware of the presence of lithium compounds in the facility and understand the specific hazards and response requirements. This may include providing specialized training or information sessions for first responders who might be called to the facility during an emergency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!