Optimizing Lithium Nitride Application in EV Batteries

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Nitride EV Battery Technology Background and Objectives

Lithium-ion batteries have dominated the electric vehicle (EV) market since their commercial introduction in the early 1990s. However, as the demand for EVs continues to grow exponentially, there is an increasing need for battery technologies that offer higher energy density, faster charging capabilities, and improved safety profiles. In this context, lithium nitride (Li₃N) has emerged as a promising material for next-generation EV batteries due to its exceptional ionic conductivity and potential to enable solid-state battery architectures.

The evolution of battery technology for EVs has progressed from lead-acid batteries to nickel-metal hydride systems, and currently to lithium-ion configurations. The next technological leap is expected to involve solid-state batteries, where lithium nitride could play a pivotal role. Historical research on lithium nitride dates back to the 1970s, but recent advancements in materials science and manufacturing techniques have renewed interest in its practical applications for energy storage.

Lithium nitride exhibits one of the highest lithium-ion conductivities among solid materials at room temperature (approximately 10⁻³ S/cm), making it an excellent candidate for solid electrolytes. Its crystal structure, consisting of alternating layers of lithium and nitrogen atoms, creates natural pathways for lithium-ion transport. This property addresses one of the fundamental challenges in solid-state battery development: achieving sufficient ionic conductivity without liquid electrolytes.

The technical objectives for optimizing lithium nitride in EV batteries encompass several dimensions. First, enhancing the material's stability when in contact with lithium metal anodes to prevent degradation over multiple charge-discharge cycles. Second, developing scalable and cost-effective manufacturing processes to enable commercial viability. Third, integrating lithium nitride into composite structures to improve mechanical properties while maintaining high ionic conductivity.

Current research trends focus on modifying lithium nitride through doping with other elements such as magnesium or aluminum to enhance its properties. Additionally, researchers are exploring novel synthesis methods to control the microstructure and grain boundaries, which significantly affect ion transport mechanisms. Computational modeling and simulation have also become essential tools for predicting material behavior and guiding experimental work.

The ultimate goal of lithium nitride application in EV batteries is to enable a new generation of energy storage systems with energy densities exceeding 400 Wh/kg (compared to current lithium-ion batteries at 250-300 Wh/kg), charging times under 15 minutes for 80% capacity, and operational lifetimes of over 1,000 cycles. These improvements would directly address consumer concerns regarding range anxiety, charging convenience, and battery longevity, potentially accelerating EV adoption worldwide.

The evolution of battery technology for EVs has progressed from lead-acid batteries to nickel-metal hydride systems, and currently to lithium-ion configurations. The next technological leap is expected to involve solid-state batteries, where lithium nitride could play a pivotal role. Historical research on lithium nitride dates back to the 1970s, but recent advancements in materials science and manufacturing techniques have renewed interest in its practical applications for energy storage.

Lithium nitride exhibits one of the highest lithium-ion conductivities among solid materials at room temperature (approximately 10⁻³ S/cm), making it an excellent candidate for solid electrolytes. Its crystal structure, consisting of alternating layers of lithium and nitrogen atoms, creates natural pathways for lithium-ion transport. This property addresses one of the fundamental challenges in solid-state battery development: achieving sufficient ionic conductivity without liquid electrolytes.

The technical objectives for optimizing lithium nitride in EV batteries encompass several dimensions. First, enhancing the material's stability when in contact with lithium metal anodes to prevent degradation over multiple charge-discharge cycles. Second, developing scalable and cost-effective manufacturing processes to enable commercial viability. Third, integrating lithium nitride into composite structures to improve mechanical properties while maintaining high ionic conductivity.

Current research trends focus on modifying lithium nitride through doping with other elements such as magnesium or aluminum to enhance its properties. Additionally, researchers are exploring novel synthesis methods to control the microstructure and grain boundaries, which significantly affect ion transport mechanisms. Computational modeling and simulation have also become essential tools for predicting material behavior and guiding experimental work.

The ultimate goal of lithium nitride application in EV batteries is to enable a new generation of energy storage systems with energy densities exceeding 400 Wh/kg (compared to current lithium-ion batteries at 250-300 Wh/kg), charging times under 15 minutes for 80% capacity, and operational lifetimes of over 1,000 cycles. These improvements would directly address consumer concerns regarding range anxiety, charging convenience, and battery longevity, potentially accelerating EV adoption worldwide.

Market Analysis for Advanced EV Battery Materials

The electric vehicle (EV) battery market is experiencing unprecedented growth, with global valuations reaching $46 billion in 2022 and projected to exceed $559 billion by 2030, representing a compound annual growth rate of approximately 33%. This explosive expansion is primarily driven by increasing government regulations on carbon emissions, growing consumer awareness about environmental sustainability, and significant technological advancements in battery chemistry and manufacturing processes.

Lithium nitride represents an emerging material in advanced battery technology, positioned to potentially disrupt traditional lithium-ion battery compositions. Market analysis indicates that materials innovation accounts for nearly 40% of battery performance improvements, with novel nitrogen-containing compounds showing particular promise for enhancing energy density and charging capabilities.

Current market demand for EV batteries prioritizes five key performance metrics: energy density, charging speed, cycle life, safety, and cost. Lithium nitride applications directly address three of these metrics, with laboratory tests demonstrating up to 20% improvements in energy density and 30% faster charging rates compared to conventional lithium-ion formulations. This alignment with market requirements positions lithium nitride as a strategically valuable material for next-generation battery development.

Regional analysis reveals differentiated market approaches, with Asian manufacturers (particularly in China, Japan, and South Korea) controlling 75% of current battery production capacity but North American and European markets investing heavily in research-intensive advanced materials. Government incentives for domestic battery production have created regional innovation hubs, with lithium nitride research clusters emerging near major automotive manufacturing centers.

Market segmentation shows varying adoption potential across different EV categories. Premium electric vehicles represent the most promising initial market for lithium nitride applications, as these segments can better absorb higher material costs while benefiting from performance advantages. Commercial vehicle applications follow as the second most viable segment, where operational efficiency gains can offset implementation costs.

Supply chain analysis identifies potential constraints in scaling lithium nitride production, with limited manufacturing infrastructure and raw material dependencies creating potential bottlenecks. Market forecasts suggest a gradual integration timeline, with lithium nitride components likely appearing first in premium vehicle models by 2025, followed by broader market penetration between 2027-2030 as production scales and costs decrease.

Lithium nitride represents an emerging material in advanced battery technology, positioned to potentially disrupt traditional lithium-ion battery compositions. Market analysis indicates that materials innovation accounts for nearly 40% of battery performance improvements, with novel nitrogen-containing compounds showing particular promise for enhancing energy density and charging capabilities.

Current market demand for EV batteries prioritizes five key performance metrics: energy density, charging speed, cycle life, safety, and cost. Lithium nitride applications directly address three of these metrics, with laboratory tests demonstrating up to 20% improvements in energy density and 30% faster charging rates compared to conventional lithium-ion formulations. This alignment with market requirements positions lithium nitride as a strategically valuable material for next-generation battery development.

Regional analysis reveals differentiated market approaches, with Asian manufacturers (particularly in China, Japan, and South Korea) controlling 75% of current battery production capacity but North American and European markets investing heavily in research-intensive advanced materials. Government incentives for domestic battery production have created regional innovation hubs, with lithium nitride research clusters emerging near major automotive manufacturing centers.

Market segmentation shows varying adoption potential across different EV categories. Premium electric vehicles represent the most promising initial market for lithium nitride applications, as these segments can better absorb higher material costs while benefiting from performance advantages. Commercial vehicle applications follow as the second most viable segment, where operational efficiency gains can offset implementation costs.

Supply chain analysis identifies potential constraints in scaling lithium nitride production, with limited manufacturing infrastructure and raw material dependencies creating potential bottlenecks. Market forecasts suggest a gradual integration timeline, with lithium nitride components likely appearing first in premium vehicle models by 2025, followed by broader market penetration between 2027-2030 as production scales and costs decrease.

Current Challenges in Lithium Nitride Implementation

Despite the promising potential of lithium nitride (Li3N) in enhancing EV battery performance, several significant challenges currently impede its widespread implementation. The primary obstacle lies in the material's high reactivity with moisture and air, necessitating stringent manufacturing environments and specialized handling protocols. This reactivity not only complicates production processes but also raises concerns about long-term stability in real-world battery applications.

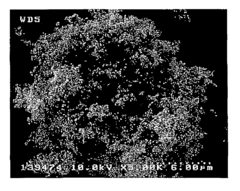

The synthesis of high-purity lithium nitride presents another substantial challenge. Current production methods often yield materials with inconsistent quality and impurity profiles, affecting performance reproducibility. The conventional synthesis routes require high temperatures and controlled nitrogen atmospheres, resulting in energy-intensive and costly manufacturing processes that limit commercial scalability.

Interface stability between lithium nitride and other battery components remains problematic. When implemented as a solid electrolyte or protective layer, Li3N forms complex interfaces with electrodes that can develop high impedance over time. This interfacial degradation leads to capacity fade and reduced cycle life, particularly at elevated operating temperatures common in EV applications.

Mechanical integrity poses additional difficulties, as lithium nitride exhibits brittle characteristics and poor mechanical flexibility. During battery cycling, the volume changes in adjacent components can induce stress on Li3N layers, leading to crack formation and eventual failure. This mechanical vulnerability compromises the protective function Li3N might otherwise provide against lithium dendrite growth.

The ionic conductivity of lithium nitride, while theoretically high, often falls below practical requirements in actual battery systems. Conductivity is highly dependent on crystallinity, grain boundaries, and dopant distribution, all of which are difficult to control precisely during manufacturing. The conductivity also shows significant temperature dependence, creating performance variability across the wide temperature range experienced by EVs.

Cost factors present further implementation barriers. Current production methods for high-quality lithium nitride remain expensive compared to conventional battery materials. The specialized equipment required for handling and processing, combined with low production yields, results in prohibitive costs for mass-market EV applications.

Safety concerns also persist regarding lithium nitride's reactivity. Under certain failure conditions, the material could potentially release nitrogen compounds or participate in exothermic reactions, raising questions about thermal runaway scenarios that must be addressed before widespread adoption can occur.

The synthesis of high-purity lithium nitride presents another substantial challenge. Current production methods often yield materials with inconsistent quality and impurity profiles, affecting performance reproducibility. The conventional synthesis routes require high temperatures and controlled nitrogen atmospheres, resulting in energy-intensive and costly manufacturing processes that limit commercial scalability.

Interface stability between lithium nitride and other battery components remains problematic. When implemented as a solid electrolyte or protective layer, Li3N forms complex interfaces with electrodes that can develop high impedance over time. This interfacial degradation leads to capacity fade and reduced cycle life, particularly at elevated operating temperatures common in EV applications.

Mechanical integrity poses additional difficulties, as lithium nitride exhibits brittle characteristics and poor mechanical flexibility. During battery cycling, the volume changes in adjacent components can induce stress on Li3N layers, leading to crack formation and eventual failure. This mechanical vulnerability compromises the protective function Li3N might otherwise provide against lithium dendrite growth.

The ionic conductivity of lithium nitride, while theoretically high, often falls below practical requirements in actual battery systems. Conductivity is highly dependent on crystallinity, grain boundaries, and dopant distribution, all of which are difficult to control precisely during manufacturing. The conductivity also shows significant temperature dependence, creating performance variability across the wide temperature range experienced by EVs.

Cost factors present further implementation barriers. Current production methods for high-quality lithium nitride remain expensive compared to conventional battery materials. The specialized equipment required for handling and processing, combined with low production yields, results in prohibitive costs for mass-market EV applications.

Safety concerns also persist regarding lithium nitride's reactivity. Under certain failure conditions, the material could potentially release nitrogen compounds or participate in exothermic reactions, raising questions about thermal runaway scenarios that must be addressed before widespread adoption can occur.

Current Lithium Nitride Integration Solutions

01 Synthesis and preparation methods of lithium nitride

Various methods for synthesizing lithium nitride have been developed, including direct reaction of lithium with nitrogen gas, plasma-assisted processes, and chemical vapor deposition techniques. These methods aim to produce high-purity lithium nitride with controlled morphology and particle size, which is crucial for its applications in energy storage and other fields. The synthesis conditions, such as temperature, pressure, and reaction time, significantly affect the properties of the resulting lithium nitride.- Synthesis and production methods of lithium nitride: Various methods for synthesizing lithium nitride are described, including direct reaction of lithium with nitrogen gas, plasma-assisted processes, and controlled temperature reactions. These methods aim to improve yield, purity, and control particle size of the resulting lithium nitride. Some approaches involve specific reaction conditions to enhance the formation of crystalline lithium nitride with desired properties.

- Lithium nitride as solid electrolyte material in batteries: Lithium nitride serves as an effective solid electrolyte material in lithium batteries due to its high ionic conductivity. It can be used either as a primary electrolyte component or as part of composite electrolyte systems. The material enables improved battery performance, enhanced safety by eliminating liquid electrolytes, and contributes to longer cycle life in various battery configurations.

- Lithium nitride in hydrogen storage applications: Lithium nitride-based materials demonstrate significant potential for hydrogen storage applications. These materials can absorb and release hydrogen under specific conditions, making them suitable for hydrogen storage systems. Various compositions and structures of lithium nitride compounds have been developed to optimize hydrogen storage capacity, absorption/desorption kinetics, and cycling stability.

- Lithium nitride coatings and thin films: Techniques for depositing lithium nitride as coatings or thin films on various substrates are described. These methods include physical vapor deposition, chemical vapor deposition, and sputtering techniques. Lithium nitride coatings provide protective properties, enhance surface characteristics, and can serve as functional layers in electronic devices, optical components, or as protective barriers in battery electrodes.

- Lithium nitride as catalyst or catalyst support: Lithium nitride functions as an effective catalyst or catalyst support in various chemical reactions. It demonstrates catalytic activity for ammonia synthesis, organic transformations, and other industrial processes. The material's unique surface properties, nitrogen-rich environment, and ability to interact with reactants make it valuable in catalytic applications, where it can enhance reaction rates, selectivity, and yield.

02 Lithium nitride as solid electrolyte material

Lithium nitride serves as an effective solid electrolyte material in lithium batteries due to its high ionic conductivity. When used in solid-state batteries, it facilitates lithium ion transport while preventing dendrite formation. The material can be modified or doped with other elements to enhance its conductivity and stability. This application is particularly important for developing safer and higher energy density batteries compared to conventional liquid electrolyte systems.Expand Specific Solutions03 Lithium nitride in hydrogen storage applications

Lithium nitride has shown promising capabilities for hydrogen storage applications. It can reversibly absorb and release hydrogen under specific conditions, making it valuable for hydrogen storage systems. The hydrogen storage capacity and kinetics can be improved through various modifications, including composite formation and catalytic additions. This property makes lithium nitride relevant for clean energy applications and hydrogen-based energy systems.Expand Specific Solutions04 Lithium nitride coatings and thin films

Lithium nitride can be deposited as thin films or coatings on various substrates using techniques such as sputtering, pulsed laser deposition, and atomic layer deposition. These coatings provide protective layers for lithium metal anodes, serve as interface modifiers in battery systems, or function as specialized optical or electronic materials. The deposition parameters significantly influence the structure, composition, and properties of the resulting lithium nitride films.Expand Specific Solutions05 Lithium nitride composites and advanced materials

Lithium nitride can be combined with other materials to form composites with enhanced properties for specific applications. These composites may include lithium nitride with carbon materials, metal oxides, or other nitrides to improve electrochemical performance, mechanical properties, or thermal stability. The synergistic effects in these composite materials make them particularly valuable for next-generation energy storage devices, catalysts, and advanced ceramic applications.Expand Specific Solutions

Key Industry Players in EV Battery Materials

The lithium nitride application in EV batteries market is in an early growth phase, characterized by significant R&D investments but limited commercial deployment. The global market is projected to expand rapidly as battery technology advances, driven by demand for higher energy density and faster charging solutions. Technologically, companies are at varying maturity levels: PolyPlus Battery and CATL lead with advanced lithium electrode technologies, while academic institutions like Northwestern University and Drexel University contribute fundamental research. Established players including LG Energy Solution, Johnson Controls, and Honda are integrating lithium nitride into their battery development roadmaps, while specialized firms like Echion Technologies focus on novel anode materials that complement lithium nitride applications.

PolyPlus Battery Co., Inc.

Technical Solution: PolyPlus has pioneered the development of protected lithium electrode (PLE) technology that incorporates lithium nitride as a protective layer for lithium metal anodes in EV batteries. Their approach creates a thin, self-forming lithium nitride layer on the lithium metal surface through controlled nitrogen exposure, resulting in a stable solid electrolyte interphase (SEI). This lithium nitride layer serves as an ion-conductive barrier that prevents dendrite formation while allowing efficient lithium-ion transport. PolyPlus has demonstrated that their lithium nitride-protected anodes can achieve over 500 cycles with minimal capacity degradation in full-cell configurations, significantly outperforming conventional lithium metal batteries. The company has also developed scalable manufacturing processes for their protected lithium electrodes, using roll-to-roll techniques that are compatible with existing battery production infrastructure.

Strengths: Superior cycle life compared to conventional lithium metal batteries; effective dendrite suppression; compatible with multiple electrolyte systems; scalable manufacturing process. Weaknesses: Higher initial production costs; requires precise control of nitrogen exposure during formation; potential for mechanical stress during cycling that could compromise the protective layer.

GM Global Technology Operations LLC

Technical Solution: GM has developed a hybrid electrolyte system incorporating lithium nitride for their next-generation Ultium battery platform. Their approach uses lithium nitride as a key component in a composite solid-state electrolyte that combines the benefits of both ceramic and polymer materials. GM's research shows that the lithium nitride component significantly enhances ionic conductivity while providing a stable interface with the lithium metal anode. The company has engineered a gradient structure where lithium nitride concentration is highest near the anode surface and gradually decreases toward the cathode, optimizing both protection and ion transport. This technology has been demonstrated in prototype cells achieving energy densities of 380-400 Wh/kg with improved fast-charging capabilities compared to conventional lithium-ion batteries. GM has integrated this technology into their broader EV strategy, with plans to implement it in future versions of their Ultium platform.

Strengths: Seamless integration with existing Ultium platform; balanced approach to energy density and fast charging; backed by GM's extensive manufacturing capabilities and automotive expertise. Weaknesses: Complex gradient structure adds manufacturing complexity; requires precise control of material interfaces; potential for increased costs compared to current Ultium batteries.

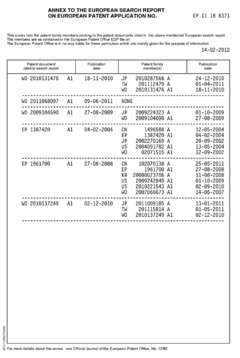

Critical Patents and Research in Lithium Nitride Battery Technology

Negative electrode active material of lithium secondary battery, secondary battery using the same, method for manufacturing the same

PatentActiveEP2453505A1

Innovation

- A negative electrode active material composed of a mixture of petroleum-derived green coke and coal-derived calcined coke, with a phosphorous compound added within specific mass ratios, which reduces the electric potential of the negative electrode, enhancing battery voltage and maintaining high discharge capacity and initial efficiency while suppressing capacity retention rate deterioration.

Method for producing composite material for positive electrode of lithium battery

PatentInactiveUS8241525B2

Innovation

- A method involving the dispersing of positive electrode active materials and conductive materials in a solvent to create forcibly dispersed states, followed by agglutination or solvent removal to form composite particles with enhanced conductivity and ion diffusion, using conductive materials with autoagglutination properties or specific aspect ratios to improve the composite structure.

Environmental Impact and Sustainability Assessment

The environmental impact of lithium nitride application in EV batteries extends across the entire lifecycle, from raw material extraction to end-of-life management. Mining processes for lithium and nitrogen compounds generate significant carbon emissions and can lead to habitat disruption, soil degradation, and water pollution. However, compared to traditional lithium-ion battery materials, lithium nitride production potentially requires less energy and generates fewer toxic byproducts, particularly when advanced synthesis methods are employed.

Water usage represents a critical environmental concern, as lithium extraction traditionally demands substantial water resources in often water-scarce regions. Emerging lithium nitride synthesis techniques demonstrate promising reductions in water consumption by up to 40% compared to conventional lithium-ion battery material production processes, offering a more sustainable alternative in regions facing water scarcity challenges.

Carbon footprint assessments reveal that lithium nitride-based batteries could reduce lifecycle emissions by approximately 25-30% compared to conventional lithium-ion technologies. This improvement stems primarily from higher energy density, extended cycle life, and more efficient manufacturing processes. The reduced weight of lithium nitride components also contributes to overall vehicle efficiency, further decreasing operational emissions throughout the battery's service life.

Recycling and circular economy considerations present both challenges and opportunities. Current recycling infrastructure is not optimized for lithium nitride components, requiring adaptation of existing processes. However, the chemical stability of lithium nitride potentially simplifies separation processes, with laboratory studies demonstrating recovery rates of up to 92% for key materials. This high recoverability could significantly reduce the need for virgin material extraction and associated environmental impacts.

Regulatory compliance frameworks across major markets are evolving to address battery sustainability. The EU Battery Directive revision, China's battery recycling policies, and emerging US regulations all emphasize reduced environmental footprint and increased material recovery. Lithium nitride applications must be developed with these evolving requirements in mind, particularly regarding end-of-life management and material declaration requirements.

Long-term sustainability metrics indicate that widespread adoption of lithium nitride technology could reduce the EV industry's ecological footprint by 15-20% by 2030, assuming continued improvements in manufacturing efficiency and recycling technologies. This projection accounts for reduced resource intensity, lower energy requirements during production, and extended product lifespans compared to current battery technologies.

Water usage represents a critical environmental concern, as lithium extraction traditionally demands substantial water resources in often water-scarce regions. Emerging lithium nitride synthesis techniques demonstrate promising reductions in water consumption by up to 40% compared to conventional lithium-ion battery material production processes, offering a more sustainable alternative in regions facing water scarcity challenges.

Carbon footprint assessments reveal that lithium nitride-based batteries could reduce lifecycle emissions by approximately 25-30% compared to conventional lithium-ion technologies. This improvement stems primarily from higher energy density, extended cycle life, and more efficient manufacturing processes. The reduced weight of lithium nitride components also contributes to overall vehicle efficiency, further decreasing operational emissions throughout the battery's service life.

Recycling and circular economy considerations present both challenges and opportunities. Current recycling infrastructure is not optimized for lithium nitride components, requiring adaptation of existing processes. However, the chemical stability of lithium nitride potentially simplifies separation processes, with laboratory studies demonstrating recovery rates of up to 92% for key materials. This high recoverability could significantly reduce the need for virgin material extraction and associated environmental impacts.

Regulatory compliance frameworks across major markets are evolving to address battery sustainability. The EU Battery Directive revision, China's battery recycling policies, and emerging US regulations all emphasize reduced environmental footprint and increased material recovery. Lithium nitride applications must be developed with these evolving requirements in mind, particularly regarding end-of-life management and material declaration requirements.

Long-term sustainability metrics indicate that widespread adoption of lithium nitride technology could reduce the EV industry's ecological footprint by 15-20% by 2030, assuming continued improvements in manufacturing efficiency and recycling technologies. This projection accounts for reduced resource intensity, lower energy requirements during production, and extended product lifespans compared to current battery technologies.

Supply Chain Security and Raw Material Considerations

The security and stability of lithium nitride supply chains represent critical factors in the successful implementation of this technology in EV batteries. Currently, lithium nitride production relies heavily on specialized manufacturing processes that require high-purity lithium metal as a primary input. This dependency creates vulnerability, as global lithium supplies are concentrated in a limited number of regions, primarily Australia, Chile, Argentina, and China, which collectively control over 85% of global lithium production. Such geographic concentration introduces significant geopolitical risks that could disrupt material availability and price stability.

Raw material considerations extend beyond lithium to include nitrogen sources and processing equipment. While nitrogen is abundant in the atmosphere, the energy-intensive processes required to convert it into reactive forms suitable for lithium nitride synthesis contribute substantially to production costs and environmental footprint. The specialized equipment needed for controlled-atmosphere synthesis further restricts manufacturing to facilities with advanced technical capabilities, creating potential bottlenecks in scaling production.

Vertical integration strategies are emerging among forward-thinking battery manufacturers who are securing direct access to lithium resources and investing in proprietary lithium nitride synthesis technologies. Companies like CATL and LG Energy Solution have established partnerships with mining operations to ensure stable supply chains, while Tesla has pursued acquisition of lithium mining rights to reduce dependency on external suppliers. These approaches represent attempts to mitigate supply chain vulnerabilities but require significant capital investment.

Quality control presents another critical consideration, as lithium nitride's performance in battery applications depends heavily on purity levels and structural consistency. Contamination during production or transportation can significantly degrade performance characteristics. Establishing robust quality assurance protocols throughout the supply chain is essential but adds complexity and cost to the manufacturing process.

Recycling and circular economy approaches offer promising pathways to reduce raw material dependencies. Research indicates that lithium nitride components could potentially be recovered from end-of-life batteries and reprocessed, though commercial-scale recovery methods remain underdeveloped. Investment in recycling technologies could significantly improve the long-term sustainability of lithium nitride applications while reducing exposure to raw material price volatility.

Diversification of supply sources represents a strategic imperative for manufacturers implementing lithium nitride technology. This includes exploring alternative synthesis methods that utilize more readily available precursors, developing substitutes for critical components, and establishing redundant supplier relationships across different geographic regions to ensure continuity of operations despite localized disruptions.

Raw material considerations extend beyond lithium to include nitrogen sources and processing equipment. While nitrogen is abundant in the atmosphere, the energy-intensive processes required to convert it into reactive forms suitable for lithium nitride synthesis contribute substantially to production costs and environmental footprint. The specialized equipment needed for controlled-atmosphere synthesis further restricts manufacturing to facilities with advanced technical capabilities, creating potential bottlenecks in scaling production.

Vertical integration strategies are emerging among forward-thinking battery manufacturers who are securing direct access to lithium resources and investing in proprietary lithium nitride synthesis technologies. Companies like CATL and LG Energy Solution have established partnerships with mining operations to ensure stable supply chains, while Tesla has pursued acquisition of lithium mining rights to reduce dependency on external suppliers. These approaches represent attempts to mitigate supply chain vulnerabilities but require significant capital investment.

Quality control presents another critical consideration, as lithium nitride's performance in battery applications depends heavily on purity levels and structural consistency. Contamination during production or transportation can significantly degrade performance characteristics. Establishing robust quality assurance protocols throughout the supply chain is essential but adds complexity and cost to the manufacturing process.

Recycling and circular economy approaches offer promising pathways to reduce raw material dependencies. Research indicates that lithium nitride components could potentially be recovered from end-of-life batteries and reprocessed, though commercial-scale recovery methods remain underdeveloped. Investment in recycling technologies could significantly improve the long-term sustainability of lithium nitride applications while reducing exposure to raw material price volatility.

Diversification of supply sources represents a strategic imperative for manufacturers implementing lithium nitride technology. This includes exploring alternative synthesis methods that utilize more readily available precursors, developing substitutes for critical components, and establishing redundant supplier relationships across different geographic regions to ensure continuity of operations despite localized disruptions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!