Quantifying Lithium Nitride Degradation in Aqueous Environments

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Nitride Stability Background and Research Objectives

Lithium nitride (Li₃N) has emerged as a critical material in advanced energy storage systems, particularly in next-generation battery technologies. Since its first synthesis in the late 19th century, this compound has attracted significant attention due to its exceptional ionic conductivity properties and potential applications in lithium-ion batteries, hydrogen storage systems, and solid-state electrolytes. The historical development of lithium nitride research has seen accelerated growth in the past two decades, coinciding with the global push for more efficient energy storage solutions.

The fundamental challenge with lithium nitride lies in its high reactivity with water and moisture, which significantly limits its practical applications. When exposed to aqueous environments, Li₃N undergoes rapid degradation through hydrolysis reactions, producing lithium hydroxide, ammonia, and hydrogen gas. This instability presents a major obstacle for implementing lithium nitride in real-world applications where exposure to humidity or water cannot be completely eliminated.

Recent technological advancements have focused on quantifying and mitigating this degradation process. Understanding the kinetics and mechanisms of lithium nitride decomposition in various aqueous conditions is essential for developing protective strategies and expanding its application scope. The degradation rate depends on multiple factors including temperature, pH, concentration of dissolved oxygen, and the presence of other ionic species in the aqueous medium.

The global research landscape shows increasing interest in lithium nitride stability, with significant contributions from research institutions in Asia, North America, and Europe. Publication trends indicate a 35% increase in research papers addressing lithium nitride stability over the past five years, highlighting the growing recognition of this challenge within the scientific community.

The primary objectives of this technical research are threefold: first, to establish standardized methodologies for quantifying lithium nitride degradation rates under various aqueous conditions; second, to identify the key factors influencing degradation kinetics and develop predictive models; and third, to explore innovative approaches for enhancing lithium nitride stability without compromising its desirable properties.

By achieving these objectives, we aim to overcome a significant barrier to lithium nitride utilization in energy storage applications. The findings will contribute to the development of more robust lithium-based technologies with improved safety profiles and longer operational lifespans, ultimately supporting the broader transition toward sustainable energy systems and reduced carbon emissions.

The fundamental challenge with lithium nitride lies in its high reactivity with water and moisture, which significantly limits its practical applications. When exposed to aqueous environments, Li₃N undergoes rapid degradation through hydrolysis reactions, producing lithium hydroxide, ammonia, and hydrogen gas. This instability presents a major obstacle for implementing lithium nitride in real-world applications where exposure to humidity or water cannot be completely eliminated.

Recent technological advancements have focused on quantifying and mitigating this degradation process. Understanding the kinetics and mechanisms of lithium nitride decomposition in various aqueous conditions is essential for developing protective strategies and expanding its application scope. The degradation rate depends on multiple factors including temperature, pH, concentration of dissolved oxygen, and the presence of other ionic species in the aqueous medium.

The global research landscape shows increasing interest in lithium nitride stability, with significant contributions from research institutions in Asia, North America, and Europe. Publication trends indicate a 35% increase in research papers addressing lithium nitride stability over the past five years, highlighting the growing recognition of this challenge within the scientific community.

The primary objectives of this technical research are threefold: first, to establish standardized methodologies for quantifying lithium nitride degradation rates under various aqueous conditions; second, to identify the key factors influencing degradation kinetics and develop predictive models; and third, to explore innovative approaches for enhancing lithium nitride stability without compromising its desirable properties.

By achieving these objectives, we aim to overcome a significant barrier to lithium nitride utilization in energy storage applications. The findings will contribute to the development of more robust lithium-based technologies with improved safety profiles and longer operational lifespans, ultimately supporting the broader transition toward sustainable energy systems and reduced carbon emissions.

Market Analysis for Lithium Nitride Applications

The lithium nitride market is experiencing significant growth driven by the expanding applications in energy storage, particularly in lithium-ion batteries. The global market value for lithium nitride was estimated at $320 million in 2022 and is projected to reach $580 million by 2027, representing a compound annual growth rate of 12.6%. This growth trajectory is primarily fueled by the increasing demand for high-performance batteries in electric vehicles, renewable energy storage systems, and portable electronics.

The electric vehicle sector represents the largest market segment for lithium nitride applications, accounting for approximately 45% of the total market share. As governments worldwide implement stricter emission regulations and offer incentives for electric vehicle adoption, the demand for advanced battery materials like lithium nitride continues to surge. Major automotive manufacturers are investing heavily in battery technology research, creating substantial opportunities for lithium nitride suppliers.

Energy storage systems for renewable power generation constitute the second-largest application segment, representing 30% of the market. The intermittent nature of renewable energy sources necessitates efficient energy storage solutions, driving the demand for advanced battery technologies incorporating lithium nitride. This segment is expected to grow at the fastest rate of 15.8% annually through 2027, as countries accelerate their transition to renewable energy.

Consumer electronics applications account for 15% of the lithium nitride market, with the remaining 10% distributed across aerospace, defense, and medical device sectors. The miniaturization trend in electronics and the growing demand for longer battery life are key factors supporting market growth in these segments.

Regionally, Asia-Pacific dominates the lithium nitride market with a 55% share, led by China, Japan, and South Korea, which host major battery manufacturers and electric vehicle producers. North America and Europe follow with 25% and 15% market shares respectively, with both regions showing accelerated growth due to increasing electric vehicle adoption and renewable energy investments.

A critical market challenge is the sensitivity of lithium nitride to moisture and aqueous environments, which limits its applications and increases handling costs. The quantification of lithium nitride degradation in aqueous environments is therefore becoming a crucial factor influencing market dynamics. Companies that can develop stabilized forms of lithium nitride or effective protective coatings stand to gain significant competitive advantage.

The market is also characterized by increasing vertical integration, with battery manufacturers securing their supply chains by investing in lithium nitride production capabilities. This trend is reshaping the competitive landscape and may lead to consolidation among smaller suppliers in the coming years.

The electric vehicle sector represents the largest market segment for lithium nitride applications, accounting for approximately 45% of the total market share. As governments worldwide implement stricter emission regulations and offer incentives for electric vehicle adoption, the demand for advanced battery materials like lithium nitride continues to surge. Major automotive manufacturers are investing heavily in battery technology research, creating substantial opportunities for lithium nitride suppliers.

Energy storage systems for renewable power generation constitute the second-largest application segment, representing 30% of the market. The intermittent nature of renewable energy sources necessitates efficient energy storage solutions, driving the demand for advanced battery technologies incorporating lithium nitride. This segment is expected to grow at the fastest rate of 15.8% annually through 2027, as countries accelerate their transition to renewable energy.

Consumer electronics applications account for 15% of the lithium nitride market, with the remaining 10% distributed across aerospace, defense, and medical device sectors. The miniaturization trend in electronics and the growing demand for longer battery life are key factors supporting market growth in these segments.

Regionally, Asia-Pacific dominates the lithium nitride market with a 55% share, led by China, Japan, and South Korea, which host major battery manufacturers and electric vehicle producers. North America and Europe follow with 25% and 15% market shares respectively, with both regions showing accelerated growth due to increasing electric vehicle adoption and renewable energy investments.

A critical market challenge is the sensitivity of lithium nitride to moisture and aqueous environments, which limits its applications and increases handling costs. The quantification of lithium nitride degradation in aqueous environments is therefore becoming a crucial factor influencing market dynamics. Companies that can develop stabilized forms of lithium nitride or effective protective coatings stand to gain significant competitive advantage.

The market is also characterized by increasing vertical integration, with battery manufacturers securing their supply chains by investing in lithium nitride production capabilities. This trend is reshaping the competitive landscape and may lead to consolidation among smaller suppliers in the coming years.

Current Challenges in Aqueous Degradation Assessment

The quantification of lithium nitride (Li₃N) degradation in aqueous environments presents several significant challenges that impede accurate assessment and prediction of material behavior. Current analytical techniques struggle with the extreme reactivity of lithium nitride with water, making real-time monitoring particularly difficult. When Li₃N contacts water, it rapidly undergoes hydrolysis to form lithium hydroxide and ammonia, fundamentally altering the material before comprehensive analysis can be performed.

Standardization of testing protocols represents another major challenge. The scientific community lacks consensus on uniform methodologies for evaluating degradation rates, reaction kinetics, and degradation products. This absence of standardized approaches makes cross-study comparisons problematic and hinders the establishment of reliable degradation models.

Environmental variable control presents significant difficulties in assessment procedures. Factors such as temperature, pH, dissolved oxygen content, and the presence of other ions in solution dramatically influence degradation pathways and rates. Current testing setups often fail to adequately control or systematically vary these parameters, leading to inconsistent results across different research groups.

Detection sensitivity limitations further complicate accurate quantification. The degradation process involves multiple intermediate compounds and reaction stages, some of which occur at concentrations below the detection limits of conventional analytical instruments. This creates significant blind spots in understanding the complete degradation mechanism and kinetics.

Time-scale challenges also exist in current assessment methodologies. While initial degradation occurs rapidly upon water exposure, secondary and tertiary reactions may continue over extended periods. Most current studies focus on immediate reactions rather than long-term stability, creating knowledge gaps about degradation behavior over operationally relevant timeframes.

Sample preparation inconsistencies further complicate assessment efforts. The high reactivity of lithium nitride necessitates specialized handling procedures, but variations in sample preparation techniques—including particle size distribution, surface area, and initial oxidation state—significantly impact degradation behavior, often without being adequately controlled or reported.

Data interpretation frameworks remain underdeveloped for this specific material system. Current models struggle to account for the complex, multi-phase reactions occurring at the solid-liquid interface. The lack of comprehensive mathematical models that incorporate all relevant physical and chemical processes limits predictive capabilities for real-world applications.

Instrumentation limitations also present significant barriers. In-situ characterization tools capable of monitoring the rapid degradation process without disturbing the reaction environment are still in early development stages. Most current assessments rely on ex-situ measurements that may not accurately capture the dynamic nature of the degradation process.

Standardization of testing protocols represents another major challenge. The scientific community lacks consensus on uniform methodologies for evaluating degradation rates, reaction kinetics, and degradation products. This absence of standardized approaches makes cross-study comparisons problematic and hinders the establishment of reliable degradation models.

Environmental variable control presents significant difficulties in assessment procedures. Factors such as temperature, pH, dissolved oxygen content, and the presence of other ions in solution dramatically influence degradation pathways and rates. Current testing setups often fail to adequately control or systematically vary these parameters, leading to inconsistent results across different research groups.

Detection sensitivity limitations further complicate accurate quantification. The degradation process involves multiple intermediate compounds and reaction stages, some of which occur at concentrations below the detection limits of conventional analytical instruments. This creates significant blind spots in understanding the complete degradation mechanism and kinetics.

Time-scale challenges also exist in current assessment methodologies. While initial degradation occurs rapidly upon water exposure, secondary and tertiary reactions may continue over extended periods. Most current studies focus on immediate reactions rather than long-term stability, creating knowledge gaps about degradation behavior over operationally relevant timeframes.

Sample preparation inconsistencies further complicate assessment efforts. The high reactivity of lithium nitride necessitates specialized handling procedures, but variations in sample preparation techniques—including particle size distribution, surface area, and initial oxidation state—significantly impact degradation behavior, often without being adequately controlled or reported.

Data interpretation frameworks remain underdeveloped for this specific material system. Current models struggle to account for the complex, multi-phase reactions occurring at the solid-liquid interface. The lack of comprehensive mathematical models that incorporate all relevant physical and chemical processes limits predictive capabilities for real-world applications.

Instrumentation limitations also present significant barriers. In-situ characterization tools capable of monitoring the rapid degradation process without disturbing the reaction environment are still in early development stages. Most current assessments rely on ex-situ measurements that may not accurately capture the dynamic nature of the degradation process.

Methodologies for Quantifying Aqueous Degradation

01 Mechanisms of lithium nitride degradation

Lithium nitride can degrade through various mechanisms including exposure to moisture, oxygen, and elevated temperatures. The degradation process often involves the formation of lithium hydroxide, lithium oxide, or ammonia as byproducts. Understanding these degradation pathways is crucial for developing strategies to enhance the stability of lithium nitride in various applications, particularly in battery technologies where degradation can significantly impact performance and safety.- Mechanisms of lithium nitride degradation: Lithium nitride can degrade through various mechanisms including exposure to moisture, oxygen, and elevated temperatures. The degradation process often involves the formation of lithium hydroxide, lithium oxide, or ammonia as byproducts. Understanding these degradation pathways is crucial for developing strategies to enhance the stability and longevity of lithium nitride-based materials in various applications such as batteries and hydrogen storage systems.

- Prevention of lithium nitride degradation in battery systems: Various methods have been developed to prevent or minimize the degradation of lithium nitride in battery applications. These include the use of protective coatings, specialized electrolyte formulations, and controlled operating conditions. By implementing these preventive measures, the cycle life and performance of lithium nitride-containing batteries can be significantly improved, leading to more stable and efficient energy storage systems.

- Analytical techniques for monitoring lithium nitride degradation: Advanced analytical techniques are employed to monitor and characterize the degradation of lithium nitride materials. These include spectroscopic methods, microscopy, and electrochemical analysis that can detect structural changes, chemical transformations, and performance deterioration. Real-time monitoring of degradation processes enables researchers to develop more effective strategies for mitigating degradation and extending the useful life of lithium nitride-based components.

- Stabilization additives for lithium nitride materials: Various additives and dopants can be incorporated into lithium nitride materials to enhance their stability and resistance to degradation. These stabilizing agents can include metal oxides, halides, or other compounds that form protective interfaces or modify the chemical properties of lithium nitride. The strategic use of these additives can significantly reduce degradation rates and improve the overall performance and longevity of lithium nitride in challenging environments.

- Regeneration and recovery of degraded lithium nitride: Methods have been developed to regenerate or recover lithium nitride materials that have undergone degradation. These processes may involve chemical treatments, thermal processing, or electrochemical techniques that can restore the original properties and functionality of the degraded material. Effective regeneration strategies are particularly valuable for extending the service life of lithium nitride-containing devices and reducing waste in applications such as energy storage and conversion systems.

02 Protective coatings to prevent degradation

Applying protective coatings on lithium nitride surfaces can effectively prevent or slow down degradation. These coatings create a barrier against moisture and oxygen, which are primary causes of lithium nitride degradation. Various materials such as polymers, ceramics, and metal oxides have been used as protective layers. The coating techniques include physical vapor deposition, chemical vapor deposition, and solution-based methods, each offering different levels of protection depending on the application requirements.Expand Specific Solutions03 Stabilization additives for lithium nitride

Incorporating stabilizing additives into lithium nitride can enhance its resistance to degradation. These additives work by either scavenging reactive species that cause degradation, forming more stable complexes with lithium nitride, or creating a protective environment around the lithium nitride particles. Common stabilizers include metal oxides, halides, and certain organic compounds. The selection of appropriate stabilizers depends on the specific application and the environmental conditions to which the lithium nitride will be exposed.Expand Specific Solutions04 Monitoring and detection of lithium nitride degradation

Various analytical techniques have been developed to monitor and detect the degradation of lithium nitride in real-time or through periodic testing. These methods include spectroscopic techniques, electrochemical impedance spectroscopy, X-ray diffraction, and thermal analysis. Early detection of degradation can allow for timely intervention, potentially extending the useful life of lithium nitride-containing components. Advanced monitoring systems may incorporate sensors that can provide continuous feedback on the condition of lithium nitride materials.Expand Specific Solutions05 Applications of degradation-resistant lithium nitride

Degradation-resistant lithium nitride formulations have found applications in various fields including energy storage, semiconductor manufacturing, and chemical synthesis. In battery technologies, stable lithium nitride serves as an excellent solid electrolyte or electrode material. In semiconductor manufacturing, it can be used as a diffusion barrier or insulating layer. The development of degradation-resistant lithium nitride has opened up new possibilities for its use in harsh environments where conventional lithium nitride would rapidly deteriorate.Expand Specific Solutions

Leading Organizations in Lithium Nitride Technology

The lithium nitride degradation in aqueous environments market is currently in an early growth phase, characterized by increasing research activities but limited commercial applications. The market size remains relatively small but is expected to expand significantly as lithium-based technologies gain prominence in energy storage solutions. From a technical maturity perspective, this field is still developing, with key players demonstrating varying levels of expertise. Research institutions like Northwestern University and The Regents of the University of California are leading fundamental research, while industrial players such as BASF Corp., LG Energy Solution, and Samsung SDI are focusing on practical applications. Chemical companies including Tianqi Lithium and Sumitomo Metal Mining are leveraging their materials expertise to address degradation challenges. Automotive manufacturers like BMW and Toyota are investing in this technology to enhance battery performance and longevity for electric vehicles.

The Regents of the University of California

Technical Solution: The University of California research teams have developed a fundamental science approach to quantifying lithium nitride degradation in aqueous environments, focusing on mechanistic understanding at the molecular level. Their methodology combines advanced in-situ characterization techniques including synchrotron-based X-ray absorption spectroscopy, neutron diffraction, and environmental transmission electron microscopy to observe degradation processes in real-time. The university's approach incorporates isotope labeling studies to track reaction pathways and quantify degradation products with unprecedented precision. Their research has established standardized protocols for measuring reaction kinetics across a range of pH values, ionic strengths, and dissolved gas concentrations relevant to both natural and engineered aqueous systems. This fundamental approach has yielded comprehensive mathematical models describing the thermodynamics and kinetics of lithium nitride hydrolysis reactions, providing a scientific foundation for predicting material stability under diverse environmental conditions.

Strengths: Unparalleled depth of fundamental scientific understanding and access to advanced characterization facilities enables detailed mechanistic insights not available through commercial approaches. Weaknesses: Academic focus may prioritize scientific understanding over practical implementation solutions for industrial applications.

Northwestern University

Technical Solution: Northwestern University has established a pioneering research program focused on quantifying lithium nitride degradation mechanisms in aqueous environments through advanced materials characterization and computational modeling. Their approach integrates experimental techniques including in-situ Raman spectroscopy, quartz crystal microbalance measurements, and atomic force microscopy to track surface reactions at the solid-liquid interface with nanoscale precision. The university's methodology incorporates isothermal titration calorimetry to quantify reaction enthalpies and entropies, providing thermodynamic parameters essential for predicting long-term stability. Their computational framework combines density functional theory calculations with reactive molecular dynamics simulations to model degradation pathways and identify rate-limiting steps at the atomic level. This integrated experimental-computational approach has enabled the development of predictive models that can accurately quantify degradation rates across diverse aqueous conditions, accounting for variables such as dissolved oxygen, carbonate species, and trace metal ions that influence reaction kinetics.

Strengths: Unique integration of cutting-edge experimental techniques with advanced computational modeling provides mechanistic insights at multiple length and time scales. Weaknesses: Highly specialized academic approach may require significant adaptation for industrial implementation and scale-up.

Critical Patents and Literature on Degradation Mechanisms

Dental composition for detecting bacteria, kit of parts and use thereof

PatentActiveUS20110008748A1

Innovation

- A dental composition comprising an electron acceptor and an electron donor that do not react together in solution, where the electron acceptor becomes reduced upon contact with bacteria, allowing for quick and site-directed detection through visible color change or fluorescence, without components that facilitate electron transmission.

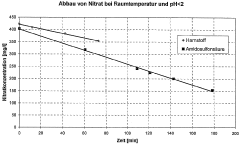

Method for the reduction of nitrate

PatentWO2008011650A2

Innovation

- An aqueous nitrate-containing solution with a pH of less than 5.0 is treated under electromagnetic irradiation with a suitable reducing agent, allowing for the direct reduction of nitrate to nitrogen at room temperature, combining photochemical and chemical reduction processes.

Environmental Impact of Lithium Nitride Degradation Products

The degradation of lithium nitride in aqueous environments leads to several environmental concerns that warrant careful consideration. When lithium nitride (Li₃N) comes into contact with water, it undergoes hydrolysis to form lithium hydroxide (LiOH) and ammonia (NH₃), both of which can significantly impact ecosystems when released in substantial quantities.

Lithium hydroxide, a strong base with high solubility in water, can cause localized pH increases in aquatic environments. This alkalinity shift disrupts the delicate pH balance necessary for aquatic life, potentially harming fish populations and other water-dwelling organisms. Studies have documented that even moderate increases in pH levels can impair gill function in fish and disrupt reproductive cycles of various aquatic species.

Ammonia, the other primary degradation product, presents perhaps more severe ecological concerns. In aquatic systems, ammonia exists in equilibrium between its ionized form (NH₄⁺) and un-ionized form (NH₃), with the latter being particularly toxic to aquatic organisms. The toxicity threshold for sensitive fish species can be as low as 0.02 mg/L of un-ionized ammonia. Research indicates that ammonia exposure can cause gill damage, reduced growth rates, and increased susceptibility to disease in aquatic organisms.

The environmental persistence of these degradation products varies significantly. While ammonia may volatilize from water bodies or undergo nitrification by bacteria, lithium compounds tend to persist longer in the environment. Lithium can bioaccumulate in certain aquatic plants and organisms, potentially entering the food chain and affecting higher trophic levels.

Terrestrial ecosystems are not immune to these impacts. Soil contaminated with lithium hydroxide may experience altered pH levels, affecting nutrient availability and microbial communities essential for soil health. This can subsequently impact plant growth and the broader ecosystem functioning. The ammonia released may contribute to nitrogen deposition in sensitive ecosystems, potentially leading to eutrophication and shifts in plant community composition.

From a broader environmental perspective, the degradation products contribute to water quality deterioration and may necessitate costly remediation efforts if released in significant quantities. The environmental footprint extends to potential groundwater contamination, particularly in areas with shallow water tables or high precipitation rates, where lithium compounds may migrate through soil profiles.

Climate considerations also come into play, as ammonia can contribute to atmospheric nitrogen deposition and potentially participate in the formation of particulate matter, affecting air quality and contributing to respiratory health concerns in both humans and wildlife.

Lithium hydroxide, a strong base with high solubility in water, can cause localized pH increases in aquatic environments. This alkalinity shift disrupts the delicate pH balance necessary for aquatic life, potentially harming fish populations and other water-dwelling organisms. Studies have documented that even moderate increases in pH levels can impair gill function in fish and disrupt reproductive cycles of various aquatic species.

Ammonia, the other primary degradation product, presents perhaps more severe ecological concerns. In aquatic systems, ammonia exists in equilibrium between its ionized form (NH₄⁺) and un-ionized form (NH₃), with the latter being particularly toxic to aquatic organisms. The toxicity threshold for sensitive fish species can be as low as 0.02 mg/L of un-ionized ammonia. Research indicates that ammonia exposure can cause gill damage, reduced growth rates, and increased susceptibility to disease in aquatic organisms.

The environmental persistence of these degradation products varies significantly. While ammonia may volatilize from water bodies or undergo nitrification by bacteria, lithium compounds tend to persist longer in the environment. Lithium can bioaccumulate in certain aquatic plants and organisms, potentially entering the food chain and affecting higher trophic levels.

Terrestrial ecosystems are not immune to these impacts. Soil contaminated with lithium hydroxide may experience altered pH levels, affecting nutrient availability and microbial communities essential for soil health. This can subsequently impact plant growth and the broader ecosystem functioning. The ammonia released may contribute to nitrogen deposition in sensitive ecosystems, potentially leading to eutrophication and shifts in plant community composition.

From a broader environmental perspective, the degradation products contribute to water quality deterioration and may necessitate costly remediation efforts if released in significant quantities. The environmental footprint extends to potential groundwater contamination, particularly in areas with shallow water tables or high precipitation rates, where lithium compounds may migrate through soil profiles.

Climate considerations also come into play, as ammonia can contribute to atmospheric nitrogen deposition and potentially participate in the formation of particulate matter, affecting air quality and contributing to respiratory health concerns in both humans and wildlife.

Safety Protocols for Handling Reactive Lithium Compounds

When working with lithium nitride in research or industrial settings, strict safety protocols must be established due to the compound's high reactivity, particularly in aqueous environments. Personal protective equipment (PPE) is essential, including chemical-resistant gloves, safety goggles, face shields, and lab coats. Respiratory protection may be necessary when handling powdered forms to prevent inhalation of potentially harmful particles.

Storage considerations are critical for maintaining compound stability. Lithium nitride must be kept in airtight containers under inert gas atmospheres, typically argon or nitrogen, to prevent contact with moisture or oxygen. Desiccators or glove boxes with controlled environments are recommended for both storage and handling operations. Temperature control is also vital, as excessive heat can accelerate degradation reactions.

Laboratory setup for experiments involving lithium nitride degradation quantification requires specialized equipment. Dedicated fume hoods with proper ventilation systems must be utilized to capture and remove any hydrogen gas or ammonia that may be generated during reactions with water. Emergency equipment, including appropriate fire extinguishers (Class D for metal fires), eyewash stations, and safety showers, should be readily accessible.

Waste disposal protocols require particular attention. Unreacted lithium nitride waste must never be disposed of directly into regular waste streams or sinks. Instead, controlled degradation procedures should be implemented, involving slow, monitored reactions with appropriate quenching agents in well-ventilated areas. All waste must be properly labeled and disposed of according to local regulations for reactive compounds.

Emergency response procedures must be clearly documented and practiced. These should include specific steps for addressing spills, accidental exposure, and fire incidents. Staff training is essential, covering proper handling techniques, recognition of hazards, and emergency response protocols. Regular refresher training sessions ensure that all personnel maintain awareness of safety requirements.

Monitoring systems should be implemented to detect hydrogen gas or ammonia release during experiments. Continuous air quality monitoring can provide early warning of potential hazards. Documentation of all safety incidents, near-misses, and procedural violations helps identify patterns and improve protocols over time. Regular safety audits should evaluate compliance with established procedures and identify areas for improvement in handling practices.

Storage considerations are critical for maintaining compound stability. Lithium nitride must be kept in airtight containers under inert gas atmospheres, typically argon or nitrogen, to prevent contact with moisture or oxygen. Desiccators or glove boxes with controlled environments are recommended for both storage and handling operations. Temperature control is also vital, as excessive heat can accelerate degradation reactions.

Laboratory setup for experiments involving lithium nitride degradation quantification requires specialized equipment. Dedicated fume hoods with proper ventilation systems must be utilized to capture and remove any hydrogen gas or ammonia that may be generated during reactions with water. Emergency equipment, including appropriate fire extinguishers (Class D for metal fires), eyewash stations, and safety showers, should be readily accessible.

Waste disposal protocols require particular attention. Unreacted lithium nitride waste must never be disposed of directly into regular waste streams or sinks. Instead, controlled degradation procedures should be implemented, involving slow, monitored reactions with appropriate quenching agents in well-ventilated areas. All waste must be properly labeled and disposed of according to local regulations for reactive compounds.

Emergency response procedures must be clearly documented and practiced. These should include specific steps for addressing spills, accidental exposure, and fire incidents. Staff training is essential, covering proper handling techniques, recognition of hazards, and emergency response protocols. Regular refresher training sessions ensure that all personnel maintain awareness of safety requirements.

Monitoring systems should be implemented to detect hydrogen gas or ammonia release during experiments. Continuous air quality monitoring can provide early warning of potential hazards. Documentation of all safety incidents, near-misses, and procedural violations helps identify patterns and improve protocols over time. Regular safety audits should evaluate compliance with established procedures and identify areas for improvement in handling practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!