How to Improve Energy Density Using Lithium Nitride Electrolytes

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Nitride Electrolyte Development History and Objectives

Lithium nitride (Li3N) has emerged as a promising solid-state electrolyte material for next-generation energy storage systems due to its exceptional ionic conductivity and potential to enhance energy density. The development of lithium nitride as an electrolyte material can be traced back to the 1970s when researchers first observed its high lithium-ion conductivity at room temperature, approximately 10^-3 S/cm, which is comparable to many liquid electrolytes used in conventional lithium-ion batteries.

The initial research on lithium nitride was primarily focused on understanding its fundamental properties and crystalline structure. Li3N possesses a layered hexagonal structure with alternating layers of Li2N and Li, which facilitates fast lithium-ion transport through the material. This unique structure contributes to its high ionic conductivity, making it an attractive candidate for solid-state electrolytes.

Throughout the 1980s and 1990s, research on lithium nitride expanded to include investigations into its electrochemical stability and compatibility with electrode materials. However, progress was hindered by challenges related to its narrow electrochemical stability window and high reactivity with atmospheric components, particularly moisture and oxygen.

A significant breakthrough occurred in the early 2000s when researchers began exploring composite systems incorporating lithium nitride. These composites aimed to leverage the high ionic conductivity of Li3N while mitigating its stability issues. The development of Li3N-based composite electrolytes marked a pivotal shift in research direction, opening new avenues for practical applications.

Recent advancements have focused on nanostructured lithium nitride materials and novel synthesis methods to enhance performance characteristics. Thin-film deposition techniques, mechanochemical synthesis, and controlled atmosphere processing have enabled the production of higher quality lithium nitride electrolytes with improved stability and conductivity.

The primary objective of current lithium nitride electrolyte research is to significantly increase energy density in lithium-based batteries by enabling the use of lithium metal anodes. Lithium metal offers the highest theoretical capacity among anode materials (3860 mAh/g), approximately ten times higher than conventional graphite anodes. Successfully implementing lithium nitride electrolytes could potentially double or triple the energy density of current lithium-ion batteries.

Additional objectives include developing manufacturing processes suitable for large-scale production, enhancing the mechanical properties to prevent dendrite formation, and improving the electrochemical stability window to accommodate high-voltage cathode materials. These goals align with the broader industry push toward safer, higher-energy-density batteries for applications ranging from portable electronics to electric vehicles and grid-scale energy storage.

The initial research on lithium nitride was primarily focused on understanding its fundamental properties and crystalline structure. Li3N possesses a layered hexagonal structure with alternating layers of Li2N and Li, which facilitates fast lithium-ion transport through the material. This unique structure contributes to its high ionic conductivity, making it an attractive candidate for solid-state electrolytes.

Throughout the 1980s and 1990s, research on lithium nitride expanded to include investigations into its electrochemical stability and compatibility with electrode materials. However, progress was hindered by challenges related to its narrow electrochemical stability window and high reactivity with atmospheric components, particularly moisture and oxygen.

A significant breakthrough occurred in the early 2000s when researchers began exploring composite systems incorporating lithium nitride. These composites aimed to leverage the high ionic conductivity of Li3N while mitigating its stability issues. The development of Li3N-based composite electrolytes marked a pivotal shift in research direction, opening new avenues for practical applications.

Recent advancements have focused on nanostructured lithium nitride materials and novel synthesis methods to enhance performance characteristics. Thin-film deposition techniques, mechanochemical synthesis, and controlled atmosphere processing have enabled the production of higher quality lithium nitride electrolytes with improved stability and conductivity.

The primary objective of current lithium nitride electrolyte research is to significantly increase energy density in lithium-based batteries by enabling the use of lithium metal anodes. Lithium metal offers the highest theoretical capacity among anode materials (3860 mAh/g), approximately ten times higher than conventional graphite anodes. Successfully implementing lithium nitride electrolytes could potentially double or triple the energy density of current lithium-ion batteries.

Additional objectives include developing manufacturing processes suitable for large-scale production, enhancing the mechanical properties to prevent dendrite formation, and improving the electrochemical stability window to accommodate high-voltage cathode materials. These goals align with the broader industry push toward safer, higher-energy-density batteries for applications ranging from portable electronics to electric vehicles and grid-scale energy storage.

Market Analysis for High Energy Density Battery Solutions

The global market for high energy density battery solutions is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicles (EVs), portable electronics, and renewable energy storage systems. Current market valuations indicate that the high-performance battery sector reached approximately $112 billion in 2022 and is projected to grow at a compound annual growth rate of 18.7% through 2030. Within this landscape, lithium-ion batteries dominate with over 70% market share, but face increasing challenges regarding energy density limitations.

Lithium nitride electrolytes represent an emerging technology with significant potential to disrupt the current market paradigm. These advanced electrolytes offer theoretical energy density improvements of 30-40% compared to conventional liquid electrolytes, potentially addressing the critical demand for batteries with higher capacity in smaller form factors. Market research indicates that manufacturers achieving even a 20% improvement in energy density could command premium pricing of 25-35% above standard offerings.

The EV segment presents the most substantial market opportunity, with automotive manufacturers actively seeking battery solutions that extend range while reducing weight. Tesla, Volkswagen Group, and BYD have all announced strategic initiatives focused on next-generation battery technologies, with specific interest in solid-state and advanced electrolyte solutions. The premium EV segment demonstrates willingness to adopt cutting-edge battery technologies at earlier stages, providing an entry point for lithium nitride electrolyte innovations.

Consumer electronics represents another significant market vertical, with smartphone and laptop manufacturers facing increasing pressure to extend device operation time without increasing battery size. Apple, Samsung, and other major OEMs have established dedicated research divisions focused exclusively on battery technology advancements, signaling strong market pull for energy density improvements.

Grid-scale energy storage presents a growing opportunity, particularly as renewable energy integration accelerates globally. This segment values cycle life and safety alongside energy density, making it potentially receptive to lithium nitride electrolyte solutions that can demonstrate improvements across these parameters.

Market barriers include cost sensitivity, with current production estimates for lithium nitride electrolytes suggesting a 40-60% premium over conventional technologies. Manufacturing scalability remains unproven at commercial volumes, creating uncertainty around mass-market adoption timelines. Additionally, the conservative nature of battery manufacturers regarding new materials introduces adoption friction that must be overcome through comprehensive performance validation.

Regional analysis reveals Asia-Pacific as the dominant manufacturing hub, with China, Japan, and South Korea collectively controlling over 80% of advanced battery production capacity. However, significant investments in North America and Europe aim to establish regional supply chains, creating potential entry points for new technologies like lithium nitride electrolytes.

Lithium nitride electrolytes represent an emerging technology with significant potential to disrupt the current market paradigm. These advanced electrolytes offer theoretical energy density improvements of 30-40% compared to conventional liquid electrolytes, potentially addressing the critical demand for batteries with higher capacity in smaller form factors. Market research indicates that manufacturers achieving even a 20% improvement in energy density could command premium pricing of 25-35% above standard offerings.

The EV segment presents the most substantial market opportunity, with automotive manufacturers actively seeking battery solutions that extend range while reducing weight. Tesla, Volkswagen Group, and BYD have all announced strategic initiatives focused on next-generation battery technologies, with specific interest in solid-state and advanced electrolyte solutions. The premium EV segment demonstrates willingness to adopt cutting-edge battery technologies at earlier stages, providing an entry point for lithium nitride electrolyte innovations.

Consumer electronics represents another significant market vertical, with smartphone and laptop manufacturers facing increasing pressure to extend device operation time without increasing battery size. Apple, Samsung, and other major OEMs have established dedicated research divisions focused exclusively on battery technology advancements, signaling strong market pull for energy density improvements.

Grid-scale energy storage presents a growing opportunity, particularly as renewable energy integration accelerates globally. This segment values cycle life and safety alongside energy density, making it potentially receptive to lithium nitride electrolyte solutions that can demonstrate improvements across these parameters.

Market barriers include cost sensitivity, with current production estimates for lithium nitride electrolytes suggesting a 40-60% premium over conventional technologies. Manufacturing scalability remains unproven at commercial volumes, creating uncertainty around mass-market adoption timelines. Additionally, the conservative nature of battery manufacturers regarding new materials introduces adoption friction that must be overcome through comprehensive performance validation.

Regional analysis reveals Asia-Pacific as the dominant manufacturing hub, with China, Japan, and South Korea collectively controlling over 80% of advanced battery production capacity. However, significant investments in North America and Europe aim to establish regional supply chains, creating potential entry points for new technologies like lithium nitride electrolytes.

Current Limitations and Challenges in Lithium Nitride Electrolytes

Despite the promising potential of lithium nitride electrolytes in next-generation battery systems, several significant limitations and challenges currently impede their widespread commercial adoption. The primary obstacle remains their relatively low ionic conductivity at room temperature, typically ranging from 10^-5 to 10^-4 S/cm, which falls short of the practical requirements for high-performance batteries (>10^-3 S/cm). This conductivity limitation directly impacts energy density by restricting ion transport efficiency across the electrolyte.

Chemical stability presents another critical challenge, as lithium nitride-based electrolytes demonstrate high reactivity with atmospheric components, particularly moisture and oxygen. This necessitates stringent manufacturing conditions and protective encapsulation, adding complexity and cost to production processes. The reactivity issue extends to electrode interfaces, where undesirable side reactions can form resistive layers that further diminish energy density and cycling performance.

Mechanical properties of lithium nitride electrolytes also pose significant engineering challenges. Many formulations exhibit brittleness and poor flexibility, leading to potential cracking during battery assembly or operation. This mechanical fragility compromises the electrolyte's ability to maintain consistent contact with electrodes during charge-discharge cycles, resulting in increased internal resistance and reduced energy efficiency.

Temperature sensitivity represents another substantial hurdle, as performance metrics of lithium nitride electrolytes show dramatic variations across operating temperature ranges. While some formulations demonstrate excellent conductivity at elevated temperatures (>80°C), their performance deteriorates significantly at ambient or lower temperatures, limiting practical applications in diverse environments.

Scalability and manufacturing complexity further constrain implementation. Current synthesis methods for high-quality lithium nitride electrolytes often involve energy-intensive processes, specialized equipment, and precise control of reaction conditions. These requirements present significant barriers to cost-effective mass production, keeping production costs prohibitively high for widespread commercial adoption.

Long-term cycling stability remains inadequately demonstrated, with most research limited to laboratory-scale testing over relatively few cycles. The gradual degradation of lithium nitride electrolytes through mechanisms such as nitrogen loss, phase transitions, or interfacial resistance buildup significantly impacts the practical energy density achievable in real-world applications.

Additionally, the environmental impact and safety concerns associated with lithium nitride materials require thorough assessment. Their potential toxicity, flammability under certain conditions, and end-of-life disposal considerations must be addressed before large-scale deployment can be considered viable.

Chemical stability presents another critical challenge, as lithium nitride-based electrolytes demonstrate high reactivity with atmospheric components, particularly moisture and oxygen. This necessitates stringent manufacturing conditions and protective encapsulation, adding complexity and cost to production processes. The reactivity issue extends to electrode interfaces, where undesirable side reactions can form resistive layers that further diminish energy density and cycling performance.

Mechanical properties of lithium nitride electrolytes also pose significant engineering challenges. Many formulations exhibit brittleness and poor flexibility, leading to potential cracking during battery assembly or operation. This mechanical fragility compromises the electrolyte's ability to maintain consistent contact with electrodes during charge-discharge cycles, resulting in increased internal resistance and reduced energy efficiency.

Temperature sensitivity represents another substantial hurdle, as performance metrics of lithium nitride electrolytes show dramatic variations across operating temperature ranges. While some formulations demonstrate excellent conductivity at elevated temperatures (>80°C), their performance deteriorates significantly at ambient or lower temperatures, limiting practical applications in diverse environments.

Scalability and manufacturing complexity further constrain implementation. Current synthesis methods for high-quality lithium nitride electrolytes often involve energy-intensive processes, specialized equipment, and precise control of reaction conditions. These requirements present significant barriers to cost-effective mass production, keeping production costs prohibitively high for widespread commercial adoption.

Long-term cycling stability remains inadequately demonstrated, with most research limited to laboratory-scale testing over relatively few cycles. The gradual degradation of lithium nitride electrolytes through mechanisms such as nitrogen loss, phase transitions, or interfacial resistance buildup significantly impacts the practical energy density achievable in real-world applications.

Additionally, the environmental impact and safety concerns associated with lithium nitride materials require thorough assessment. Their potential toxicity, flammability under certain conditions, and end-of-life disposal considerations must be addressed before large-scale deployment can be considered viable.

Current Technical Approaches to Lithium Nitride Implementation

01 Lithium nitride-based solid electrolytes for high energy density batteries

Lithium nitride-based solid electrolytes offer high ionic conductivity and can significantly enhance the energy density of lithium batteries. These materials provide a stable interface between the electrode and electrolyte, reducing interfacial resistance and enabling higher energy storage capacity. The incorporation of lithium nitride in solid-state batteries allows for the use of lithium metal anodes, which have higher theoretical capacity compared to conventional graphite anodes, thereby increasing the overall energy density of the battery system.- Lithium nitride-based solid electrolytes for high energy density batteries: Lithium nitride (Li3N) and its derivatives serve as promising solid electrolytes for high energy density batteries due to their excellent lithium-ion conductivity. These materials enable the development of all-solid-state batteries with improved safety and energy density compared to conventional liquid electrolyte systems. The incorporation of lithium nitride-based electrolytes allows for higher operating voltages and better compatibility with high-capacity electrode materials.

- Composite electrolytes containing lithium nitride for enhanced ionic conductivity: Composite electrolytes incorporating lithium nitride with other materials such as polymers, ceramics, or glass can achieve enhanced ionic conductivity while maintaining mechanical stability. These composite structures create favorable ion transport pathways while addressing the mechanical limitations of pure lithium nitride. The synergistic combination of materials results in electrolytes with improved performance characteristics suitable for next-generation energy storage applications.

- Doped lithium nitride electrolytes for improved electrochemical performance: Doping lithium nitride with elements such as magnesium, aluminum, or transition metals can significantly enhance its electrochemical properties. These dopants modify the crystal structure and electronic properties, leading to improved ionic conductivity, electrochemical stability, and interfacial compatibility with electrodes. The strategic introduction of dopants enables tailored electrolyte properties that contribute to higher energy density battery systems.

- Lithium nitride as an interface modifier in battery systems: Lithium nitride can be utilized as an interface modifier between electrodes and electrolytes to enhance the stability and performance of high energy density batteries. When applied as a thin layer or incorporated at interfaces, it helps reduce impedance, prevent unwanted side reactions, and facilitate lithium ion transport. This interface engineering approach improves cycle life and enables the use of high-capacity electrode materials that would otherwise be incompatible with conventional electrolytes.

- Manufacturing processes for lithium nitride electrolytes with controlled morphology: Advanced manufacturing techniques for lithium nitride electrolytes focus on controlling morphology, particle size, and crystallinity to optimize energy density. Methods such as ball milling, vapor deposition, and solution-based synthesis allow for the production of lithium nitride with specific microstructures that enhance ionic conductivity. These processing techniques enable the fabrication of thin, dense electrolyte layers that minimize resistance while maintaining mechanical integrity, directly contributing to improved energy density in battery systems.

02 Composite electrolytes containing lithium nitride for improved conductivity

Composite electrolytes that incorporate lithium nitride with other materials such as polymers or ceramics demonstrate enhanced ionic conductivity and mechanical stability. These composite structures create efficient lithium-ion transport pathways while maintaining structural integrity under various operating conditions. The synergistic effect between lithium nitride and other components results in electrolytes with superior performance characteristics, including higher energy density and improved cycle life compared to conventional liquid electrolytes.Expand Specific Solutions03 Doped lithium nitride electrolytes for enhanced electrochemical performance

Doping lithium nitride with elements such as magnesium, aluminum, or transition metals can significantly improve its electrochemical properties. These dopants modify the crystal structure and electronic properties of lithium nitride, resulting in higher ionic conductivity and better stability. Doped lithium nitride electrolytes enable faster charging rates and higher energy density in battery applications, making them promising candidates for next-generation energy storage systems.Expand Specific Solutions04 Thin-film lithium nitride electrolytes for miniaturized high-energy devices

Thin-film lithium nitride electrolytes are particularly suitable for miniaturized energy storage devices with high energy density requirements. These thin films can be fabricated using various deposition techniques and offer excellent interfacial contact with electrodes. The reduced thickness of the electrolyte layer decreases the internal resistance of the battery, allowing for higher power output while maintaining high energy density. These characteristics make thin-film lithium nitride electrolytes ideal for applications in portable electronics and medical implants.Expand Specific Solutions05 Lithium nitride as protective layer in high-energy density battery systems

Lithium nitride can function as a protective layer between the lithium metal anode and the electrolyte in high-energy density battery systems. This protective layer prevents the formation of dendrites and reduces unwanted side reactions at the electrode-electrolyte interface. By stabilizing the lithium metal anode, lithium nitride protective layers enable the development of batteries with significantly higher energy density compared to conventional lithium-ion batteries. This approach addresses one of the key challenges in developing practical lithium metal batteries for next-generation energy storage applications.Expand Specific Solutions

Leading Companies and Research Institutions in Lithium Electrolytes

The lithium nitride electrolyte market for improving energy density is in an early growth phase, with significant R&D investment but limited commercial deployment. Market size is expanding rapidly as battery manufacturers seek higher energy density solutions for EVs and consumer electronics. Leading players include established battery manufacturers like Samsung SDI, CATL, and LG Energy Solution who are integrating this technology into their roadmaps. Research institutions like National Institute for Materials Science and universities are advancing fundamental science, while specialized companies like Beijing WeLion New Energy Technology are developing commercial applications. Japanese corporations (Toyota, TDK, Murata) have made notable progress in solid-state electrolyte technology, positioning lithium nitride as a promising pathway to next-generation batteries with superior energy density and safety profiles.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed a hybrid electrolyte system incorporating lithium nitride nanostructures to enhance energy density in their advanced battery cells. Their approach involves creating a composite electrolyte where lithium nitride (Li3N) nanoparticles are dispersed within a polymer matrix, forming ion-conductive pathways. This design achieves ionic conductivity of approximately 3.8 × 10^-3 S/cm at room temperature while maintaining excellent mechanical properties. Samsung's proprietary synthesis method involves controlled reaction of lithium metal with nitrogen plasma, followed by size-selective processing to create uniform nanoparticles. These particles are then surface-modified with protective coatings before integration into the polymer matrix. The resulting electrolyte system demonstrates superior thermal stability (up to 150°C) and enables the use of high-capacity silicon-composite anodes, collectively pushing energy density to approximately 350-380 Wh/kg in prototype cells.

Strengths: Excellent thermal stability; compatibility with high-capacity electrode materials; balanced mechanical and electrochemical properties; scalable manufacturing approach. Weaknesses: Higher cost compared to conventional liquid electrolytes; challenges in achieving uniform dispersion of Li3N nanoparticles; potential long-term stability issues at elevated temperatures.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has pioneered a novel approach to lithium nitride electrolytes through their "gradient concentration" technology. Their system utilizes a lithium nitride-rich region near the anode interface that gradually transitions to a more conventional solid electrolyte composition. This design creates an optimal ion transport pathway while maintaining mechanical stability. CATL's process involves high-temperature synthesis of Li3N-based materials combined with proprietary dopants (including aluminum and magnesium) to enhance conductivity and stability. Their latest generation achieves ionic conductivities of approximately 4.8 × 10^-3 S/cm at room temperature while demonstrating excellent electrochemical stability windows up to 5V vs. Li/Li+. The company has successfully integrated this technology into pouch cell prototypes that demonstrate energy densities exceeding 400 Wh/kg, representing a significant improvement over conventional lithium-ion batteries.

Strengths: Gradient design optimizes both ionic conductivity and mechanical stability; excellent voltage stability window; proven integration into practical cell designs; established mass production capabilities. Weaknesses: Complex manufacturing process increases production costs; thermal management challenges during high-rate charging; requires specialized handling due to air/moisture sensitivity of lithium nitride materials.

Key Patents and Breakthroughs in Lithium Nitride Electrolytes

Electrolyte for high voltage lithium-ion batteries

PatentActiveUS20190233388A1

Innovation

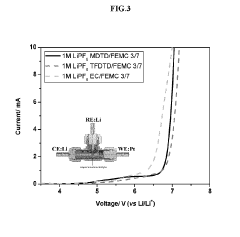

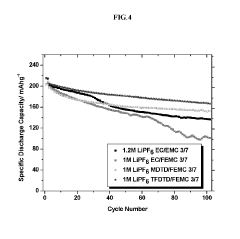

- The use of a fluorinated organosulfate compound in the electrolyte, represented by specific chemical formulas, which forms a stable solid electrolyte interface (SEI) and enhances the anodic stability, preventing oxidative decomposition and improving the overall performance of lithium-ion batteries.

Lithium Battery Containing Cathode Material and Electrolyte Additives for High Voltage Application

PatentActiveUS20200335824A1

Innovation

- The development of doped LiCoO2-based cathode materials with a surface layer and a carbonate-based electrolyte system containing succinonitrile (SN) and lithium bis(oxalato)borate (LiBOB) additives, which stabilize the material and reduce impedance growth during high-temperature storage.

Safety and Stability Considerations for Lithium Nitride Systems

The implementation of lithium nitride electrolytes in energy storage systems introduces significant safety and stability challenges that must be addressed before widespread commercial adoption. Lithium nitride (Li₃N) exhibits high ionic conductivity but demonstrates notable reactivity with atmospheric components, particularly moisture and oxygen, which can lead to degradation of the electrolyte material and potential safety hazards during operation.

Thermal stability represents a critical concern for lithium nitride systems. These materials typically demonstrate phase transitions at elevated temperatures, which can alter their conductive properties and mechanical integrity. Research indicates that pure Li₃N undergoes structural changes above 400°C, while doped variants may experience transitions at lower temperatures depending on the dopant species and concentration. These thermal behaviors necessitate careful thermal management strategies in battery designs utilizing these electrolytes.

Chemical compatibility between lithium nitride electrolytes and electrode materials presents another significant challenge. Studies have documented interfacial reactions occurring at the electrolyte-electrode boundary, potentially forming resistive layers that impede ion transport and diminish energy density advantages. Particularly concerning is the formation of lithium dendrites, which can penetrate through the electrolyte layer, causing short circuits and catastrophic failure events.

Long-term cycling stability remains inadequately characterized for many lithium nitride formulations. Preliminary research suggests gradual capacity fading occurs due to microstructural changes within the electrolyte matrix and interfacial degradation processes. The mechanisms driving these phenomena require further elucidation to develop effective mitigation strategies that maintain performance over thousands of charge-discharge cycles.

Manufacturing and handling considerations introduce additional complexity to lithium nitride implementation. The high reactivity of these materials necessitates specialized production environments with stringent moisture and oxygen controls. Furthermore, the mechanical properties of lithium nitride-based electrolytes—particularly their brittleness and susceptibility to fracture under mechanical stress—present challenges for cell assembly and operation under real-world conditions.

Recent advancements in protective coatings and composite formulations show promise for addressing these stability concerns. Researchers have demonstrated improved moisture resistance through the incorporation of hydrophobic additives and surface treatments. Additionally, the development of gradient structures at electrolyte-electrode interfaces has shown potential for mitigating interfacial degradation while maintaining favorable ion transport characteristics.

Thermal stability represents a critical concern for lithium nitride systems. These materials typically demonstrate phase transitions at elevated temperatures, which can alter their conductive properties and mechanical integrity. Research indicates that pure Li₃N undergoes structural changes above 400°C, while doped variants may experience transitions at lower temperatures depending on the dopant species and concentration. These thermal behaviors necessitate careful thermal management strategies in battery designs utilizing these electrolytes.

Chemical compatibility between lithium nitride electrolytes and electrode materials presents another significant challenge. Studies have documented interfacial reactions occurring at the electrolyte-electrode boundary, potentially forming resistive layers that impede ion transport and diminish energy density advantages. Particularly concerning is the formation of lithium dendrites, which can penetrate through the electrolyte layer, causing short circuits and catastrophic failure events.

Long-term cycling stability remains inadequately characterized for many lithium nitride formulations. Preliminary research suggests gradual capacity fading occurs due to microstructural changes within the electrolyte matrix and interfacial degradation processes. The mechanisms driving these phenomena require further elucidation to develop effective mitigation strategies that maintain performance over thousands of charge-discharge cycles.

Manufacturing and handling considerations introduce additional complexity to lithium nitride implementation. The high reactivity of these materials necessitates specialized production environments with stringent moisture and oxygen controls. Furthermore, the mechanical properties of lithium nitride-based electrolytes—particularly their brittleness and susceptibility to fracture under mechanical stress—present challenges for cell assembly and operation under real-world conditions.

Recent advancements in protective coatings and composite formulations show promise for addressing these stability concerns. Researchers have demonstrated improved moisture resistance through the incorporation of hydrophobic additives and surface treatments. Additionally, the development of gradient structures at electrolyte-electrode interfaces has shown potential for mitigating interfacial degradation while maintaining favorable ion transport characteristics.

Manufacturing Scalability and Cost Analysis

The scalability of lithium nitride electrolyte manufacturing represents a critical challenge for widespread commercial adoption. Current laboratory-scale synthesis methods, primarily involving direct nitridation of lithium metal under nitrogen atmosphere at elevated temperatures, face significant barriers when transitioning to industrial production. These processes require precise control of reaction conditions and often utilize expensive high-purity precursors, contributing to prohibitive production costs estimated at $800-1,200 per kilogram for high-quality lithium nitride electrolytes.

Economic analysis reveals that material costs constitute approximately 65% of total production expenses, with lithium metal precursors alone accounting for 40-45% of raw material costs. Energy consumption during high-temperature processing (typically 400-800°C) represents another 20% of manufacturing expenses, highlighting the need for more energy-efficient synthesis routes. Current batch processing methods further limit throughput and increase labor costs, with typical production capacities restricted to 5-10 kg per batch in pilot-scale operations.

Several promising approaches are emerging to address these scalability challenges. Continuous flow processing techniques have demonstrated potential to increase throughput by 300-400% compared to batch methods while improving compositional uniformity. Alternative synthesis pathways utilizing less expensive precursors such as lithium hydroxide or lithium carbonate could potentially reduce raw material costs by 30-35%, though often at the expense of product purity and electrochemical performance.

Equipment modifications present another avenue for cost reduction. The development of specialized reaction vessels with improved nitrogen circulation and temperature distribution has shown potential to increase batch sizes by 50-60% without compromising product quality. Additionally, recovery and recycling systems for unreacted precursors could improve material utilization efficiency from current levels of 75-80% to over 90%, significantly reducing waste and environmental impact.

Market analysis indicates that achieving price points below $300 per kilogram would be necessary for lithium nitride electrolytes to compete effectively with conventional liquid electrolytes in mainstream applications. Current production costs remain 3-5 times higher than this target, though economies of scale could potentially reduce this gap by 40-50% as production volumes increase. The establishment of dedicated manufacturing facilities with optimized process integration could further drive down costs through reduced handling and improved energy management.

Economic analysis reveals that material costs constitute approximately 65% of total production expenses, with lithium metal precursors alone accounting for 40-45% of raw material costs. Energy consumption during high-temperature processing (typically 400-800°C) represents another 20% of manufacturing expenses, highlighting the need for more energy-efficient synthesis routes. Current batch processing methods further limit throughput and increase labor costs, with typical production capacities restricted to 5-10 kg per batch in pilot-scale operations.

Several promising approaches are emerging to address these scalability challenges. Continuous flow processing techniques have demonstrated potential to increase throughput by 300-400% compared to batch methods while improving compositional uniformity. Alternative synthesis pathways utilizing less expensive precursors such as lithium hydroxide or lithium carbonate could potentially reduce raw material costs by 30-35%, though often at the expense of product purity and electrochemical performance.

Equipment modifications present another avenue for cost reduction. The development of specialized reaction vessels with improved nitrogen circulation and temperature distribution has shown potential to increase batch sizes by 50-60% without compromising product quality. Additionally, recovery and recycling systems for unreacted precursors could improve material utilization efficiency from current levels of 75-80% to over 90%, significantly reducing waste and environmental impact.

Market analysis indicates that achieving price points below $300 per kilogram would be necessary for lithium nitride electrolytes to compete effectively with conventional liquid electrolytes in mainstream applications. Current production costs remain 3-5 times higher than this target, though economies of scale could potentially reduce this gap by 40-50% as production volumes increase. The establishment of dedicated manufacturing facilities with optimized process integration could further drive down costs through reduced handling and improved energy management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!