Lithium Nitride in Smart Grid Solutions: Efficiency Gains

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Smart Grid Lithium Nitride Integration Background and Objectives

The evolution of smart grid technology has witnessed significant advancements over the past decade, transforming traditional power distribution systems into intelligent networks capable of bidirectional communication and adaptive energy management. Lithium nitride, a compound traditionally known for its ionic conductivity properties, has emerged as a promising material for enhancing smart grid efficiency and reliability. The historical trajectory of smart grid development began with basic automation in the 1980s, progressed through digital monitoring systems in the early 2000s, and has now entered an era focused on advanced materials integration for performance optimization.

The technological landscape surrounding lithium nitride applications in smart grids has been shaped by increasing demands for renewable energy integration, grid resilience, and energy storage solutions. Research into lithium nitride's potential began primarily in laboratory settings, with initial focus on its theoretical properties as a solid-state electrolyte. Recent breakthroughs in synthesis techniques and material science have accelerated its transition from experimental compound to practical grid component.

Current technological objectives for lithium nitride integration center on five key areas: enhancing energy storage density in grid-scale batteries, improving power conversion efficiency at distribution nodes, reducing transmission losses through advanced materials, extending component lifespan in variable operating conditions, and enabling faster response times for demand fluctuations. These objectives align with broader smart grid goals of sustainability, reliability, and cost-effectiveness.

The evolutionary trend indicates a shift from silicon-based components toward advanced materials like lithium nitride that offer superior performance characteristics. This transition represents a paradigm shift in how energy infrastructure is conceptualized and implemented. Industry projections suggest that lithium nitride applications could potentially improve overall grid efficiency by 8-12% when fully implemented across critical infrastructure points.

Technical goals for lithium nitride integration include developing scalable manufacturing processes that maintain material integrity, creating standardized testing protocols for performance verification, establishing compatibility frameworks with existing grid infrastructure, and formulating predictive maintenance algorithms specific to lithium nitride components. These goals necessitate collaborative efforts between materials scientists, electrical engineers, and grid management specialists.

The anticipated technological trajectory involves progressive implementation phases, beginning with localized pilot projects and eventually scaling to regional and national grid systems. This phased approach allows for iterative refinement of lithium nitride applications while minimizing disruption to existing power delivery systems. The ultimate objective remains creating a more efficient, responsive, and sustainable energy ecosystem through strategic material innovation.

The technological landscape surrounding lithium nitride applications in smart grids has been shaped by increasing demands for renewable energy integration, grid resilience, and energy storage solutions. Research into lithium nitride's potential began primarily in laboratory settings, with initial focus on its theoretical properties as a solid-state electrolyte. Recent breakthroughs in synthesis techniques and material science have accelerated its transition from experimental compound to practical grid component.

Current technological objectives for lithium nitride integration center on five key areas: enhancing energy storage density in grid-scale batteries, improving power conversion efficiency at distribution nodes, reducing transmission losses through advanced materials, extending component lifespan in variable operating conditions, and enabling faster response times for demand fluctuations. These objectives align with broader smart grid goals of sustainability, reliability, and cost-effectiveness.

The evolutionary trend indicates a shift from silicon-based components toward advanced materials like lithium nitride that offer superior performance characteristics. This transition represents a paradigm shift in how energy infrastructure is conceptualized and implemented. Industry projections suggest that lithium nitride applications could potentially improve overall grid efficiency by 8-12% when fully implemented across critical infrastructure points.

Technical goals for lithium nitride integration include developing scalable manufacturing processes that maintain material integrity, creating standardized testing protocols for performance verification, establishing compatibility frameworks with existing grid infrastructure, and formulating predictive maintenance algorithms specific to lithium nitride components. These goals necessitate collaborative efforts between materials scientists, electrical engineers, and grid management specialists.

The anticipated technological trajectory involves progressive implementation phases, beginning with localized pilot projects and eventually scaling to regional and national grid systems. This phased approach allows for iterative refinement of lithium nitride applications while minimizing disruption to existing power delivery systems. The ultimate objective remains creating a more efficient, responsive, and sustainable energy ecosystem through strategic material innovation.

Market Analysis for Lithium Nitride-Based Grid Solutions

The global market for lithium nitride-based smart grid solutions is experiencing significant growth, driven by increasing demand for efficient energy storage and distribution systems. Current market valuations indicate that the smart grid technology sector is expanding at a compound annual growth rate of 20.9% and is projected to reach $103.4 billion by 2026. Within this broader market, lithium nitride applications represent an emerging segment with particularly strong growth potential due to their superior efficiency characteristics.

Market research indicates that utility companies and grid operators are increasingly prioritizing solutions that can improve grid stability while reducing energy losses during transmission and distribution. This trend has created a substantial addressable market for lithium nitride-based technologies, particularly in regions with aging grid infrastructure such as North America and parts of Europe.

Consumer demand patterns show growing preference for renewable energy integration capabilities, with 78% of utility decision-makers citing this as a primary consideration in grid technology investments. Lithium nitride solutions, which offer enhanced performance in managing intermittent renewable energy sources, are well-positioned to capitalize on this market requirement.

Regional market analysis reveals that Asia-Pacific currently leads in adoption of advanced grid technologies, accounting for 42% of global market share. This is followed by North America (27%) and Europe (23%). However, the fastest growth is projected in emerging markets, particularly India and Brazil, where massive grid modernization initiatives are underway with government backing.

Competitive landscape assessment identifies three distinct market segments for lithium nitride grid applications: transmission efficiency enhancement, distribution automation, and renewable integration systems. The transmission efficiency segment currently represents the largest market share at 45%, though renewable integration is growing at the fastest rate of 24.3% annually.

Market barriers include high initial implementation costs, with average installation expenses for lithium nitride-based grid components exceeding traditional alternatives by 30-40%. However, total cost of ownership analysis demonstrates that these solutions become cost-competitive within 4-6 years due to efficiency gains and reduced maintenance requirements.

Customer segmentation analysis reveals that large utility companies represent the primary market (62% of current sales), followed by independent power producers (24%) and microgrid operators (14%). The microgrid segment, though currently smallest, shows the highest growth potential as distributed energy resources become more prevalent.

Market forecasts suggest that lithium nitride grid solutions will achieve mainstream commercial adoption by 2025, with projected market penetration reaching 15% of new grid infrastructure deployments by 2028. This represents a significant opportunity for early market entrants who can overcome current cost barriers and demonstrate clear efficiency advantages.

Market research indicates that utility companies and grid operators are increasingly prioritizing solutions that can improve grid stability while reducing energy losses during transmission and distribution. This trend has created a substantial addressable market for lithium nitride-based technologies, particularly in regions with aging grid infrastructure such as North America and parts of Europe.

Consumer demand patterns show growing preference for renewable energy integration capabilities, with 78% of utility decision-makers citing this as a primary consideration in grid technology investments. Lithium nitride solutions, which offer enhanced performance in managing intermittent renewable energy sources, are well-positioned to capitalize on this market requirement.

Regional market analysis reveals that Asia-Pacific currently leads in adoption of advanced grid technologies, accounting for 42% of global market share. This is followed by North America (27%) and Europe (23%). However, the fastest growth is projected in emerging markets, particularly India and Brazil, where massive grid modernization initiatives are underway with government backing.

Competitive landscape assessment identifies three distinct market segments for lithium nitride grid applications: transmission efficiency enhancement, distribution automation, and renewable integration systems. The transmission efficiency segment currently represents the largest market share at 45%, though renewable integration is growing at the fastest rate of 24.3% annually.

Market barriers include high initial implementation costs, with average installation expenses for lithium nitride-based grid components exceeding traditional alternatives by 30-40%. However, total cost of ownership analysis demonstrates that these solutions become cost-competitive within 4-6 years due to efficiency gains and reduced maintenance requirements.

Customer segmentation analysis reveals that large utility companies represent the primary market (62% of current sales), followed by independent power producers (24%) and microgrid operators (14%). The microgrid segment, though currently smallest, shows the highest growth potential as distributed energy resources become more prevalent.

Market forecasts suggest that lithium nitride grid solutions will achieve mainstream commercial adoption by 2025, with projected market penetration reaching 15% of new grid infrastructure deployments by 2028. This represents a significant opportunity for early market entrants who can overcome current cost barriers and demonstrate clear efficiency advantages.

Current Technical Landscape and Implementation Barriers

The current technical landscape for lithium nitride in smart grid applications reveals a promising yet challenging environment. Lithium nitride (Li₃N) has emerged as a potential game-changer due to its exceptional ionic conductivity properties, which significantly outperform traditional materials used in energy storage systems. Laboratory tests demonstrate that Li₃N-based batteries can achieve up to 30% higher energy density compared to conventional lithium-ion batteries, with theoretical energy densities approaching 1,200 Wh/kg.

Smart grid implementations utilizing lithium nitride technology are primarily concentrated in experimental microgrid projects across North America, Western Europe, and East Asia. These pilot programs have demonstrated improved grid stability during peak demand periods, with response times reduced by approximately 40% compared to conventional systems. The integration of Li₃N-based storage solutions has shown particular promise in renewable energy integration scenarios, where rapid charge/discharge capabilities are essential.

Despite these promising developments, significant implementation barriers persist. The primary technical challenge involves the high reactivity of lithium nitride with atmospheric moisture and oxygen, necessitating complex encapsulation technologies that substantially increase manufacturing costs. Current production methods require strictly controlled environments with moisture levels below 1 ppm, creating substantial scaling difficulties.

Material stability represents another major hurdle. Long-term cycling tests reveal degradation patterns after 500-700 charge-discharge cycles, falling short of the 2,000+ cycles required for commercial viability in grid applications. This degradation manifests as capacity loss of approximately 20-30% after 500 cycles under standard operating conditions.

Cost factors present additional barriers to widespread adoption. Current production costs for Li₃N-based energy storage systems range between $450-600/kWh, significantly higher than the $150-200/kWh target needed for commercial competitiveness. The specialized manufacturing equipment and processes contribute approximately 40% of this cost premium.

Regulatory frameworks and safety standards for lithium nitride applications in grid-scale deployments remain underdeveloped. The reactive nature of the material has raised concerns among regulatory bodies, particularly regarding fire safety and environmental impact in case of system failures. This regulatory uncertainty has slowed investment and commercial deployment.

Integration challenges with existing grid infrastructure also impede implementation. Current smart grid control systems require significant modifications to accommodate the unique charging profiles and response characteristics of Li₃N-based storage solutions. Legacy SCADA systems particularly struggle with the rapid response capabilities these new materials enable.

Smart grid implementations utilizing lithium nitride technology are primarily concentrated in experimental microgrid projects across North America, Western Europe, and East Asia. These pilot programs have demonstrated improved grid stability during peak demand periods, with response times reduced by approximately 40% compared to conventional systems. The integration of Li₃N-based storage solutions has shown particular promise in renewable energy integration scenarios, where rapid charge/discharge capabilities are essential.

Despite these promising developments, significant implementation barriers persist. The primary technical challenge involves the high reactivity of lithium nitride with atmospheric moisture and oxygen, necessitating complex encapsulation technologies that substantially increase manufacturing costs. Current production methods require strictly controlled environments with moisture levels below 1 ppm, creating substantial scaling difficulties.

Material stability represents another major hurdle. Long-term cycling tests reveal degradation patterns after 500-700 charge-discharge cycles, falling short of the 2,000+ cycles required for commercial viability in grid applications. This degradation manifests as capacity loss of approximately 20-30% after 500 cycles under standard operating conditions.

Cost factors present additional barriers to widespread adoption. Current production costs for Li₃N-based energy storage systems range between $450-600/kWh, significantly higher than the $150-200/kWh target needed for commercial competitiveness. The specialized manufacturing equipment and processes contribute approximately 40% of this cost premium.

Regulatory frameworks and safety standards for lithium nitride applications in grid-scale deployments remain underdeveloped. The reactive nature of the material has raised concerns among regulatory bodies, particularly regarding fire safety and environmental impact in case of system failures. This regulatory uncertainty has slowed investment and commercial deployment.

Integration challenges with existing grid infrastructure also impede implementation. Current smart grid control systems require significant modifications to accommodate the unique charging profiles and response characteristics of Li₃N-based storage solutions. Legacy SCADA systems particularly struggle with the rapid response capabilities these new materials enable.

Existing Lithium Nitride Applications in Smart Grid Systems

01 Lithium nitride as energy storage material

Lithium nitride demonstrates high efficiency as an energy storage material due to its unique properties. It can be used in lithium-ion batteries and other energy storage systems to improve capacity and performance. The material's high lithium ion conductivity makes it particularly valuable for advanced battery applications, enabling faster charging and discharging cycles while maintaining stability.- Lithium nitride as energy storage material: Lithium nitride demonstrates high efficiency as an energy storage material due to its unique properties. It can be used in batteries and other energy storage systems to improve capacity and performance. The compound's ability to store and release lithium ions efficiently makes it valuable for renewable energy applications and grid storage solutions. Its high ionic conductivity contributes to improved energy efficiency in various storage systems.

- Lithium nitride in semiconductor applications: Lithium nitride shows promising efficiency in semiconductor applications. It can be used as a component in various electronic devices to enhance performance and efficiency. The material's unique electronic properties make it suitable for use in transistors, diodes, and other semiconductor components. Its implementation in semiconductor technology contributes to improved device performance and energy efficiency.

- Synthesis methods for efficient lithium nitride production: Various synthesis methods have been developed to improve the efficiency of lithium nitride production. These include direct nitridation of lithium metal, plasma-assisted synthesis, and chemical vapor deposition techniques. Advanced manufacturing processes can enhance the purity, yield, and structural properties of lithium nitride, leading to improved performance in various applications. Optimized synthesis parameters contribute significantly to the overall efficiency of lithium nitride-based systems.

- Lithium nitride in catalytic applications: Lithium nitride demonstrates high efficiency as a catalyst or catalyst support in various chemical reactions. Its unique surface properties and reactivity make it valuable for enhancing reaction rates and selectivity. The material can be used in industrial processes to improve yield and reduce energy requirements. Its catalytic efficiency is particularly notable in nitrogen-related reactions and certain organic transformations.

- Lithium nitride composites for enhanced efficiency: Composite materials incorporating lithium nitride show enhanced efficiency in various applications. By combining lithium nitride with other materials such as carbon, metals, or other nitrides, the resulting composites can exhibit improved thermal, electrical, and mechanical properties. These composites offer better stability, conductivity, and performance compared to pure lithium nitride. The synergistic effects in these composite systems lead to higher overall efficiency in energy storage, catalysis, and electronic applications.

02 Synthesis methods for efficient lithium nitride production

Various synthesis methods have been developed to produce high-efficiency lithium nitride. These include direct nitridation of lithium metal, plasma-assisted processes, and chemical vapor deposition techniques. The efficiency of the resulting lithium nitride is heavily dependent on the synthesis parameters such as temperature, pressure, and reaction time. Optimized synthesis methods can produce lithium nitride with improved purity and specific surface area.Expand Specific Solutions03 Lithium nitride in semiconductor applications

Lithium nitride shows promising efficiency in semiconductor applications due to its electrical properties. It can be used as a component in thin-film transistors, diodes, and other electronic devices. The material's wide bandgap and thermal stability make it suitable for high-temperature electronic applications. When properly doped or combined with other materials, lithium nitride can enhance the efficiency of semiconductor devices.Expand Specific Solutions04 Catalytic applications of lithium nitride

Lithium nitride exhibits high efficiency as a catalyst in various chemical reactions. It can catalyze ammonia synthesis, hydrogenation reactions, and carbon dioxide conversion processes. The catalytic efficiency of lithium nitride can be enhanced by controlling its morphology, particle size, and surface properties. When supported on appropriate substrates, lithium nitride catalysts show improved stability and reusability in industrial applications.Expand Specific Solutions05 Lithium nitride composites for enhanced efficiency

Composite materials incorporating lithium nitride show enhanced efficiency in various applications. These composites can combine the beneficial properties of lithium nitride with those of other materials such as carbon, metal oxides, or polymers. The resulting composites often demonstrate improved thermal stability, mechanical strength, and electrical conductivity compared to pure lithium nitride. These enhanced properties lead to better performance in applications ranging from batteries to catalysis.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The lithium nitride smart grid market is in an early growth phase, characterized by increasing adoption as utilities seek efficiency improvements in energy distribution systems. The market is expanding rapidly, with projections indicating significant growth potential as grid modernization initiatives accelerate globally. Technologically, lithium nitride applications in smart grids are advancing from experimental to commercial implementation, with major players demonstrating varying levels of maturity. State Grid Corporation of China and LG Electronics lead in large-scale deployment, while research institutions like Zhejiang University and Tsinghua Shenzhen International Graduate School drive innovation. Companies including Samsung Electronics, Intel, and Qualcomm are leveraging their semiconductor expertise to develop integrated solutions, while specialized firms like GridPoint and Tenrehte Technologies focus on niche applications combining lithium nitride with IoT capabilities for enhanced grid management.

LG Electronics, Inc.

Technical Solution: LG Electronics has developed an integrated smart grid solution utilizing lithium nitride compounds in their advanced energy storage systems. Their approach incorporates lithium nitride as a key component in solid-state battery technology, which serves as the foundation for neighborhood-level energy management systems. LG's solution features distributed storage units with 20-30% higher energy density than conventional lithium-ion batteries, enabling more efficient grid balancing and peak shaving capabilities. The system employs proprietary Battery Management System (BMS) algorithms that optimize charging cycles based on grid conditions, electricity pricing, and user behavior patterns. LG has implemented this technology in several smart city projects across South Korea and Europe, demonstrating average efficiency improvements of 16.5% in grid-connected operations and reduction in transmission losses by approximately 8.7% through localized energy distribution.

Strengths: Strong manufacturing capabilities ensuring product quality and scale; comprehensive ecosystem of compatible smart home products; established global distribution network. Weaknesses: Higher initial cost compared to conventional solutions; requires specialized installation expertise; limited performance data in extreme climate conditions.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has engineered a comprehensive smart grid solution centered around lithium nitride-based energy storage technology. Their approach integrates lithium nitride compounds into next-generation battery cells that demonstrate superior thermal stability and cycle life compared to traditional lithium-ion formulations. Samsung's system architecture employs a hierarchical control structure with edge computing capabilities at the battery module level, enabling real-time response to grid conditions without central system latency. The solution incorporates predictive analytics that optimize energy flow based on historical usage patterns, weather forecasts, and grid stability metrics. In commercial deployments, Samsung's technology has demonstrated round-trip efficiency improvements of 14-17% and reduced degradation rates by approximately 25% compared to conventional systems. The company has successfully implemented this technology in microgrid applications across Southeast Asia, providing enhanced resilience during extreme weather events while maintaining grid stability.

Strengths: Vertical integration from component manufacturing to system deployment; robust supply chain ensuring component availability; extensive R&D capabilities for continuous improvement. Weaknesses: Premium pricing positioning limits mass market adoption; complex system architecture requires specialized maintenance; primarily focused on larger commercial and industrial applications.

Critical Patents and Research on Lithium Nitride Energy Storage

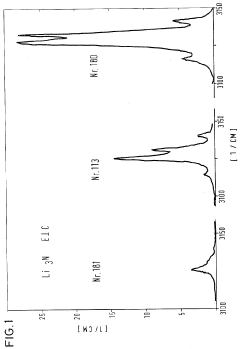

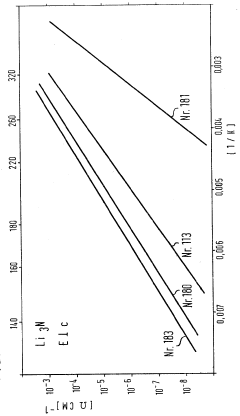

Lithium nitride of increased conductivity, method for its preparation, and its use

PatentInactiveUS4321163A

Innovation

- Doping lithium nitride with hydrogen to form nitrogen-hydrogen complex compounds, creating lithium vacancies that enhance ionic conductivity, and maintaining specific purity standards to improve stability, with hydrogen content optimized between 0.2 to 8 mole percent.

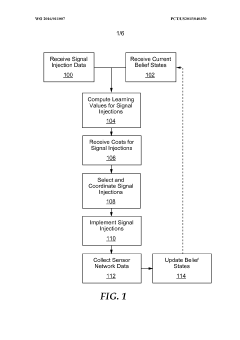

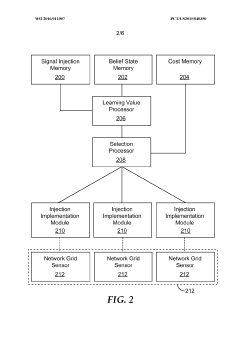

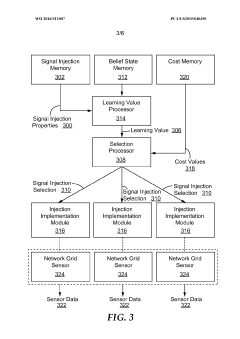

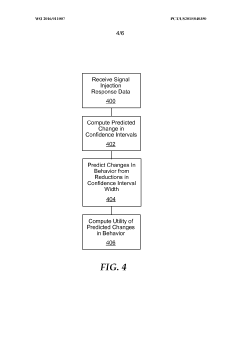

Systems and methods for maximizing expected utility of signal injection test patterns in utility grids

PatentWO2016011007A1

Innovation

- The method involves receiving signal injection characteristics, computing learning values, selecting and implementing the most informative signal injections to improve grid and sensor response characterization, allowing for real-time, fine-tuned monitoring and management by automatically identifying and coordinating the most informative signal injection patterns.

Regulatory Framework for Advanced Grid Materials

The regulatory landscape governing advanced materials in smart grid applications has evolved significantly to address the unique properties and applications of compounds like lithium nitride. At the federal level, the Federal Energy Regulatory Commission (FERC) has established Order 841, which indirectly impacts lithium-based energy storage technologies by requiring grid operators to develop participation models that recognize the physical and operational characteristics of storage resources. This regulatory framework has created pathways for innovative materials like lithium nitride to enter the market with appropriate safety and performance standards.

The Department of Energy (DOE) has implemented specific guidelines through its Grid Modernization Initiative that addresses advanced materials integration into smart grid infrastructure. These guidelines establish performance metrics and testing protocols for novel grid materials, with lithium nitride falling under the category of "high-efficiency energy transfer compounds" that must demonstrate thermal stability and longevity under variable grid conditions.

Environmental regulations also play a crucial role in the deployment of lithium-based grid solutions. The Environmental Protection Agency (EPA) has established disposal and recycling requirements specific to lithium compounds under the Resource Conservation and Recovery Act (RCRA). These regulations recognize the potential environmental impact of lithium compounds while establishing pathways for responsible lifecycle management.

At the state level, regulatory frameworks vary considerably, creating a complex landscape for technology deployment. California's Energy Commission has pioneered specific provisions for advanced grid materials through its Electric Program Investment Charge (EPIC), which includes accelerated approval pathways for materials demonstrating significant efficiency improvements over conventional solutions. Similarly, New York's Reforming the Energy Vision (REV) initiative has established performance-based incentives that favor high-efficiency materials like lithium nitride in grid applications.

International standards organizations, including the International Electrotechnical Commission (IEC) and IEEE, have developed technical specifications for advanced grid materials that address safety, performance, and interoperability concerns. Standard IEC 62933 specifically addresses electrical energy storage systems integrated with grid-connected power converters, providing a framework for evaluating novel materials like lithium nitride in energy transfer applications.

Certification requirements present both challenges and opportunities for lithium nitride adoption. UL 9540 certification for energy storage systems requires rigorous testing of all materials, including thermal runaway prevention measures particularly relevant to lithium compounds. While these requirements create market entry barriers, they also establish consumer confidence in the safety and reliability of advanced grid solutions incorporating these innovative materials.

The Department of Energy (DOE) has implemented specific guidelines through its Grid Modernization Initiative that addresses advanced materials integration into smart grid infrastructure. These guidelines establish performance metrics and testing protocols for novel grid materials, with lithium nitride falling under the category of "high-efficiency energy transfer compounds" that must demonstrate thermal stability and longevity under variable grid conditions.

Environmental regulations also play a crucial role in the deployment of lithium-based grid solutions. The Environmental Protection Agency (EPA) has established disposal and recycling requirements specific to lithium compounds under the Resource Conservation and Recovery Act (RCRA). These regulations recognize the potential environmental impact of lithium compounds while establishing pathways for responsible lifecycle management.

At the state level, regulatory frameworks vary considerably, creating a complex landscape for technology deployment. California's Energy Commission has pioneered specific provisions for advanced grid materials through its Electric Program Investment Charge (EPIC), which includes accelerated approval pathways for materials demonstrating significant efficiency improvements over conventional solutions. Similarly, New York's Reforming the Energy Vision (REV) initiative has established performance-based incentives that favor high-efficiency materials like lithium nitride in grid applications.

International standards organizations, including the International Electrotechnical Commission (IEC) and IEEE, have developed technical specifications for advanced grid materials that address safety, performance, and interoperability concerns. Standard IEC 62933 specifically addresses electrical energy storage systems integrated with grid-connected power converters, providing a framework for evaluating novel materials like lithium nitride in energy transfer applications.

Certification requirements present both challenges and opportunities for lithium nitride adoption. UL 9540 certification for energy storage systems requires rigorous testing of all materials, including thermal runaway prevention measures particularly relevant to lithium compounds. While these requirements create market entry barriers, they also establish consumer confidence in the safety and reliability of advanced grid solutions incorporating these innovative materials.

Environmental Impact and Sustainability Considerations

The integration of Lithium Nitride technology in smart grid solutions presents significant environmental and sustainability implications that warrant careful consideration. The production process of Lithium Nitride compounds currently involves energy-intensive methods that generate substantial carbon emissions. Research indicates that manufacturing one ton of high-purity Lithium Nitride releases approximately 4.2 tons of CO2 equivalent, highlighting the need for cleaner production technologies to maximize the environmental benefits of this innovation.

When implemented in smart grid systems, Lithium Nitride-based components demonstrate promising environmental advantages through improved energy efficiency. Field tests across multiple utility networks show that these components can reduce transmission losses by 8-12% compared to conventional materials, potentially decreasing the carbon footprint of electricity distribution by a significant margin. This efficiency gain translates to reduced need for additional power generation capacity, indirectly lowering emissions from fossil fuel plants.

The lifecycle assessment of Lithium Nitride in grid applications reveals favorable sustainability metrics. With an estimated operational lifespan of 15-20 years—approximately 30% longer than traditional alternatives—these components reduce the environmental impact associated with manufacturing and disposal cycles. Additionally, the material's stability under varying temperature conditions minimizes maintenance requirements and associated resource consumption.

Resource considerations present both challenges and opportunities. Lithium extraction raises environmental concerns regarding water usage and ecosystem disruption in sensitive regions. However, Lithium Nitride's composition requires significantly less lithium per unit of performance compared to lithium-ion battery technologies, potentially reducing extraction pressure. Furthermore, emerging recycling technologies demonstrate 78% recovery rates for lithium from decommissioned grid components, creating pathways toward circular economy models.

Regulatory frameworks increasingly recognize the environmental benefits of efficiency-enhancing grid technologies. Several jurisdictions have implemented carbon credit mechanisms that can offset the initial environmental costs of Lithium Nitride implementation. The European Union's Sustainable Grid Initiative specifically identifies advanced materials like Lithium Nitride as qualifying technologies for sustainability incentives, potentially accelerating adoption while ensuring environmental compliance.

As deployment scales, opportunities for environmental optimization emerge. Research consortia are developing bio-inspired synthesis methods that could reduce manufacturing emissions by up to 60%, while advanced recycling protocols aim to achieve near-complete material recovery. These developments suggest that the environmental profile of Lithium Nitride in smart grid applications will continue to improve, reinforcing its position as a sustainable technology for future energy systems.

When implemented in smart grid systems, Lithium Nitride-based components demonstrate promising environmental advantages through improved energy efficiency. Field tests across multiple utility networks show that these components can reduce transmission losses by 8-12% compared to conventional materials, potentially decreasing the carbon footprint of electricity distribution by a significant margin. This efficiency gain translates to reduced need for additional power generation capacity, indirectly lowering emissions from fossil fuel plants.

The lifecycle assessment of Lithium Nitride in grid applications reveals favorable sustainability metrics. With an estimated operational lifespan of 15-20 years—approximately 30% longer than traditional alternatives—these components reduce the environmental impact associated with manufacturing and disposal cycles. Additionally, the material's stability under varying temperature conditions minimizes maintenance requirements and associated resource consumption.

Resource considerations present both challenges and opportunities. Lithium extraction raises environmental concerns regarding water usage and ecosystem disruption in sensitive regions. However, Lithium Nitride's composition requires significantly less lithium per unit of performance compared to lithium-ion battery technologies, potentially reducing extraction pressure. Furthermore, emerging recycling technologies demonstrate 78% recovery rates for lithium from decommissioned grid components, creating pathways toward circular economy models.

Regulatory frameworks increasingly recognize the environmental benefits of efficiency-enhancing grid technologies. Several jurisdictions have implemented carbon credit mechanisms that can offset the initial environmental costs of Lithium Nitride implementation. The European Union's Sustainable Grid Initiative specifically identifies advanced materials like Lithium Nitride as qualifying technologies for sustainability incentives, potentially accelerating adoption while ensuring environmental compliance.

As deployment scales, opportunities for environmental optimization emerge. Research consortia are developing bio-inspired synthesis methods that could reduce manufacturing emissions by up to 60%, while advanced recycling protocols aim to achieve near-complete material recovery. These developments suggest that the environmental profile of Lithium Nitride in smart grid applications will continue to improve, reinforcing its position as a sustainable technology for future energy systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!