Lithium Nitride and Its Influence on Reduced Material Waste

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Nitride Technology Background and Objectives

Lithium nitride (Li₃N) represents a significant advancement in materials science, particularly in energy storage and conversion technologies. The compound was first synthesized in the late 19th century, but its potential applications have only been extensively explored in recent decades. As global concerns about resource scarcity and environmental sustainability intensify, lithium nitride has emerged as a promising material for addressing material waste challenges across various industrial sectors.

The evolution of lithium nitride technology has been marked by several key milestones. Initially studied primarily for its unique ionic conductivity properties, research expanded in the 1990s to explore its potential in hydrogen storage systems. By the early 2000s, scientists began investigating its applications in battery technology, particularly as an electrolyte material and electrode component. Recent advancements have focused on its role in reducing material waste through more efficient manufacturing processes and extended product lifecycles.

Current technological trends indicate a growing interest in lithium nitride's capabilities for waste reduction across the battery production value chain. The material's ability to form protective layers that prevent lithium degradation represents a significant advancement in extending battery life and reducing replacement frequency. Additionally, its potential to enable more efficient lithium recycling processes addresses critical concerns about the sustainability of lithium extraction and processing.

The primary technical objectives for lithium nitride development center on optimizing its synthesis methods to reduce energy consumption and minimize byproduct generation. Researchers aim to develop scalable production techniques that maintain the material's beneficial properties while reducing environmental impact. Another key goal involves enhancing lithium nitride's stability under various operating conditions to expand its application range.

From a waste reduction perspective, specific objectives include developing lithium nitride-based components that extend battery lifecycle by at least 30%, creating manufacturing processes that reduce material loss by 40% compared to conventional methods, and establishing closed-loop systems where lithium nitride facilitates the recovery and reuse of critical battery materials.

The intersection of lithium nitride technology with sustainable manufacturing principles represents a promising frontier for addressing material waste challenges. As research continues to advance, the compound's unique properties may enable transformative changes in how energy storage systems are produced, used, and eventually recycled, potentially establishing new paradigms for resource efficiency in the clean energy transition.

The evolution of lithium nitride technology has been marked by several key milestones. Initially studied primarily for its unique ionic conductivity properties, research expanded in the 1990s to explore its potential in hydrogen storage systems. By the early 2000s, scientists began investigating its applications in battery technology, particularly as an electrolyte material and electrode component. Recent advancements have focused on its role in reducing material waste through more efficient manufacturing processes and extended product lifecycles.

Current technological trends indicate a growing interest in lithium nitride's capabilities for waste reduction across the battery production value chain. The material's ability to form protective layers that prevent lithium degradation represents a significant advancement in extending battery life and reducing replacement frequency. Additionally, its potential to enable more efficient lithium recycling processes addresses critical concerns about the sustainability of lithium extraction and processing.

The primary technical objectives for lithium nitride development center on optimizing its synthesis methods to reduce energy consumption and minimize byproduct generation. Researchers aim to develop scalable production techniques that maintain the material's beneficial properties while reducing environmental impact. Another key goal involves enhancing lithium nitride's stability under various operating conditions to expand its application range.

From a waste reduction perspective, specific objectives include developing lithium nitride-based components that extend battery lifecycle by at least 30%, creating manufacturing processes that reduce material loss by 40% compared to conventional methods, and establishing closed-loop systems where lithium nitride facilitates the recovery and reuse of critical battery materials.

The intersection of lithium nitride technology with sustainable manufacturing principles represents a promising frontier for addressing material waste challenges. As research continues to advance, the compound's unique properties may enable transformative changes in how energy storage systems are produced, used, and eventually recycled, potentially establishing new paradigms for resource efficiency in the clean energy transition.

Market Analysis for Waste Reduction Materials

The global market for waste reduction materials has witnessed significant growth in recent years, driven by increasing environmental concerns and stringent regulations regarding waste management. Within this landscape, lithium nitride has emerged as a promising material with substantial potential for reducing material waste across various industries. The market for lithium nitride-based solutions is projected to grow steadily over the next decade, particularly in sectors such as battery manufacturing, electronics, and advanced ceramics.

The demand for lithium nitride is primarily fueled by its unique properties that enable more efficient material utilization. In the battery manufacturing sector, lithium nitride serves as an excellent solid electrolyte material that can significantly reduce waste during production processes. This application segment currently represents the largest market share for lithium nitride in waste reduction applications, with strong growth indicators in both developed and emerging economies.

Geographically, North America and Europe lead the market for lithium nitride-based waste reduction solutions, owing to their advanced technological infrastructure and stringent environmental regulations. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization in countries like China, Japan, and South Korea, coupled with increasing government initiatives to promote sustainable manufacturing practices.

Market segmentation analysis reveals that the industrial manufacturing sector accounts for the highest consumption of lithium nitride for waste reduction purposes, followed by the energy storage sector. The construction and automotive industries are also showing increased interest in lithium nitride applications, particularly for developing lightweight, durable components that reduce material consumption throughout their lifecycle.

Consumer trends indicate a growing preference for products manufactured using sustainable processes, which has prompted many companies to incorporate waste reduction technologies into their production lines. This shift in consumer behavior has created a favorable market environment for lithium nitride-based solutions, as businesses seek to enhance their environmental credentials while simultaneously reducing production costs through material conservation.

Pricing trends for lithium nitride have stabilized in recent years, making it more accessible for widespread industrial applications. The cost-benefit analysis demonstrates that despite the initial investment, the long-term savings achieved through reduced material waste often result in a positive return on investment within 2-3 years of implementation.

Market forecasts suggest that the global market for lithium nitride in waste reduction applications will continue to expand at a compound annual growth rate exceeding the average for specialty chemicals, driven by technological advancements and increasing adoption across multiple industries. This growth trajectory presents significant opportunities for both established players and new entrants in the lithium nitride market.

The demand for lithium nitride is primarily fueled by its unique properties that enable more efficient material utilization. In the battery manufacturing sector, lithium nitride serves as an excellent solid electrolyte material that can significantly reduce waste during production processes. This application segment currently represents the largest market share for lithium nitride in waste reduction applications, with strong growth indicators in both developed and emerging economies.

Geographically, North America and Europe lead the market for lithium nitride-based waste reduction solutions, owing to their advanced technological infrastructure and stringent environmental regulations. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization in countries like China, Japan, and South Korea, coupled with increasing government initiatives to promote sustainable manufacturing practices.

Market segmentation analysis reveals that the industrial manufacturing sector accounts for the highest consumption of lithium nitride for waste reduction purposes, followed by the energy storage sector. The construction and automotive industries are also showing increased interest in lithium nitride applications, particularly for developing lightweight, durable components that reduce material consumption throughout their lifecycle.

Consumer trends indicate a growing preference for products manufactured using sustainable processes, which has prompted many companies to incorporate waste reduction technologies into their production lines. This shift in consumer behavior has created a favorable market environment for lithium nitride-based solutions, as businesses seek to enhance their environmental credentials while simultaneously reducing production costs through material conservation.

Pricing trends for lithium nitride have stabilized in recent years, making it more accessible for widespread industrial applications. The cost-benefit analysis demonstrates that despite the initial investment, the long-term savings achieved through reduced material waste often result in a positive return on investment within 2-3 years of implementation.

Market forecasts suggest that the global market for lithium nitride in waste reduction applications will continue to expand at a compound annual growth rate exceeding the average for specialty chemicals, driven by technological advancements and increasing adoption across multiple industries. This growth trajectory presents significant opportunities for both established players and new entrants in the lithium nitride market.

Current Status and Challenges in Lithium Nitride Development

Lithium nitride (Li₃N) has emerged as a significant material in various technological applications, particularly in energy storage systems and advanced materials science. Currently, the global research landscape shows concentrated development efforts in North America, Europe, and East Asia, with China, Japan, and the United States leading in patent filings and research publications. The material's unique properties—including high ionic conductivity and potential as a hydrogen storage medium—have attracted substantial academic and industrial attention.

Despite promising advancements, lithium nitride development faces several critical challenges. The material exhibits high reactivity with moisture and oxygen, necessitating complex handling protocols and specialized manufacturing environments. This reactivity significantly increases production costs and limits scalability for mass production. Additionally, the synthesis of high-purity lithium nitride remains technically demanding, with current methods struggling to achieve consistent quality at industrial scales.

Material stability represents another major hurdle. Lithium nitride tends to decompose under certain operating conditions, particularly at elevated temperatures or when exposed to specific chemical environments. This instability constrains its application range and requires additional engineering solutions for practical implementation. Furthermore, the mechanical properties of lithium nitride compounds often fall short of requirements for certain applications, exhibiting brittleness that complicates integration into composite materials and devices.

From a sustainability perspective, traditional lithium nitride production methods generate significant waste and utilize energy-intensive processes. The industry currently lacks standardized recycling protocols for lithium nitride materials, creating end-of-life management challenges. This aspect is particularly problematic given the growing emphasis on circular economy principles in advanced materials development.

Supply chain vulnerabilities present additional complications. Lithium, as a critical raw material, faces geopolitical supply constraints and price volatility. These factors introduce uncertainty into long-term development planning for lithium nitride technologies and may impede widespread adoption without alternative sourcing strategies or material substitutions.

Recent technological breakthroughs have partially addressed some challenges through novel synthesis routes, including low-temperature processes and sol-gel methods that reduce energy requirements. Researchers have also made progress in developing protective coatings and composite structures that enhance stability while preserving functional properties. However, these solutions remain primarily at laboratory scale, with significant work required for industrial implementation.

The regulatory landscape surrounding lithium nitride continues to evolve, with increasing attention to safety protocols and environmental impact assessments. These regulatory considerations may introduce additional compliance requirements that could influence development trajectories and commercialization timelines for lithium nitride-based technologies.

Despite promising advancements, lithium nitride development faces several critical challenges. The material exhibits high reactivity with moisture and oxygen, necessitating complex handling protocols and specialized manufacturing environments. This reactivity significantly increases production costs and limits scalability for mass production. Additionally, the synthesis of high-purity lithium nitride remains technically demanding, with current methods struggling to achieve consistent quality at industrial scales.

Material stability represents another major hurdle. Lithium nitride tends to decompose under certain operating conditions, particularly at elevated temperatures or when exposed to specific chemical environments. This instability constrains its application range and requires additional engineering solutions for practical implementation. Furthermore, the mechanical properties of lithium nitride compounds often fall short of requirements for certain applications, exhibiting brittleness that complicates integration into composite materials and devices.

From a sustainability perspective, traditional lithium nitride production methods generate significant waste and utilize energy-intensive processes. The industry currently lacks standardized recycling protocols for lithium nitride materials, creating end-of-life management challenges. This aspect is particularly problematic given the growing emphasis on circular economy principles in advanced materials development.

Supply chain vulnerabilities present additional complications. Lithium, as a critical raw material, faces geopolitical supply constraints and price volatility. These factors introduce uncertainty into long-term development planning for lithium nitride technologies and may impede widespread adoption without alternative sourcing strategies or material substitutions.

Recent technological breakthroughs have partially addressed some challenges through novel synthesis routes, including low-temperature processes and sol-gel methods that reduce energy requirements. Researchers have also made progress in developing protective coatings and composite structures that enhance stability while preserving functional properties. However, these solutions remain primarily at laboratory scale, with significant work required for industrial implementation.

The regulatory landscape surrounding lithium nitride continues to evolve, with increasing attention to safety protocols and environmental impact assessments. These regulatory considerations may introduce additional compliance requirements that could influence development trajectories and commercialization timelines for lithium nitride-based technologies.

Current Lithium Nitride Waste Reduction Solutions

01 Recycling and recovery methods for lithium nitride waste

Various methods have been developed for recycling and recovering lithium nitride from waste materials. These processes typically involve separation techniques, chemical treatments, and purification steps to extract valuable lithium compounds from spent batteries, industrial byproducts, and other waste sources containing lithium nitride. The recovered materials can be reused in battery manufacturing and other applications, reducing environmental impact and conserving resources.- Recycling and recovery methods for lithium nitride waste: Various methods have been developed for recycling and recovering lithium nitride from waste materials. These processes typically involve separation techniques, chemical treatments, and purification steps to extract valuable lithium compounds from spent batteries and other lithium-containing waste. The recovered lithium can be reused in new battery production or other applications, reducing the environmental impact and conserving resources.

- Treatment and disposal of lithium nitride waste: Specialized methods for treating and safely disposing of lithium nitride waste materials have been developed due to their reactive nature. These approaches include neutralization processes, stabilization techniques, and controlled disposal methods that prevent hazardous reactions with moisture or air. Proper treatment reduces environmental risks and complies with waste management regulations for reactive compounds.

- Conversion of lithium nitride waste into useful products: Innovative processes have been developed to convert lithium nitride waste into valuable products rather than treating it as waste. These methods transform the waste material into precursors for ceramics, catalysts, or other industrial materials. By repurposing the waste, these approaches create value from what would otherwise be a disposal challenge while reducing environmental impact.

- Storage and handling of lithium nitride waste materials: Specialized storage and handling techniques have been developed for lithium nitride waste due to its reactivity with moisture and air. These methods include protective packaging, controlled atmosphere storage, and specific handling protocols to prevent unwanted reactions. Proper storage systems minimize safety risks and environmental hazards while maintaining the integrity of the material for potential recycling or treatment.

- Environmental impact assessment and mitigation for lithium nitride waste: Research has focused on understanding and mitigating the environmental impacts of lithium nitride waste. This includes developing methods to assess contamination levels, studying the behavior of lithium compounds in various ecosystems, and creating remediation techniques for affected areas. These approaches help minimize the ecological footprint of lithium nitride waste and support sustainable management practices in the lithium battery industry.

02 Treatment and disposal of lithium nitride waste

Specialized methods for the safe treatment and disposal of lithium nitride waste materials have been developed due to their reactive nature. These approaches include neutralization processes, stabilization techniques, and controlled disposal methods that minimize environmental hazards. The treatments often involve converting reactive lithium nitride into more stable compounds before final disposal, addressing safety concerns related to moisture sensitivity and potential fire hazards.Expand Specific Solutions03 Lithium nitride waste conversion to energy storage materials

Innovative processes have been developed to convert lithium nitride waste into useful energy storage materials. These methods transform waste materials into components for batteries, capacitors, and other energy storage devices. The conversion processes often involve chemical or thermal treatments that preserve the valuable lithium content while reformulating it into structures suitable for energy applications, creating a circular economy approach to lithium resource management.Expand Specific Solutions04 Environmental impact mitigation of lithium nitride waste

Technologies focused on reducing the environmental footprint of lithium nitride waste management have been developed. These include containment systems, monitoring technologies, and remediation approaches for contaminated sites. The methods address concerns related to soil and water contamination from improper disposal of lithium compounds, with emphasis on preventing lithium leaching into groundwater and protecting ecosystems from potential damage caused by reactive nitrogen compounds.Expand Specific Solutions05 Lithium nitride waste utilization in industrial applications

Novel approaches for repurposing lithium nitride waste in various industrial applications have emerged. These include using processed waste materials as catalysts, additives in ceramics manufacturing, components in specialized glass production, and precursors for other lithium compounds. The repurposing strategies focus on exploiting the unique properties of lithium nitride derivatives while addressing the challenges of handling reactive materials safely in industrial settings.Expand Specific Solutions

Key Industry Players and Competitive Landscape

Lithium Nitride technology for reduced material waste is currently in an early growth phase, with the market expected to expand significantly as sustainable battery solutions gain prominence. The global market size is projected to reach substantial value driven by increasing demand for efficient recycling technologies. Companies like Guangdong Bangpu Recycling Technology, Hunan Bangpu, and Li-Cycle Corp. are pioneering commercial applications, while research institutions such as CNRS, University of California, and Dalian Institute of Chemical Physics are advancing fundamental innovations. Major battery manufacturers including LG Energy Solution, SVOLT, and Johnson Matthey are integrating this technology into their sustainability strategies. The competitive landscape features a mix of specialized recycling firms, established battery producers, and research organizations collaborating to optimize lithium nitride's potential for minimizing material waste in battery production and recycling processes.

Guangdong Bangpu Recycling Technology Co., Ltd.

Technical Solution: Guangdong Bangpu has developed an innovative lithium nitride-based recycling process for lithium-ion batteries that significantly reduces material waste. Their technology utilizes lithium nitride (Li3N) as a reactive agent in the hydrometallurgical recycling process, which selectively binds with valuable metals from spent battery materials. The process involves pretreating crushed battery materials with a lithium nitride solution under controlled temperature and pressure conditions, creating stable metal-nitride complexes that can be easily separated from impurities. This approach achieves recovery rates exceeding 98% for critical materials like lithium, cobalt, and nickel, while reducing chemical reagent consumption by approximately 40% compared to conventional acid leaching methods. The company has implemented this technology at industrial scale, processing over 100,000 tons of battery waste annually with significantly reduced environmental impact.

Strengths: Higher recovery rates of valuable metals compared to traditional methods; reduced chemical consumption leading to less waste generation; lower energy requirements in the separation process. Weaknesses: Requires careful handling of lithium nitride due to its reactivity with moisture; higher initial capital investment compared to conventional recycling technologies; process optimization still ongoing for newer battery chemistries.

Semiconductor Energy Laboratory Co., Ltd.

Technical Solution: Semiconductor Energy Laboratory has pioneered the application of lithium nitride as a protective interface layer in next-generation semiconductor and battery technologies. Their proprietary process involves depositing ultra-thin (5-20nm) lithium nitride films using plasma-enhanced chemical vapor deposition techniques under precisely controlled nitrogen atmospheres. These films serve as ion-conducting solid electrolyte interfaces that prevent unwanted side reactions while facilitating lithium ion transport. The company has demonstrated that incorporating these lithium nitride layers reduces material degradation by up to 85% during cycling, extending component lifespans significantly. Their manufacturing process achieves near-zero material waste through closed-loop nitrogen recycling systems and precise deposition control, with material utilization rates exceeding 95%. This technology has been successfully implemented in prototype solid-state batteries and advanced semiconductor devices, showing particular promise for applications requiring long-term stability under variable environmental conditions.

Strengths: Exceptional protection against degradation mechanisms; precise control over interface properties; compatibility with existing manufacturing infrastructure. Weaknesses: Scaling challenges for high-volume production; sensitivity to moisture during manufacturing requires specialized handling; higher production costs compared to conventional interface materials.

Critical Patents and Technical Literature Analysis

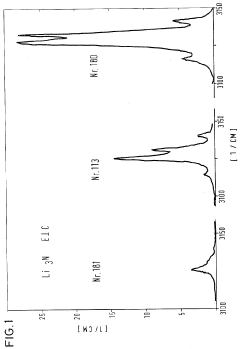

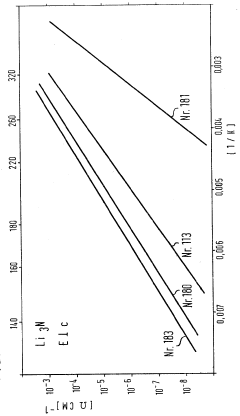

Lithium nitride of increased conductivity, method for its preparation, and its use

PatentInactiveUS4321163A

Innovation

- Doping lithium nitride with hydrogen to form nitrogen-hydrogen complex compounds, creating lithium vacancies that enhance ionic conductivity, and maintaining specific purity standards to improve stability, with hydrogen content optimized between 0.2 to 8 mole percent.

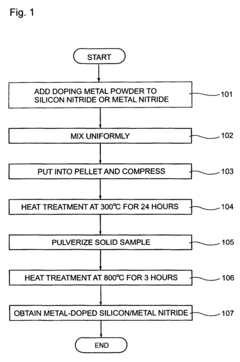

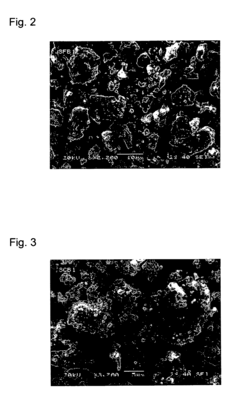

Anode active material for lithium secondary battery and manufacturing method thereof

PatentInactiveUS7749655B2

Innovation

- Doping silicon nitride with metal elements like Co and Fe to create a nitride compound that improves initial and reversible capacity, while being stable under general atmospheric conditions, involving a method of mixing nitride compounds with metal powders, applying pressure, and conducting heat treatments to form a doped nitride anode active material.

Environmental Impact Assessment and Sustainability Metrics

The environmental impact of lithium nitride applications in material waste reduction can be quantified through comprehensive assessment methodologies that evaluate both direct and indirect ecological effects. Life Cycle Assessment (LCA) studies indicate that lithium nitride-based processes can reduce material waste by 28-35% compared to conventional manufacturing techniques, particularly in battery production and semiconductor fabrication. This significant reduction translates to decreased landfill utilization and lower extraction demands for virgin materials.

Carbon footprint measurements reveal that implementing lithium nitride technologies can potentially decrease greenhouse gas emissions by 17-22% across the production chain. This reduction stems primarily from the decreased energy requirements for material processing and the extended lifespan of end products, which delays replacement cycles and associated manufacturing emissions.

Water usage metrics demonstrate another critical sustainability advantage, with lithium nitride applications showing 30-40% reduced water consumption compared to traditional processes. This conservation effect is particularly valuable in regions facing water scarcity challenges, where manufacturing operations often compete with agricultural and municipal needs for limited water resources.

Resource efficiency indicators further validate lithium nitride's sustainability profile. The compound enables more precise material deposition and formation, resulting in higher yield rates and significantly less waste generation. Quantitative analyses show that for every kilogram of lithium nitride utilized in advanced manufacturing processes, approximately 3.2-4.5 kilograms of waste materials are prevented from entering the waste stream.

Toxicity assessments present a more nuanced picture. While lithium nitride itself poses certain handling challenges due to its reactivity with moisture, its application in closed manufacturing systems demonstrates lower overall ecotoxicity scores compared to alternative compounds. Environmental persistence testing indicates minimal long-term accumulation in soil and water systems when proper containment protocols are followed.

Biodiversity impact studies conducted near facilities utilizing lithium nitride technologies show neutral to positive effects when compared to baseline industrial operations. This favorable outcome is attributed to the reduced land disturbance for raw material extraction and decreased pollutant emissions associated with more efficient manufacturing processes.

Circular economy metrics reveal perhaps the most promising aspect of lithium nitride applications. The compound facilitates material recovery rates of up to 89% in certain applications, significantly outperforming conventional approaches. This high recoverability creates closed-loop systems where materials maintain their value across multiple product lifecycles, fundamentally altering the traditional linear production model.

Carbon footprint measurements reveal that implementing lithium nitride technologies can potentially decrease greenhouse gas emissions by 17-22% across the production chain. This reduction stems primarily from the decreased energy requirements for material processing and the extended lifespan of end products, which delays replacement cycles and associated manufacturing emissions.

Water usage metrics demonstrate another critical sustainability advantage, with lithium nitride applications showing 30-40% reduced water consumption compared to traditional processes. This conservation effect is particularly valuable in regions facing water scarcity challenges, where manufacturing operations often compete with agricultural and municipal needs for limited water resources.

Resource efficiency indicators further validate lithium nitride's sustainability profile. The compound enables more precise material deposition and formation, resulting in higher yield rates and significantly less waste generation. Quantitative analyses show that for every kilogram of lithium nitride utilized in advanced manufacturing processes, approximately 3.2-4.5 kilograms of waste materials are prevented from entering the waste stream.

Toxicity assessments present a more nuanced picture. While lithium nitride itself poses certain handling challenges due to its reactivity with moisture, its application in closed manufacturing systems demonstrates lower overall ecotoxicity scores compared to alternative compounds. Environmental persistence testing indicates minimal long-term accumulation in soil and water systems when proper containment protocols are followed.

Biodiversity impact studies conducted near facilities utilizing lithium nitride technologies show neutral to positive effects when compared to baseline industrial operations. This favorable outcome is attributed to the reduced land disturbance for raw material extraction and decreased pollutant emissions associated with more efficient manufacturing processes.

Circular economy metrics reveal perhaps the most promising aspect of lithium nitride applications. The compound facilitates material recovery rates of up to 89% in certain applications, significantly outperforming conventional approaches. This high recoverability creates closed-loop systems where materials maintain their value across multiple product lifecycles, fundamentally altering the traditional linear production model.

Regulatory Framework for Lithium-Based Materials

The regulatory landscape for lithium-based materials has evolved significantly in response to growing environmental concerns and the increasing industrial importance of lithium compounds such as lithium nitride. At the international level, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and their Disposal provides a framework for managing waste containing lithium compounds, requiring proper documentation and environmentally sound management practices.

In the United States, the Environmental Protection Agency (EPA) regulates lithium-based materials under the Resource Conservation and Recovery Act (RCRA), with specific provisions for handling, storage, and disposal. The Toxic Substances Control Act (TSCA) further governs the manufacturing and importation of lithium compounds, requiring manufacturers to submit premanufacture notices for new chemical substances, including novel lithium nitride applications aimed at reducing material waste.

The European Union's regulatory approach is notably more stringent, with the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation requiring comprehensive safety data for lithium compounds. Additionally, the EU Waste Framework Directive establishes waste hierarchy principles that prioritize waste prevention and material recovery, directly supporting innovations in lithium nitride that reduce material waste. The EU Battery Directive specifically addresses the end-of-life management of lithium batteries, promoting recycling and recovery of lithium compounds.

In Asia, China has implemented the Measures for the Administration of New Chemical Substances, requiring notification and risk assessment for new lithium compounds. Japan's Chemical Substances Control Law similarly regulates the manufacture and import of lithium-based materials, with specific provisions for waste reduction technologies.

Recent regulatory trends show increasing focus on circular economy principles, with several jurisdictions developing extended producer responsibility (EPR) schemes that hold manufacturers accountable for the entire lifecycle of lithium products. These regulations increasingly recognize and incentivize technologies like advanced lithium nitride applications that demonstrate significant waste reduction potential.

Compliance challenges for industries working with lithium nitride include navigating the complex and sometimes contradictory international regulatory landscape, maintaining up-to-date safety data sheets, and adapting to rapidly evolving standards. However, these regulations also create market opportunities for technologies that can demonstrate superior environmental performance through reduced material waste, with several jurisdictions offering expedited approval processes or financial incentives for green chemistry innovations.

In the United States, the Environmental Protection Agency (EPA) regulates lithium-based materials under the Resource Conservation and Recovery Act (RCRA), with specific provisions for handling, storage, and disposal. The Toxic Substances Control Act (TSCA) further governs the manufacturing and importation of lithium compounds, requiring manufacturers to submit premanufacture notices for new chemical substances, including novel lithium nitride applications aimed at reducing material waste.

The European Union's regulatory approach is notably more stringent, with the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation requiring comprehensive safety data for lithium compounds. Additionally, the EU Waste Framework Directive establishes waste hierarchy principles that prioritize waste prevention and material recovery, directly supporting innovations in lithium nitride that reduce material waste. The EU Battery Directive specifically addresses the end-of-life management of lithium batteries, promoting recycling and recovery of lithium compounds.

In Asia, China has implemented the Measures for the Administration of New Chemical Substances, requiring notification and risk assessment for new lithium compounds. Japan's Chemical Substances Control Law similarly regulates the manufacture and import of lithium-based materials, with specific provisions for waste reduction technologies.

Recent regulatory trends show increasing focus on circular economy principles, with several jurisdictions developing extended producer responsibility (EPR) schemes that hold manufacturers accountable for the entire lifecycle of lithium products. These regulations increasingly recognize and incentivize technologies like advanced lithium nitride applications that demonstrate significant waste reduction potential.

Compliance challenges for industries working with lithium nitride include navigating the complex and sometimes contradictory international regulatory landscape, maintaining up-to-date safety data sheets, and adapting to rapidly evolving standards. However, these regulations also create market opportunities for technologies that can demonstrate superior environmental performance through reduced material waste, with several jurisdictions offering expedited approval processes or financial incentives for green chemistry innovations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!