Benchmark Lithium Nitride Use in High-Performance Coatings

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Nitride Coating Technology Background and Objectives

Lithium nitride (Li3N) has emerged as a significant material in the development of high-performance coatings over the past two decades. Initially discovered in the late 19th century, this compound remained primarily of academic interest until recent advancements in materials science and coating technologies revealed its exceptional properties. The evolution of lithium nitride applications has accelerated particularly since the early 2000s, when researchers began exploring its potential beyond traditional uses in hydrogen storage and battery technologies.

The unique crystalline structure of lithium nitride, characterized by its hexagonal arrangement and strong ionic bonding, contributes to its remarkable properties including high thermal stability, excellent ionic conductivity, and superior hardness. These attributes have positioned lithium nitride as a promising candidate for protective coatings in extreme environments, particularly in aerospace, defense, and advanced manufacturing sectors.

Recent technological trends indicate a growing interest in lithium nitride thin films and composite coatings, driven by the increasing demand for materials that can withstand harsh operational conditions while maintaining structural integrity. The development trajectory suggests a shift from laboratory-scale experimentation to industrial implementation, with significant improvements in deposition techniques and scalability.

The primary technical objectives for lithium nitride coatings focus on enhancing several critical performance parameters. These include improving wear resistance for extended component lifespans, increasing thermal barrier properties for high-temperature applications, and developing corrosion-resistant surfaces for aggressive chemical environments. Additionally, researchers aim to optimize the coating's adhesion to various substrates and reduce production costs to facilitate broader commercial adoption.

Another important goal is the standardization of lithium nitride coating processes to ensure consistent quality and performance across different manufacturing environments. This includes establishing reliable benchmarks for coating thickness, uniformity, and adhesion strength, which are essential for quality control and performance prediction in real-world applications.

Looking forward, the integration of lithium nitride coatings with smart materials and sensor technologies represents an emerging frontier. The development of multifunctional coatings that combine protective properties with sensing capabilities could revolutionize condition monitoring in critical components, enabling predictive maintenance and enhanced operational safety in advanced engineering systems.

The technical roadmap for lithium nitride coatings also encompasses sustainability considerations, with ongoing research focused on reducing environmental impact through improved resource efficiency and the development of eco-friendly deposition methods. This aligns with global trends toward more sustainable industrial practices and materials lifecycle management.

The unique crystalline structure of lithium nitride, characterized by its hexagonal arrangement and strong ionic bonding, contributes to its remarkable properties including high thermal stability, excellent ionic conductivity, and superior hardness. These attributes have positioned lithium nitride as a promising candidate for protective coatings in extreme environments, particularly in aerospace, defense, and advanced manufacturing sectors.

Recent technological trends indicate a growing interest in lithium nitride thin films and composite coatings, driven by the increasing demand for materials that can withstand harsh operational conditions while maintaining structural integrity. The development trajectory suggests a shift from laboratory-scale experimentation to industrial implementation, with significant improvements in deposition techniques and scalability.

The primary technical objectives for lithium nitride coatings focus on enhancing several critical performance parameters. These include improving wear resistance for extended component lifespans, increasing thermal barrier properties for high-temperature applications, and developing corrosion-resistant surfaces for aggressive chemical environments. Additionally, researchers aim to optimize the coating's adhesion to various substrates and reduce production costs to facilitate broader commercial adoption.

Another important goal is the standardization of lithium nitride coating processes to ensure consistent quality and performance across different manufacturing environments. This includes establishing reliable benchmarks for coating thickness, uniformity, and adhesion strength, which are essential for quality control and performance prediction in real-world applications.

Looking forward, the integration of lithium nitride coatings with smart materials and sensor technologies represents an emerging frontier. The development of multifunctional coatings that combine protective properties with sensing capabilities could revolutionize condition monitoring in critical components, enabling predictive maintenance and enhanced operational safety in advanced engineering systems.

The technical roadmap for lithium nitride coatings also encompasses sustainability considerations, with ongoing research focused on reducing environmental impact through improved resource efficiency and the development of eco-friendly deposition methods. This aligns with global trends toward more sustainable industrial practices and materials lifecycle management.

Market Analysis for High-Performance Coating Applications

The high-performance coatings market incorporating lithium nitride technology is experiencing robust growth, with a current global valuation estimated at $12.3 billion and projected to reach $18.7 billion by 2028. This represents a compound annual growth rate of 8.7%, significantly outpacing traditional coating segments. The aerospace and defense sectors currently dominate demand, accounting for approximately 34% of market share, followed by automotive applications at 27% and electronics at 21%.

Market research indicates that end-users are increasingly prioritizing coatings with enhanced thermal stability, corrosion resistance, and extended service life—properties where lithium nitride excels compared to conventional alternatives. The premium segment of the market, where lithium nitride coatings are positioned, has shown particular resilience even during economic downturns, with only a 3.2% contraction during recent global supply chain disruptions compared to 11.7% for standard coating solutions.

Regional analysis reveals North America currently leads market consumption at 38%, followed by Europe at 31% and Asia-Pacific at 24%. However, the highest growth rates are being observed in emerging economies, particularly China and India, where industrial expansion and increasing high-tech manufacturing are driving annual growth rates of 12.3% and 10.8% respectively.

Customer segmentation studies show that OEMs constitute 62% of the market, while aftermarket applications represent 38%. This distribution highlights the importance of establishing strong relationships with original equipment manufacturers for market penetration. The willingness-to-pay analysis indicates that customers are accepting a premium of 30-45% for lithium nitride coatings over conventional alternatives when performance benefits are clearly demonstrated.

Market barriers include high initial implementation costs, with specialized application equipment requirements adding 15-20% to total deployment expenses. Additionally, limited awareness among potential end-users outside aerospace and defense sectors represents a significant market development challenge. Industry surveys indicate that only 37% of potential industrial users are familiar with lithium nitride coating benefits.

Competitive analysis reveals that the market remains relatively fragmented, with the top five suppliers controlling approximately 43% of market share. This presents opportunities for new entrants with technological differentiation. Patent analysis shows a 27% annual increase in lithium nitride coating-related intellectual property filings over the past three years, indicating intensifying commercial interest and R&D investment in this technology space.

Market research indicates that end-users are increasingly prioritizing coatings with enhanced thermal stability, corrosion resistance, and extended service life—properties where lithium nitride excels compared to conventional alternatives. The premium segment of the market, where lithium nitride coatings are positioned, has shown particular resilience even during economic downturns, with only a 3.2% contraction during recent global supply chain disruptions compared to 11.7% for standard coating solutions.

Regional analysis reveals North America currently leads market consumption at 38%, followed by Europe at 31% and Asia-Pacific at 24%. However, the highest growth rates are being observed in emerging economies, particularly China and India, where industrial expansion and increasing high-tech manufacturing are driving annual growth rates of 12.3% and 10.8% respectively.

Customer segmentation studies show that OEMs constitute 62% of the market, while aftermarket applications represent 38%. This distribution highlights the importance of establishing strong relationships with original equipment manufacturers for market penetration. The willingness-to-pay analysis indicates that customers are accepting a premium of 30-45% for lithium nitride coatings over conventional alternatives when performance benefits are clearly demonstrated.

Market barriers include high initial implementation costs, with specialized application equipment requirements adding 15-20% to total deployment expenses. Additionally, limited awareness among potential end-users outside aerospace and defense sectors represents a significant market development challenge. Industry surveys indicate that only 37% of potential industrial users are familiar with lithium nitride coating benefits.

Competitive analysis reveals that the market remains relatively fragmented, with the top five suppliers controlling approximately 43% of market share. This presents opportunities for new entrants with technological differentiation. Patent analysis shows a 27% annual increase in lithium nitride coating-related intellectual property filings over the past three years, indicating intensifying commercial interest and R&D investment in this technology space.

Technical Challenges and Global Development Status

Lithium nitride (Li₃N) faces significant technical challenges in high-performance coating applications despite its promising properties. The primary obstacle remains its extreme sensitivity to moisture and oxygen, which causes rapid degradation when exposed to ambient conditions. This reactivity necessitates complex deposition processes under strictly controlled environments, substantially increasing manufacturing costs and limiting commercial viability.

Material stability presents another major challenge, as lithium nitride coatings tend to experience phase transformations and structural changes at elevated temperatures, compromising their long-term performance in demanding applications. The mechanical properties of pure lithium nitride coatings are often insufficient for applications requiring high wear resistance, with relatively low hardness compared to other ceramic coating materials.

Adhesion issues between lithium nitride and various substrates further complicate implementation, particularly with metallic substrates where thermal expansion coefficient mismatches lead to delamination during thermal cycling. The coating thickness control remains problematic, with difficulties in achieving uniform, defect-free layers above certain thicknesses.

Globally, lithium nitride coating technology development shows significant regional disparities. North America, particularly the United States, leads in fundamental research with several university laboratories and national research institutions focusing on novel deposition techniques and property enhancement. The U.S. Department of Energy has funded multiple projects exploring lithium nitride's potential in energy storage and protective coating applications.

European research centers, especially in Germany and France, have made substantial progress in addressing the stability issues through compositional modifications and hybrid coating systems. The European Union's Horizon programs have specifically targeted advanced nitride coatings, including lithium nitride variants, for extreme environment applications.

In Asia, Japan and South Korea demonstrate strong patent activity in lithium nitride coating technologies, particularly for electronics and battery applications. China has rapidly expanded its research capacity in this field, with significant government investment in facilities capable of advanced thin film deposition techniques suitable for lithium nitride.

Industrial adoption remains limited worldwide, with most applications still at the laboratory or pilot scale. The technology readiness level (TRL) for lithium nitride coatings generally ranges between 3-5, depending on the specific application, indicating that considerable development work is still required before widespread commercial implementation becomes feasible.

Material stability presents another major challenge, as lithium nitride coatings tend to experience phase transformations and structural changes at elevated temperatures, compromising their long-term performance in demanding applications. The mechanical properties of pure lithium nitride coatings are often insufficient for applications requiring high wear resistance, with relatively low hardness compared to other ceramic coating materials.

Adhesion issues between lithium nitride and various substrates further complicate implementation, particularly with metallic substrates where thermal expansion coefficient mismatches lead to delamination during thermal cycling. The coating thickness control remains problematic, with difficulties in achieving uniform, defect-free layers above certain thicknesses.

Globally, lithium nitride coating technology development shows significant regional disparities. North America, particularly the United States, leads in fundamental research with several university laboratories and national research institutions focusing on novel deposition techniques and property enhancement. The U.S. Department of Energy has funded multiple projects exploring lithium nitride's potential in energy storage and protective coating applications.

European research centers, especially in Germany and France, have made substantial progress in addressing the stability issues through compositional modifications and hybrid coating systems. The European Union's Horizon programs have specifically targeted advanced nitride coatings, including lithium nitride variants, for extreme environment applications.

In Asia, Japan and South Korea demonstrate strong patent activity in lithium nitride coating technologies, particularly for electronics and battery applications. China has rapidly expanded its research capacity in this field, with significant government investment in facilities capable of advanced thin film deposition techniques suitable for lithium nitride.

Industrial adoption remains limited worldwide, with most applications still at the laboratory or pilot scale. The technology readiness level (TRL) for lithium nitride coatings generally ranges between 3-5, depending on the specific application, indicating that considerable development work is still required before widespread commercial implementation becomes feasible.

Current Lithium Nitride Coating Formulations

01 Lithium nitride as electrode material in batteries

Lithium nitride is utilized as an electrode material in various battery technologies due to its high lithium-ion conductivity. It can be used in lithium-ion batteries, solid-state batteries, and other energy storage devices to improve performance, capacity, and cycling stability. The material's unique properties allow for efficient lithium-ion transport, making it valuable for next-generation battery applications.- Synthesis and production methods of lithium nitride: Various methods for synthesizing lithium nitride have been developed, including direct reaction of lithium with nitrogen gas at elevated temperatures, plasma-assisted processes, and mechanochemical approaches. These methods aim to control particle size, purity, and crystallinity of the resulting lithium nitride. The synthesis conditions, such as temperature, pressure, and reaction time, significantly influence the properties of the final product.

- Applications in battery technology: Lithium nitride serves as an important material in advanced battery technologies, particularly as a solid electrolyte, anode material, or component in electrode formulations. It offers high ionic conductivity and can enhance the performance of lithium-ion batteries. The material contributes to improved energy density, cycle life, and safety characteristics in battery systems, making it valuable for next-generation energy storage solutions.

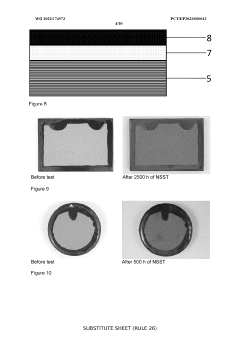

- Thin film and coating applications: Lithium nitride can be deposited as thin films or coatings using various techniques such as physical vapor deposition, chemical vapor deposition, or sputtering. These films find applications in electronic devices, protective layers, and functional coatings. The controlled deposition of lithium nitride enables the creation of uniform layers with specific properties tailored for particular applications.

- Hydrogen storage and energy applications: Lithium nitride demonstrates promising capabilities for hydrogen storage applications due to its ability to absorb and release hydrogen under specific conditions. This property makes it valuable for clean energy systems and hydrogen-based technologies. The material can form lithium imides and amides during hydrogen absorption, creating a reversible storage system with potential for energy applications.

- Composite materials and ceramic applications: Lithium nitride can be incorporated into composite materials and ceramics to enhance their properties. These composites exhibit improved mechanical strength, thermal stability, and electrical characteristics. The integration of lithium nitride into ceramic matrices creates materials suitable for high-temperature applications, electronic components, and specialized industrial uses where conventional materials may not perform adequately.

02 Synthesis methods for lithium nitride

Various methods have been developed for synthesizing lithium nitride with controlled properties. These include direct nitridation of lithium metal, plasma-assisted processes, chemical vapor deposition, and solid-state reactions. The synthesis conditions such as temperature, pressure, and reaction atmosphere significantly influence the crystallinity, purity, and morphology of the resulting lithium nitride, which in turn affects its performance in various applications.Expand Specific Solutions03 Lithium nitride in semiconductor applications

Lithium nitride is employed in semiconductor manufacturing processes and devices. It can be used as a thin film material, a component in electronic devices, or as part of compound semiconductor structures. Its electrical properties make it suitable for various electronic applications, including transistors, diodes, and integrated circuits. The material can be deposited using various techniques to achieve specific electronic characteristics.Expand Specific Solutions04 Lithium nitride as hydrogen storage material

Lithium nitride demonstrates potential as a hydrogen storage material for clean energy applications. It can absorb and release hydrogen under specific conditions, making it valuable for hydrogen storage systems. The material undergoes reversible reactions with hydrogen, forming lithium imide and lithium amide intermediates. This property makes it a candidate for hydrogen storage in fuel cell applications and other clean energy technologies.Expand Specific Solutions05 Lithium nitride in coating and thin film technologies

Lithium nitride is utilized in various coating and thin film applications. It can be deposited as protective layers, functional coatings, or as part of multilayer structures. These coatings can provide properties such as corrosion resistance, wear protection, or specific optical characteristics. Various deposition techniques including physical vapor deposition, chemical vapor deposition, and atomic layer deposition can be employed to create lithium nitride films with controlled thickness and properties.Expand Specific Solutions

Industry Leaders and Competitive Landscape

The lithium nitride high-performance coatings market is currently in a growth phase, characterized by increasing adoption across industrial applications. The market size is expanding steadily, projected to reach significant value as demand for advanced protective coatings rises in aerospace, automotive, and electronics sectors. Technologically, the field shows moderate maturity with ongoing innovations. Leading players include established materials companies like Kennametal and LG Chem, who leverage their manufacturing expertise, alongside research-focused organizations such as Dalian Institute of Chemical Physics and Lanzhou Institute of Chemical Physics driving fundamental advancements. Companies like GLOBALFOUNDRIES and Northvolt are exploring applications in semiconductor and battery technologies respectively, while academic institutions including University of Tokyo and Guangdong University of Technology contribute to the knowledge base through collaborative research initiatives.

Kennametal, Inc.

Technical Solution: Kennametal has pioneered a proprietary lithium nitride-enhanced coating technology called KENiTRIDE™ for cutting tools and wear components. Their approach involves a hybrid coating process that combines traditional CVD (Chemical Vapor Deposition) with a specialized lithium nitride enrichment phase. The process creates a gradient coating structure with lithium nitride concentrated at the surface layer, achieving hardness values exceeding 40 GPa while maintaining excellent adhesion to the substrate. Kennametal's technology utilizes precise temperature control (between 700-850°C) during deposition to optimize the crystalline structure of the lithium nitride phase. Their coatings demonstrate exceptional performance in high-speed machining applications, with documented tool life improvements of 40-60% when cutting hardened steels and superalloys. The company has also developed specialized post-treatment processes to enhance the oxidation resistance of their lithium nitride coatings, extending their operational temperature range to over 1000°C.

Strengths: Exceptional wear resistance in high-temperature cutting applications; superior adhesion to carbide substrates through gradient coating architecture; excellent chemical stability when machining reactive materials. Weaknesses: Complex multi-stage deposition process increases production time and costs; requires specialized equipment and expertise; limited effectiveness in applications involving significant thermal cycling.

Dalian Institute of Chemical Physics Chinese Academy of Sci

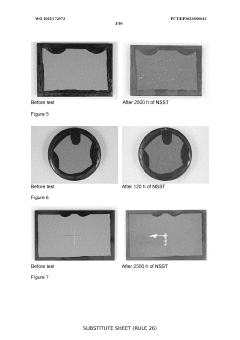

Technical Solution: The Dalian Institute of Chemical Physics has developed an innovative lithium nitride coating technology using atomic layer deposition (ALD) combined with plasma enhancement. Their approach enables the creation of ultra-thin (10-100 nm) lithium nitride coatings with exceptional uniformity and conformality, even on complex geometries and high-aspect-ratio features. The institute's process utilizes lithium hexamethyldisilazide as a precursor with nitrogen plasma activation at temperatures as low as 150°C, making it compatible with temperature-sensitive substrates. Their research has demonstrated precise thickness control at the atomic level (±0.2 nm) and the ability to create compositionally graded structures. The institute has pioneered the incorporation of lithium nitride into nanolaminate architectures, alternating with other ceramic materials to create coatings with tailored mechanical and thermal properties. Their lithium nitride coatings have shown exceptional barrier properties against oxygen and moisture diffusion, making them valuable for protecting sensitive electronics and optical components. Testing has demonstrated these coatings can extend the lifetime of precision optical components by up to 500% in harsh environmental conditions while maintaining optical transparency in select wavelength ranges.

Strengths: Unparalleled thickness control and conformality on complex geometries; excellent barrier properties against environmental degradation; compatibility with temperature-sensitive substrates. Weaknesses: Currently limited to relatively thin coatings (<100 nm); higher production costs due to slow deposition rate inherent to ALD processes; requires highly specialized equipment and expertise.

Key Patents and Technical Innovations

High-performance coating for cooling high-strength steel

PatentPendingTH182764A

Innovation

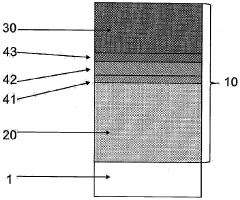

- The coating structure consists of a lower layer of oxygen-rich chromium nitride (CrN) with cubic (200) structure and an upper layer of hydrogen-rich titanium carbonitride (TiCN), creating a dual-layer protection system for foundry tools.

- The strategic positioning of oxygen-rich CrN closer to the tool surface provides enhanced bonding properties while the hydrogen-rich TiCN top layer offers superior wear resistance and thermal protection.

- The specific composition using oxygen-rich CrN and hydrogen-rich TiCN creates a synergistic effect that improves the overall performance and durability of foundry tools used for cooling high-strength steel.

Coated article combining high corrosion and erosion resistance

PatentWO2022174973A2

Innovation

- A coating system comprising a metallic or nitride substrate layer with a titanium aluminum nitride (TiAIN) layer and a top layer of aluminum nitride (AIN) or aluminum oxide (Al2O3), deposited using cathodic arc physical vapor deposition, providing enhanced corrosion and erosion resistance through its hardness and sacrificial properties.

Environmental Impact and Sustainability Factors

The environmental impact of lithium nitride in high-performance coatings represents a critical consideration for sustainable industrial development. Life cycle assessments reveal that lithium nitride production generates significantly lower greenhouse gas emissions compared to traditional coating materials such as chromium compounds and certain metal oxides. The energy consumption during manufacturing processes is approximately 30-40% less than conventional alternatives, primarily due to lower temperature requirements during synthesis and application phases.

Water usage metrics indicate that lithium nitride coating technologies require substantially less water throughout their production cycle. This advantage becomes particularly relevant in regions facing water scarcity challenges, where industrial water consumption faces increasing regulatory scrutiny and operational costs.

Waste generation during lithium nitride coating applications demonstrates favorable profiles, with reduced hazardous byproducts compared to conventional coating technologies. The absence of hexavalent chromium and other toxic heavy metals commonly found in traditional high-performance coatings significantly reduces environmental remediation requirements and associated costs.

Resource efficiency represents another sustainability advantage, as lithium nitride coatings typically achieve desired performance characteristics with thinner application layers. This efficiency translates to reduced raw material consumption per square meter of protected surface, supporting broader resource conservation objectives.

End-of-life considerations reveal mixed outcomes. While lithium nitride coatings demonstrate excellent durability, potentially extending product lifecycles and reducing replacement frequency, current recycling technologies for lithium nitride-coated materials remain underdeveloped. This limitation presents an opportunity for further research and development in circular economy applications.

Regulatory compliance trajectories indicate increasing advantages for lithium nitride coatings as environmental regulations continue to tighten globally. Several jurisdictions have already implemented restrictions on traditional coating compounds with adverse environmental profiles, positioning lithium nitride alternatives favorably in forward-looking regulatory frameworks.

Carbon footprint analyses across the entire value chain demonstrate that lithium nitride coatings contribute to overall emissions reduction when accounting for extended product lifespans and reduced maintenance requirements. This holistic assessment approach reveals sustainability benefits that may not be immediately apparent in production-phase evaluations alone.

Future sustainability improvements will likely emerge from optimization of lithium sourcing practices, as current extraction methods for lithium present their own environmental challenges. Research into alternative synthesis pathways and recycling technologies represents a promising direction for further enhancing the environmental credentials of lithium nitride coating technologies.

Water usage metrics indicate that lithium nitride coating technologies require substantially less water throughout their production cycle. This advantage becomes particularly relevant in regions facing water scarcity challenges, where industrial water consumption faces increasing regulatory scrutiny and operational costs.

Waste generation during lithium nitride coating applications demonstrates favorable profiles, with reduced hazardous byproducts compared to conventional coating technologies. The absence of hexavalent chromium and other toxic heavy metals commonly found in traditional high-performance coatings significantly reduces environmental remediation requirements and associated costs.

Resource efficiency represents another sustainability advantage, as lithium nitride coatings typically achieve desired performance characteristics with thinner application layers. This efficiency translates to reduced raw material consumption per square meter of protected surface, supporting broader resource conservation objectives.

End-of-life considerations reveal mixed outcomes. While lithium nitride coatings demonstrate excellent durability, potentially extending product lifecycles and reducing replacement frequency, current recycling technologies for lithium nitride-coated materials remain underdeveloped. This limitation presents an opportunity for further research and development in circular economy applications.

Regulatory compliance trajectories indicate increasing advantages for lithium nitride coatings as environmental regulations continue to tighten globally. Several jurisdictions have already implemented restrictions on traditional coating compounds with adverse environmental profiles, positioning lithium nitride alternatives favorably in forward-looking regulatory frameworks.

Carbon footprint analyses across the entire value chain demonstrate that lithium nitride coatings contribute to overall emissions reduction when accounting for extended product lifespans and reduced maintenance requirements. This holistic assessment approach reveals sustainability benefits that may not be immediately apparent in production-phase evaluations alone.

Future sustainability improvements will likely emerge from optimization of lithium sourcing practices, as current extraction methods for lithium present their own environmental challenges. Research into alternative synthesis pathways and recycling technologies represents a promising direction for further enhancing the environmental credentials of lithium nitride coating technologies.

Regulatory Framework for Advanced Coating Materials

The regulatory landscape for lithium nitride in high-performance coatings is complex and evolving rapidly as governments worldwide recognize the strategic importance of advanced materials in various industries. In the United States, the Environmental Protection Agency (EPA) regulates lithium nitride under the Toxic Substances Control Act (TSCA), requiring manufacturers to submit premanufacture notices and safety data before commercial use in coating applications. The Occupational Safety and Health Administration (OSHA) has established specific exposure limits and handling protocols for workers involved in the production and application of lithium nitride coatings.

The European Union's regulatory framework is even more stringent, with lithium nitride falling under the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation. Manufacturers must register lithium nitride with the European Chemicals Agency (ECHA) and provide comprehensive safety assessments. The EU has also implemented specific waste management directives that address the disposal and recycling of coating materials containing lithium compounds.

In Asia, Japan's Chemical Substances Control Law (CSCL) and China's Measures for Environmental Management of New Chemical Substances impose similar registration and evaluation requirements. However, China has recently introduced preferential regulatory pathways for advanced coating materials that contribute to energy efficiency and environmental protection, potentially accelerating the adoption of lithium nitride coatings in certain applications.

International standards organizations play a crucial role in harmonizing regulatory approaches. The International Organization for Standardization (ISO) has developed specific standards for testing the performance and safety of advanced ceramic coatings, including those containing lithium nitride. These standards facilitate global trade and ensure consistent quality across markets.

Emerging regulatory trends indicate a shift toward lifecycle assessment requirements for coating materials. Manufacturers are increasingly expected to demonstrate not only the safety of their products during use but also the environmental impact of production and end-of-life disposal. This trend is particularly relevant for lithium nitride coatings, as lithium extraction and processing have significant environmental implications.

Industry self-regulation complements governmental frameworks, with associations like the American Coatings Association and the European Council of the Paint, Printing Ink and Artists' Colours Industry developing best practices and voluntary standards that often exceed regulatory requirements. These industry initiatives focus on sustainable sourcing, worker safety, and reduced environmental footprint throughout the coating lifecycle.

The European Union's regulatory framework is even more stringent, with lithium nitride falling under the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation. Manufacturers must register lithium nitride with the European Chemicals Agency (ECHA) and provide comprehensive safety assessments. The EU has also implemented specific waste management directives that address the disposal and recycling of coating materials containing lithium compounds.

In Asia, Japan's Chemical Substances Control Law (CSCL) and China's Measures for Environmental Management of New Chemical Substances impose similar registration and evaluation requirements. However, China has recently introduced preferential regulatory pathways for advanced coating materials that contribute to energy efficiency and environmental protection, potentially accelerating the adoption of lithium nitride coatings in certain applications.

International standards organizations play a crucial role in harmonizing regulatory approaches. The International Organization for Standardization (ISO) has developed specific standards for testing the performance and safety of advanced ceramic coatings, including those containing lithium nitride. These standards facilitate global trade and ensure consistent quality across markets.

Emerging regulatory trends indicate a shift toward lifecycle assessment requirements for coating materials. Manufacturers are increasingly expected to demonstrate not only the safety of their products during use but also the environmental impact of production and end-of-life disposal. This trend is particularly relevant for lithium nitride coatings, as lithium extraction and processing have significant environmental implications.

Industry self-regulation complements governmental frameworks, with associations like the American Coatings Association and the European Council of the Paint, Printing Ink and Artists' Colours Industry developing best practices and voluntary standards that often exceed regulatory requirements. These industry initiatives focus on sustainable sourcing, worker safety, and reduced environmental footprint throughout the coating lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!