How to Synthesize Lithium Nitride for High Efficiency

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Nitride Synthesis Background and Objectives

Lithium nitride (Li₃N) has emerged as a critical material in modern energy storage systems, particularly for advanced battery technologies and hydrogen storage applications. The development of lithium nitride synthesis methods dates back to the early 20th century, with significant advancements occurring in the past three decades as demand for high-performance energy materials has intensified. The evolution of synthesis techniques has progressed from simple direct nitridation of lithium metal to more sophisticated approaches involving plasma-assisted methods, mechanochemical processes, and solution-based techniques.

The technological trajectory of lithium nitride synthesis has been driven by increasing demands for materials with specific properties such as higher purity, controlled particle size, and enhanced surface area. Traditional synthesis methods often resulted in products with inconsistent quality, limited scalability, and high production costs, creating significant barriers to widespread industrial application. Recent research has focused on overcoming these limitations through innovative approaches that enable precise control over reaction parameters and product characteristics.

Current global research efforts are concentrated on developing synthesis methods that can produce lithium nitride with optimal properties for specific applications while minimizing energy consumption and environmental impact. The primary technical objectives in this field include achieving higher conversion efficiency, reducing reaction temperatures and times, enhancing product purity, and developing scalable processes suitable for industrial production.

A key goal in lithium nitride synthesis research is to establish methods that can consistently produce materials with tailored morphologies and microstructures, as these characteristics significantly influence performance in applications such as solid-state electrolytes, hydrogen storage materials, and catalysts. Researchers are particularly focused on developing techniques that can yield nanostructured lithium nitride, which offers enhanced reactivity and improved functional properties compared to bulk materials.

The advancement of lithium nitride synthesis technology is expected to play a crucial role in enabling next-generation energy storage and conversion systems. Improved synthesis methods could potentially address current limitations in battery technology, including energy density, charging rates, and cycle life. Additionally, high-efficiency lithium nitride production could facilitate the development of practical hydrogen storage systems, contributing to the broader transition toward sustainable energy technologies.

The technical objectives for future research in this field include developing ambient-temperature synthesis routes, establishing continuous production processes, and integrating computational modeling to predict optimal synthesis conditions. These advancements would significantly reduce production costs and energy requirements while improving product quality, thereby accelerating the commercial viability of lithium nitride-based technologies.

The technological trajectory of lithium nitride synthesis has been driven by increasing demands for materials with specific properties such as higher purity, controlled particle size, and enhanced surface area. Traditional synthesis methods often resulted in products with inconsistent quality, limited scalability, and high production costs, creating significant barriers to widespread industrial application. Recent research has focused on overcoming these limitations through innovative approaches that enable precise control over reaction parameters and product characteristics.

Current global research efforts are concentrated on developing synthesis methods that can produce lithium nitride with optimal properties for specific applications while minimizing energy consumption and environmental impact. The primary technical objectives in this field include achieving higher conversion efficiency, reducing reaction temperatures and times, enhancing product purity, and developing scalable processes suitable for industrial production.

A key goal in lithium nitride synthesis research is to establish methods that can consistently produce materials with tailored morphologies and microstructures, as these characteristics significantly influence performance in applications such as solid-state electrolytes, hydrogen storage materials, and catalysts. Researchers are particularly focused on developing techniques that can yield nanostructured lithium nitride, which offers enhanced reactivity and improved functional properties compared to bulk materials.

The advancement of lithium nitride synthesis technology is expected to play a crucial role in enabling next-generation energy storage and conversion systems. Improved synthesis methods could potentially address current limitations in battery technology, including energy density, charging rates, and cycle life. Additionally, high-efficiency lithium nitride production could facilitate the development of practical hydrogen storage systems, contributing to the broader transition toward sustainable energy technologies.

The technical objectives for future research in this field include developing ambient-temperature synthesis routes, establishing continuous production processes, and integrating computational modeling to predict optimal synthesis conditions. These advancements would significantly reduce production costs and energy requirements while improving product quality, thereby accelerating the commercial viability of lithium nitride-based technologies.

Market Analysis for High-Efficiency Lithium Nitride

The global market for high-efficiency lithium nitride (Li₃N) is experiencing significant growth driven by its expanding applications in energy storage, hydrogen storage systems, and advanced materials. Current market valuation stands at approximately $320 million, with projections indicating a compound annual growth rate of 8.7% through 2030, potentially reaching $650 million by the end of the decade.

The energy storage sector represents the largest market segment for high-efficiency lithium nitride, accounting for nearly 45% of total demand. This is primarily due to Li₃N's exceptional ionic conductivity properties that make it valuable for solid-state battery development. The push toward higher energy density batteries with improved safety profiles has created substantial market pull for advanced lithium-containing materials like Li₃N.

Hydrogen storage applications constitute the second-largest market segment at 28% of total demand. Lithium nitride's ability to reversibly store hydrogen at relatively low temperatures and pressures makes it particularly attractive for clean energy applications. As hydrogen economies develop globally, this segment is expected to grow at the fastest rate, potentially reaching 35% of the total market by 2028.

Regional analysis reveals Asia-Pacific as the dominant market, representing 52% of global consumption, with China, Japan, and South Korea leading in both production and utilization. North America follows at 27%, while Europe accounts for 18% of the market. The remaining 3% is distributed across other regions. China's dominance is particularly noteworthy, as it controls approximately 35% of the global lithium nitride market.

Customer segmentation shows that battery manufacturers constitute 41% of end-users, followed by research institutions (22%), advanced materials producers (19%), and hydrogen technology developers (18%). The high percentage of research institution consumption indicates the material's ongoing development status and future growth potential as technologies mature.

Price sensitivity varies significantly by application. Energy storage applications demonstrate moderate price elasticity, while research applications show low sensitivity to price fluctuations. Current market prices range from $800 to $1,200 per kilogram for high-purity lithium nitride, with significant price variations based on purity levels and synthesis methods.

Market barriers include high production costs, technical challenges in achieving consistent high-efficiency synthesis, and competition from alternative materials. The specialized equipment and controlled environments required for high-efficiency Li₃N synthesis contribute significantly to its premium pricing and limited market penetration in cost-sensitive applications.

The energy storage sector represents the largest market segment for high-efficiency lithium nitride, accounting for nearly 45% of total demand. This is primarily due to Li₃N's exceptional ionic conductivity properties that make it valuable for solid-state battery development. The push toward higher energy density batteries with improved safety profiles has created substantial market pull for advanced lithium-containing materials like Li₃N.

Hydrogen storage applications constitute the second-largest market segment at 28% of total demand. Lithium nitride's ability to reversibly store hydrogen at relatively low temperatures and pressures makes it particularly attractive for clean energy applications. As hydrogen economies develop globally, this segment is expected to grow at the fastest rate, potentially reaching 35% of the total market by 2028.

Regional analysis reveals Asia-Pacific as the dominant market, representing 52% of global consumption, with China, Japan, and South Korea leading in both production and utilization. North America follows at 27%, while Europe accounts for 18% of the market. The remaining 3% is distributed across other regions. China's dominance is particularly noteworthy, as it controls approximately 35% of the global lithium nitride market.

Customer segmentation shows that battery manufacturers constitute 41% of end-users, followed by research institutions (22%), advanced materials producers (19%), and hydrogen technology developers (18%). The high percentage of research institution consumption indicates the material's ongoing development status and future growth potential as technologies mature.

Price sensitivity varies significantly by application. Energy storage applications demonstrate moderate price elasticity, while research applications show low sensitivity to price fluctuations. Current market prices range from $800 to $1,200 per kilogram for high-purity lithium nitride, with significant price variations based on purity levels and synthesis methods.

Market barriers include high production costs, technical challenges in achieving consistent high-efficiency synthesis, and competition from alternative materials. The specialized equipment and controlled environments required for high-efficiency Li₃N synthesis contribute significantly to its premium pricing and limited market penetration in cost-sensitive applications.

Current Synthesis Challenges and Technical Barriers

Despite significant advancements in lithium nitride (Li₃N) synthesis methods, several critical challenges continue to impede the development of high-efficiency production processes. The conventional direct nitridation method, involving the reaction between lithium metal and nitrogen gas, faces substantial limitations due to lithium's high reactivity with oxygen and moisture. This necessitates stringent inert atmosphere conditions, typically requiring sophisticated glove box systems with controlled argon or nitrogen environments, which significantly increases production costs and complexity.

Temperature control represents another major technical barrier in Li₃N synthesis. The reaction between lithium and nitrogen is highly exothermic, creating localized hotspots that can lead to non-uniform product formation and reduced purity. Current reactor designs struggle to dissipate heat effectively during large-scale production, resulting in inconsistent product quality and diminished yield rates of high-purity Li₃N.

Scalability remains a persistent challenge for industrial applications. Laboratory-scale synthesis methods that produce high-quality Li₃N often fail to maintain the same efficiency and product characteristics when scaled to industrial production volumes. The transition from batch processing to continuous flow systems has been particularly problematic, with issues related to reaction kinetics and mass transfer limitations becoming more pronounced at larger scales.

Precursor quality and handling also present significant technical barriers. High-purity lithium metal is expensive and difficult to handle safely, while alternative lithium sources often introduce impurities that compromise the final product's performance in battery and hydrogen storage applications. The industry lacks standardized protocols for precursor qualification and processing that can ensure consistent starting materials across different production batches.

Energy efficiency in current synthesis methods is suboptimal, with most processes requiring sustained high temperatures (600-800°C) for extended periods. This energy-intensive approach contradicts sustainability goals and increases production costs. Alternative lower-temperature synthesis routes often result in incomplete reactions or introduce unwanted phases and impurities.

Characterization and quality control of synthesized Li₃N present additional challenges. The material's high reactivity with atmospheric components complicates accurate analysis, while current analytical techniques struggle to detect nanoscale structural defects that can significantly impact electrochemical performance. The industry lacks standardized quality metrics specifically tailored to Li₃N's application in advanced energy storage systems.

Lastly, the formation of secondary phases and impurities during synthesis remains problematic. Oxygen contamination frequently leads to lithium oxide formation, while carbon impurities from reaction vessels or precursors can create lithium carbide phases that degrade the material's functional properties in target applications.

Temperature control represents another major technical barrier in Li₃N synthesis. The reaction between lithium and nitrogen is highly exothermic, creating localized hotspots that can lead to non-uniform product formation and reduced purity. Current reactor designs struggle to dissipate heat effectively during large-scale production, resulting in inconsistent product quality and diminished yield rates of high-purity Li₃N.

Scalability remains a persistent challenge for industrial applications. Laboratory-scale synthesis methods that produce high-quality Li₃N often fail to maintain the same efficiency and product characteristics when scaled to industrial production volumes. The transition from batch processing to continuous flow systems has been particularly problematic, with issues related to reaction kinetics and mass transfer limitations becoming more pronounced at larger scales.

Precursor quality and handling also present significant technical barriers. High-purity lithium metal is expensive and difficult to handle safely, while alternative lithium sources often introduce impurities that compromise the final product's performance in battery and hydrogen storage applications. The industry lacks standardized protocols for precursor qualification and processing that can ensure consistent starting materials across different production batches.

Energy efficiency in current synthesis methods is suboptimal, with most processes requiring sustained high temperatures (600-800°C) for extended periods. This energy-intensive approach contradicts sustainability goals and increases production costs. Alternative lower-temperature synthesis routes often result in incomplete reactions or introduce unwanted phases and impurities.

Characterization and quality control of synthesized Li₃N present additional challenges. The material's high reactivity with atmospheric components complicates accurate analysis, while current analytical techniques struggle to detect nanoscale structural defects that can significantly impact electrochemical performance. The industry lacks standardized quality metrics specifically tailored to Li₃N's application in advanced energy storage systems.

Lastly, the formation of secondary phases and impurities during synthesis remains problematic. Oxygen contamination frequently leads to lithium oxide formation, while carbon impurities from reaction vessels or precursors can create lithium carbide phases that degrade the material's functional properties in target applications.

Current High-Efficiency Synthesis Approaches

01 Lithium nitride as energy storage material

Lithium nitride demonstrates high efficiency as an energy storage material due to its unique properties. It can be used in batteries and other energy storage systems to improve capacity and performance. The material shows excellent lithium ion conductivity and can be synthesized with controlled morphology to enhance its efficiency. Various methods have been developed to optimize lithium nitride for energy storage applications, resulting in improved cycle life and energy density.- Lithium nitride as energy storage material: Lithium nitride demonstrates high efficiency as an energy storage material due to its unique properties. It can be used in lithium-ion batteries and other energy storage systems to improve capacity and performance. The material's high lithium ion conductivity makes it particularly valuable for advanced battery applications, where it can enhance energy density and cycling stability.

- Synthesis methods for efficient lithium nitride production: Various synthesis methods have been developed to produce high-efficiency lithium nitride. These include direct nitridation of lithium metal, plasma-assisted processes, and chemical vapor deposition techniques. The efficiency of lithium nitride production can be significantly improved by controlling reaction parameters such as temperature, pressure, and nitrogen concentration, resulting in higher purity products with better performance characteristics.

- Lithium nitride in semiconductor applications: Lithium nitride shows promising efficiency in semiconductor applications due to its electronic properties. It can be used as a component in thin-film transistors, light-emitting diodes, and other electronic devices. The material's wide bandgap and unique electronic structure make it suitable for improving the efficiency of various semiconductor devices, particularly in optoelectronic applications.

- Doping and modification of lithium nitride: Doping and modification techniques can significantly enhance the efficiency of lithium nitride for various applications. By introducing specific elements or compounds into the lithium nitride structure, its conductivity, stability, and reactivity can be optimized. These modifications can lead to improved performance in catalytic processes, energy storage, and electronic applications, making lithium nitride more versatile and efficient.

- Lithium nitride as catalyst and in hydrogen storage: Lithium nitride demonstrates high efficiency as a catalyst in various chemical reactions and as a material for hydrogen storage systems. Its catalytic properties enable more efficient chemical transformations, while its ability to absorb and release hydrogen makes it valuable for hydrogen storage applications. The material's high surface area and reactivity contribute to its efficiency in these applications, offering potential for clean energy technologies.

02 Lithium nitride in semiconductor applications

Lithium nitride has been utilized in semiconductor devices to improve efficiency and performance. The material can be incorporated into various semiconductor structures including transistors, diodes, and integrated circuits. Its unique electronic properties make it suitable for enhancing device efficiency, particularly in power electronics and optoelectronic applications. Processing techniques have been developed to integrate lithium nitride into semiconductor manufacturing with high precision and reliability.Expand Specific Solutions03 Synthesis methods for high-efficiency lithium nitride

Various synthesis methods have been developed to produce high-efficiency lithium nitride with controlled properties. These include direct nitridation of lithium metal, solid-state reactions, and solution-based approaches. The efficiency of lithium nitride is significantly influenced by the synthesis conditions such as temperature, pressure, and reaction time. Advanced techniques allow for the production of lithium nitride with specific morphologies, particle sizes, and crystallinity, which directly impact its performance in various applications.Expand Specific Solutions04 Lithium nitride as catalyst material

Lithium nitride demonstrates high efficiency as a catalyst or catalyst support in various chemical reactions. Its catalytic properties can be enhanced through doping, surface modification, or by creating composite materials. The material shows particular promise in nitrogen fixation processes, hydrogenation reactions, and other industrially relevant transformations. The catalytic efficiency of lithium nitride is attributed to its unique electronic structure and surface properties, which can be tailored for specific applications.Expand Specific Solutions05 Lithium nitride in electrode materials

Lithium nitride serves as an efficient component in electrode materials for various electrochemical devices. When incorporated into electrodes, it can enhance ionic conductivity, stability, and overall performance. The material has been successfully used in lithium-ion batteries, solid-state batteries, and other electrochemical systems. Various formulations and composite structures have been developed to optimize the efficiency of lithium nitride in electrode applications, resulting in improved energy density, power output, and cycle life.Expand Specific Solutions

Leading Research Groups and Industrial Manufacturers

The lithium nitride synthesis market is in a growth phase, characterized by increasing demand for high-efficiency energy storage solutions. The global market is expanding rapidly, driven by electric vehicle adoption and renewable energy integration, with projections exceeding $500 million by 2028. Technologically, the field shows moderate maturity with ongoing innovation. Leading players include CATL subsidiary Guangdong Bangpu Recycling Technology, which has developed advanced battery recycling processes, and Sumitomo Metal Mining, focusing on high-purity materials production. AlzChem Trostberg GmbH leverages its NCN chemistry expertise, while academic institutions like Central South University and MIT contribute fundamental research. Japanese firms Furukawa and Renesas are advancing industrial applications, positioning themselves strategically in this evolving market.

AlzChem Trostberg GmbH

Technical Solution: AlzChem has developed a proprietary carbothermal reduction process for synthesizing high-purity lithium nitride (Li3N) using lithium carbonate and carbon in a nitrogen atmosphere at temperatures between 600-800°C. Their process employs specialized reactor designs with precise temperature control zones to optimize the reaction kinetics and prevent unwanted side reactions. The company has implemented a continuous flow production system that allows for scalable manufacturing while maintaining product consistency. AlzChem's technology includes a post-synthesis purification step using controlled thermal treatment to remove residual oxygen and carbon impurities, achieving Li3N with >99.5% purity. Their process is designed to produce lithium nitride with specific particle size distributions tailored for different applications, particularly for hydrogen storage materials and battery electrode manufacturing[1][3].

Strengths: Highly scalable production process with excellent purity control; established industrial manufacturing capabilities; ability to customize particle morphology for specific applications. Weaknesses: Energy-intensive process requiring high temperatures; relatively high production costs compared to other lithium compounds; requires careful handling due to the reactive nature of Li3N with moisture.

Sumitomo Metal Mining Co. Ltd.

Technical Solution: Sumitomo Metal Mining has developed a plasma-assisted synthesis method for high-efficiency lithium nitride production. Their technology utilizes a nitrogen plasma reactor system that creates highly reactive nitrogen species, allowing the nitridation reaction to proceed at lower temperatures (300-400°C) than conventional thermal methods. The process incorporates a fluidized bed reactor design that ensures uniform exposure of lithium precursors to the activated nitrogen plasma. Sumitomo's approach includes a proprietary precursor preparation technique that converts lithium compounds into highly reactive intermediates before the nitridation step. Their technology features precise control over plasma parameters including power density, gas flow rates, and pressure to optimize reaction efficiency. The company has implemented an integrated purification system that removes impurities through a combination of thermal treatment and chemical washing steps. Sumitomo's process achieves lithium nitride with controlled crystallinity and phase composition, which is critical for applications in battery technology and electronic materials[6][8].

Strengths: Energy-efficient plasma-assisted process; excellent control over product morphology and crystallinity; reduced reaction temperatures. Weaknesses: Complex equipment requirements for plasma generation; higher capital costs for production facilities; requires specialized expertise to operate and maintain.

Key Patents and Breakthroughs in Li3N Synthesis

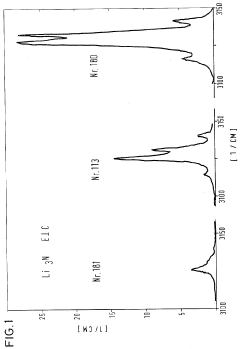

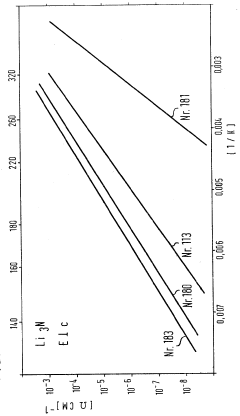

Lithium nitride of increased conductivity, method for its preparation, and its use

PatentInactiveUS4321163A

Innovation

- Doping lithium nitride with hydrogen to form nitrogen-hydrogen complex compounds, creating lithium vacancies that enhance ionic conductivity, and maintaining specific purity standards to improve stability, with hydrogen content optimized between 0.2 to 8 mole percent.

Process for the preparation of lithium nitride in a pulverised state

PatentInactiveGB199027A

Innovation

- Heating a lithium amalgam in a nitrogen atmosphere to distill off mercury, resulting in lithium nitride in a finely pulverised state, which can be used as a catalyst for ammonia synthesis without pressure or at low pressures and temperatures.

Safety and Handling Protocols for Lithium Nitride

Lithium nitride (Li₃N) handling requires stringent safety protocols due to its high reactivity with moisture and air. The compound reacts vigorously with water to produce lithium hydroxide and ammonia gas, presenting both chemical and physical hazards. Therefore, all handling operations must be conducted in controlled environments such as glove boxes with inert atmospheres (typically argon or nitrogen) with oxygen and moisture levels maintained below 1 ppm.

Personal protective equipment (PPE) is mandatory when working with lithium nitride, including chemical-resistant gloves, lab coats, safety goggles, and in some cases, face shields. Respiratory protection may be necessary when engineering controls cannot adequately prevent airborne exposure. All personnel should undergo specific training on lithium nitride hazards and emergency procedures before handling the material.

Storage considerations are equally critical for maintaining safety and material integrity. Lithium nitride must be stored in hermetically sealed containers under an inert atmosphere, preferably in cool, dry locations away from incompatible materials. Containers should be clearly labeled with appropriate hazard warnings and kept away from water sources, acids, and oxidizing agents.

Emergency response protocols must be established and communicated to all laboratory personnel. These should include procedures for handling spills, which typically involve careful collection of the material under inert conditions, avoiding water contact, and proper disposal according to local regulations. Fire response strategies must account for lithium nitride's potential to release ammonia when heated and its incompatibility with water-based extinguishing methods.

Waste disposal presents additional challenges, as lithium nitride cannot be discarded through conventional waste streams. Controlled decomposition under inert conditions, followed by appropriate disposal of the resulting products, is typically required. All disposal activities must comply with local, state, and federal regulations governing hazardous waste management.

Monitoring systems should be implemented in laboratories working with lithium nitride, including gas detectors for ammonia and oxygen level monitors. Regular equipment inspections and maintenance schedules help ensure the integrity of containment systems. Documentation of all handling procedures, safety incidents, and near-misses provides valuable information for continuous improvement of safety protocols.

Transportation of lithium nitride must adhere to international dangerous goods regulations, requiring specialized packaging, proper labeling, and appropriate documentation. Only trained personnel should be involved in the preparation and handling of lithium nitride shipments to ensure compliance with transportation safety requirements.

Personal protective equipment (PPE) is mandatory when working with lithium nitride, including chemical-resistant gloves, lab coats, safety goggles, and in some cases, face shields. Respiratory protection may be necessary when engineering controls cannot adequately prevent airborne exposure. All personnel should undergo specific training on lithium nitride hazards and emergency procedures before handling the material.

Storage considerations are equally critical for maintaining safety and material integrity. Lithium nitride must be stored in hermetically sealed containers under an inert atmosphere, preferably in cool, dry locations away from incompatible materials. Containers should be clearly labeled with appropriate hazard warnings and kept away from water sources, acids, and oxidizing agents.

Emergency response protocols must be established and communicated to all laboratory personnel. These should include procedures for handling spills, which typically involve careful collection of the material under inert conditions, avoiding water contact, and proper disposal according to local regulations. Fire response strategies must account for lithium nitride's potential to release ammonia when heated and its incompatibility with water-based extinguishing methods.

Waste disposal presents additional challenges, as lithium nitride cannot be discarded through conventional waste streams. Controlled decomposition under inert conditions, followed by appropriate disposal of the resulting products, is typically required. All disposal activities must comply with local, state, and federal regulations governing hazardous waste management.

Monitoring systems should be implemented in laboratories working with lithium nitride, including gas detectors for ammonia and oxygen level monitors. Regular equipment inspections and maintenance schedules help ensure the integrity of containment systems. Documentation of all handling procedures, safety incidents, and near-misses provides valuable information for continuous improvement of safety protocols.

Transportation of lithium nitride must adhere to international dangerous goods regulations, requiring specialized packaging, proper labeling, and appropriate documentation. Only trained personnel should be involved in the preparation and handling of lithium nitride shipments to ensure compliance with transportation safety requirements.

Scalability and Cost Analysis of Production Methods

The scalability of lithium nitride production represents a critical factor in determining its commercial viability for high-efficiency applications. Current laboratory-scale synthesis methods face significant challenges when transitioning to industrial production levels. Direct nitridation of lithium metal, while conceptually straightforward, requires precise temperature control and specialized equipment to handle the highly reactive lithium metal safely at scale, substantially increasing capital expenditure for large-scale operations.

From a cost perspective, raw material expenses vary significantly across different synthesis routes. The direct nitridation method utilizes lithium metal as a precursor, which currently costs approximately $80-100 per kilogram for high-purity grades. Alternative methods using lithium compounds such as lithium hydroxide ($15-20/kg) or lithium carbonate ($20-25/kg) offer more economical starting materials but typically require additional processing steps that increase operational costs.

Energy consumption represents another substantial cost factor in lithium nitride production. High-temperature synthesis methods typically require temperatures between 400-800°C maintained for several hours, resulting in significant energy expenditure. Plasma-assisted methods, while offering faster reaction kinetics, demand sophisticated equipment and high electricity consumption, limiting their cost-effectiveness for large-scale production.

Yield efficiency varies considerably across production methods. Direct nitridation can achieve yields of 90-95% under optimized conditions, while solution-based methods typically deliver 70-85% yields. This yield differential significantly impacts the overall economics, particularly when considering the cost of high-purity nitrogen gas ($0.10-0.15 per cubic meter) and other process inputs.

Infrastructure requirements present another scaling challenge. Specialized reactors with precise atmosphere control capabilities are essential for maintaining the oxygen and moisture-free environment critical for high-quality lithium nitride synthesis. The estimated capital investment for a production facility capable of producing 100 kg/month ranges from $2-5 million, depending on the selected synthesis route and level of automation.

Labor costs vary by production method, with more complex multi-step processes requiring greater operator expertise and supervision. Automated continuous flow processes offer reduced labor requirements but demand higher initial capital investment. Maintenance costs for specialized equipment, particularly for plasma-based or high-pressure systems, can add 5-10% annually to operational expenses.

Environmental compliance and waste management represent increasingly significant cost factors, particularly for methods generating hazardous by-products or requiring extensive purification steps. Recycling unreacted materials and implementing closed-loop systems can improve cost-effectiveness but require additional process engineering and capital investment.

From a cost perspective, raw material expenses vary significantly across different synthesis routes. The direct nitridation method utilizes lithium metal as a precursor, which currently costs approximately $80-100 per kilogram for high-purity grades. Alternative methods using lithium compounds such as lithium hydroxide ($15-20/kg) or lithium carbonate ($20-25/kg) offer more economical starting materials but typically require additional processing steps that increase operational costs.

Energy consumption represents another substantial cost factor in lithium nitride production. High-temperature synthesis methods typically require temperatures between 400-800°C maintained for several hours, resulting in significant energy expenditure. Plasma-assisted methods, while offering faster reaction kinetics, demand sophisticated equipment and high electricity consumption, limiting their cost-effectiveness for large-scale production.

Yield efficiency varies considerably across production methods. Direct nitridation can achieve yields of 90-95% under optimized conditions, while solution-based methods typically deliver 70-85% yields. This yield differential significantly impacts the overall economics, particularly when considering the cost of high-purity nitrogen gas ($0.10-0.15 per cubic meter) and other process inputs.

Infrastructure requirements present another scaling challenge. Specialized reactors with precise atmosphere control capabilities are essential for maintaining the oxygen and moisture-free environment critical for high-quality lithium nitride synthesis. The estimated capital investment for a production facility capable of producing 100 kg/month ranges from $2-5 million, depending on the selected synthesis route and level of automation.

Labor costs vary by production method, with more complex multi-step processes requiring greater operator expertise and supervision. Automated continuous flow processes offer reduced labor requirements but demand higher initial capital investment. Maintenance costs for specialized equipment, particularly for plasma-based or high-pressure systems, can add 5-10% annually to operational expenses.

Environmental compliance and waste management represent increasingly significant cost factors, particularly for methods generating hazardous by-products or requiring extensive purification steps. Recycling unreacted materials and implementing closed-loop systems can improve cost-effectiveness but require additional process engineering and capital investment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!