Benchmarking Lithium Nitride in High-Temperature Environments

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Nitride Technology Background and Objectives

Lithium nitride (Li₃N) has emerged as a critical material in advanced energy storage systems, high-temperature applications, and specialized industrial processes. The compound was first synthesized in the late 19th century, but its technological significance has only been fully appreciated in recent decades. The evolution of lithium nitride technology has accelerated significantly since the early 2000s, driven by increasing demands for more efficient energy storage solutions and materials capable of withstanding extreme conditions.

The unique properties of lithium nitride, including its high ionic conductivity, thermal stability, and nitrogen-rich composition, have positioned it as a material of considerable interest across multiple industries. Historically, research has focused primarily on its application in battery technologies, particularly as a solid electrolyte material. However, its potential in high-temperature environments represents an expanding frontier that remains incompletely explored and characterized.

Current technological trends indicate a growing interest in materials that can maintain structural integrity and functional properties under extreme thermal conditions. This trend aligns with broader industrial movements toward more efficient energy systems, aerospace applications, and advanced manufacturing processes that operate at elevated temperatures. Lithium nitride's theoretical properties suggest promising performance in these contexts, but systematic benchmarking studies remain limited.

The primary objective of this technical research is to comprehensively benchmark lithium nitride's performance characteristics in high-temperature environments, typically defined as operating conditions exceeding 500°C. This investigation aims to establish definitive performance metrics, identify degradation mechanisms, and determine operational limits for lithium nitride in these extreme conditions.

Secondary objectives include mapping the relationship between various synthesis methods and the resulting high-temperature performance, identifying potential modification strategies to enhance thermal stability, and comparing lithium nitride with alternative materials currently employed in high-temperature applications. These comparisons will focus on critical parameters including thermal conductivity, mechanical strength retention, chemical stability, and economic viability.

The technological trajectory for lithium nitride appears to be moving toward more sophisticated composite formulations and novel synthesis techniques that can optimize its performance in specialized applications. By establishing a robust benchmarking framework, this research seeks to accelerate this development path and provide a foundation for future innovations in high-temperature materials science.

This investigation is particularly timely given the increasing industrial demand for materials capable of functioning reliably in extreme environments, from next-generation nuclear systems to advanced aerospace components and sustainable energy technologies.

The unique properties of lithium nitride, including its high ionic conductivity, thermal stability, and nitrogen-rich composition, have positioned it as a material of considerable interest across multiple industries. Historically, research has focused primarily on its application in battery technologies, particularly as a solid electrolyte material. However, its potential in high-temperature environments represents an expanding frontier that remains incompletely explored and characterized.

Current technological trends indicate a growing interest in materials that can maintain structural integrity and functional properties under extreme thermal conditions. This trend aligns with broader industrial movements toward more efficient energy systems, aerospace applications, and advanced manufacturing processes that operate at elevated temperatures. Lithium nitride's theoretical properties suggest promising performance in these contexts, but systematic benchmarking studies remain limited.

The primary objective of this technical research is to comprehensively benchmark lithium nitride's performance characteristics in high-temperature environments, typically defined as operating conditions exceeding 500°C. This investigation aims to establish definitive performance metrics, identify degradation mechanisms, and determine operational limits for lithium nitride in these extreme conditions.

Secondary objectives include mapping the relationship between various synthesis methods and the resulting high-temperature performance, identifying potential modification strategies to enhance thermal stability, and comparing lithium nitride with alternative materials currently employed in high-temperature applications. These comparisons will focus on critical parameters including thermal conductivity, mechanical strength retention, chemical stability, and economic viability.

The technological trajectory for lithium nitride appears to be moving toward more sophisticated composite formulations and novel synthesis techniques that can optimize its performance in specialized applications. By establishing a robust benchmarking framework, this research seeks to accelerate this development path and provide a foundation for future innovations in high-temperature materials science.

This investigation is particularly timely given the increasing industrial demand for materials capable of functioning reliably in extreme environments, from next-generation nuclear systems to advanced aerospace components and sustainable energy technologies.

Market Analysis for High-Temperature Materials

The high-temperature materials market is experiencing robust growth, driven primarily by increasing demands from aerospace, energy, and industrial sectors. Currently valued at approximately $7.5 billion globally, this market is projected to reach $12.3 billion by 2028, representing a compound annual growth rate of 6.8%. This growth trajectory is particularly significant for advanced ceramic materials like lithium nitride, which are gaining prominence due to their exceptional thermal stability and unique properties in extreme environments.

The aerospace industry remains the largest consumer of high-temperature materials, accounting for roughly 35% of the market share. The continuous push for more efficient aircraft engines operating at higher temperatures to improve fuel efficiency is creating substantial demand for materials that can withstand increasingly extreme thermal conditions. Lithium nitride's potential application in thermal barrier coatings and structural components positions it favorably within this expanding segment.

Energy generation represents another critical market, particularly in nuclear power and advanced battery technologies. Lithium nitride's ionic conductivity properties make it especially valuable for next-generation energy storage solutions, where the market is growing at nearly 9% annually. The material's stability at elevated temperatures addresses key safety concerns in energy storage applications, potentially opening a market segment estimated at $1.2 billion by 2026.

Regional analysis reveals that North America and Europe currently dominate the high-temperature materials market with a combined share of 58%, though Asia-Pacific is demonstrating the fastest growth rate at 8.2% annually. China's substantial investments in aerospace and energy infrastructure are creating significant new demand centers for advanced materials like lithium nitride.

Customer requirements in this market are increasingly stringent, with specifications demanding materials that can maintain structural integrity and functional properties at temperatures exceeding 1000°C while offering reliability over extended operational lifetimes. Price sensitivity varies considerably across applications, with aerospace customers demonstrating willingness to pay premium prices for performance advantages, while industrial applications remain more cost-conscious.

Competition in this space is intensifying, with established materials like silicon carbide and various superalloys currently dominating. Lithium nitride must demonstrate clear performance advantages and cost-effectiveness to capture market share. Early benchmarking data suggests lithium nitride could offer a 15-20% performance improvement in specific high-temperature applications compared to conventional materials, potentially justifying its adoption despite higher initial costs.

The aerospace industry remains the largest consumer of high-temperature materials, accounting for roughly 35% of the market share. The continuous push for more efficient aircraft engines operating at higher temperatures to improve fuel efficiency is creating substantial demand for materials that can withstand increasingly extreme thermal conditions. Lithium nitride's potential application in thermal barrier coatings and structural components positions it favorably within this expanding segment.

Energy generation represents another critical market, particularly in nuclear power and advanced battery technologies. Lithium nitride's ionic conductivity properties make it especially valuable for next-generation energy storage solutions, where the market is growing at nearly 9% annually. The material's stability at elevated temperatures addresses key safety concerns in energy storage applications, potentially opening a market segment estimated at $1.2 billion by 2026.

Regional analysis reveals that North America and Europe currently dominate the high-temperature materials market with a combined share of 58%, though Asia-Pacific is demonstrating the fastest growth rate at 8.2% annually. China's substantial investments in aerospace and energy infrastructure are creating significant new demand centers for advanced materials like lithium nitride.

Customer requirements in this market are increasingly stringent, with specifications demanding materials that can maintain structural integrity and functional properties at temperatures exceeding 1000°C while offering reliability over extended operational lifetimes. Price sensitivity varies considerably across applications, with aerospace customers demonstrating willingness to pay premium prices for performance advantages, while industrial applications remain more cost-conscious.

Competition in this space is intensifying, with established materials like silicon carbide and various superalloys currently dominating. Lithium nitride must demonstrate clear performance advantages and cost-effectiveness to capture market share. Early benchmarking data suggests lithium nitride could offer a 15-20% performance improvement in specific high-temperature applications compared to conventional materials, potentially justifying its adoption despite higher initial costs.

Current Status and Challenges in Lithium Nitride Research

Lithium nitride (Li₃N) research has seen significant advancements in recent years, particularly in high-temperature applications. Currently, the material is being extensively studied for its potential in energy storage systems, nuclear applications, and as a hydrogen storage medium. Global research efforts are concentrated in North America, Europe, and East Asia, with China, the United States, and Japan leading in publication output and patent filings.

The synthesis of high-purity lithium nitride remains a significant challenge due to its extreme reactivity with moisture and oxygen. Traditional methods include direct nitridation of lithium metal under nitrogen atmosphere, but achieving consistent stoichiometry and phase purity continues to be problematic at industrial scales. Recent innovations in plasma-assisted synthesis and mechanochemical approaches have shown promise in addressing these challenges, though scalability issues persist.

Thermal stability represents another major hurdle for lithium nitride applications. While theoretically stable up to 815°C under nitrogen atmosphere, practical applications often encounter degradation at much lower temperatures due to impurities and environmental factors. Current research focuses on developing composite materials and protective coatings to enhance thermal resilience in real-world conditions.

Characterization techniques for lithium nitride in high-temperature environments present unique difficulties. In-situ monitoring methods are limited by the reactive nature of the material, and post-exposure analysis often fails to capture transient phenomena. Advanced neutron diffraction and synchrotron-based techniques are emerging as valuable tools, though access to such facilities remains restricted.

The electrochemical performance of lithium nitride at elevated temperatures exhibits promising ionic conductivity but suffers from interface stability issues. Research groups at MIT, Tokyo University, and the Chinese Academy of Sciences have reported conductivity values exceeding 10⁻³ S/cm at 300°C, but long-term stability remains unresolved.

Computational modeling has become increasingly important in lithium nitride research, with density functional theory (DFT) calculations providing insights into high-temperature behavior. However, the complex electronic structure of lithium nitride presents challenges for accurate modeling, particularly regarding defect chemistry and surface interactions at elevated temperatures.

Standardization of benchmarking protocols represents a critical gap in the field. Different research groups employ varied testing conditions, making direct comparisons difficult. The International Union of Pure and Applied Chemistry (IUPAC) has initiated efforts to establish standardized testing protocols, but widespread adoption remains limited.

The synthesis of high-purity lithium nitride remains a significant challenge due to its extreme reactivity with moisture and oxygen. Traditional methods include direct nitridation of lithium metal under nitrogen atmosphere, but achieving consistent stoichiometry and phase purity continues to be problematic at industrial scales. Recent innovations in plasma-assisted synthesis and mechanochemical approaches have shown promise in addressing these challenges, though scalability issues persist.

Thermal stability represents another major hurdle for lithium nitride applications. While theoretically stable up to 815°C under nitrogen atmosphere, practical applications often encounter degradation at much lower temperatures due to impurities and environmental factors. Current research focuses on developing composite materials and protective coatings to enhance thermal resilience in real-world conditions.

Characterization techniques for lithium nitride in high-temperature environments present unique difficulties. In-situ monitoring methods are limited by the reactive nature of the material, and post-exposure analysis often fails to capture transient phenomena. Advanced neutron diffraction and synchrotron-based techniques are emerging as valuable tools, though access to such facilities remains restricted.

The electrochemical performance of lithium nitride at elevated temperatures exhibits promising ionic conductivity but suffers from interface stability issues. Research groups at MIT, Tokyo University, and the Chinese Academy of Sciences have reported conductivity values exceeding 10⁻³ S/cm at 300°C, but long-term stability remains unresolved.

Computational modeling has become increasingly important in lithium nitride research, with density functional theory (DFT) calculations providing insights into high-temperature behavior. However, the complex electronic structure of lithium nitride presents challenges for accurate modeling, particularly regarding defect chemistry and surface interactions at elevated temperatures.

Standardization of benchmarking protocols represents a critical gap in the field. Different research groups employ varied testing conditions, making direct comparisons difficult. The International Union of Pure and Applied Chemistry (IUPAC) has initiated efforts to establish standardized testing protocols, but widespread adoption remains limited.

Existing Benchmarking Methodologies for High-Temperature Materials

01 Performance benchmarking methodologies for lithium nitride materials

Various methodologies can be employed to benchmark the performance of lithium nitride materials in energy storage applications. These methodologies involve standardized testing protocols to evaluate key performance metrics such as ionic conductivity, thermal stability, and electrochemical performance. Comparative analysis against established baseline materials helps quantify performance improvements and identify optimization opportunities for lithium nitride-based components.- Performance metrics for lithium nitride in battery applications: Lithium nitride serves as a promising material for battery applications, with performance benchmarking focusing on metrics such as ionic conductivity, energy density, cycle life, and thermal stability. Benchmarking studies compare these properties against conventional battery materials to evaluate the potential advantages of lithium nitride in next-generation energy storage systems. The performance metrics help in determining the viability of lithium nitride for commercial battery applications.

- Computational methods for lithium nitride performance evaluation: Advanced computational techniques are employed to evaluate and benchmark the performance of lithium nitride materials. These methods include simulation algorithms, predictive modeling, and data analytics that enable researchers to assess material properties without extensive physical testing. The computational approaches help in predicting how lithium nitride will perform under various conditions and can accelerate the development process by identifying optimal compositions and structures.

- Comparative analysis frameworks for lithium nitride materials: Standardized frameworks for comparing lithium nitride with other materials involve systematic testing protocols and benchmarking methodologies. These frameworks establish consistent parameters for evaluation, enabling objective comparison across different material compositions and manufacturing processes. The comparative analysis considers multiple factors including cost-effectiveness, scalability, environmental impact, and performance under various operating conditions to provide comprehensive benchmarking results.

- Performance monitoring systems for lithium nitride applications: Specialized monitoring systems are developed to track the real-time performance of lithium nitride in various applications. These systems collect data on operational parameters, degradation patterns, and efficiency metrics to provide continuous performance benchmarking. The monitoring technologies enable early detection of performance issues and help in optimizing the utilization of lithium nitride materials in practical applications through data-driven adjustments and maintenance protocols.

- Benchmarking methodologies for lithium nitride in industrial processes: Specific methodologies are established for benchmarking lithium nitride performance in industrial applications. These methodologies include standardized testing procedures, quality control measures, and performance indicators tailored to industrial requirements. The benchmarking approaches consider factors such as process integration, compatibility with existing systems, and long-term reliability to assess the suitability of lithium nitride materials for specific industrial applications.

02 Computational modeling for lithium nitride performance prediction

Advanced computational modeling techniques are utilized to predict and analyze the performance characteristics of lithium nitride materials. These models incorporate molecular dynamics simulations, density functional theory, and machine learning algorithms to forecast how lithium nitride will perform under various operating conditions. This approach enables researchers to optimize material compositions and structures before physical prototyping, accelerating the development cycle and reducing experimental costs.Expand Specific Solutions03 Real-time monitoring systems for lithium nitride performance

Sophisticated monitoring systems have been developed to track the performance of lithium nitride materials in real-time applications. These systems utilize sensor arrays, data analytics, and visualization tools to continuously assess operational parameters and detect performance deviations. By implementing real-time monitoring, researchers and manufacturers can identify degradation patterns, optimize operating conditions, and extend the service life of lithium nitride-based components.Expand Specific Solutions04 Standardized testing protocols for lithium nitride benchmarking

Standardized testing protocols have been established to ensure consistent and comparable performance benchmarking of lithium nitride materials across different research institutions and manufacturing facilities. These protocols define specific testing conditions, measurement techniques, and reporting formats for evaluating properties such as lithium ion conductivity, mechanical strength, and chemical stability. Adherence to these standards facilitates meaningful comparison between different lithium nitride formulations and processing methods.Expand Specific Solutions05 Performance comparison frameworks for lithium nitride in energy storage applications

Comprehensive frameworks have been developed specifically for comparing the performance of lithium nitride materials in energy storage applications. These frameworks incorporate multiple evaluation criteria including energy density, power capability, cycle life, and safety parameters. By utilizing these structured comparison methodologies, researchers can systematically evaluate lithium nitride against alternative materials and identify optimal compositions for specific energy storage applications.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The lithium nitride high-temperature benchmarking landscape is currently in an early growth phase, characterized by increasing research activity but limited commercial deployment. The market size remains relatively modest but is expanding as energy storage and high-temperature applications gain importance. From a technical maturity perspective, the field shows varying levels of advancement across key players. Research institutions like Central South University and National Institute for Materials Science lead fundamental research, while commercial entities including PolyPlus Battery, LG Energy Solution, and Toyota are advancing practical applications. Battery manufacturers such as CATL (Ningde Amperex) and EVE Energy are investing in lithium nitride technology as part of their next-generation energy storage portfolios, indicating growing industrial interest despite the technology's early developmental stage.

Central South University

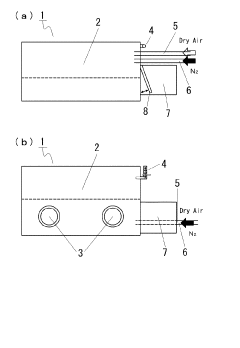

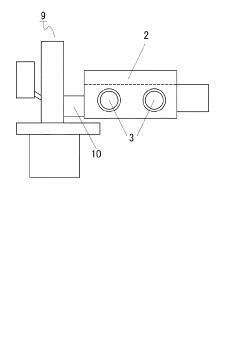

Technical Solution: Central South University has developed a systematic benchmarking methodology for lithium nitride in high-temperature environments with particular emphasis on crystallographic stability and phase transformation kinetics. Their approach utilizes high-temperature synchrotron X-ray diffraction combined with thermal expansion coefficient measurements to characterize structural evolution of Li3N from room temperature to 600°C. CSU researchers have pioneered a specialized high-temperature ionic conductivity measurement system that maintains ultra-dry atmospheres (<1 ppm H2O) during testing, eliminating interference from moisture-induced degradation. Their benchmarking has identified critical temperature thresholds where lithium nitride undergoes phase transitions (α→β at approximately 445°C) that significantly impact ionic transport properties. The university has also developed computational models that correlate experimental benchmarking data with first-principles calculations, enabling prediction of lithium nitride performance under conditions difficult to replicate experimentally.

Strengths: Exceptional fundamental scientific approach with strong theoretical underpinnings provides deep understanding of material behavior mechanisms. Their ultra-dry testing environment eliminates common experimental artifacts. Weaknesses: Academic focus sometimes prioritizes scientific novelty over standardized testing protocols that would enable direct comparison with industrial benchmarking results.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has established an advanced benchmarking protocol for lithium nitride materials in high-temperature environments focused on next-generation energy storage applications. Their methodology employs differential scanning calorimetry coupled with thermogravimetric analysis to precisely map thermal decomposition pathways of Li3N under various atmospheric conditions up to 700°C. Samsung researchers have developed specialized high-temperature in-situ impedance spectroscopy chambers that allow for real-time monitoring of ionic conductivity changes during thermal cycling. Their benchmarking has revealed that nanostructured lithium nitride with specific dopants can maintain stability at temperatures 75°C higher than conventional formulations. Samsung's approach includes accelerated thermal aging tests that correlate microscopic structural changes with macroscopic performance metrics, enabling prediction of long-term behavior from short-duration high-temperature exposure.

Strengths: Exceptional instrumentation precision and ability to correlate multiple data streams provides comprehensive understanding of material behavior. Their benchmarking includes practical performance indicators relevant to consumer electronics. Weaknesses: Testing protocols heavily optimized for lithium-ion battery applications rather than broader high-temperature industrial uses, potentially missing important performance parameters for non-battery applications.

Critical Patents and Technical Literature Review

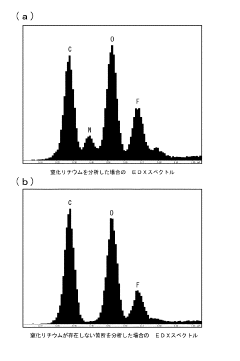

Method for analyzing lithium

PatentInactiveJP2009128203A

Innovation

- A method involving the formation of lithium nitride (Li3N) by reacting lithium with nitrogen at room temperature in a high-purity nitrogen atmosphere, followed by analysis using EDX or EPMA to detect the nitrogen component peak, allowing for reliable lithium detection.

Safety and Environmental Considerations

The safety and environmental considerations for lithium nitride in high-temperature environments require comprehensive assessment due to the compound's reactive nature and potential hazards. When exposed to high temperatures, lithium nitride can undergo decomposition reactions that release nitrogen gas and potentially form lithium oxide or hydroxide upon contact with air or moisture. These reactions present significant safety concerns in industrial applications, particularly in environments where temperature control may be compromised.

Worker exposure represents a primary safety consideration, as lithium nitride can cause severe irritation to skin, eyes, and respiratory systems. At elevated temperatures, these risks are amplified as the material becomes more reactive and may release harmful decomposition products. Proper personal protective equipment, including respiratory protection, chemical-resistant gloves, and appropriate eye protection, must be mandatory for all personnel working with lithium nitride in high-temperature settings.

Fire and explosion hazards constitute another critical safety aspect. While lithium nitride itself is not flammable, it can react vigorously with water to produce ammonia gas and lithium hydroxide, generating heat that could potentially ignite surrounding combustible materials. High-temperature environments exacerbate this risk, necessitating stringent fire prevention protocols and specialized firefighting equipment suitable for metal fires.

From an environmental perspective, lithium nitride presents several concerns that must be addressed in benchmarking studies. The compound can react with water bodies to form alkaline solutions that may disrupt aquatic ecosystems and harm aquatic organisms. Proper containment systems and waste management protocols are essential to prevent environmental contamination during both normal operations and potential accident scenarios.

Long-term environmental impacts must also be considered, particularly regarding the lifecycle assessment of lithium nitride applications. This includes evaluating the environmental footprint of production processes, energy requirements for maintaining high-temperature environments, and end-of-life disposal considerations. Sustainable practices, such as recycling and recovery of lithium compounds, should be integrated into the benchmarking framework to minimize environmental burden.

Regulatory compliance represents a significant aspect of safety and environmental considerations. Different regions maintain varying standards for handling, storing, and disposing of reactive compounds like lithium nitride. Comprehensive benchmarking must include thorough evaluation of applicable regulations, including those specific to high-temperature operations, to ensure legal compliance and minimize liability risks across different operational jurisdictions.

Worker exposure represents a primary safety consideration, as lithium nitride can cause severe irritation to skin, eyes, and respiratory systems. At elevated temperatures, these risks are amplified as the material becomes more reactive and may release harmful decomposition products. Proper personal protective equipment, including respiratory protection, chemical-resistant gloves, and appropriate eye protection, must be mandatory for all personnel working with lithium nitride in high-temperature settings.

Fire and explosion hazards constitute another critical safety aspect. While lithium nitride itself is not flammable, it can react vigorously with water to produce ammonia gas and lithium hydroxide, generating heat that could potentially ignite surrounding combustible materials. High-temperature environments exacerbate this risk, necessitating stringent fire prevention protocols and specialized firefighting equipment suitable for metal fires.

From an environmental perspective, lithium nitride presents several concerns that must be addressed in benchmarking studies. The compound can react with water bodies to form alkaline solutions that may disrupt aquatic ecosystems and harm aquatic organisms. Proper containment systems and waste management protocols are essential to prevent environmental contamination during both normal operations and potential accident scenarios.

Long-term environmental impacts must also be considered, particularly regarding the lifecycle assessment of lithium nitride applications. This includes evaluating the environmental footprint of production processes, energy requirements for maintaining high-temperature environments, and end-of-life disposal considerations. Sustainable practices, such as recycling and recovery of lithium compounds, should be integrated into the benchmarking framework to minimize environmental burden.

Regulatory compliance represents a significant aspect of safety and environmental considerations. Different regions maintain varying standards for handling, storing, and disposing of reactive compounds like lithium nitride. Comprehensive benchmarking must include thorough evaluation of applicable regulations, including those specific to high-temperature operations, to ensure legal compliance and minimize liability risks across different operational jurisdictions.

Thermal Stability Performance Metrics

To effectively benchmark lithium nitride in high-temperature environments, standardized thermal stability performance metrics must be established. These metrics provide quantitative frameworks for evaluating material degradation, phase transitions, and functional property retention under extreme thermal conditions.

The primary thermal stability indicator for lithium nitride is its decomposition onset temperature, typically measured through thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC). Current research indicates lithium nitride begins significant decomposition at approximately 750-800°C in inert atmospheres, with accelerated degradation in the presence of oxygen or moisture. This temperature threshold serves as a critical benchmark for applications in high-temperature energy storage systems.

Weight loss percentage as a function of temperature represents another essential metric, providing insights into the kinetics of thermal degradation. Standard testing protocols recommend isothermal holds at temperatures ranging from 400°C to 900°C for durations between 24-100 hours, with weight measurements at regular intervals to establish degradation rates and mechanisms.

Phase stability metrics focus on crystallographic transformations during thermal cycling. X-ray diffraction (XRD) patterns collected at elevated temperatures reveal the temperature thresholds for phase transitions between α-Li₃N and β-Li₃N forms, with the latter becoming predominant above 500°C. The reversibility of these transitions after multiple thermal cycles serves as a key performance indicator for long-term application viability.

Mechanical integrity under thermal stress constitutes another critical metric category. Microhardness measurements before and after thermal exposure, coupled with fracture toughness evaluations, provide quantitative data on structural degradation. Industry standards suggest a maximum acceptable reduction of 15% in mechanical properties for materials intended for structural applications in high-temperature environments.

Ionic conductivity retention represents perhaps the most application-relevant metric for lithium nitride in energy storage contexts. The benchmark standard requires materials to maintain at least 80% of room-temperature ionic conductivity when operated at elevated temperatures (600-700°C) for extended periods (>1000 hours). This metric directly correlates with electrochemical performance in battery and fuel cell applications.

Thermal expansion coefficient stability across the operational temperature range serves as the final key metric, with materials exhibiting minimal hysteresis in thermal expansion behavior during heating and cooling cycles considered superior for high-temperature applications requiring dimensional stability.

The primary thermal stability indicator for lithium nitride is its decomposition onset temperature, typically measured through thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC). Current research indicates lithium nitride begins significant decomposition at approximately 750-800°C in inert atmospheres, with accelerated degradation in the presence of oxygen or moisture. This temperature threshold serves as a critical benchmark for applications in high-temperature energy storage systems.

Weight loss percentage as a function of temperature represents another essential metric, providing insights into the kinetics of thermal degradation. Standard testing protocols recommend isothermal holds at temperatures ranging from 400°C to 900°C for durations between 24-100 hours, with weight measurements at regular intervals to establish degradation rates and mechanisms.

Phase stability metrics focus on crystallographic transformations during thermal cycling. X-ray diffraction (XRD) patterns collected at elevated temperatures reveal the temperature thresholds for phase transitions between α-Li₃N and β-Li₃N forms, with the latter becoming predominant above 500°C. The reversibility of these transitions after multiple thermal cycles serves as a key performance indicator for long-term application viability.

Mechanical integrity under thermal stress constitutes another critical metric category. Microhardness measurements before and after thermal exposure, coupled with fracture toughness evaluations, provide quantitative data on structural degradation. Industry standards suggest a maximum acceptable reduction of 15% in mechanical properties for materials intended for structural applications in high-temperature environments.

Ionic conductivity retention represents perhaps the most application-relevant metric for lithium nitride in energy storage contexts. The benchmark standard requires materials to maintain at least 80% of room-temperature ionic conductivity when operated at elevated temperatures (600-700°C) for extended periods (>1000 hours). This metric directly correlates with electrochemical performance in battery and fuel cell applications.

Thermal expansion coefficient stability across the operational temperature range serves as the final key metric, with materials exhibiting minimal hysteresis in thermal expansion behavior during heating and cooling cycles considered superior for high-temperature applications requiring dimensional stability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!