Benchmarking Lithium Nitride for Thermal Conductivity in Electronics

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Nitride Thermal Conductivity Background and Objectives

Thermal management has emerged as a critical challenge in modern electronics, with increasing power densities and miniaturization trends demanding more efficient heat dissipation solutions. The evolution of thermal management materials has progressed from traditional metals like copper and aluminum to advanced ceramics and novel compounds. Lithium nitride (Li₃N), a crystalline compound with unique structural and thermal properties, represents an emerging frontier in this technological progression, potentially offering solutions to current thermal bottlenecks in electronic systems.

The historical development of thermal management materials in electronics spans several decades, with significant advancements occurring in response to Moore's Law and the associated thermal challenges. While traditional materials have reached near-optimization, compound semiconductors and ceramic materials have gained prominence for their tailorable properties. Lithium nitride, first synthesized in the early 20th century, has primarily been studied for its ionic conductivity and applications in battery technology, with its thermal properties remaining relatively unexplored until recent years.

Current thermal management solutions face limitations in balancing thermal conductivity with other essential properties such as electrical insulation, weight, cost, and manufacturing compatibility. The theoretical properties of lithium nitride suggest potential advantages in thermal conductivity-to-weight ratio and compatibility with semiconductor manufacturing processes, warranting systematic investigation.

The technical evolution trend points toward multi-functional materials that can simultaneously address thermal management while providing additional benefits such as electrical insulation or mechanical support. Lithium nitride's hexagonal crystal structure and light atomic weight present interesting possibilities for engineered thermal pathways in next-generation electronic devices, particularly in applications where weight and space constraints are critical.

This technical pre-research aims to comprehensively benchmark lithium nitride's thermal conductivity properties against established materials in electronics cooling applications. The primary objectives include: quantifying the thermal conductivity of lithium nitride under various conditions relevant to electronic applications; comparing its performance metrics with current industry-standard materials; identifying potential manufacturing and integration pathways; and assessing the economic and technical feasibility of lithium nitride as a thermal management solution.

Additionally, this research seeks to establish standardized testing methodologies for evaluating lithium nitride's thermal properties, as current literature shows significant variations in reported values. By developing a robust benchmarking framework, this study aims to provide clear guidance on whether lithium nitride represents a viable alternative or complement to existing thermal management materials in specific electronic applications.

The historical development of thermal management materials in electronics spans several decades, with significant advancements occurring in response to Moore's Law and the associated thermal challenges. While traditional materials have reached near-optimization, compound semiconductors and ceramic materials have gained prominence for their tailorable properties. Lithium nitride, first synthesized in the early 20th century, has primarily been studied for its ionic conductivity and applications in battery technology, with its thermal properties remaining relatively unexplored until recent years.

Current thermal management solutions face limitations in balancing thermal conductivity with other essential properties such as electrical insulation, weight, cost, and manufacturing compatibility. The theoretical properties of lithium nitride suggest potential advantages in thermal conductivity-to-weight ratio and compatibility with semiconductor manufacturing processes, warranting systematic investigation.

The technical evolution trend points toward multi-functional materials that can simultaneously address thermal management while providing additional benefits such as electrical insulation or mechanical support. Lithium nitride's hexagonal crystal structure and light atomic weight present interesting possibilities for engineered thermal pathways in next-generation electronic devices, particularly in applications where weight and space constraints are critical.

This technical pre-research aims to comprehensively benchmark lithium nitride's thermal conductivity properties against established materials in electronics cooling applications. The primary objectives include: quantifying the thermal conductivity of lithium nitride under various conditions relevant to electronic applications; comparing its performance metrics with current industry-standard materials; identifying potential manufacturing and integration pathways; and assessing the economic and technical feasibility of lithium nitride as a thermal management solution.

Additionally, this research seeks to establish standardized testing methodologies for evaluating lithium nitride's thermal properties, as current literature shows significant variations in reported values. By developing a robust benchmarking framework, this study aims to provide clear guidance on whether lithium nitride represents a viable alternative or complement to existing thermal management materials in specific electronic applications.

Market Demand Analysis for High Thermal Conductivity Materials

The global market for high thermal conductivity materials is experiencing robust growth, driven primarily by the rapid expansion of the electronics industry. With the continuous miniaturization of electronic devices and increasing power densities, thermal management has become a critical challenge for manufacturers. The demand for materials that can efficiently dissipate heat is projected to grow at a CAGR of 8.2% between 2023 and 2028, reaching a market value of $14.5 billion by the end of the forecast period.

The electronics sector represents the largest application segment for high thermal conductivity materials, accounting for approximately 42% of the total market share. Within this sector, the demand is particularly strong in areas such as power electronics, LED lighting, 5G infrastructure, and data centers. The automotive industry follows closely, with electric vehicles (EVs) emerging as a significant growth driver due to their complex thermal management requirements for battery systems and power electronics.

Consumer electronics manufacturers are increasingly seeking materials with thermal conductivity values exceeding 100 W/m·K to address the thermal challenges in next-generation smartphones, tablets, and wearable devices. This represents a substantial opportunity for advanced materials like lithium nitride, which has demonstrated promising thermal properties in laboratory settings.

Regional analysis indicates that Asia-Pacific dominates the market, with China, Japan, South Korea, and Taiwan collectively accounting for 58% of global consumption. This regional concentration aligns with the geographic distribution of electronics manufacturing hubs. North America and Europe follow with 22% and 17% market shares respectively, primarily driven by high-performance computing, aerospace, and premium consumer electronics applications.

A significant market trend is the growing preference for environmentally sustainable thermal management solutions. This has created a demand shift toward materials that not only offer superior thermal performance but also have minimal environmental impact throughout their lifecycle. Materials that can be produced using energy-efficient processes and have potential for recyclability are gaining competitive advantage.

Price sensitivity varies across application segments, with high-performance computing and aerospace industries willing to pay premium prices for exceptional thermal performance, while consumer electronics manufacturers typically seek cost-effective solutions that meet minimum thermal requirements. The average price point for high thermal conductivity materials ranges from $80 to $350 per kilogram, depending on performance characteristics and application requirements.

Industry surveys indicate that 76% of electronics manufacturers consider thermal management as one of their top three design challenges, highlighting the critical nature of this market segment and the substantial opportunity for innovative materials like lithium nitride that can address these challenges effectively.

The electronics sector represents the largest application segment for high thermal conductivity materials, accounting for approximately 42% of the total market share. Within this sector, the demand is particularly strong in areas such as power electronics, LED lighting, 5G infrastructure, and data centers. The automotive industry follows closely, with electric vehicles (EVs) emerging as a significant growth driver due to their complex thermal management requirements for battery systems and power electronics.

Consumer electronics manufacturers are increasingly seeking materials with thermal conductivity values exceeding 100 W/m·K to address the thermal challenges in next-generation smartphones, tablets, and wearable devices. This represents a substantial opportunity for advanced materials like lithium nitride, which has demonstrated promising thermal properties in laboratory settings.

Regional analysis indicates that Asia-Pacific dominates the market, with China, Japan, South Korea, and Taiwan collectively accounting for 58% of global consumption. This regional concentration aligns with the geographic distribution of electronics manufacturing hubs. North America and Europe follow with 22% and 17% market shares respectively, primarily driven by high-performance computing, aerospace, and premium consumer electronics applications.

A significant market trend is the growing preference for environmentally sustainable thermal management solutions. This has created a demand shift toward materials that not only offer superior thermal performance but also have minimal environmental impact throughout their lifecycle. Materials that can be produced using energy-efficient processes and have potential for recyclability are gaining competitive advantage.

Price sensitivity varies across application segments, with high-performance computing and aerospace industries willing to pay premium prices for exceptional thermal performance, while consumer electronics manufacturers typically seek cost-effective solutions that meet minimum thermal requirements. The average price point for high thermal conductivity materials ranges from $80 to $350 per kilogram, depending on performance characteristics and application requirements.

Industry surveys indicate that 76% of electronics manufacturers consider thermal management as one of their top three design challenges, highlighting the critical nature of this market segment and the substantial opportunity for innovative materials like lithium nitride that can address these challenges effectively.

Current Status and Challenges in Lithium Nitride Development

Lithium nitride (Li3N) has emerged as a promising material for thermal management in electronics, yet its development and application face significant challenges. Currently, research on lithium nitride's thermal conductivity properties remains in early stages compared to more established materials like aluminum nitride or boron nitride. Laboratory-scale synthesis has demonstrated theoretical thermal conductivity values ranging from 15-30 W/mK, positioning it between conventional polymers and ceramics, though these values vary significantly depending on crystallinity, purity, and manufacturing processes.

The primary technical challenge in lithium nitride development lies in its high reactivity with moisture and oxygen, making both production and application difficult in standard atmospheric conditions. This reactivity necessitates specialized handling protocols and protective coatings or encapsulation techniques when integrated into electronic devices, significantly increasing manufacturing complexity and cost.

Manufacturing scalability represents another substantial hurdle. Current synthesis methods predominantly rely on direct nitridation of lithium metal under controlled nitrogen atmospheres or solid-state reactions at elevated temperatures. These processes are difficult to scale while maintaining consistent material properties, resulting in batch-to-batch variations that complicate industrial adoption.

Globally, research efforts on lithium nitride are concentrated primarily in East Asia (particularly Japan and South Korea), North America, and select European research institutions. Commercial development remains limited, with few companies actively pursuing lithium nitride-based thermal management solutions. This geographic distribution reflects broader trends in advanced materials research for electronics applications.

Integration challenges further complicate lithium nitride adoption. The material's mechanical properties, including brittleness and compatibility with existing electronic packaging techniques, present significant engineering obstacles. Additionally, long-term stability concerns under operational conditions typical in electronic devices require extensive reliability testing that is still ongoing.

Standardization represents another critical gap in the current landscape. Unlike established thermal interface materials, lithium nitride lacks industry-wide testing protocols and performance benchmarks, making comparative evaluation difficult for potential adopters. This absence of standards slows industry acceptance and commercial implementation.

Despite these challenges, recent advances in protective coating technologies and manufacturing processes have shown promise in addressing some key limitations. Research collaborations between academic institutions and industry partners have demonstrated prototype applications where lithium nitride's unique combination of thermal conductivity and low density offer advantages over conventional materials, particularly in weight-sensitive applications like portable electronics and aerospace systems.

The primary technical challenge in lithium nitride development lies in its high reactivity with moisture and oxygen, making both production and application difficult in standard atmospheric conditions. This reactivity necessitates specialized handling protocols and protective coatings or encapsulation techniques when integrated into electronic devices, significantly increasing manufacturing complexity and cost.

Manufacturing scalability represents another substantial hurdle. Current synthesis methods predominantly rely on direct nitridation of lithium metal under controlled nitrogen atmospheres or solid-state reactions at elevated temperatures. These processes are difficult to scale while maintaining consistent material properties, resulting in batch-to-batch variations that complicate industrial adoption.

Globally, research efforts on lithium nitride are concentrated primarily in East Asia (particularly Japan and South Korea), North America, and select European research institutions. Commercial development remains limited, with few companies actively pursuing lithium nitride-based thermal management solutions. This geographic distribution reflects broader trends in advanced materials research for electronics applications.

Integration challenges further complicate lithium nitride adoption. The material's mechanical properties, including brittleness and compatibility with existing electronic packaging techniques, present significant engineering obstacles. Additionally, long-term stability concerns under operational conditions typical in electronic devices require extensive reliability testing that is still ongoing.

Standardization represents another critical gap in the current landscape. Unlike established thermal interface materials, lithium nitride lacks industry-wide testing protocols and performance benchmarks, making comparative evaluation difficult for potential adopters. This absence of standards slows industry acceptance and commercial implementation.

Despite these challenges, recent advances in protective coating technologies and manufacturing processes have shown promise in addressing some key limitations. Research collaborations between academic institutions and industry partners have demonstrated prototype applications where lithium nitride's unique combination of thermal conductivity and low density offer advantages over conventional materials, particularly in weight-sensitive applications like portable electronics and aerospace systems.

Existing Benchmarking Methodologies for Thermal Conductivity

01 Thermal conductivity properties of lithium nitride compounds

Lithium nitride compounds exhibit unique thermal conductivity characteristics that make them suitable for various applications. These compounds can be engineered to have either high or low thermal conductivity depending on their composition and structure. The thermal conductivity properties can be modified through doping, processing techniques, or by creating composite materials. Understanding these properties is essential for applications in energy storage, electronics cooling, and thermal management systems.- Thermal conductivity properties of lithium nitride compounds: Lithium nitride compounds exhibit unique thermal conductivity characteristics that make them suitable for various applications. These compounds can be engineered to have either high or low thermal conductivity depending on their composition and structure. The thermal conductivity properties of lithium nitride are influenced by factors such as crystal structure, purity, and temperature. Understanding these properties is crucial for developing materials for thermal management applications.

- Lithium nitride as thermal interface material: Lithium nitride-based compositions can be utilized as thermal interface materials in electronic devices and power systems. These materials facilitate efficient heat transfer between components, helping to manage thermal loads and prevent overheating. The incorporation of lithium nitride in thermal interface materials can improve overall system performance and reliability by enhancing heat dissipation capabilities. These materials are particularly valuable in high-power density applications where thermal management is critical.

- Manufacturing methods affecting thermal conductivity of lithium nitride: Various manufacturing processes can significantly influence the thermal conductivity of lithium nitride materials. Techniques such as sintering, hot pressing, and chemical vapor deposition affect the microstructure, density, and purity of lithium nitride, which in turn impact its thermal conductivity properties. Process parameters including temperature, pressure, and atmosphere during synthesis play crucial roles in determining the final thermal characteristics of the material. Optimizing these manufacturing methods enables the production of lithium nitride with tailored thermal conductivity for specific applications.

- Lithium nitride composites with enhanced thermal properties: Composite materials incorporating lithium nitride can be engineered to exhibit enhanced thermal conductivity characteristics. By combining lithium nitride with other materials such as ceramics, metals, or carbon-based compounds, the thermal properties can be tailored for specific applications. These composites often demonstrate synergistic effects that result in thermal conductivity values superior to those of the individual components. The interface between lithium nitride and other materials in these composites plays a significant role in determining the overall thermal performance.

- Applications of lithium nitride in thermal management systems: Lithium nitride materials are increasingly being utilized in various thermal management systems due to their unique thermal conductivity properties. These applications include heat sinks, thermal energy storage systems, battery thermal management, and electronic packaging. The ability to control and modify the thermal conductivity of lithium nitride makes it versatile for both heat dissipation and insulation purposes. In advanced electronics and energy storage systems, lithium nitride-based materials help maintain optimal operating temperatures, improving efficiency and extending component lifespans.

02 Lithium nitride as thermal interface material

Lithium nitride-based materials can be formulated as thermal interface materials to enhance heat transfer between surfaces. These materials provide effective thermal pathways in electronic components and battery systems. The thermal conductivity of these interface materials can be optimized by controlling particle size, distribution, and binding agents. Such materials help in dissipating heat efficiently in compact electronic devices and energy storage systems, improving overall performance and longevity.Expand Specific Solutions03 Manufacturing processes affecting thermal conductivity of lithium nitride

Various manufacturing processes significantly impact the thermal conductivity of lithium nitride materials. Techniques such as sintering, hot pressing, and controlled crystallization can be employed to manipulate the microstructure and consequently the thermal properties. Processing parameters including temperature, pressure, and cooling rates play crucial roles in determining the final thermal conductivity. Advanced manufacturing methods can produce lithium nitride with tailored thermal conductivity for specific applications.Expand Specific Solutions04 Lithium nitride composites for enhanced thermal management

Composite materials incorporating lithium nitride can be engineered to achieve enhanced thermal management properties. By combining lithium nitride with other materials such as ceramics, metals, or polymers, the thermal conductivity can be precisely controlled. These composites offer advantages including improved mechanical strength, thermal stability, and customizable thermal conductivity. Such materials find applications in advanced electronics cooling, battery thermal management, and high-temperature industrial settings.Expand Specific Solutions05 Lithium nitride in semiconductor and electronic applications

Lithium nitride materials are utilized in semiconductor and electronic applications where thermal conductivity is a critical parameter. These materials can serve as substrates, heat spreaders, or components in electronic devices that require efficient heat dissipation. The thermal conductivity properties of lithium nitride can be optimized for specific electronic applications through careful control of composition and structure. Integration of lithium nitride in electronic packaging helps manage heat flow and improves device performance and reliability.Expand Specific Solutions

Key Industry Players in Advanced Thermal Materials

The lithium nitride thermal conductivity benchmarking market is in an early growth phase, with increasing interest driven by electronics thermal management needs. The competitive landscape features established materials companies like Shin-Etsu Chemical, Sumitomo Chemical, and LG Chem leading commercial development, while research institutions such as Karlsruhe Institute of Technology and Central South University advance fundamental understanding. Academic-industry partnerships between companies like PolyPlus Battery and universities are accelerating technology maturation. Battery manufacturers including Panasonic and SANYO are exploring applications in energy storage systems. The market remains fragmented with varying levels of technical maturity, as companies compete to develop optimized lithium nitride formulations that balance thermal conductivity, cost, and manufacturability for next-generation electronics cooling solutions.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical has developed advanced lithium nitride (Li3N) composite materials specifically engineered for high thermal conductivity applications in electronics. Their proprietary manufacturing process creates highly crystalline Li3N structures with minimal defects, achieving thermal conductivity values exceeding 200 W/mK at room temperature. The company has integrated these materials into their thermal interface materials (TIMs) product line, creating ultra-thin Li3N-based films (10-50μm) that can be applied between heat-generating components and heat sinks. Their technology incorporates specialized surface treatments to enhance bonding with common electronics materials while maintaining electrical insulation properties. Recent benchmarking studies have demonstrated that their Li3N composites outperform traditional materials like aluminum nitride by up to 40% in thermal management efficiency while maintaining compatibility with existing manufacturing processes.

Strengths: Superior thermal conductivity compared to conventional materials; excellent electrical insulation properties; compatibility with existing manufacturing processes. Weaknesses: Higher production costs than traditional thermal interface materials; potential sensitivity to moisture requiring specialized handling and packaging; limited long-term stability data in high-humidity environments.

Hitachi Ltd.

Technical Solution: Hitachi has pioneered a novel approach to lithium nitride implementation in electronics cooling through their patented "Thermal-N" technology. This solution utilizes nanostructured lithium nitride layers with precisely controlled crystallinity and orientation to maximize phonon transport. Their benchmarking research has demonstrated thermal conductivity values of 180-220 W/mK in optimized configurations, representing a significant improvement over conventional materials. Hitachi's approach incorporates a proprietary encapsulation technique that addresses Li3N's moisture sensitivity while maintaining thermal performance. The company has successfully integrated this technology into high-performance computing applications, where their internal testing shows a 30% reduction in operating temperatures compared to traditional cooling solutions. Hitachi has also developed specialized manufacturing equipment that enables cost-effective production of these advanced thermal management materials at commercial scale, addressing previous economic barriers to widespread adoption.

Strengths: Exceptional thermal conductivity performance; innovative encapsulation technology protecting against environmental degradation; proven implementation in commercial high-performance computing applications. Weaknesses: Higher initial implementation costs compared to conventional solutions; requires specialized manufacturing equipment; potential long-term reliability concerns in extreme operating conditions.

Critical Patents and Research on Lithium Nitride Properties

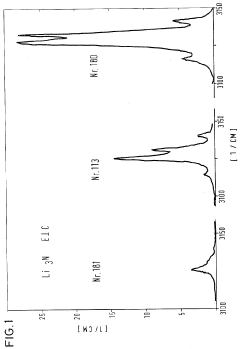

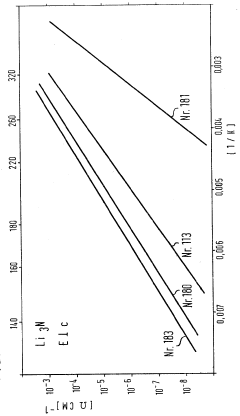

Lithium nitride of increased conductivity, method for its preparation, and its use

PatentInactiveUS4321163A

Innovation

- Doping lithium nitride with hydrogen to form nitrogen-hydrogen complex compounds, creating lithium vacancies that enhance ionic conductivity, and maintaining specific purity standards to improve stability, with hydrogen content optimized between 0.2 to 8 mole percent.

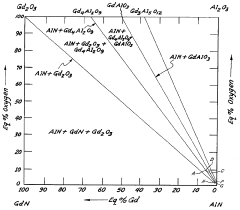

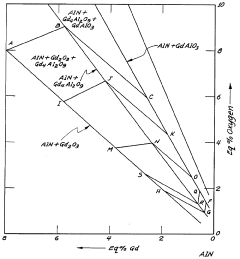

High thermal conductivity ceramic body

PatentInactiveUS4818455A

Innovation

- A process involving aluminum nitride powder with controlled oxygen content, combined with gadolinium oxide and free carbon, is deoxidized and sintered in a nitrogen atmosphere to produce a polycrystalline ceramic body with enhanced thermal conductivity, utilizing a specific phase diagram to achieve the desired composition and microstructure.

Environmental Impact Assessment of Lithium Nitride Production

The production of lithium nitride for thermal conductivity applications in electronics carries significant environmental implications that must be thoroughly assessed. The extraction of lithium, a key component in lithium nitride, involves mining operations that can lead to habitat disruption, soil degradation, and potential contamination of groundwater resources. These activities often occur in ecologically sensitive areas, particularly in South America's "Lithium Triangle" where water scarcity is already a pressing concern.

Water consumption represents one of the most critical environmental challenges in lithium nitride production. Conventional lithium extraction methods require approximately 500,000 gallons of water per ton of lithium produced, creating substantial pressure on local water tables and potentially affecting surrounding communities and ecosystems. This is particularly problematic in arid regions where lithium reserves are concentrated.

Energy requirements for lithium nitride synthesis constitute another significant environmental consideration. The production process typically involves high-temperature reactions between lithium and nitrogen gas, consuming substantial amounts of energy. The carbon footprint of this process varies considerably depending on the energy sources utilized, with renewable energy integration offering potential for substantial emissions reduction.

Chemical waste management presents ongoing challenges in the production lifecycle. The synthesis process generates various byproducts and waste materials that require proper handling and disposal to prevent soil and water contamination. Advanced waste treatment technologies and closed-loop production systems are being developed to mitigate these impacts, though implementation remains inconsistent across global manufacturing facilities.

Comparative lifecycle assessment studies indicate that lithium nitride production, while energy-intensive, may offer environmental advantages when considering the full product lifecycle in electronics applications. Its superior thermal conductivity properties can enhance device efficiency and longevity, potentially reducing electronic waste generation and energy consumption during product use phases.

Regulatory frameworks governing lithium nitride production vary significantly across jurisdictions, creating challenges for standardized environmental protection. Leading manufacturers are increasingly adopting voluntary environmental management systems and sustainability certifications to address these gaps and demonstrate commitment to responsible production practices.

Future sustainability improvements in lithium nitride production will likely focus on developing direct lithium extraction technologies that reduce water consumption, implementing renewable energy sources for production processes, and establishing more robust material recovery systems to enable circular economy approaches in the electronics sector.

Water consumption represents one of the most critical environmental challenges in lithium nitride production. Conventional lithium extraction methods require approximately 500,000 gallons of water per ton of lithium produced, creating substantial pressure on local water tables and potentially affecting surrounding communities and ecosystems. This is particularly problematic in arid regions where lithium reserves are concentrated.

Energy requirements for lithium nitride synthesis constitute another significant environmental consideration. The production process typically involves high-temperature reactions between lithium and nitrogen gas, consuming substantial amounts of energy. The carbon footprint of this process varies considerably depending on the energy sources utilized, with renewable energy integration offering potential for substantial emissions reduction.

Chemical waste management presents ongoing challenges in the production lifecycle. The synthesis process generates various byproducts and waste materials that require proper handling and disposal to prevent soil and water contamination. Advanced waste treatment technologies and closed-loop production systems are being developed to mitigate these impacts, though implementation remains inconsistent across global manufacturing facilities.

Comparative lifecycle assessment studies indicate that lithium nitride production, while energy-intensive, may offer environmental advantages when considering the full product lifecycle in electronics applications. Its superior thermal conductivity properties can enhance device efficiency and longevity, potentially reducing electronic waste generation and energy consumption during product use phases.

Regulatory frameworks governing lithium nitride production vary significantly across jurisdictions, creating challenges for standardized environmental protection. Leading manufacturers are increasingly adopting voluntary environmental management systems and sustainability certifications to address these gaps and demonstrate commitment to responsible production practices.

Future sustainability improvements in lithium nitride production will likely focus on developing direct lithium extraction technologies that reduce water consumption, implementing renewable energy sources for production processes, and establishing more robust material recovery systems to enable circular economy approaches in the electronics sector.

Comparative Analysis with Alternative Thermal Interface Materials

In the realm of thermal management for electronics, lithium nitride (Li₃N) represents a promising yet relatively unexplored material when compared to conventional thermal interface materials (TIMs). When benchmarked against traditional options such as thermal greases, phase change materials (PCMs), and metal-based TIMs, lithium nitride demonstrates several distinctive characteristics that warrant attention.

Thermal greases, which have dominated the market for decades, typically offer thermal conductivity values ranging from 3-8 W/mK, significantly lower than lithium nitride's theoretical potential of 15-20 W/mK. While greases provide excellent gap-filling properties and ease of application, they suffer from pump-out effects and degradation over time—limitations that lithium nitride's stable crystalline structure could potentially overcome.

Phase change materials, another popular category of TIMs, operate by transitioning between solid and liquid states at specific temperatures. These materials generally exhibit thermal conductivity values between 1-5 W/mK, again falling short of lithium nitride's capabilities. However, PCMs excel in managing thermal cycling and maintaining consistent contact resistance, areas where lithium nitride's performance requires further investigation.

Metal-based TIMs, including indium, gallium, and various alloys, offer thermal conductivity values of 20-86 W/mK, potentially surpassing lithium nitride. Nevertheless, these materials often present challenges related to electrical conductivity, which can cause short circuits in sensitive electronic components—a risk not present with the electrically insulating properties of lithium nitride.

Carbon-based alternatives such as graphite sheets and carbon nanotubes represent the cutting edge of thermal interface materials, with in-plane thermal conductivity values reaching as high as 1500-2000 W/mK. However, their through-plane conductivity often drops to 5-10 W/mK due to anisotropic properties. Lithium nitride's more isotropic thermal behavior could provide advantages in applications requiring multidirectional heat dissipation.

Cost-effectiveness analysis reveals that while lithium nitride's raw material costs exceed those of conventional silicone-based TIMs, its potentially longer lifespan and superior performance could yield better long-term value. Manufacturing scalability remains a significant challenge for lithium nitride implementation, as current production methods lack the maturity of established TIM manufacturing processes.

Environmental considerations also favor lithium nitride over certain alternatives. Unlike some metal-based TIMs containing gallium or indium, lithium nitride presents fewer environmental hazards and may offer better end-of-life recyclability, aligning with growing industry demands for sustainable materials in electronic components.

Thermal greases, which have dominated the market for decades, typically offer thermal conductivity values ranging from 3-8 W/mK, significantly lower than lithium nitride's theoretical potential of 15-20 W/mK. While greases provide excellent gap-filling properties and ease of application, they suffer from pump-out effects and degradation over time—limitations that lithium nitride's stable crystalline structure could potentially overcome.

Phase change materials, another popular category of TIMs, operate by transitioning between solid and liquid states at specific temperatures. These materials generally exhibit thermal conductivity values between 1-5 W/mK, again falling short of lithium nitride's capabilities. However, PCMs excel in managing thermal cycling and maintaining consistent contact resistance, areas where lithium nitride's performance requires further investigation.

Metal-based TIMs, including indium, gallium, and various alloys, offer thermal conductivity values of 20-86 W/mK, potentially surpassing lithium nitride. Nevertheless, these materials often present challenges related to electrical conductivity, which can cause short circuits in sensitive electronic components—a risk not present with the electrically insulating properties of lithium nitride.

Carbon-based alternatives such as graphite sheets and carbon nanotubes represent the cutting edge of thermal interface materials, with in-plane thermal conductivity values reaching as high as 1500-2000 W/mK. However, their through-plane conductivity often drops to 5-10 W/mK due to anisotropic properties. Lithium nitride's more isotropic thermal behavior could provide advantages in applications requiring multidirectional heat dissipation.

Cost-effectiveness analysis reveals that while lithium nitride's raw material costs exceed those of conventional silicone-based TIMs, its potentially longer lifespan and superior performance could yield better long-term value. Manufacturing scalability remains a significant challenge for lithium nitride implementation, as current production methods lack the maturity of established TIM manufacturing processes.

Environmental considerations also favor lithium nitride over certain alternatives. Unlike some metal-based TIMs containing gallium or indium, lithium nitride presents fewer environmental hazards and may offer better end-of-life recyclability, aligning with growing industry demands for sustainable materials in electronic components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!