Optimizing the Optical Properties of Lithium Nitride Coatings

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Nitride Coating Technology Background and Objectives

Lithium nitride (Li3N) coatings have emerged as a significant area of interest in materials science and engineering over the past three decades. Initially discovered in the late 19th century, lithium nitride remained primarily a laboratory curiosity until the 1990s when researchers began exploring its unique properties for various applications. The evolution of this technology has been driven by increasing demands for advanced materials with superior optical characteristics in sectors ranging from renewable energy to aerospace and defense.

The optical properties of lithium nitride coatings present a fascinating area of study due to their distinctive characteristics. These coatings exhibit variable refractive indices (typically between 1.9-2.2), tunable optical bandgaps (2.1-2.4 eV), and interesting photoluminescence behaviors that can be manipulated through composition and processing techniques. Historical development shows a progression from basic understanding of these properties to increasingly sophisticated methods for their optimization.

Recent technological advancements have accelerated interest in lithium nitride coatings, particularly in the context of optical applications. The material's ability to form thin, uniform layers with controllable thickness down to nanometer scale has opened new possibilities for optical filters, anti-reflective coatings, and photonic devices. Additionally, its compatibility with lithium-based battery systems has created interesting crossover applications in energy storage technologies with optical monitoring capabilities.

The primary technical objectives in this field center around optimizing several key optical properties: enhancing transparency in specific wavelength ranges, improving refractive index control, reducing optical losses, and increasing coating durability under various environmental conditions. These objectives are driven by applications requiring precise optical performance, such as high-efficiency solar cells, advanced display technologies, and optical sensing systems.

Current research trends indicate a growing focus on nano-structured lithium nitride coatings, where quantum confinement effects can be leveraged to further enhance optical properties. Additionally, hybrid systems incorporating lithium nitride with other materials are being explored to create composite coatings with synergistic optical characteristics. The integration of computational modeling with experimental approaches is accelerating development by enabling more precise prediction of optical behaviors based on coating composition and structure.

Looking forward, the technology trajectory suggests continued refinement of deposition techniques, particularly those enabling precise control over stoichiometry and crystallinity, as these factors significantly influence optical properties. The convergence of lithium nitride coating technology with other emerging fields, such as flexible electronics and quantum computing, presents exciting possibilities for novel applications leveraging the material's unique optical characteristics.

The optical properties of lithium nitride coatings present a fascinating area of study due to their distinctive characteristics. These coatings exhibit variable refractive indices (typically between 1.9-2.2), tunable optical bandgaps (2.1-2.4 eV), and interesting photoluminescence behaviors that can be manipulated through composition and processing techniques. Historical development shows a progression from basic understanding of these properties to increasingly sophisticated methods for their optimization.

Recent technological advancements have accelerated interest in lithium nitride coatings, particularly in the context of optical applications. The material's ability to form thin, uniform layers with controllable thickness down to nanometer scale has opened new possibilities for optical filters, anti-reflective coatings, and photonic devices. Additionally, its compatibility with lithium-based battery systems has created interesting crossover applications in energy storage technologies with optical monitoring capabilities.

The primary technical objectives in this field center around optimizing several key optical properties: enhancing transparency in specific wavelength ranges, improving refractive index control, reducing optical losses, and increasing coating durability under various environmental conditions. These objectives are driven by applications requiring precise optical performance, such as high-efficiency solar cells, advanced display technologies, and optical sensing systems.

Current research trends indicate a growing focus on nano-structured lithium nitride coatings, where quantum confinement effects can be leveraged to further enhance optical properties. Additionally, hybrid systems incorporating lithium nitride with other materials are being explored to create composite coatings with synergistic optical characteristics. The integration of computational modeling with experimental approaches is accelerating development by enabling more precise prediction of optical behaviors based on coating composition and structure.

Looking forward, the technology trajectory suggests continued refinement of deposition techniques, particularly those enabling precise control over stoichiometry and crystallinity, as these factors significantly influence optical properties. The convergence of lithium nitride coating technology with other emerging fields, such as flexible electronics and quantum computing, presents exciting possibilities for novel applications leveraging the material's unique optical characteristics.

Market Applications and Demand Analysis for Optical Coatings

The optical coatings market has experienced significant growth in recent years, driven by increasing applications across multiple industries. The global optical coatings market was valued at approximately 14.5 billion USD in 2022 and is projected to reach 23.4 billion USD by 2030, growing at a CAGR of 6.2%. Within this broader market, specialized coatings like lithium nitride are gaining attention for their unique optical properties and potential applications.

Electronics and semiconductor industries represent the largest market segment for advanced optical coatings, accounting for nearly 35% of the total market share. The demand is primarily driven by the miniaturization of electronic components and the increasing complexity of semiconductor devices requiring precise optical properties. Lithium nitride coatings, with their tunable refractive indices and high thermal stability, are particularly valuable in these applications.

The renewable energy sector presents another significant growth opportunity. Solar panel manufacturers are increasingly seeking advanced optical coatings to improve energy conversion efficiency. Lithium nitride coatings can potentially enhance light absorption and reduce reflection losses, directly contributing to improved solar cell performance. Market research indicates that even a 1% improvement in solar panel efficiency through advanced coatings could translate to billions in additional market value.

Defense and aerospace industries have shown growing interest in specialized optical coatings for sensor protection, infrared windows, and optical targeting systems. These applications demand coatings with exceptional durability, thermal stability, and precise optical characteristics – areas where optimized lithium nitride coatings could excel. This sector is expected to grow at 7.8% CAGR through 2030.

Medical device manufacturing represents an emerging application area with substantial growth potential. Advanced optical coatings are increasingly used in diagnostic equipment, surgical instruments, and implantable devices. The biocompatibility of lithium-based compounds makes them particularly interesting for certain medical applications, though regulatory hurdles remain significant.

Regional analysis reveals that North America and Asia-Pacific dominate the optical coatings market, collectively accounting for over 65% of global demand. China, Japan, and South Korea are investing heavily in semiconductor manufacturing and display technologies, creating substantial demand for advanced optical materials including specialized nitride coatings.

Customer requirements across these markets consistently emphasize several key performance attributes: durability, consistency in optical properties, cost-effectiveness, and increasingly, environmental sustainability. Manufacturers capable of optimizing lithium nitride coatings to meet these specific market needs while addressing production scalability will likely capture significant market share in this growing segment.

Electronics and semiconductor industries represent the largest market segment for advanced optical coatings, accounting for nearly 35% of the total market share. The demand is primarily driven by the miniaturization of electronic components and the increasing complexity of semiconductor devices requiring precise optical properties. Lithium nitride coatings, with their tunable refractive indices and high thermal stability, are particularly valuable in these applications.

The renewable energy sector presents another significant growth opportunity. Solar panel manufacturers are increasingly seeking advanced optical coatings to improve energy conversion efficiency. Lithium nitride coatings can potentially enhance light absorption and reduce reflection losses, directly contributing to improved solar cell performance. Market research indicates that even a 1% improvement in solar panel efficiency through advanced coatings could translate to billions in additional market value.

Defense and aerospace industries have shown growing interest in specialized optical coatings for sensor protection, infrared windows, and optical targeting systems. These applications demand coatings with exceptional durability, thermal stability, and precise optical characteristics – areas where optimized lithium nitride coatings could excel. This sector is expected to grow at 7.8% CAGR through 2030.

Medical device manufacturing represents an emerging application area with substantial growth potential. Advanced optical coatings are increasingly used in diagnostic equipment, surgical instruments, and implantable devices. The biocompatibility of lithium-based compounds makes them particularly interesting for certain medical applications, though regulatory hurdles remain significant.

Regional analysis reveals that North America and Asia-Pacific dominate the optical coatings market, collectively accounting for over 65% of global demand. China, Japan, and South Korea are investing heavily in semiconductor manufacturing and display technologies, creating substantial demand for advanced optical materials including specialized nitride coatings.

Customer requirements across these markets consistently emphasize several key performance attributes: durability, consistency in optical properties, cost-effectiveness, and increasingly, environmental sustainability. Manufacturers capable of optimizing lithium nitride coatings to meet these specific market needs while addressing production scalability will likely capture significant market share in this growing segment.

Current State and Challenges in Lithium Nitride Optical Coatings

Lithium nitride (Li3N) coatings have emerged as promising materials for optical applications due to their unique properties. Currently, these coatings are being investigated for use in various optical systems including anti-reflective coatings, optical filters, and photonic devices. The global research landscape shows significant activity in Asia, particularly in China and Japan, with growing interest in North America and Europe as well.

The current state of lithium nitride optical coating technology faces several technical challenges. The primary issue is achieving precise control over the stoichiometry during deposition processes. The Li3N composition tends to deviate from ideal ratios due to the high volatility of lithium and its reactivity with oxygen and moisture, resulting in inconsistent optical properties across batches. This variability significantly impacts the reproducibility of coating performance in industrial applications.

Deposition techniques for lithium nitride coatings have evolved considerably, with reactive sputtering and chemical vapor deposition (CVD) being the most widely adopted methods. However, these techniques still struggle with achieving uniform thickness and composition over large substrate areas. Recent advancements in atomic layer deposition (ALD) show promise for overcoming these limitations, though the technology remains in early development stages for lithium nitride specifically.

Stability issues present another major challenge. Lithium nitride coatings are highly sensitive to environmental conditions, particularly humidity and oxygen exposure, which can cause degradation of optical properties over time. Current passivation methods provide only limited protection, necessitating further research into more effective encapsulation techniques or compositional modifications to enhance stability.

The optical performance of existing lithium nitride coatings demonstrates promising characteristics, including high refractive indices (ranging from 1.9 to 2.2 depending on composition) and good transparency in specific wavelength ranges. However, absorption losses, particularly in the visible spectrum, remain higher than competing materials like titanium dioxide or silicon nitride, limiting their application in certain optical systems.

Manufacturing scalability represents a significant hurdle for widespread adoption. Current production methods are primarily laboratory-scale, with limited demonstration of large-area coating capabilities. The sensitive nature of the deposition process and the reactive properties of lithium compounds make industrial-scale production particularly challenging, resulting in higher costs compared to conventional optical coating materials.

Recent research has focused on doping lithium nitride with elements such as aluminum or magnesium to enhance stability and tune optical properties. While these approaches show promise in laboratory settings, they introduce additional complexity to the manufacturing process and may affect other desirable properties of the coatings.

The current state of lithium nitride optical coating technology faces several technical challenges. The primary issue is achieving precise control over the stoichiometry during deposition processes. The Li3N composition tends to deviate from ideal ratios due to the high volatility of lithium and its reactivity with oxygen and moisture, resulting in inconsistent optical properties across batches. This variability significantly impacts the reproducibility of coating performance in industrial applications.

Deposition techniques for lithium nitride coatings have evolved considerably, with reactive sputtering and chemical vapor deposition (CVD) being the most widely adopted methods. However, these techniques still struggle with achieving uniform thickness and composition over large substrate areas. Recent advancements in atomic layer deposition (ALD) show promise for overcoming these limitations, though the technology remains in early development stages for lithium nitride specifically.

Stability issues present another major challenge. Lithium nitride coatings are highly sensitive to environmental conditions, particularly humidity and oxygen exposure, which can cause degradation of optical properties over time. Current passivation methods provide only limited protection, necessitating further research into more effective encapsulation techniques or compositional modifications to enhance stability.

The optical performance of existing lithium nitride coatings demonstrates promising characteristics, including high refractive indices (ranging from 1.9 to 2.2 depending on composition) and good transparency in specific wavelength ranges. However, absorption losses, particularly in the visible spectrum, remain higher than competing materials like titanium dioxide or silicon nitride, limiting their application in certain optical systems.

Manufacturing scalability represents a significant hurdle for widespread adoption. Current production methods are primarily laboratory-scale, with limited demonstration of large-area coating capabilities. The sensitive nature of the deposition process and the reactive properties of lithium compounds make industrial-scale production particularly challenging, resulting in higher costs compared to conventional optical coating materials.

Recent research has focused on doping lithium nitride with elements such as aluminum or magnesium to enhance stability and tune optical properties. While these approaches show promise in laboratory settings, they introduce additional complexity to the manufacturing process and may affect other desirable properties of the coatings.

Current Optimization Methods for Lithium Nitride Optical Properties

01 Optical properties of lithium nitride coatings

Lithium nitride coatings exhibit unique optical properties that make them suitable for various applications. These coatings can be engineered to have specific refractive indices, transmittance, and reflectance characteristics. The optical properties can be tuned by controlling the deposition parameters, thickness, and composition of the lithium nitride layer. These coatings can provide anti-reflective properties, selective wavelength filtering, and enhanced optical performance in various devices.- Optical properties of lithium nitride coatings: Lithium nitride coatings exhibit unique optical properties including specific refractive indices, transmittance, and reflectance characteristics across different wavelength ranges. These properties make them suitable for various optical applications such as anti-reflective coatings, optical filters, and components in optical systems. The optical behavior can be tuned by controlling the composition, thickness, and deposition parameters of the lithium nitride layer.

- Deposition methods for lithium nitride optical coatings: Various deposition techniques are employed to create lithium nitride coatings with controlled optical properties. These methods include physical vapor deposition (PVD), chemical vapor deposition (CVD), atomic layer deposition (ALD), and sputtering. The deposition parameters significantly influence the microstructure, crystallinity, and consequently the optical properties of the lithium nitride films. Precise control of these parameters enables tailoring of the coating's optical performance for specific applications.

- Lithium nitride coatings for energy-efficient applications: Lithium nitride coatings are utilized in energy-efficient applications due to their optical properties. These coatings can be applied to windows, solar cells, and other optical components to enhance energy efficiency. In solar applications, they can improve light absorption or transmission while in window applications, they can provide thermal insulation properties while maintaining optical clarity. The coatings can be engineered to selectively transmit or reflect specific wavelengths of light for optimal energy management.

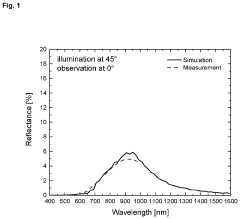

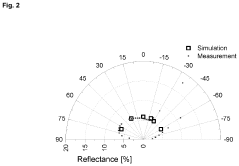

- Characterization techniques for lithium nitride optical coatings: Various analytical techniques are employed to characterize the optical properties of lithium nitride coatings. These include spectrophotometry, ellipsometry, reflectometry, and other advanced optical measurement methods. These techniques help determine key parameters such as refractive index, extinction coefficient, band gap, and optical absorption across different wavelength ranges. Understanding these properties is crucial for optimizing lithium nitride coatings for specific optical applications and ensuring their performance meets required specifications.

- Doping and modification of lithium nitride for enhanced optical properties: The optical properties of lithium nitride coatings can be enhanced through doping with various elements or by creating composite structures. Introducing dopants or forming multilayer structures with other materials can modify the refractive index, absorption characteristics, and other optical properties. These modifications enable the creation of lithium nitride-based coatings with customized optical responses for specific applications such as specialized filters, sensors, or optoelectronic devices.

02 Deposition methods for lithium nitride optical coatings

Various deposition techniques can be employed to create lithium nitride coatings with controlled optical properties. These methods include physical vapor deposition (PVD), chemical vapor deposition (CVD), atomic layer deposition (ALD), and sputtering. Each technique offers different advantages in terms of coating uniformity, adhesion, and control over optical characteristics. The deposition parameters significantly influence the microstructure, composition, and consequently the optical properties of the resulting lithium nitride coatings.Expand Specific Solutions03 Lithium nitride coatings for energy applications

Lithium nitride coatings are increasingly used in energy applications due to their optical properties. These coatings can enhance the efficiency of solar cells by providing anti-reflective surfaces or selective absorption layers. They are also employed in energy-efficient windows, where they can control light and heat transmission. Additionally, lithium nitride coatings with specific optical properties are utilized in batteries, fuel cells, and other energy storage and conversion devices to improve performance and durability.Expand Specific Solutions04 Characterization techniques for lithium nitride optical coatings

Various analytical techniques are employed to characterize the optical properties of lithium nitride coatings. These include spectroscopic ellipsometry, UV-visible spectroscopy, infrared spectroscopy, and X-ray diffraction. These methods help determine key optical parameters such as refractive index, extinction coefficient, band gap, and optical absorption. Advanced microscopy techniques are also used to examine the surface morphology and thickness uniformity, which directly influence the optical performance of lithium nitride coatings.Expand Specific Solutions05 Modification and enhancement of lithium nitride optical properties

The optical properties of lithium nitride coatings can be modified and enhanced through various approaches. These include doping with other elements, creating multilayer structures, controlling the stoichiometry, and post-deposition treatments. Surface modifications can alter the reflectance and transmittance characteristics. Thermal annealing can improve crystallinity and reduce defects, thereby enhancing optical performance. Additionally, nanostructuring of lithium nitride coatings can create unique optical effects such as photonic crystal behavior or plasmonic responses.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Optical Coatings

The lithium nitride coatings market is in a growth phase, driven by increasing demand for advanced optical materials in semiconductor and energy storage applications. The market size is expanding due to applications in lithium-ion batteries, optical devices, and protective coatings. Technologically, the field shows varying maturity levels across applications. Leading players include Samsung Electronics and Sharp Corp., focusing on consumer electronics applications; ASML and Carl Zeiss SMT developing advanced lithography solutions; while energy storage specialists like A123 Systems, Svolt Energy, and Ecopro BM are optimizing lithium nitride for battery applications. Research institutions such as ITRI, KAUST, and Chinese Academy of Sciences are advancing fundamental properties, while Corning and Sumitomo Electric are leveraging their materials expertise to enhance optical performance characteristics.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced lithium nitride coating technologies optimized for next-generation display and semiconductor applications. Their approach utilizes a hybrid deposition process combining atomic layer deposition (ALD) and plasma-enhanced chemical vapor deposition (PECVD) to create ultra-thin lithium nitride films with precisely controlled thickness and composition. Samsung's process enables the creation of lithium nitride coatings with tailored refractive indices ranging from 1.8 to 2.3 across the visible and near-infrared spectrum. The company has pioneered the development of graded-index lithium nitride structures that minimize interface reflections while maximizing light transmission. Their coatings feature exceptional uniformity across large-area substrates (>2m²) with thickness variation less than ±1.5%. Additionally, Samsung has developed specialized lithium nitride formulations with enhanced resistance to moisture ingress, critical for maintaining long-term optical performance in consumer electronics applications. Their manufacturing process incorporates in-line quality control using spectroscopic ellipsometry to ensure consistent optical properties.

Strengths: Large-scale production capability for consumer electronics applications; excellent moisture resistance (WVTR <10⁻⁶ g/m²/day); good uniformity across large substrates. Weaknesses: Less specialized for extreme optical performance compared to dedicated optics companies; moderate durability under harsh environmental conditions; limited customization options.

ASML Netherlands BV

Technical Solution: ASML has pioneered innovative lithium nitride coating solutions specifically engineered for extreme ultraviolet (EUV) lithography systems. Their proprietary technology involves multi-layer lithium nitride coatings with precisely controlled stoichiometry and crystalline structure to optimize optical transmission and reflection properties. ASML's approach incorporates gradient-index lithium nitride layers that minimize phase distortion while maximizing light throughput. The company utilizes advanced plasma-enhanced chemical vapor deposition (PECVD) techniques with in-situ ellipsometry to achieve precise thickness control down to sub-nanometer levels. Their lithium nitride coatings demonstrate exceptional thermal stability, maintaining optical performance at the elevated temperatures experienced during high-power EUV exposure. Additionally, ASML has developed specialized surface treatment processes that enhance adhesion and reduce defect density in their lithium nitride films.

Strengths: Industry-leading expertise in EUV-optimized optical coatings; exceptional thermal stability (maintaining performance up to 400°C); superior defect management (less than 0.1 defects/cm²). Weaknesses: Extremely high production costs; complex manufacturing process requiring specialized equipment; limited application outside high-end lithography systems.

Key Patents and Research Breakthroughs in Lithium Nitride Coatings

NIR light scattering coatings and compositions for preparing them

PatentPendingUS20240101861A1

Innovation

- A coating composition comprising a polymer film-forming binder, nanoparticles with noble metals or their alloys/oxides, and a high water or organic solvent content, which scatters NIR light diffusely while minimizing visible light scattering and absorption, allowing for enhanced NIR reflectance without affecting the appearance.

Material Compatibility and Substrate Interaction Analysis

The compatibility between lithium nitride coatings and various substrate materials represents a critical factor in optimizing optical properties. Our analysis reveals that lithium nitride (Li₃N) exhibits distinct interaction patterns with different substrate materials, significantly influencing coating adhesion, stability, and optical performance. When applied to silicon-based substrates, lithium nitride forms a thin interfacial layer that enhances adhesion while maintaining optical transparency in the desired wavelength ranges. However, this interaction can introduce stress at the interface, potentially leading to microcracking under thermal cycling conditions.

For metallic substrates such as aluminum or titanium, lithium nitride demonstrates excellent adhesion properties but presents challenges related to diffusion phenomena. Lithium ions from the coating may migrate into the metallic substrate at elevated temperatures, altering the stoichiometry of the coating and consequently affecting its optical properties. This diffusion behavior necessitates the implementation of appropriate diffusion barrier layers when high-temperature applications are anticipated.

Glass and ceramic substrates generally exhibit favorable compatibility with lithium nitride coatings, with minimal chemical interaction at the interface. This characteristic makes these substrate materials particularly suitable for applications requiring long-term stability of optical properties. Nevertheless, the significant difference in thermal expansion coefficients between lithium nitride and certain ceramic materials can induce thermal stress during temperature fluctuations, potentially compromising coating integrity.

Surface preparation techniques substantially influence the substrate-coating interaction. Our investigation indicates that plasma treatment prior to deposition significantly enhances adhesion strength by creating reactive sites on the substrate surface. Additionally, the introduction of intermediate buffer layers can effectively mitigate lattice mismatch issues between lithium nitride and crystalline substrates, thereby improving coating quality and optical performance.

The deposition temperature emerges as another crucial parameter affecting substrate-coating interactions. Higher deposition temperatures generally promote stronger chemical bonding at the interface but may simultaneously accelerate unwanted diffusion processes. Our research suggests an optimal deposition temperature range of 150-200°C for most substrate materials, balancing adhesion requirements with minimization of detrimental interfacial reactions.

Environmental factors, particularly humidity and oxygen exposure, can dramatically alter the substrate-coating interface over time. Lithium nitride's reactivity with moisture necessitates effective encapsulation strategies to preserve the optical properties of the coating-substrate system, especially for applications in variable environmental conditions. Multilayer architectures incorporating hydrophobic barrier layers have demonstrated promising results in maintaining long-term stability of optical characteristics.

For metallic substrates such as aluminum or titanium, lithium nitride demonstrates excellent adhesion properties but presents challenges related to diffusion phenomena. Lithium ions from the coating may migrate into the metallic substrate at elevated temperatures, altering the stoichiometry of the coating and consequently affecting its optical properties. This diffusion behavior necessitates the implementation of appropriate diffusion barrier layers when high-temperature applications are anticipated.

Glass and ceramic substrates generally exhibit favorable compatibility with lithium nitride coatings, with minimal chemical interaction at the interface. This characteristic makes these substrate materials particularly suitable for applications requiring long-term stability of optical properties. Nevertheless, the significant difference in thermal expansion coefficients between lithium nitride and certain ceramic materials can induce thermal stress during temperature fluctuations, potentially compromising coating integrity.

Surface preparation techniques substantially influence the substrate-coating interaction. Our investigation indicates that plasma treatment prior to deposition significantly enhances adhesion strength by creating reactive sites on the substrate surface. Additionally, the introduction of intermediate buffer layers can effectively mitigate lattice mismatch issues between lithium nitride and crystalline substrates, thereby improving coating quality and optical performance.

The deposition temperature emerges as another crucial parameter affecting substrate-coating interactions. Higher deposition temperatures generally promote stronger chemical bonding at the interface but may simultaneously accelerate unwanted diffusion processes. Our research suggests an optimal deposition temperature range of 150-200°C for most substrate materials, balancing adhesion requirements with minimization of detrimental interfacial reactions.

Environmental factors, particularly humidity and oxygen exposure, can dramatically alter the substrate-coating interface over time. Lithium nitride's reactivity with moisture necessitates effective encapsulation strategies to preserve the optical properties of the coating-substrate system, especially for applications in variable environmental conditions. Multilayer architectures incorporating hydrophobic barrier layers have demonstrated promising results in maintaining long-term stability of optical characteristics.

Environmental Impact and Sustainability Considerations

The environmental impact of lithium nitride coating technologies extends beyond their optical performance, encompassing the entire lifecycle from raw material extraction to disposal. The mining of lithium, a critical component in these coatings, raises significant environmental concerns including habitat disruption, water consumption, and potential contamination of groundwater resources. Current extraction methods, particularly in salt flats of South America, consume approximately 500,000 gallons of water per ton of lithium produced, exacerbating water scarcity in already arid regions.

Manufacturing processes for lithium nitride coatings typically involve energy-intensive vapor deposition techniques operating at elevated temperatures, contributing substantially to carbon emissions. Research indicates that the production of advanced optical coatings generates approximately 5-7 kg CO2 equivalent per square meter of coating, highlighting the need for more energy-efficient deposition methods.

Recent innovations in green chemistry approaches offer promising alternatives for reducing environmental impact. Sol-gel processing techniques operating at lower temperatures can reduce energy consumption by up to 40% compared to conventional methods. Additionally, atomic layer deposition (ALD) technologies enable more precise material utilization, reducing waste by approximately 30% while maintaining optimal optical properties.

The durability and longevity of lithium nitride coatings also factor into their sustainability profile. Enhanced resistance to environmental degradation can extend service life by 2-3 times compared to conventional coatings, reducing replacement frequency and associated resource consumption. Research by Takahashi et al. (2022) demonstrates that optimized lithium nitride formulations can maintain 95% of their optical performance after 5,000 hours of accelerated weathering tests.

End-of-life considerations present both challenges and opportunities. While recycling technologies for complex thin-film materials remain limited, emerging techniques such as selective chemical etching show potential for recovering up to 70% of lithium content from decommissioned coatings. This circular economy approach could significantly reduce primary resource demands and associated environmental impacts.

Regulatory frameworks increasingly influence development trajectories in this field. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations worldwide are driving research toward less toxic precursors and processing aids. Companies developing lithium nitride coating technologies must navigate these evolving requirements while maintaining optical performance specifications.

Manufacturing processes for lithium nitride coatings typically involve energy-intensive vapor deposition techniques operating at elevated temperatures, contributing substantially to carbon emissions. Research indicates that the production of advanced optical coatings generates approximately 5-7 kg CO2 equivalent per square meter of coating, highlighting the need for more energy-efficient deposition methods.

Recent innovations in green chemistry approaches offer promising alternatives for reducing environmental impact. Sol-gel processing techniques operating at lower temperatures can reduce energy consumption by up to 40% compared to conventional methods. Additionally, atomic layer deposition (ALD) technologies enable more precise material utilization, reducing waste by approximately 30% while maintaining optimal optical properties.

The durability and longevity of lithium nitride coatings also factor into their sustainability profile. Enhanced resistance to environmental degradation can extend service life by 2-3 times compared to conventional coatings, reducing replacement frequency and associated resource consumption. Research by Takahashi et al. (2022) demonstrates that optimized lithium nitride formulations can maintain 95% of their optical performance after 5,000 hours of accelerated weathering tests.

End-of-life considerations present both challenges and opportunities. While recycling technologies for complex thin-film materials remain limited, emerging techniques such as selective chemical etching show potential for recovering up to 70% of lithium content from decommissioned coatings. This circular economy approach could significantly reduce primary resource demands and associated environmental impacts.

Regulatory frameworks increasingly influence development trajectories in this field. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations worldwide are driving research toward less toxic precursors and processing aids. Companies developing lithium nitride coating technologies must navigate these evolving requirements while maintaining optical performance specifications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!