How to Control Degradation Rates in Polysilane Materials?

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polysilane Degradation Control Objectives

Controlling the degradation rates in polysilane materials is a critical objective in the field of polymer science and materials engineering. The primary goal is to enhance the stability and longevity of polysilane-based products, which have shown great potential in various applications such as photoresists, precursors for silicon carbide ceramics, and optoelectronic devices. By effectively managing the degradation process, researchers aim to expand the practical utility of these materials and overcome current limitations in their performance.

One of the key objectives is to mitigate the photo-oxidative degradation of polysilanes, which occurs when these materials are exposed to light and oxygen. This process can lead to chain scission and the formation of silanol groups, ultimately resulting in the deterioration of the material's properties. Researchers are focusing on developing strategies to enhance the photostability of polysilanes without compromising their unique electronic and optical characteristics.

Another important goal is to control the thermal degradation of polysilanes, which becomes significant at elevated temperatures. The thermal stability of these materials is crucial for their use in high-temperature applications and processing techniques. Scientists are working on improving the thermal resistance of polysilanes by modifying their molecular structure and incorporating stabilizing additives.

The development of novel polysilane architectures with inherent resistance to degradation is also a primary objective. This includes the design of copolymers, branched structures, and hybrid materials that can maintain their integrity under various environmental conditions. By tailoring the molecular composition and structure, researchers aim to create polysilanes with enhanced durability and extended functional lifetimes.

Furthermore, there is a strong focus on understanding the fundamental mechanisms of polysilane degradation at the molecular level. This knowledge is essential for developing targeted strategies to control and slow down the degradation processes. Advanced analytical techniques and computational modeling are being employed to gain deeper insights into the degradation pathways and kinetics.

The optimization of processing conditions and the development of protective coatings or encapsulation methods are also key objectives in controlling polysilane degradation rates. These approaches aim to minimize exposure to degradation-inducing factors and create more robust polysilane-based products. Additionally, researchers are exploring the potential of self-healing polysilane materials that can autonomously repair damage and extend their operational lifespan.

Ultimately, the overarching goal of controlling degradation rates in polysilane materials is to unlock their full potential for advanced technological applications. By addressing these objectives, scientists and engineers hope to pave the way for the widespread adoption of polysilanes in fields such as electronics, photonics, and advanced materials, where long-term stability and reliability are paramount.

One of the key objectives is to mitigate the photo-oxidative degradation of polysilanes, which occurs when these materials are exposed to light and oxygen. This process can lead to chain scission and the formation of silanol groups, ultimately resulting in the deterioration of the material's properties. Researchers are focusing on developing strategies to enhance the photostability of polysilanes without compromising their unique electronic and optical characteristics.

Another important goal is to control the thermal degradation of polysilanes, which becomes significant at elevated temperatures. The thermal stability of these materials is crucial for their use in high-temperature applications and processing techniques. Scientists are working on improving the thermal resistance of polysilanes by modifying their molecular structure and incorporating stabilizing additives.

The development of novel polysilane architectures with inherent resistance to degradation is also a primary objective. This includes the design of copolymers, branched structures, and hybrid materials that can maintain their integrity under various environmental conditions. By tailoring the molecular composition and structure, researchers aim to create polysilanes with enhanced durability and extended functional lifetimes.

Furthermore, there is a strong focus on understanding the fundamental mechanisms of polysilane degradation at the molecular level. This knowledge is essential for developing targeted strategies to control and slow down the degradation processes. Advanced analytical techniques and computational modeling are being employed to gain deeper insights into the degradation pathways and kinetics.

The optimization of processing conditions and the development of protective coatings or encapsulation methods are also key objectives in controlling polysilane degradation rates. These approaches aim to minimize exposure to degradation-inducing factors and create more robust polysilane-based products. Additionally, researchers are exploring the potential of self-healing polysilane materials that can autonomously repair damage and extend their operational lifespan.

Ultimately, the overarching goal of controlling degradation rates in polysilane materials is to unlock their full potential for advanced technological applications. By addressing these objectives, scientists and engineers hope to pave the way for the widespread adoption of polysilanes in fields such as electronics, photonics, and advanced materials, where long-term stability and reliability are paramount.

Market Applications of Polysilane Materials

Polysilane materials have found diverse applications across various industries due to their unique properties and versatility. In the electronics sector, these materials have gained significant traction as photoresists in semiconductor manufacturing processes. Their high sensitivity to UV light and excellent resolution capabilities make them ideal for creating intricate patterns on silicon wafers, enabling the production of smaller and more efficient microchips.

The optoelectronics industry has also embraced polysilanes for their exceptional optical properties. These materials exhibit strong photoluminescence and electroluminescence, making them suitable for use in organic light-emitting diodes (OLEDs) and other display technologies. The potential for flexible and large-area displays has driven research into polysilane-based devices, with promising results in terms of brightness and energy efficiency.

In the field of energy storage and conversion, polysilanes have shown promise as components in lithium-ion batteries and solar cells. Their ability to form stable, conductive films has led to investigations into their use as electrode materials and charge transport layers. This application could potentially contribute to the development of more efficient and longer-lasting energy storage solutions.

The aerospace and automotive industries have explored polysilanes as precursors for silicon carbide (SiC) ceramics. When subjected to high temperatures, polysilanes can be converted into SiC, which possesses excellent thermal and mechanical properties. This transformation has opened up possibilities for lightweight, heat-resistant components in aircraft engines and automotive parts.

Biomedical applications of polysilanes have also emerged, particularly in drug delivery systems and biosensors. The biocompatibility of certain polysilane derivatives, combined with their ability to encapsulate and release drugs in a controlled manner, has attracted attention in pharmaceutical research. Additionally, the sensitivity of polysilanes to specific biomolecules has led to their use in developing highly sensitive and selective biosensors for medical diagnostics.

In the field of coatings and surface treatments, polysilanes have found applications as protective layers and adhesion promoters. Their ability to form strong chemical bonds with various substrates, coupled with their resistance to weathering and chemical attack, makes them valuable in industries ranging from construction to consumer electronics.

The growing demand for advanced materials in these diverse sectors has driven the expansion of the polysilane market. However, the widespread adoption of these materials is contingent upon addressing challenges related to their stability and degradation rates, which directly impact their performance and longevity in various applications.

The optoelectronics industry has also embraced polysilanes for their exceptional optical properties. These materials exhibit strong photoluminescence and electroluminescence, making them suitable for use in organic light-emitting diodes (OLEDs) and other display technologies. The potential for flexible and large-area displays has driven research into polysilane-based devices, with promising results in terms of brightness and energy efficiency.

In the field of energy storage and conversion, polysilanes have shown promise as components in lithium-ion batteries and solar cells. Their ability to form stable, conductive films has led to investigations into their use as electrode materials and charge transport layers. This application could potentially contribute to the development of more efficient and longer-lasting energy storage solutions.

The aerospace and automotive industries have explored polysilanes as precursors for silicon carbide (SiC) ceramics. When subjected to high temperatures, polysilanes can be converted into SiC, which possesses excellent thermal and mechanical properties. This transformation has opened up possibilities for lightweight, heat-resistant components in aircraft engines and automotive parts.

Biomedical applications of polysilanes have also emerged, particularly in drug delivery systems and biosensors. The biocompatibility of certain polysilane derivatives, combined with their ability to encapsulate and release drugs in a controlled manner, has attracted attention in pharmaceutical research. Additionally, the sensitivity of polysilanes to specific biomolecules has led to their use in developing highly sensitive and selective biosensors for medical diagnostics.

In the field of coatings and surface treatments, polysilanes have found applications as protective layers and adhesion promoters. Their ability to form strong chemical bonds with various substrates, coupled with their resistance to weathering and chemical attack, makes them valuable in industries ranging from construction to consumer electronics.

The growing demand for advanced materials in these diverse sectors has driven the expansion of the polysilane market. However, the widespread adoption of these materials is contingent upon addressing challenges related to their stability and degradation rates, which directly impact their performance and longevity in various applications.

Current Challenges in Polysilane Stability

Polysilane materials have garnered significant attention in various fields due to their unique electronic and optical properties. However, their widespread application is hindered by stability issues, particularly their susceptibility to degradation. The current challenges in polysilane stability primarily stem from their sensitivity to environmental factors and inherent structural vulnerabilities.

One of the major obstacles is photodegradation. Polysilanes are highly sensitive to UV light, which can trigger chain scission and lead to rapid degradation of the material. This photosensitivity limits their use in applications exposed to sunlight or UV radiation, such as outdoor electronic devices or solar cells. Researchers are grappling with the task of enhancing UV resistance without compromising the desirable properties of polysilanes.

Thermal stability presents another significant challenge. Many polysilanes exhibit relatively low decomposition temperatures, which restricts their use in high-temperature applications. The silicon-silicon backbone can undergo thermally-induced rearrangements or cleavage, resulting in loss of molecular weight and alteration of material properties. Improving thermal stability while maintaining processability remains a key focus area for materials scientists.

Oxidative degradation is also a critical concern. The silicon-silicon bonds in polysilanes are susceptible to oxidation, especially in the presence of moisture or oxygen. This can lead to the formation of siloxane linkages and eventual breakdown of the polymer chain. Developing effective strategies to protect polysilanes from oxidative processes without compromising their functionality is an ongoing challenge.

The mechanical stability of polysilane films and coatings is another area requiring attention. Many polysilanes exhibit brittleness and poor adhesion to substrates, limiting their durability in practical applications. Enhancing the mechanical properties without sacrificing the electronic and optical characteristics is a delicate balance that researchers are striving to achieve.

Furthermore, the stability of polysilanes in various solvents and chemical environments poses challenges for their integration into complex systems. Some polysilanes are prone to degradation or undesired reactions when exposed to certain solvents or reactive species, limiting their compatibility in multi-component devices or chemical processes.

Lastly, the long-term stability and aging behavior of polysilanes under normal operating conditions remain poorly understood. Predicting and controlling the gradual changes in material properties over extended periods is crucial for ensuring the reliability and longevity of polysilane-based technologies. This requires the development of accelerated aging tests and more sophisticated analytical techniques to study degradation mechanisms at the molecular level.

One of the major obstacles is photodegradation. Polysilanes are highly sensitive to UV light, which can trigger chain scission and lead to rapid degradation of the material. This photosensitivity limits their use in applications exposed to sunlight or UV radiation, such as outdoor electronic devices or solar cells. Researchers are grappling with the task of enhancing UV resistance without compromising the desirable properties of polysilanes.

Thermal stability presents another significant challenge. Many polysilanes exhibit relatively low decomposition temperatures, which restricts their use in high-temperature applications. The silicon-silicon backbone can undergo thermally-induced rearrangements or cleavage, resulting in loss of molecular weight and alteration of material properties. Improving thermal stability while maintaining processability remains a key focus area for materials scientists.

Oxidative degradation is also a critical concern. The silicon-silicon bonds in polysilanes are susceptible to oxidation, especially in the presence of moisture or oxygen. This can lead to the formation of siloxane linkages and eventual breakdown of the polymer chain. Developing effective strategies to protect polysilanes from oxidative processes without compromising their functionality is an ongoing challenge.

The mechanical stability of polysilane films and coatings is another area requiring attention. Many polysilanes exhibit brittleness and poor adhesion to substrates, limiting their durability in practical applications. Enhancing the mechanical properties without sacrificing the electronic and optical characteristics is a delicate balance that researchers are striving to achieve.

Furthermore, the stability of polysilanes in various solvents and chemical environments poses challenges for their integration into complex systems. Some polysilanes are prone to degradation or undesired reactions when exposed to certain solvents or reactive species, limiting their compatibility in multi-component devices or chemical processes.

Lastly, the long-term stability and aging behavior of polysilanes under normal operating conditions remain poorly understood. Predicting and controlling the gradual changes in material properties over extended periods is crucial for ensuring the reliability and longevity of polysilane-based technologies. This requires the development of accelerated aging tests and more sophisticated analytical techniques to study degradation mechanisms at the molecular level.

Existing Degradation Control Strategies

01 Degradation mechanisms of polysilane materials

Polysilane materials can degrade through various mechanisms, including photodegradation, thermal degradation, and oxidative degradation. These processes can lead to chain scission, crosslinking, or formation of siloxane bonds, affecting the material's properties and performance over time.- Degradation mechanisms of polysilane materials: Polysilane materials can degrade through various mechanisms, including photodegradation, thermal degradation, and oxidative degradation. These processes can lead to chain scission, crosslinking, or formation of siloxane bonds, affecting the material's properties and performance over time.

- Factors influencing degradation rates of polysilanes: The degradation rates of polysilane materials are influenced by factors such as molecular weight, side group structure, environmental conditions (temperature, humidity, UV exposure), and the presence of additives or stabilizers. Understanding these factors is crucial for predicting and controlling the degradation behavior of polysilanes in various applications.

- Methods to measure and analyze polysilane degradation: Various analytical techniques are employed to measure and analyze the degradation of polysilane materials. These may include spectroscopic methods (UV-Vis, FTIR, NMR), chromatography, thermal analysis (TGA, DSC), and microscopy techniques. These methods help in quantifying degradation rates and understanding the underlying mechanisms.

- Strategies to improve stability and reduce degradation rates: Researchers have developed strategies to enhance the stability and reduce degradation rates of polysilane materials. These approaches include chemical modifications, incorporation of stabilizers or antioxidants, encapsulation techniques, and the development of copolymers or blends with improved resistance to degradation.

- Applications considering polysilane degradation rates: The degradation rates of polysilane materials are crucial considerations in various applications, such as photoresists, optoelectronic devices, and coatings. Understanding and controlling degradation rates enable the development of materials with tailored lifespans and performance characteristics suitable for specific end-uses.

02 Factors influencing degradation rates of polysilanes

The degradation rates of polysilane materials are influenced by factors such as molecular weight, side-chain structure, environmental conditions (e.g., temperature, humidity, UV exposure), and the presence of additives or stabilizers. Understanding these factors is crucial for predicting and controlling the degradation behavior of polysilanes in various applications.Expand Specific Solutions03 Methods to control and modify degradation rates

Techniques to control and modify the degradation rates of polysilane materials include incorporating stabilizers, using protective coatings, modifying the molecular structure, and optimizing processing conditions. These methods can help tailor the degradation behavior to suit specific application requirements.Expand Specific Solutions04 Characterization techniques for degradation studies

Various analytical techniques are employed to study the degradation rates and mechanisms of polysilane materials. These include spectroscopic methods (e.g., UV-Vis, FTIR, NMR), thermal analysis (e.g., TGA, DSC), chromatography, and microscopy techniques. These methods provide insights into the chemical and physical changes occurring during degradation.Expand Specific Solutions05 Applications considering polysilane degradation rates

The degradation rates of polysilane materials are crucial considerations in various applications, including photoresists, optoelectronic devices, and biodegradable polymers. Understanding and controlling degradation behavior is essential for optimizing material performance and longevity in these applications.Expand Specific Solutions

Key Players in Polysilane Research and Industry

The control of degradation rates in polysilane materials is a niche but growing field within advanced materials science. The market is in its early stages, with research-driven innovation leading commercial applications. Key players like JSR Corp., Kaneka Corp., and Wacker Chemie AG are leveraging their expertise in specialty chemicals and polymers to develop novel polysilane formulations with tunable degradation properties. The technology's maturity is still evolving, with academic institutions like Shandong University and the National University of Defense Technology contributing fundamental research. As applications in electronics, photonics, and biomedicine emerge, the market is poised for expansion, though currently limited in size.

JSR Corp.

Technical Solution: JSR Corp. has developed a proprietary technology for controlling degradation rates in polysilane materials, focusing on their application in photoresists and electronic materials. Their approach involves the incorporation of UV-absorbing moieties into the polysilane backbone, which significantly enhances the material's resistance to photodegradation[4]. JSR has also implemented a unique end-capping technique that reduces the susceptibility of polysilanes to thermal oxidation[5]. Furthermore, they have developed a novel processing method that allows for the creation of polysilane thin films with controlled porosity, which can be used to fine-tune the degradation rate for specific applications[6].

Strengths: Strong presence in the electronics and semiconductor industries, advanced material science capabilities. Weaknesses: Limited focus on non-electronic applications of polysilanes.

Wacker Chemie AG

Technical Solution: Wacker Chemie AG has developed advanced techniques for controlling degradation rates in polysilane materials. Their approach involves the use of stabilizers and cross-linking agents to enhance the thermal and photochemical stability of polysilanes[1]. They have implemented a novel synthesis method that allows for precise control over the molecular weight and polydispersity of polysilanes, which directly impacts their degradation behavior[2]. Additionally, Wacker has pioneered the use of surface modification techniques to create protective layers on polysilane films, significantly reducing their susceptibility to environmental degradation[3].

Strengths: Extensive experience in silicon chemistry, strong R&D capabilities, and a wide range of applications. Weaknesses: High production costs and potential environmental concerns associated with some stabilizing additives.

Innovative Approaches to Polysilane Stabilization

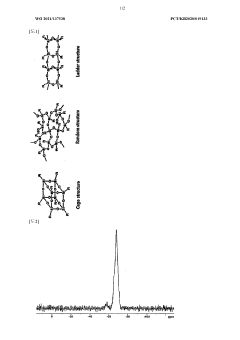

Polysilanes of medium chain length and a method for the production of same

PatentWO2012001180A1

Innovation

- A method for producing medium-chain polysilanes with direct Si-Si bonds, using plasma-assisted synthesis and specific reaction conditions to achieve polysilanes with controlled chain lengths, solubility, and purity, allowing for efficient deposition of silicon and minimizing contamination.

Method for preparing ladder-type polysilsesquioxane of which molecular weight is selectively controllable

PatentWO2021137538A1

Innovation

- A method involving the preparation of a hydrous solution with a solvent and hydrolysis of silane, followed by adding a weak base catalyst and [3-(Methacryloyloxy)propyl]trimethoxysilane, with specific solvent and catalyst ratios, and adjusting stirring time to control the molecular weight of the synthesized ladder-type polysilsesquioxane between 700 and 6000 g/mol.

Environmental Impact of Polysilane Degradation

The environmental impact of polysilane degradation is a critical aspect to consider when evaluating the sustainability and long-term effects of these materials. Polysilanes, known for their unique electronic and optical properties, undergo degradation processes that can have significant implications for the environment.

One of the primary concerns is the release of silicon-based compounds during the degradation of polysilanes. As these materials break down, they can potentially leach silicon-containing molecules into soil and water systems. This process may alter the silicon cycle in ecosystems, affecting the growth and development of various organisms, particularly diatoms and other silicon-dependent species.

The degradation of polysilanes can also lead to the formation of silica nanoparticles. These nanoparticles, while not inherently toxic, can accumulate in aquatic environments and potentially impact the respiratory systems of marine life. Furthermore, the increased presence of silica nanoparticles in water bodies may alter light penetration, affecting photosynthetic processes in aquatic plants and algae.

Another environmental consideration is the potential for polysilane degradation products to interact with other pollutants in the environment. These interactions could lead to the formation of complex compounds with unknown toxicological profiles, potentially exacerbating existing environmental issues or creating new ones.

The rate of polysilane degradation also plays a crucial role in its environmental impact. Rapid degradation may lead to sudden releases of degradation products, overwhelming natural systems' ability to process and integrate these materials. Conversely, extremely slow degradation rates could result in long-term accumulation of polysilanes in the environment, leading to persistent exposure for various organisms.

It is essential to consider the end-of-life management of polysilane-containing products. Improper disposal or inadequate recycling processes may exacerbate the environmental impact of these materials. Developing effective recycling and disposal methods that minimize the release of degradation products into the environment is crucial for mitigating potential ecological harm.

Research into the biodegradability of polysilanes and their degradation products is ongoing. Some studies suggest that certain microorganisms may be capable of metabolizing polysilane degradation products, potentially offering a natural mitigation strategy. However, the efficiency and widespread applicability of such biological processes require further investigation.

One of the primary concerns is the release of silicon-based compounds during the degradation of polysilanes. As these materials break down, they can potentially leach silicon-containing molecules into soil and water systems. This process may alter the silicon cycle in ecosystems, affecting the growth and development of various organisms, particularly diatoms and other silicon-dependent species.

The degradation of polysilanes can also lead to the formation of silica nanoparticles. These nanoparticles, while not inherently toxic, can accumulate in aquatic environments and potentially impact the respiratory systems of marine life. Furthermore, the increased presence of silica nanoparticles in water bodies may alter light penetration, affecting photosynthetic processes in aquatic plants and algae.

Another environmental consideration is the potential for polysilane degradation products to interact with other pollutants in the environment. These interactions could lead to the formation of complex compounds with unknown toxicological profiles, potentially exacerbating existing environmental issues or creating new ones.

The rate of polysilane degradation also plays a crucial role in its environmental impact. Rapid degradation may lead to sudden releases of degradation products, overwhelming natural systems' ability to process and integrate these materials. Conversely, extremely slow degradation rates could result in long-term accumulation of polysilanes in the environment, leading to persistent exposure for various organisms.

It is essential to consider the end-of-life management of polysilane-containing products. Improper disposal or inadequate recycling processes may exacerbate the environmental impact of these materials. Developing effective recycling and disposal methods that minimize the release of degradation products into the environment is crucial for mitigating potential ecological harm.

Research into the biodegradability of polysilanes and their degradation products is ongoing. Some studies suggest that certain microorganisms may be capable of metabolizing polysilane degradation products, potentially offering a natural mitigation strategy. However, the efficiency and widespread applicability of such biological processes require further investigation.

Regulatory Framework for Polysilane Materials

The regulatory framework for polysilane materials is a complex and evolving landscape that plays a crucial role in controlling degradation rates and ensuring the safe use of these materials. As polysilanes gain prominence in various industries, regulatory bodies worldwide have been developing guidelines and standards to address their unique properties and potential risks.

In the United States, the Environmental Protection Agency (EPA) has taken the lead in regulating polysilane materials under the Toxic Substances Control Act (TSCA). The EPA requires manufacturers and importers to submit premanufacture notices (PMNs) for new polysilane compounds, allowing the agency to assess potential risks and impose necessary restrictions. Additionally, the Occupational Safety and Health Administration (OSHA) has established workplace safety guidelines for handling polysilane materials, including exposure limits and personal protective equipment requirements.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to polysilane materials. Under REACH, manufacturers and importers must register polysilane substances with the European Chemicals Agency (ECHA) and provide comprehensive safety data. This regulatory framework aims to ensure the safe use of polysilanes while promoting innovation and competitiveness in the chemical industry.

In Japan, the Ministry of Economy, Trade, and Industry (METI) oversees the regulation of polysilane materials through the Chemical Substances Control Law (CSCL). This law requires manufacturers and importers to notify the government of new chemical substances, including polysilanes, and undergo safety assessments before commercialization.

International organizations, such as the International Organization for Standardization (ISO), have also contributed to the regulatory framework by developing standards for polysilane materials. These standards address various aspects, including terminology, testing methods, and quality control measures, which help harmonize practices across different countries and industries.

As research on controlling degradation rates in polysilane materials progresses, regulatory bodies are likely to update their frameworks to incorporate new findings and address emerging concerns. This may include more specific guidelines on stabilization techniques, storage conditions, and disposal methods for polysilane materials. Manufacturers and researchers working with polysilanes must stay informed about these evolving regulations to ensure compliance and optimize their degradation control strategies.

In the United States, the Environmental Protection Agency (EPA) has taken the lead in regulating polysilane materials under the Toxic Substances Control Act (TSCA). The EPA requires manufacturers and importers to submit premanufacture notices (PMNs) for new polysilane compounds, allowing the agency to assess potential risks and impose necessary restrictions. Additionally, the Occupational Safety and Health Administration (OSHA) has established workplace safety guidelines for handling polysilane materials, including exposure limits and personal protective equipment requirements.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to polysilane materials. Under REACH, manufacturers and importers must register polysilane substances with the European Chemicals Agency (ECHA) and provide comprehensive safety data. This regulatory framework aims to ensure the safe use of polysilanes while promoting innovation and competitiveness in the chemical industry.

In Japan, the Ministry of Economy, Trade, and Industry (METI) oversees the regulation of polysilane materials through the Chemical Substances Control Law (CSCL). This law requires manufacturers and importers to notify the government of new chemical substances, including polysilanes, and undergo safety assessments before commercialization.

International organizations, such as the International Organization for Standardization (ISO), have also contributed to the regulatory framework by developing standards for polysilane materials. These standards address various aspects, including terminology, testing methods, and quality control measures, which help harmonize practices across different countries and industries.

As research on controlling degradation rates in polysilane materials progresses, regulatory bodies are likely to update their frameworks to incorporate new findings and address emerging concerns. This may include more specific guidelines on stabilization techniques, storage conditions, and disposal methods for polysilane materials. Manufacturers and researchers working with polysilanes must stay informed about these evolving regulations to ensure compliance and optimize their degradation control strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!