How to Enhance Conformal Coating for High-RF Frequency Environments

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

RF Conformal Coating Background and Objectives

Conformal coating technology has evolved significantly over the past four decades, transitioning from simple protective layers to sophisticated engineered materials designed to shield electronic components from environmental factors. Initially developed for military and aerospace applications in the 1970s, these coatings have become increasingly critical in modern electronics operating in high-frequency environments. The radio frequency (RF) spectrum utilization has expanded dramatically, with applications now routinely operating at frequencies exceeding 5 GHz and extending into millimeter wave bands (30-300 GHz) for 5G and beyond.

Traditional conformal coatings were primarily designed to protect against moisture, dust, and chemical contaminants. However, as electronic devices operate at increasingly higher frequencies, these conventional coatings have demonstrated limitations in maintaining signal integrity and preventing electromagnetic interference (EMI). The dielectric properties of coating materials become particularly significant at high frequencies, where even minor variations can lead to signal attenuation, impedance mismatching, and performance degradation.

The technical evolution trajectory shows a clear shift from acrylic and silicone-based coatings toward advanced formulations incorporating specialized fillers and engineered polymers. Recent developments have focused on nanomaterial-enhanced coatings that offer superior RF transparency while maintaining robust environmental protection. These advancements align with the industry's push toward miniaturization, higher operating frequencies, and increased reliability requirements.

The primary objective of enhancing conformal coatings for high-RF environments is to develop solutions that provide excellent environmental protection while minimizing impact on RF performance. Specifically, this involves creating coatings with controlled dielectric constants, low loss tangents across broad frequency ranges, and consistent electrical properties under varying environmental conditions. Additionally, these coatings must maintain traditional protective qualities against moisture, chemicals, and mechanical stress.

Secondary objectives include improving application methods to ensure uniform coating thickness, developing materials compatible with automated manufacturing processes, and creating solutions that can be selectively applied to avoid coating sensitive areas such as RF transmission lines and antennas. Cost-effectiveness and environmental sustainability represent additional considerations, as the industry moves away from solvent-based formulations containing volatile organic compounds (VOCs).

The technological trajectory indicates growing interest in adaptive coatings that can respond to environmental changes and self-healing formulations that extend product lifespans. Research is increasingly focused on understanding the complex interactions between coating materials and electromagnetic waves at frequencies above 10 GHz, where traditional modeling approaches become less accurate and material properties exhibit greater frequency dependence.

Traditional conformal coatings were primarily designed to protect against moisture, dust, and chemical contaminants. However, as electronic devices operate at increasingly higher frequencies, these conventional coatings have demonstrated limitations in maintaining signal integrity and preventing electromagnetic interference (EMI). The dielectric properties of coating materials become particularly significant at high frequencies, where even minor variations can lead to signal attenuation, impedance mismatching, and performance degradation.

The technical evolution trajectory shows a clear shift from acrylic and silicone-based coatings toward advanced formulations incorporating specialized fillers and engineered polymers. Recent developments have focused on nanomaterial-enhanced coatings that offer superior RF transparency while maintaining robust environmental protection. These advancements align with the industry's push toward miniaturization, higher operating frequencies, and increased reliability requirements.

The primary objective of enhancing conformal coatings for high-RF environments is to develop solutions that provide excellent environmental protection while minimizing impact on RF performance. Specifically, this involves creating coatings with controlled dielectric constants, low loss tangents across broad frequency ranges, and consistent electrical properties under varying environmental conditions. Additionally, these coatings must maintain traditional protective qualities against moisture, chemicals, and mechanical stress.

Secondary objectives include improving application methods to ensure uniform coating thickness, developing materials compatible with automated manufacturing processes, and creating solutions that can be selectively applied to avoid coating sensitive areas such as RF transmission lines and antennas. Cost-effectiveness and environmental sustainability represent additional considerations, as the industry moves away from solvent-based formulations containing volatile organic compounds (VOCs).

The technological trajectory indicates growing interest in adaptive coatings that can respond to environmental changes and self-healing formulations that extend product lifespans. Research is increasingly focused on understanding the complex interactions between coating materials and electromagnetic waves at frequencies above 10 GHz, where traditional modeling approaches become less accurate and material properties exhibit greater frequency dependence.

Market Demand Analysis for High-RF Protective Solutions

The global market for high-RF protective solutions has experienced significant growth in recent years, driven by the rapid expansion of wireless communication technologies, 5G deployment, and the increasing use of high-frequency applications in various industries. The conformal coating segment specifically has seen heightened demand as electronic devices operate at increasingly higher frequencies, necessitating more effective protection against environmental factors.

The telecommunications sector represents the largest market segment for high-RF protective solutions, with an estimated annual growth rate of 7.8% through 2025. This growth is primarily fueled by the ongoing global 5G infrastructure buildout, which requires components capable of functioning reliably at frequencies up to 39 GHz and beyond. Network equipment manufacturers are actively seeking advanced conformal coating solutions that can maintain signal integrity while providing environmental protection.

Aerospace and defense applications constitute another substantial market segment, where high-RF protective solutions must perform under extreme conditions. Military communication systems, radar equipment, and satellite components all require specialized conformal coatings that can withstand thermal cycling, vibration, and radiation while maintaining RF transparency at frequencies often exceeding 20 GHz.

Consumer electronics manufacturers are increasingly incorporating high-frequency components into their products, from smartphones to IoT devices. This trend has created growing demand for thin, lightweight conformal coatings that offer protection without compromising device performance or adding significant weight. The miniaturization of electronic components further intensifies the need for precisely applied protective solutions.

Automotive applications represent an emerging market with substantial growth potential, particularly with the advancement of autonomous driving technologies and vehicle-to-everything (V2X) communication systems. These applications require conformal coatings that can protect sensitive electronics while allowing high-frequency signals to transmit without interference.

Regional analysis indicates that North America currently leads the market for high-RF protective solutions, followed closely by Asia-Pacific. However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years, driven by expanding electronics manufacturing capabilities and increasing adoption of 5G technologies across China, South Korea, and Japan.

Customer requirements are evolving toward solutions that offer multi-functional protection—not only safeguarding against moisture and contaminants but also providing thermal management capabilities and electromagnetic interference (EMI) shielding. This trend toward integrated protective solutions represents a significant opportunity for innovation in the high-RF conformal coating market.

The telecommunications sector represents the largest market segment for high-RF protective solutions, with an estimated annual growth rate of 7.8% through 2025. This growth is primarily fueled by the ongoing global 5G infrastructure buildout, which requires components capable of functioning reliably at frequencies up to 39 GHz and beyond. Network equipment manufacturers are actively seeking advanced conformal coating solutions that can maintain signal integrity while providing environmental protection.

Aerospace and defense applications constitute another substantial market segment, where high-RF protective solutions must perform under extreme conditions. Military communication systems, radar equipment, and satellite components all require specialized conformal coatings that can withstand thermal cycling, vibration, and radiation while maintaining RF transparency at frequencies often exceeding 20 GHz.

Consumer electronics manufacturers are increasingly incorporating high-frequency components into their products, from smartphones to IoT devices. This trend has created growing demand for thin, lightweight conformal coatings that offer protection without compromising device performance or adding significant weight. The miniaturization of electronic components further intensifies the need for precisely applied protective solutions.

Automotive applications represent an emerging market with substantial growth potential, particularly with the advancement of autonomous driving technologies and vehicle-to-everything (V2X) communication systems. These applications require conformal coatings that can protect sensitive electronics while allowing high-frequency signals to transmit without interference.

Regional analysis indicates that North America currently leads the market for high-RF protective solutions, followed closely by Asia-Pacific. However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years, driven by expanding electronics manufacturing capabilities and increasing adoption of 5G technologies across China, South Korea, and Japan.

Customer requirements are evolving toward solutions that offer multi-functional protection—not only safeguarding against moisture and contaminants but also providing thermal management capabilities and electromagnetic interference (EMI) shielding. This trend toward integrated protective solutions represents a significant opportunity for innovation in the high-RF conformal coating market.

Current Challenges in High-Frequency Conformal Coating

Conformal coating technologies face significant challenges in high-RF frequency environments, particularly as electronic devices continue to miniaturize while operating at increasingly higher frequencies. Traditional conformal coating materials exhibit limitations when exposed to frequencies above 1 GHz, where signal integrity becomes critically important. The dielectric properties of conventional coatings can cause signal attenuation, impedance mismatches, and unwanted capacitive coupling effects that degrade RF performance.

A primary challenge is the trade-off between protection and RF transparency. While thicker coatings provide better environmental protection, they often introduce greater signal losses at high frequencies. Conversely, thinner coatings may preserve signal integrity but offer insufficient protection against moisture, chemicals, and mechanical stress. This dichotomy creates significant design constraints for engineers working on high-frequency applications.

Material selection presents another substantial hurdle. Many conventional coating materials such as acrylics, silicones, and urethanes exhibit dielectric constants and loss tangents that become problematic at gigahertz frequencies. These properties can vary significantly with frequency, temperature, and humidity, making performance prediction difficult across operating conditions. Furthermore, the presence of ionic impurities in coating materials can lead to increased conductivity and signal leakage at high frequencies.

Application uniformity represents a critical challenge that directly impacts RF performance. Variations in coating thickness as small as a few microns can create impedance discontinuities that reflect RF energy and degrade signal quality. Current application methods struggle to achieve the necessary precision over complex board geometries, especially around fine-pitch components and high-frequency transmission lines where coating control is most critical.

The increasing integration of mixed-signal designs compounds these challenges. Modern electronic assemblies often combine high-frequency RF circuits with digital and analog sections, each with different coating requirements. Selective coating approaches are needed but remain difficult to implement with the precision required for advanced RF applications.

Temperature stability of conformal coatings presents yet another challenge. High-frequency RF circuits often generate significant heat, and many coating materials exhibit changing dielectric properties as temperatures fluctuate. This can lead to performance drift in critical RF parameters such as insertion loss and return loss, particularly in applications requiring precise impedance matching.

Testing and qualification methodologies for high-frequency coatings remain underdeveloped. Standard industry tests focus primarily on environmental protection rather than RF performance preservation. This gap in testing protocols makes it difficult to validate coating solutions specifically for high-frequency applications, leading to uncertainty in long-term reliability and performance.

A primary challenge is the trade-off between protection and RF transparency. While thicker coatings provide better environmental protection, they often introduce greater signal losses at high frequencies. Conversely, thinner coatings may preserve signal integrity but offer insufficient protection against moisture, chemicals, and mechanical stress. This dichotomy creates significant design constraints for engineers working on high-frequency applications.

Material selection presents another substantial hurdle. Many conventional coating materials such as acrylics, silicones, and urethanes exhibit dielectric constants and loss tangents that become problematic at gigahertz frequencies. These properties can vary significantly with frequency, temperature, and humidity, making performance prediction difficult across operating conditions. Furthermore, the presence of ionic impurities in coating materials can lead to increased conductivity and signal leakage at high frequencies.

Application uniformity represents a critical challenge that directly impacts RF performance. Variations in coating thickness as small as a few microns can create impedance discontinuities that reflect RF energy and degrade signal quality. Current application methods struggle to achieve the necessary precision over complex board geometries, especially around fine-pitch components and high-frequency transmission lines where coating control is most critical.

The increasing integration of mixed-signal designs compounds these challenges. Modern electronic assemblies often combine high-frequency RF circuits with digital and analog sections, each with different coating requirements. Selective coating approaches are needed but remain difficult to implement with the precision required for advanced RF applications.

Temperature stability of conformal coatings presents yet another challenge. High-frequency RF circuits often generate significant heat, and many coating materials exhibit changing dielectric properties as temperatures fluctuate. This can lead to performance drift in critical RF parameters such as insertion loss and return loss, particularly in applications requiring precise impedance matching.

Testing and qualification methodologies for high-frequency coatings remain underdeveloped. Standard industry tests focus primarily on environmental protection rather than RF performance preservation. This gap in testing protocols makes it difficult to validate coating solutions specifically for high-frequency applications, leading to uncertainty in long-term reliability and performance.

Existing High-Frequency Conformal Coating Solutions

01 Advanced material compositions for conformal coatings

Various material compositions can enhance the performance of conformal coatings. These include polymer blends, nanocomposites, and specialized formulations that improve adhesion, durability, and protection against environmental factors. These advanced materials can provide better coverage, flexibility, and resistance to moisture, chemicals, and temperature fluctuations, resulting in improved protection for electronic components and circuit boards.- Advanced material compositions for conformal coatings: Various material compositions can enhance the performance of conformal coatings. These include polymer blends, nanocomposites, and specialized formulations that improve adhesion, durability, and protection against environmental factors. These advanced materials can provide better coverage, flexibility, and resistance to moisture, chemicals, and temperature fluctuations, resulting in superior protection for electronic components and circuit boards.

- Application techniques for improved coating uniformity: Specialized application methods can significantly enhance the uniformity and effectiveness of conformal coatings. These techniques include automated spray systems, vapor deposition, dipping processes, and precision dispensing methods. Proper application ensures complete coverage of components, elimination of air pockets, and consistent coating thickness, which are critical for maximizing protection and extending the lifespan of electronic assemblies.

- Thermal management enhancements in conformal coatings: Conformal coatings can be enhanced with thermal management properties to improve heat dissipation in electronic components. These coatings incorporate thermally conductive materials or are designed with specific structures that facilitate heat transfer while maintaining electrical insulation. Such enhancements are particularly valuable for high-power electronics and densely packed circuit boards where heat buildup can compromise performance and reliability.

- Protection enhancements for harsh environments: Specialized conformal coating formulations can provide enhanced protection for electronics operating in harsh or extreme environments. These coatings offer superior resistance against moisture, chemicals, salt spray, vibration, and temperature extremes. They may incorporate additional barrier properties, UV stabilizers, or anti-corrosion additives to ensure long-term reliability of electronic components in challenging conditions such as automotive, marine, aerospace, or industrial applications.

- Curing and processing innovations: Advanced curing and processing methods can significantly enhance the performance and efficiency of conformal coating applications. These innovations include UV-curing systems, controlled atmosphere processing, multi-stage curing protocols, and accelerated drying techniques. Improved curing processes result in better adhesion, reduced processing time, lower energy consumption, and enhanced coating properties such as hardness, flexibility, and chemical resistance.

02 Application techniques for improved coating uniformity

Specialized application methods can significantly enhance the uniformity and effectiveness of conformal coatings. These techniques include automated spray systems, vapor deposition processes, dipping methods, and precision dispensing technologies. By optimizing the application process, manufacturers can achieve more consistent coating thickness, better coverage of complex geometries, and improved protection of sensitive electronic components.Expand Specific Solutions03 Thermal management enhancements in conformal coatings

Conformal coatings can be enhanced to provide improved thermal management properties. By incorporating thermally conductive materials or designing specialized coating structures, these enhanced formulations help dissipate heat more effectively from electronic components. This thermal management capability is particularly important for high-power electronics and densely packed circuit boards, where heat buildup can lead to performance degradation and reduced reliability.Expand Specific Solutions04 Protection against harsh environmental conditions

Enhanced conformal coatings can provide superior protection against extreme environmental conditions. These specialized formulations offer improved resistance to moisture, chemicals, salt spray, vibration, and temperature extremes. By creating a more effective barrier against these environmental stressors, the enhanced coatings can significantly extend the operational life and reliability of electronic assemblies in challenging environments such as automotive, aerospace, and industrial applications.Expand Specific Solutions05 Integration with electronic manufacturing processes

Conformal coating enhancements can be designed to better integrate with modern electronic manufacturing processes. These improvements include faster curing systems, reworkable formulations, selective coating technologies, and compatibility with automated inspection systems. By optimizing the coating process for manufacturing efficiency, these enhancements reduce production time, lower costs, and improve quality control while maintaining or improving the protective properties of the coating.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The conformal coating market for high-RF frequency environments is currently in a growth phase, with increasing demand driven by 5G infrastructure, aerospace applications, and advanced electronics. The global market size is projected to reach $15 billion by 2027, expanding at a CAGR of approximately 7%. Technologically, the field shows varying maturity levels across different applications. Industry leaders like 3M Innovative Properties and Nordson Corp. have established robust coating solutions, while companies such as Skyworks Solutions and Applied Materials are advancing specialized RF-compatible formulations. Emerging players including Murata Manufacturing and GLOBALFOUNDRIES are developing innovative approaches to address thermal management and signal integrity challenges in high-frequency environments. The competitive landscape features both traditional coating manufacturers and semiconductor specialists working to overcome the unique challenges of RF interference and thermal dissipation.

3M Innovative Properties Co.

Technical Solution: 3M has developed advanced conformal coating solutions specifically engineered for high-RF frequency environments. Their technology utilizes fluoropolymer-based materials that provide exceptional dielectric properties with minimal signal loss at frequencies up to 110 GHz[1]. The coatings incorporate nano-scale ceramic fillers that enhance thermal stability while maintaining excellent electrical insulation characteristics. 3M's process involves precision application methods including vapor deposition and automated selective coating that ensures uniform thickness (typically 25-75 microns) across complex PCB geometries[2]. Their multi-layer approach creates a gradient structure that optimizes both adhesion to substrates and surface properties for RF performance. The coatings also feature hydrophobic characteristics with water contact angles exceeding 110°, providing superior moisture protection while maintaining low dielectric constants (typically 2.1-2.8) and loss tangents below 0.002 at high frequencies[3].

Strengths: Superior dielectric properties specifically optimized for RF applications; excellent thickness uniformity control; strong moisture and environmental protection. Weaknesses: Higher cost compared to standard conformal coatings; may require specialized application equipment; some formulations have limited reworkability after curing.

Nordson Corp.

Technical Solution: Nordson has pioneered automated precision dispensing systems for conformal coating application in high-RF environments. Their technology combines material science innovations with advanced application equipment to address the unique challenges of RF circuit protection. Nordson's conformal coating solutions feature specialized silicone and acrylic formulations with carefully controlled dielectric constants (typically 2.5-3.2) and dissipation factors below 0.001 at frequencies up to 45 GHz[1]. Their proprietary selective coating process utilizes computer-controlled robotic systems with five-axis movement capability and real-time viscosity monitoring to achieve coating thickness variations of less than ±5 microns across the substrate[2]. This precision is critical for maintaining consistent RF performance. Additionally, Nordson has developed UV-traceable additives that enable automated optical inspection without affecting electrical properties, ensuring quality control in high-volume manufacturing environments. Their coatings also incorporate specialized adhesion promoters that maintain strong bonding to diverse substrate materials even under thermal cycling conditions typical in RF applications[3].

Strengths: Industry-leading application precision and thickness control; integrated inspection capabilities; excellent adhesion to various substrate materials. Weaknesses: Equipment requires significant capital investment; some formulations have limited high-temperature performance; application process requires careful environmental control.

Key Innovations in RF-Resistant Coating Materials

Down hole wireless data and power transmission system

PatentInactiveEP2951392A2

Innovation

- A conformal coating with a substrate material and embedded Mie Resonance based dielectric rods is applied to production pipes, allowing wireless signals to bend around obstructions, enhancing transmission range and efficiency by reducing signal loss.

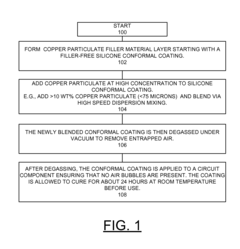

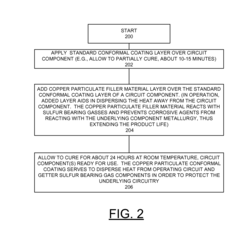

Implementing conformal coating composition for high current circuit applications

PatentInactiveUS20160192481A1

Innovation

- A copper particulate filler material layer is added over a standard conformal coating on circuit components, which reacts with sulfur-bearing gases to form Cu2S, preventing corrosion and acting as a heat disperser, thereby extending the life of high current circuit components.

EMI/EMC Compliance Standards for Coated Electronics

Compliance with EMI/EMC standards is critical for electronic devices utilizing conformal coatings in high-RF frequency environments. The International Electrotechnical Commission (IEC) has established several key standards, including IEC 61000 for electromagnetic compatibility and IEC 60601 specifically for medical devices. These standards define acceptable emission limits and immunity requirements that coated electronics must meet to ensure proper functionality without interference.

In the United States, the Federal Communications Commission (FCC) enforces Part 15 regulations for electronic devices, which establish specific limits for radiated and conducted emissions. For military and aerospace applications, MIL-STD-461 provides comprehensive EMI/EMC requirements with particularly stringent specifications for high-frequency environments where conformal coatings are essential for protection.

The European Union enforces the EMC Directive (2014/30/EU), requiring all electronic equipment sold within the EU to demonstrate electromagnetic compatibility. This directive is particularly relevant for conformal coating applications as it addresses both emissions from devices and their immunity to external electromagnetic disturbances.

Testing methodologies for coated electronics typically include radiated emissions testing (CISPR 22/EN 55022), conducted emissions testing (CISPR 16), and immunity testing against electrostatic discharge (IEC 61000-4-2). Advanced conformal coating solutions must be designed to maintain these compliance standards while providing environmental protection.

Recent developments in standards have begun to address the unique challenges of high-RF frequency environments, where traditional coating materials may exhibit unexpected behaviors. The IPC-CC-830C standard specifically addresses conformal coating materials and their application processes, providing guidelines for coating thickness, coverage, and adhesion that impact EMI/EMC performance.

Material selection for conformal coatings has significant implications for EMI/EMC compliance. Acrylic coatings offer good dielectric properties but may be less effective at higher frequencies. Silicone coatings provide excellent flexibility and thermal stability but can impact signal integrity at extreme frequencies. Parylene coatings, while offering superior barrier properties, require specialized application equipment and careful thickness control to maintain RF transparency.

Testing protocols for coated electronics in high-RF environments have evolved to include specialized chambers and equipment capable of measuring performance across broader frequency ranges. These advanced testing methodologies help manufacturers validate that their conformal coating solutions maintain compliance with relevant standards while providing the necessary environmental protection.

In the United States, the Federal Communications Commission (FCC) enforces Part 15 regulations for electronic devices, which establish specific limits for radiated and conducted emissions. For military and aerospace applications, MIL-STD-461 provides comprehensive EMI/EMC requirements with particularly stringent specifications for high-frequency environments where conformal coatings are essential for protection.

The European Union enforces the EMC Directive (2014/30/EU), requiring all electronic equipment sold within the EU to demonstrate electromagnetic compatibility. This directive is particularly relevant for conformal coating applications as it addresses both emissions from devices and their immunity to external electromagnetic disturbances.

Testing methodologies for coated electronics typically include radiated emissions testing (CISPR 22/EN 55022), conducted emissions testing (CISPR 16), and immunity testing against electrostatic discharge (IEC 61000-4-2). Advanced conformal coating solutions must be designed to maintain these compliance standards while providing environmental protection.

Recent developments in standards have begun to address the unique challenges of high-RF frequency environments, where traditional coating materials may exhibit unexpected behaviors. The IPC-CC-830C standard specifically addresses conformal coating materials and their application processes, providing guidelines for coating thickness, coverage, and adhesion that impact EMI/EMC performance.

Material selection for conformal coatings has significant implications for EMI/EMC compliance. Acrylic coatings offer good dielectric properties but may be less effective at higher frequencies. Silicone coatings provide excellent flexibility and thermal stability but can impact signal integrity at extreme frequencies. Parylene coatings, while offering superior barrier properties, require specialized application equipment and careful thickness control to maintain RF transparency.

Testing protocols for coated electronics in high-RF environments have evolved to include specialized chambers and equipment capable of measuring performance across broader frequency ranges. These advanced testing methodologies help manufacturers validate that their conformal coating solutions maintain compliance with relevant standards while providing the necessary environmental protection.

Environmental Impact of Advanced Coating Materials

The environmental impact of advanced coating materials used in high-RF frequency environments represents a critical consideration in the sustainable development of electronic protection technologies. Traditional conformal coatings often contain volatile organic compounds (VOCs), heavy metals, and other environmentally harmful substances that pose significant risks to ecosystems and human health. As the electronics industry expands, particularly in high-frequency applications, the volume of these materials entering the environment through manufacturing processes, product use, and end-of-life disposal continues to grow exponentially.

Recent advancements in environmentally friendly coating materials show promising alternatives that maintain high-RF performance while reducing ecological footprints. Water-based acrylic formulations have emerged as viable substitutes for solvent-based systems, reducing VOC emissions by up to 80% during application processes. Similarly, UV-curable coatings eliminate solvent emissions entirely while providing excellent protection in high-frequency environments, though their production still involves energy-intensive processes.

Biodegradable coating materials derived from natural polymers represent another frontier in sustainable protection solutions. These materials, including modified cellulose derivatives and chitosan-based formulations, demonstrate encouraging RF transparency while offering end-of-life decomposition capabilities that traditional synthetic polymers lack. However, their long-term stability in extreme operating conditions remains under investigation.

Life cycle assessment (LCA) studies of advanced coating materials reveal complex environmental trade-offs. While newer formulations may reduce immediate application impacts, some require rare earth elements or energy-intensive manufacturing processes that shift rather than eliminate environmental burdens. Complete cradle-to-grave analysis indicates that nano-enhanced coatings, despite their superior RF performance and reduced material requirements, may present novel environmental challenges through potential nanoparticle release during weathering or disposal.

Regulatory frameworks worldwide are increasingly addressing these environmental concerns. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have already limited certain compounds in electronic applications, driving innovation toward greener alternatives. Similar initiatives in North America and Asia are accelerating the transition to environmentally responsible coating technologies while maintaining the performance requirements essential for high-RF applications.

Recent advancements in environmentally friendly coating materials show promising alternatives that maintain high-RF performance while reducing ecological footprints. Water-based acrylic formulations have emerged as viable substitutes for solvent-based systems, reducing VOC emissions by up to 80% during application processes. Similarly, UV-curable coatings eliminate solvent emissions entirely while providing excellent protection in high-frequency environments, though their production still involves energy-intensive processes.

Biodegradable coating materials derived from natural polymers represent another frontier in sustainable protection solutions. These materials, including modified cellulose derivatives and chitosan-based formulations, demonstrate encouraging RF transparency while offering end-of-life decomposition capabilities that traditional synthetic polymers lack. However, their long-term stability in extreme operating conditions remains under investigation.

Life cycle assessment (LCA) studies of advanced coating materials reveal complex environmental trade-offs. While newer formulations may reduce immediate application impacts, some require rare earth elements or energy-intensive manufacturing processes that shift rather than eliminate environmental burdens. Complete cradle-to-grave analysis indicates that nano-enhanced coatings, despite their superior RF performance and reduced material requirements, may present novel environmental challenges through potential nanoparticle release during weathering or disposal.

Regulatory frameworks worldwide are increasingly addressing these environmental concerns. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have already limited certain compounds in electronic applications, driving innovation toward greener alternatives. Similar initiatives in North America and Asia are accelerating the transition to environmentally responsible coating technologies while maintaining the performance requirements essential for high-RF applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!