How to Enhance Isocyanate Storage and Handling Safety?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Safety Background and Objectives

Isocyanates are highly reactive chemicals widely used in the production of polyurethanes, a versatile class of materials found in numerous industrial and consumer applications. The safe storage and handling of isocyanates have been a critical concern in the chemical industry for decades due to their potential health and environmental hazards. Exposure to isocyanates can cause severe respiratory issues, skin irritation, and allergic reactions, making proper safety measures essential.

The evolution of isocyanate safety practices has been driven by a growing understanding of their risks and the development of more stringent regulations. Initially, safety measures were primarily focused on personal protective equipment and basic containment strategies. However, as research advanced, the industry recognized the need for more comprehensive approaches to mitigate risks throughout the entire lifecycle of isocyanate handling and storage.

Recent technological advancements have opened new avenues for enhancing isocyanate safety. These include improved containment systems, real-time monitoring technologies, and innovative materials for protective equipment. The integration of digital solutions and automation has also played a significant role in reducing human exposure and improving overall safety protocols.

The primary objective in enhancing isocyanate storage and handling safety is to minimize the risk of exposure and potential accidents while maintaining operational efficiency. This involves developing robust storage systems that prevent leaks and spills, implementing advanced handling procedures that reduce direct contact, and creating comprehensive emergency response plans.

Another crucial goal is to improve early detection and warning systems for potential hazards. This includes the development of more sensitive and reliable sensors for detecting isocyanate vapors, as well as the implementation of integrated monitoring systems that can provide real-time data on storage conditions and potential risks.

Education and training remain fundamental objectives in isocyanate safety enhancement. As new technologies and procedures are introduced, there is a continuous need to update and refine training programs to ensure that all personnel involved in isocyanate handling are equipped with the latest knowledge and skills.

Looking forward, the industry aims to further innovate in areas such as inherently safer design principles for isocyanate storage facilities, development of less hazardous alternatives or modified isocyanates with reduced risks, and the integration of artificial intelligence and machine learning for predictive safety analytics. These advancements are expected to significantly contribute to the ongoing efforts to enhance isocyanate storage and handling safety, ensuring a safer work environment and reduced environmental impact.

The evolution of isocyanate safety practices has been driven by a growing understanding of their risks and the development of more stringent regulations. Initially, safety measures were primarily focused on personal protective equipment and basic containment strategies. However, as research advanced, the industry recognized the need for more comprehensive approaches to mitigate risks throughout the entire lifecycle of isocyanate handling and storage.

Recent technological advancements have opened new avenues for enhancing isocyanate safety. These include improved containment systems, real-time monitoring technologies, and innovative materials for protective equipment. The integration of digital solutions and automation has also played a significant role in reducing human exposure and improving overall safety protocols.

The primary objective in enhancing isocyanate storage and handling safety is to minimize the risk of exposure and potential accidents while maintaining operational efficiency. This involves developing robust storage systems that prevent leaks and spills, implementing advanced handling procedures that reduce direct contact, and creating comprehensive emergency response plans.

Another crucial goal is to improve early detection and warning systems for potential hazards. This includes the development of more sensitive and reliable sensors for detecting isocyanate vapors, as well as the implementation of integrated monitoring systems that can provide real-time data on storage conditions and potential risks.

Education and training remain fundamental objectives in isocyanate safety enhancement. As new technologies and procedures are introduced, there is a continuous need to update and refine training programs to ensure that all personnel involved in isocyanate handling are equipped with the latest knowledge and skills.

Looking forward, the industry aims to further innovate in areas such as inherently safer design principles for isocyanate storage facilities, development of less hazardous alternatives or modified isocyanates with reduced risks, and the integration of artificial intelligence and machine learning for predictive safety analytics. These advancements are expected to significantly contribute to the ongoing efforts to enhance isocyanate storage and handling safety, ensuring a safer work environment and reduced environmental impact.

Market Demand for Safe Isocyanate Handling

The market demand for safe isocyanate handling has been steadily increasing due to the growing awareness of the potential hazards associated with these chemicals and the stringent regulations governing their use. Isocyanates are widely used in various industries, including automotive, construction, furniture, and electronics, primarily for the production of polyurethane foams, coatings, and adhesives. As the global polyurethane market continues to expand, projected to reach $79 billion by 2025, the need for improved safety measures in isocyanate handling becomes paramount.

Industrial safety concerns have become a significant driver for market growth in safe isocyanate handling solutions. Exposure to isocyanates can cause severe health issues, including respiratory problems, skin irritation, and allergic reactions. These risks have led to increased demand for advanced storage systems, personal protective equipment (PPE), and automated handling technologies that minimize human contact with isocyanates.

The automotive industry, a major consumer of isocyanate-based products, has been at the forefront of adopting safer handling practices. With the rise of electric vehicles and the continued emphasis on lightweight materials, the use of polyurethane components in automobiles is expected to grow, further driving the demand for safe handling solutions.

Environmental regulations, such as the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and the United States' Occupational Safety and Health Administration (OSHA) standards, have also played a crucial role in shaping market demand. These regulations mandate strict safety protocols for isocyanate handling, storage, and disposal, compelling companies to invest in compliant technologies and practices.

The construction sector, another significant user of isocyanate-based products, has seen increased demand for spray polyurethane foam (SPF) insulation. This trend has led to a corresponding rise in the need for safe handling equipment and training programs for construction workers and contractors.

Emerging economies, particularly in Asia-Pacific and Latin America, are experiencing rapid industrialization and urbanization, driving the demand for polyurethane products and, consequently, safe isocyanate handling solutions. These regions present significant growth opportunities for manufacturers of safety equipment and storage systems.

The COVID-19 pandemic has further emphasized the importance of worker safety and health, potentially accelerating the adoption of advanced handling technologies and remote monitoring systems for isocyanate storage and use. This shift towards automation and digitalization in chemical handling is expected to continue, creating new market opportunities for innovative safety solutions.

Industrial safety concerns have become a significant driver for market growth in safe isocyanate handling solutions. Exposure to isocyanates can cause severe health issues, including respiratory problems, skin irritation, and allergic reactions. These risks have led to increased demand for advanced storage systems, personal protective equipment (PPE), and automated handling technologies that minimize human contact with isocyanates.

The automotive industry, a major consumer of isocyanate-based products, has been at the forefront of adopting safer handling practices. With the rise of electric vehicles and the continued emphasis on lightweight materials, the use of polyurethane components in automobiles is expected to grow, further driving the demand for safe handling solutions.

Environmental regulations, such as the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and the United States' Occupational Safety and Health Administration (OSHA) standards, have also played a crucial role in shaping market demand. These regulations mandate strict safety protocols for isocyanate handling, storage, and disposal, compelling companies to invest in compliant technologies and practices.

The construction sector, another significant user of isocyanate-based products, has seen increased demand for spray polyurethane foam (SPF) insulation. This trend has led to a corresponding rise in the need for safe handling equipment and training programs for construction workers and contractors.

Emerging economies, particularly in Asia-Pacific and Latin America, are experiencing rapid industrialization and urbanization, driving the demand for polyurethane products and, consequently, safe isocyanate handling solutions. These regions present significant growth opportunities for manufacturers of safety equipment and storage systems.

The COVID-19 pandemic has further emphasized the importance of worker safety and health, potentially accelerating the adoption of advanced handling technologies and remote monitoring systems for isocyanate storage and use. This shift towards automation and digitalization in chemical handling is expected to continue, creating new market opportunities for innovative safety solutions.

Current Challenges in Isocyanate Storage

The storage and handling of isocyanates present significant challenges due to their highly reactive nature and potential health hazards. One of the primary concerns is the moisture sensitivity of isocyanates, which can lead to unwanted reactions and degradation of the product. Exposure to even small amounts of moisture can cause polymerization, resulting in the formation of solids or gels that can clog equipment and compromise product quality.

Temperature control is another critical challenge in isocyanate storage. These compounds are sensitive to both high and low temperatures, requiring careful management of storage conditions. Excessive heat can accelerate degradation and increase the risk of pressure buildup in storage containers, while freezing temperatures can cause crystallization and separation of some isocyanate formulations.

The potential for isocyanate vapors to escape during storage and handling poses significant health risks to workers. Inhalation of these vapors can cause respiratory irritation, sensitization, and in severe cases, asthma-like reactions. Ensuring proper ventilation and implementing effective vapor containment systems are ongoing challenges in isocyanate storage facilities.

Corrosion of storage tanks and transfer equipment is a persistent issue, particularly with certain types of isocyanates. This can lead to leaks, contamination, and compromised structural integrity of storage vessels. Selecting appropriate materials for tanks, piping, and seals that are resistant to isocyanate-induced corrosion is crucial but often complex.

The reactivity of isocyanates also presents fire and explosion hazards. While not inherently flammable, some isocyanates can react violently with water, producing heat and potentially igniting nearby combustible materials. Designing storage areas with appropriate fire suppression systems and implementing rigorous safety protocols are ongoing challenges.

Long-term storage stability is another concern, as some isocyanates can undergo slow degradation over time, even under optimal conditions. This necessitates careful inventory management and regular quality checks to ensure that stored materials remain within specification.

Regulatory compliance adds another layer of complexity to isocyanate storage. Evolving environmental and safety regulations require constant adaptation of storage practices, often necessitating significant investments in infrastructure and training. Keeping up with these changing requirements while maintaining operational efficiency is an ongoing challenge for many facilities.

Temperature control is another critical challenge in isocyanate storage. These compounds are sensitive to both high and low temperatures, requiring careful management of storage conditions. Excessive heat can accelerate degradation and increase the risk of pressure buildup in storage containers, while freezing temperatures can cause crystallization and separation of some isocyanate formulations.

The potential for isocyanate vapors to escape during storage and handling poses significant health risks to workers. Inhalation of these vapors can cause respiratory irritation, sensitization, and in severe cases, asthma-like reactions. Ensuring proper ventilation and implementing effective vapor containment systems are ongoing challenges in isocyanate storage facilities.

Corrosion of storage tanks and transfer equipment is a persistent issue, particularly with certain types of isocyanates. This can lead to leaks, contamination, and compromised structural integrity of storage vessels. Selecting appropriate materials for tanks, piping, and seals that are resistant to isocyanate-induced corrosion is crucial but often complex.

The reactivity of isocyanates also presents fire and explosion hazards. While not inherently flammable, some isocyanates can react violently with water, producing heat and potentially igniting nearby combustible materials. Designing storage areas with appropriate fire suppression systems and implementing rigorous safety protocols are ongoing challenges.

Long-term storage stability is another concern, as some isocyanates can undergo slow degradation over time, even under optimal conditions. This necessitates careful inventory management and regular quality checks to ensure that stored materials remain within specification.

Regulatory compliance adds another layer of complexity to isocyanate storage. Evolving environmental and safety regulations require constant adaptation of storage practices, often necessitating significant investments in infrastructure and training. Keeping up with these changing requirements while maintaining operational efficiency is an ongoing challenge for many facilities.

Existing Isocyanate Safety Solutions

01 Personal protective equipment for isocyanate handling

Proper personal protective equipment (PPE) is crucial when handling isocyanates. This includes using appropriate respirators, gloves, and protective clothing to minimize exposure risks. Implementing safety protocols and training for workers on the correct use of PPE is essential for maintaining a safe work environment when dealing with isocyanates.- Personal protective equipment for isocyanate handling: Proper personal protective equipment (PPE) is crucial when handling isocyanates. This includes using appropriate respirators, gloves, and protective clothing to minimize exposure risks. Implementing safety protocols and training for workers on the correct use of PPE is essential for maintaining a safe work environment when dealing with isocyanates.

- Ventilation and exposure control measures: Adequate ventilation systems and exposure control measures are vital for isocyanate safety. This includes the use of local exhaust ventilation, fume hoods, and enclosed processing systems to minimize airborne isocyanate concentrations. Regular monitoring of air quality and implementing engineering controls can significantly reduce the risk of exposure in industrial settings.

- Safe storage and handling practices: Proper storage and handling of isocyanates are critical for safety. This involves using appropriate containers, maintaining suitable temperature and humidity conditions, and implementing spill containment measures. Developing and following standard operating procedures for isocyanate handling, including proper labeling and segregation from incompatible materials, is essential for preventing accidents and exposure.

- Emergency response and first aid procedures: Establishing comprehensive emergency response and first aid procedures is crucial for isocyanate safety. This includes having readily available eyewash stations, safety showers, and appropriate spill clean-up materials. Training personnel on proper emergency response techniques and ensuring quick access to medical assistance in case of exposure are important aspects of isocyanate safety protocols.

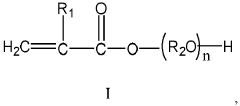

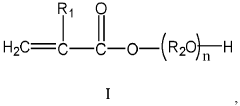

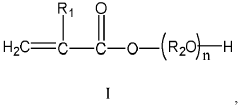

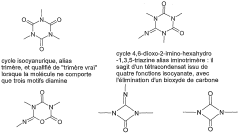

- Safer alternatives and isocyanate-free formulations: Research and development of safer alternatives and isocyanate-free formulations can significantly improve workplace safety. This includes exploring alternative chemistries, developing low-emission or blocked isocyanates, and investigating novel polyurethane technologies that reduce or eliminate the use of free isocyanates. Implementing these safer alternatives can help mitigate the risks associated with traditional isocyanate-based systems.

02 Ventilation and exposure control measures

Effective ventilation systems and exposure control measures are vital for isocyanate safety. This includes local exhaust ventilation, enclosed processes, and monitoring systems to detect and control isocyanate vapors. Implementing engineering controls to minimize worker exposure and maintain air quality in the workplace is crucial for preventing health hazards associated with isocyanates.Expand Specific Solutions03 Safe storage and handling practices

Proper storage and handling practices are essential for isocyanate safety. This includes using appropriate containers, maintaining proper temperature and humidity conditions, and implementing spill containment measures. Developing and following standard operating procedures for the safe transport, storage, and handling of isocyanates is crucial to prevent accidents and exposure risks.Expand Specific Solutions04 Emergency response and first aid procedures

Establishing comprehensive emergency response and first aid procedures is critical for isocyanate safety. This includes developing protocols for spill management, decontamination, and medical treatment in case of exposure. Training personnel on proper emergency response techniques and ensuring the availability of appropriate first aid equipment and materials is essential for minimizing the impact of potential incidents.Expand Specific Solutions05 Substitution and alternative technologies

Exploring substitution options and alternative technologies can significantly improve isocyanate safety. This involves researching and implementing less hazardous alternatives to isocyanates where possible, or developing new processes that reduce or eliminate the use of isocyanates. Adopting safer alternatives and innovative technologies can help minimize the risks associated with isocyanate exposure in various industries.Expand Specific Solutions

Key Players in Isocyanate Industry

The market for enhancing isocyanate storage and handling safety is in a mature stage, driven by stringent regulations and growing awareness of workplace safety. The global market size is estimated to be in the billions, with steady growth expected due to increasing industrial applications. Technologically, solutions are well-established but continually evolving, with major players like Wanhua Chemical, BASF, Covestro, and Asahi Kasei leading innovation. These companies are focusing on developing advanced storage systems, improved handling equipment, and safer formulations to mitigate risks associated with isocyanate exposure and reactivity.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical Group has developed advanced isocyanate storage and handling systems that incorporate multiple safety features. Their approach includes the use of specialized storage tanks with temperature control systems to maintain optimal conditions and prevent degradation[1]. They have implemented a closed-loop transfer system that minimizes exposure risks during handling and transportation[2]. Additionally, Wanhua has developed proprietary vapor recovery technology that captures and recycles isocyanate vapors, reducing emissions and improving overall safety[3]. The company also utilizes advanced monitoring systems with real-time data analytics to detect potential issues before they escalate into safety hazards[4].

Strengths: Comprehensive safety approach, innovative vapor recovery technology, and advanced monitoring systems. Weaknesses: Potentially higher implementation costs and complexity of integrated systems.

Covestro Deutschland AG

Technical Solution: Covestro has implemented a multi-faceted approach to enhance isocyanate storage and handling safety. They have developed a patented tank design that incorporates a double-wall structure with inert gas blanketing to prevent moisture ingress and reduce fire risks[1]. Their handling systems feature automated transfer mechanisms that minimize human contact with isocyanates[2]. Covestro has also introduced smart sensors and IoT-enabled monitoring devices that provide continuous real-time data on storage conditions, including temperature, pressure, and humidity levels[3]. Furthermore, they have implemented a comprehensive employee training program focused on isocyanate safety protocols and emergency response procedures[4].

Strengths: Advanced tank design, automated handling systems, and comprehensive safety training. Weaknesses: High initial investment costs and potential over-reliance on technology.

Innovative Approaches to Isocyanate Safety

A method for stably storing an isocyanate composition

PatentInactiveEP4036139A1

Innovation

- Incorporating a beta-dicarbonyl compound into the isocyanate composition, specifically at concentrations of 0.005-2 wt%, helps stabilize the viscosity, thereby extending the storage time to at least 7 days at 50°C, and preventing quality degradation.

Compositions exhibiting good mixing properties and use of silyl derivatives as isocyanate additives, in particular of isocyanate mixture

PatentWO2006070100A1

Innovation

- Incorporating silylated derivatives as adjuvants in isocyanate compositions, which include dihydrocarbylsilylene and hydrocarbyl(hydrocarbyloxy)silylene groups, to improve compatibility with solvents and reduce hydrolysis reactions, thereby enhancing stability and safety by preventing carbon dioxide and urea formation.

Regulatory Framework for Isocyanate Use

The regulatory framework for isocyanate use is a complex and evolving landscape designed to ensure the safe handling, storage, and application of these highly reactive chemicals. At the forefront of this framework is the Occupational Safety and Health Administration (OSHA) in the United States, which has established comprehensive standards for isocyanate exposure limits and safety protocols. OSHA's Hazard Communication Standard (HCS) mandates that employers provide workers with information and training on isocyanate hazards and appropriate protective measures.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation plays a crucial role in governing isocyanate use. REACH requires manufacturers and importers to register substances and provide safety data, ensuring a high level of protection for human health and the environment. The Classification, Labeling, and Packaging (CLP) Regulation further harmonizes the criteria for classification of substances and mixtures, including isocyanates.

The Environmental Protection Agency (EPA) in the U.S. regulates isocyanates under the Toxic Substances Control Act (TSCA), which gives the agency authority to require reporting, record-keeping, and testing of chemicals that may pose environmental or health risks. The EPA has also implemented Significant New Use Rules (SNURs) for certain isocyanates, requiring notification before they can be used in new ways that may increase exposure.

Industry-specific regulations also contribute to the framework. For instance, the automotive industry, a major user of isocyanates in polyurethane production, must adhere to strict guidelines set by organizations like the International Automotive Task Force (IATF). These standards often exceed general regulatory requirements, focusing on quality management systems that inherently improve safety practices.

Global harmonization efforts, such as the Globally Harmonized System of Classification and Labeling of Chemicals (GHS), have been instrumental in standardizing hazard communication across borders. This system provides a common set of criteria for classifying chemicals according to their health, physical, and environmental hazards, facilitating international trade while maintaining safety standards.

Continuous updates to these regulations reflect ongoing research into isocyanate health effects and advancements in safety technologies. For example, recent amendments to OSHA's Respiratory Protection Standard have implications for isocyanate handlers, emphasizing the importance of proper respirator selection and fit testing. Similarly, the EU's REACH regulation undergoes regular reviews, with the potential for additional restrictions on isocyanate use based on emerging scientific evidence.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation plays a crucial role in governing isocyanate use. REACH requires manufacturers and importers to register substances and provide safety data, ensuring a high level of protection for human health and the environment. The Classification, Labeling, and Packaging (CLP) Regulation further harmonizes the criteria for classification of substances and mixtures, including isocyanates.

The Environmental Protection Agency (EPA) in the U.S. regulates isocyanates under the Toxic Substances Control Act (TSCA), which gives the agency authority to require reporting, record-keeping, and testing of chemicals that may pose environmental or health risks. The EPA has also implemented Significant New Use Rules (SNURs) for certain isocyanates, requiring notification before they can be used in new ways that may increase exposure.

Industry-specific regulations also contribute to the framework. For instance, the automotive industry, a major user of isocyanates in polyurethane production, must adhere to strict guidelines set by organizations like the International Automotive Task Force (IATF). These standards often exceed general regulatory requirements, focusing on quality management systems that inherently improve safety practices.

Global harmonization efforts, such as the Globally Harmonized System of Classification and Labeling of Chemicals (GHS), have been instrumental in standardizing hazard communication across borders. This system provides a common set of criteria for classifying chemicals according to their health, physical, and environmental hazards, facilitating international trade while maintaining safety standards.

Continuous updates to these regulations reflect ongoing research into isocyanate health effects and advancements in safety technologies. For example, recent amendments to OSHA's Respiratory Protection Standard have implications for isocyanate handlers, emphasizing the importance of proper respirator selection and fit testing. Similarly, the EU's REACH regulation undergoes regular reviews, with the potential for additional restrictions on isocyanate use based on emerging scientific evidence.

Environmental Impact of Isocyanates

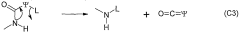

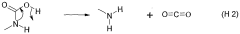

Isocyanates, widely used in the production of polyurethanes, pose significant environmental concerns due to their reactivity and potential for release. When exposed to the environment, these compounds can have detrimental effects on ecosystems and human health. In aquatic environments, isocyanates rapidly hydrolyze, forming amines and carbon dioxide. This process can lead to changes in water pH and potentially harm aquatic organisms. The resulting amines may persist longer in the environment and can be toxic to various aquatic species.

In terrestrial ecosystems, isocyanates can react with soil moisture, potentially altering soil chemistry and affecting plant growth. The release of isocyanates into the air, often occurring during manufacturing processes or accidental spills, can contribute to the formation of ground-level ozone and particulate matter, both of which are known air pollutants. These compounds can also react with other atmospheric chemicals, potentially forming secondary pollutants with unknown environmental impacts.

The environmental fate of isocyanates is complex and depends on various factors, including temperature, humidity, and the presence of other chemicals. In some cases, isocyanates may form stable urea compounds in the environment, which can persist for extended periods. This persistence raises concerns about long-term environmental accumulation and potential chronic effects on ecosystems.

Bioaccumulation of isocyanates in the food chain is another area of environmental concern. While isocyanates themselves do not typically bioaccumulate due to their reactivity, their breakdown products may accumulate in certain organisms, potentially leading to ecological imbalances and health risks for higher-order consumers, including humans.

To mitigate these environmental impacts, stringent control measures are essential in isocyanate handling and storage. Proper containment systems, efficient air filtration, and wastewater treatment are crucial in preventing environmental releases. Additionally, the development of less reactive or environmentally benign alternatives to traditional isocyanates is an active area of research, aiming to reduce the environmental footprint of polyurethane production.

Monitoring and assessing the environmental impact of isocyanates require sophisticated analytical techniques. Advances in environmental monitoring technologies have improved the ability to detect and quantify isocyanates and their breakdown products in various environmental matrices. This enhanced monitoring capability is crucial for understanding the long-term environmental effects and for developing more effective mitigation strategies.

In terrestrial ecosystems, isocyanates can react with soil moisture, potentially altering soil chemistry and affecting plant growth. The release of isocyanates into the air, often occurring during manufacturing processes or accidental spills, can contribute to the formation of ground-level ozone and particulate matter, both of which are known air pollutants. These compounds can also react with other atmospheric chemicals, potentially forming secondary pollutants with unknown environmental impacts.

The environmental fate of isocyanates is complex and depends on various factors, including temperature, humidity, and the presence of other chemicals. In some cases, isocyanates may form stable urea compounds in the environment, which can persist for extended periods. This persistence raises concerns about long-term environmental accumulation and potential chronic effects on ecosystems.

Bioaccumulation of isocyanates in the food chain is another area of environmental concern. While isocyanates themselves do not typically bioaccumulate due to their reactivity, their breakdown products may accumulate in certain organisms, potentially leading to ecological imbalances and health risks for higher-order consumers, including humans.

To mitigate these environmental impacts, stringent control measures are essential in isocyanate handling and storage. Proper containment systems, efficient air filtration, and wastewater treatment are crucial in preventing environmental releases. Additionally, the development of less reactive or environmentally benign alternatives to traditional isocyanates is an active area of research, aiming to reduce the environmental footprint of polyurethane production.

Monitoring and assessing the environmental impact of isocyanates require sophisticated analytical techniques. Advances in environmental monitoring technologies have improved the ability to detect and quantify isocyanates and their breakdown products in various environmental matrices. This enhanced monitoring capability is crucial for understanding the long-term environmental effects and for developing more effective mitigation strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!