How to Enhance Photocatalytic Activity of TMD Nanosheets

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TMD Photocatalysis Background and Objectives

Transition metal dichalcogenides (TMDs) have emerged as a revolutionary class of two-dimensional materials with exceptional properties for photocatalytic applications. Since the isolation of graphene in 2004, research into 2D materials has expanded dramatically, with TMDs gaining significant attention due to their unique electronic structure, tunable bandgaps, and high surface-to-volume ratios. These characteristics make them particularly promising for addressing global energy and environmental challenges through photocatalytic processes.

The historical development of TMD photocatalysis can be traced back to early investigations of bulk TMDs in the 1970s. However, the field experienced a renaissance following the successful exfoliation of single-layer MoS2 in 2011, which revealed dramatically enhanced photocatalytic properties compared to bulk counterparts. This breakthrough demonstrated that reducing dimensionality could significantly alter electronic properties and catalytic activity.

Current technological trends in TMD photocatalysis focus on several key areas: bandgap engineering through alloying and defect introduction; heterostructure formation with other 2D materials; surface functionalization; and phase engineering between semiconducting (2H) and metallic (1T) polymorphs. These approaches aim to overcome inherent limitations in light absorption range, charge carrier mobility, and surface reaction kinetics.

The fundamental photocatalytic mechanism in TMDs involves three critical steps: photon absorption to generate electron-hole pairs, charge carrier separation and transport, and surface redox reactions. Each step presents optimization opportunities that researchers are actively exploring to enhance overall efficiency. Recent advances in synthetic methods have enabled precise control over TMD nanosheet thickness, lateral dimensions, edge structures, and defect densities—all critical parameters affecting photocatalytic performance.

The primary objectives of enhancing TMD photocatalytic activity include expanding the light absorption spectrum to utilize more solar energy, improving charge separation efficiency to reduce recombination losses, increasing active site density for catalytic reactions, and enhancing stability under operating conditions. These goals align with broader societal needs for sustainable hydrogen production, environmental remediation, and CO2 reduction technologies.

Looking forward, TMD photocatalysis research aims to achieve practical solar-to-chemical energy conversion efficiencies exceeding 10%, develop scalable synthesis methods for industrial applications, and create integrated systems that combine TMDs with complementary materials for multi-functional catalytic platforms. The field is progressing toward more sophisticated understanding of structure-property relationships that will enable rational design of next-generation photocatalysts with tailored properties for specific applications.

The historical development of TMD photocatalysis can be traced back to early investigations of bulk TMDs in the 1970s. However, the field experienced a renaissance following the successful exfoliation of single-layer MoS2 in 2011, which revealed dramatically enhanced photocatalytic properties compared to bulk counterparts. This breakthrough demonstrated that reducing dimensionality could significantly alter electronic properties and catalytic activity.

Current technological trends in TMD photocatalysis focus on several key areas: bandgap engineering through alloying and defect introduction; heterostructure formation with other 2D materials; surface functionalization; and phase engineering between semiconducting (2H) and metallic (1T) polymorphs. These approaches aim to overcome inherent limitations in light absorption range, charge carrier mobility, and surface reaction kinetics.

The fundamental photocatalytic mechanism in TMDs involves three critical steps: photon absorption to generate electron-hole pairs, charge carrier separation and transport, and surface redox reactions. Each step presents optimization opportunities that researchers are actively exploring to enhance overall efficiency. Recent advances in synthetic methods have enabled precise control over TMD nanosheet thickness, lateral dimensions, edge structures, and defect densities—all critical parameters affecting photocatalytic performance.

The primary objectives of enhancing TMD photocatalytic activity include expanding the light absorption spectrum to utilize more solar energy, improving charge separation efficiency to reduce recombination losses, increasing active site density for catalytic reactions, and enhancing stability under operating conditions. These goals align with broader societal needs for sustainable hydrogen production, environmental remediation, and CO2 reduction technologies.

Looking forward, TMD photocatalysis research aims to achieve practical solar-to-chemical energy conversion efficiencies exceeding 10%, develop scalable synthesis methods for industrial applications, and create integrated systems that combine TMDs with complementary materials for multi-functional catalytic platforms. The field is progressing toward more sophisticated understanding of structure-property relationships that will enable rational design of next-generation photocatalysts with tailored properties for specific applications.

Market Applications of Enhanced TMD Photocatalysts

Enhanced TMD (transition metal dichalcogenide) nanosheets with improved photocatalytic activity are finding significant applications across multiple industrial sectors, driving market growth and technological innovation. The water treatment industry represents one of the most promising application areas, where TMD photocatalysts are being deployed for the degradation of persistent organic pollutants, pharmaceutical residues, and industrial dyes. Their ability to operate under visible light makes them particularly valuable for sustainable water purification systems in both developed and developing regions.

The renewable energy sector is rapidly adopting enhanced TMD photocatalysts for photocatalytic hydrogen production. These materials offer advantages in water splitting applications due to their tunable band gaps, high surface area, and improved charge separation properties. Commercial systems utilizing TMD-based photocatalysts are beginning to emerge, particularly in regions with abundant sunlight and growing hydrogen economies.

Environmental remediation represents another significant market, with TMD photocatalysts being employed for air purification systems that can degrade volatile organic compounds (VOCs), nitrogen oxides, and other atmospheric pollutants. Indoor air quality applications in commercial buildings, hospitals, and residential settings are driving adoption in this segment.

The chemical manufacturing industry is exploring TMD photocatalysts for green synthesis pathways that reduce energy requirements and waste production. Selective oxidation reactions, CO2 reduction to value-added chemicals, and other photocatalytic transformations are being commercialized, offering more sustainable alternatives to traditional chemical processes.

Agricultural applications are emerging as farmers seek sustainable solutions for pest management and soil remediation. TMD photocatalysts are being tested for degradation of pesticide residues and for soil decontamination, with field trials showing promising results in various climatic conditions.

The biomedical sector represents a growing niche market, where TMD photocatalysts are being investigated for antimicrobial applications, photodynamic therapy, and controlled drug delivery systems. Their biocompatibility and ability to generate reactive oxygen species under specific light conditions make them valuable for these specialized applications.

Consumer products incorporating TMD photocatalysts are also gaining traction, including self-cleaning surfaces, antimicrobial textiles, and advanced air purifiers. These products leverage the photocatalytic properties to provide continuous disinfection and decontamination capabilities in everyday environments.

The automotive and construction industries are exploring TMD photocatalysts for self-cleaning coatings, air-purifying concrete, and other smart materials that can reduce maintenance costs while providing environmental benefits. These applications represent significant volume potential as adoption increases across these major industrial sectors.

The renewable energy sector is rapidly adopting enhanced TMD photocatalysts for photocatalytic hydrogen production. These materials offer advantages in water splitting applications due to their tunable band gaps, high surface area, and improved charge separation properties. Commercial systems utilizing TMD-based photocatalysts are beginning to emerge, particularly in regions with abundant sunlight and growing hydrogen economies.

Environmental remediation represents another significant market, with TMD photocatalysts being employed for air purification systems that can degrade volatile organic compounds (VOCs), nitrogen oxides, and other atmospheric pollutants. Indoor air quality applications in commercial buildings, hospitals, and residential settings are driving adoption in this segment.

The chemical manufacturing industry is exploring TMD photocatalysts for green synthesis pathways that reduce energy requirements and waste production. Selective oxidation reactions, CO2 reduction to value-added chemicals, and other photocatalytic transformations are being commercialized, offering more sustainable alternatives to traditional chemical processes.

Agricultural applications are emerging as farmers seek sustainable solutions for pest management and soil remediation. TMD photocatalysts are being tested for degradation of pesticide residues and for soil decontamination, with field trials showing promising results in various climatic conditions.

The biomedical sector represents a growing niche market, where TMD photocatalysts are being investigated for antimicrobial applications, photodynamic therapy, and controlled drug delivery systems. Their biocompatibility and ability to generate reactive oxygen species under specific light conditions make them valuable for these specialized applications.

Consumer products incorporating TMD photocatalysts are also gaining traction, including self-cleaning surfaces, antimicrobial textiles, and advanced air purifiers. These products leverage the photocatalytic properties to provide continuous disinfection and decontamination capabilities in everyday environments.

The automotive and construction industries are exploring TMD photocatalysts for self-cleaning coatings, air-purifying concrete, and other smart materials that can reduce maintenance costs while providing environmental benefits. These applications represent significant volume potential as adoption increases across these major industrial sectors.

Current Limitations in TMD Nanosheets Photocatalytic Performance

Despite significant advancements in transition metal dichalcogenide (TMD) nanosheets for photocatalytic applications, several critical limitations continue to hinder their optimal performance. The inherent band structure of most TMDs presents a fundamental challenge, as many exhibit either inappropriate band gaps or unfavorable band edge positions for efficient photocatalytic reactions. This structural limitation restricts their ability to effectively harvest visible light and generate the necessary redox potentials for target reactions.

Rapid charge carrier recombination represents another significant barrier to TMD photocatalytic efficiency. When photogenerated electrons and holes recombine before participating in surface redox reactions, quantum efficiency decreases dramatically. This recombination process is particularly problematic in pristine TMD nanosheets due to their limited charge separation mechanisms and the presence of defect sites that act as recombination centers.

Surface area constraints further limit catalytic performance. While exfoliation techniques have improved, achieving consistent, large-scale production of high-quality, atomically thin TMD nanosheets with maximized active surface area remains challenging. The tendency of nanosheets to restack during processing and application reduces accessible active sites and hampers mass transfer during catalytic reactions.

Stability issues under photocatalytic conditions pose additional challenges. Many TMD materials suffer from photocorrosion or oxidative degradation during extended operation, particularly in aqueous environments. This degradation progressively diminishes catalytic activity and limits practical application lifespans, especially for water splitting and environmental remediation applications.

The limited visible light absorption range of certain TMDs restricts their solar energy utilization efficiency. While some TMDs possess suitable band gaps for visible light absorption, others primarily respond to UV radiation, which constitutes only a small fraction of the solar spectrum. This spectral mismatch significantly reduces overall energy conversion efficiency in solar-driven applications.

Scalability and reproducibility concerns also impede commercial viability. Current synthesis methods often produce TMD nanosheets with inconsistent thickness, lateral dimensions, and defect densities, leading to variable photocatalytic performance. The complex relationship between synthesis parameters and resulting nanosheet properties makes standardization difficult, hampering industrial adoption.

Finally, the relatively poor understanding of structure-activity relationships in TMD photocatalysis limits rational design approaches. The complex interplay between electronic structure, morphology, defects, and catalytic activity remains incompletely characterized, making systematic improvement strategies challenging to implement.

Rapid charge carrier recombination represents another significant barrier to TMD photocatalytic efficiency. When photogenerated electrons and holes recombine before participating in surface redox reactions, quantum efficiency decreases dramatically. This recombination process is particularly problematic in pristine TMD nanosheets due to their limited charge separation mechanisms and the presence of defect sites that act as recombination centers.

Surface area constraints further limit catalytic performance. While exfoliation techniques have improved, achieving consistent, large-scale production of high-quality, atomically thin TMD nanosheets with maximized active surface area remains challenging. The tendency of nanosheets to restack during processing and application reduces accessible active sites and hampers mass transfer during catalytic reactions.

Stability issues under photocatalytic conditions pose additional challenges. Many TMD materials suffer from photocorrosion or oxidative degradation during extended operation, particularly in aqueous environments. This degradation progressively diminishes catalytic activity and limits practical application lifespans, especially for water splitting and environmental remediation applications.

The limited visible light absorption range of certain TMDs restricts their solar energy utilization efficiency. While some TMDs possess suitable band gaps for visible light absorption, others primarily respond to UV radiation, which constitutes only a small fraction of the solar spectrum. This spectral mismatch significantly reduces overall energy conversion efficiency in solar-driven applications.

Scalability and reproducibility concerns also impede commercial viability. Current synthesis methods often produce TMD nanosheets with inconsistent thickness, lateral dimensions, and defect densities, leading to variable photocatalytic performance. The complex relationship between synthesis parameters and resulting nanosheet properties makes standardization difficult, hampering industrial adoption.

Finally, the relatively poor understanding of structure-activity relationships in TMD photocatalysis limits rational design approaches. The complex interplay between electronic structure, morphology, defects, and catalytic activity remains incompletely characterized, making systematic improvement strategies challenging to implement.

State-of-the-Art TMD Photocatalytic Enhancement Methods

01 Synthesis methods for TMD nanosheets with enhanced photocatalytic activity

Various synthesis methods can be employed to create transition metal dichalcogenide (TMD) nanosheets with improved photocatalytic properties. These methods include hydrothermal synthesis, chemical vapor deposition, and liquid exfoliation techniques. The synthesis parameters significantly influence the crystallinity, thickness, and surface area of the nanosheets, which directly impact their photocatalytic performance. Controlling these parameters allows for the creation of TMD nanosheets with optimized band gaps and charge carrier mobility for efficient photocatalytic reactions.- Synthesis methods of TMD nanosheets for photocatalytic applications: Various synthesis methods can be employed to produce transition metal dichalcogenide (TMD) nanosheets with enhanced photocatalytic activity. These methods include hydrothermal synthesis, chemical vapor deposition, liquid exfoliation, and electrochemical approaches. The synthesis parameters significantly influence the crystallinity, thickness, and surface area of the nanosheets, which in turn affect their photocatalytic performance. Controlling these parameters allows for the creation of TMD nanosheets with optimized properties for specific photocatalytic reactions.

- Doping and heterostructure formation to enhance photocatalytic activity: Doping TMD nanosheets with various elements or forming heterostructures with other materials can significantly enhance their photocatalytic activity. Introducing dopants such as nitrogen, phosphorus, or transition metals can modify the electronic structure, reduce bandgap, and improve charge separation efficiency. Creating heterostructures by combining TMD nanosheets with other semiconductors, noble metals, or carbon-based materials facilitates efficient charge transfer and extends the light absorption range, resulting in improved photocatalytic performance for various applications including water splitting and pollutant degradation.

- Surface modification and defect engineering of TMD nanosheets: Surface modification and defect engineering are effective strategies to enhance the photocatalytic activity of TMD nanosheets. Creating controlled defects, such as sulfur vacancies or edge sites, can introduce active catalytic centers and modify electronic properties. Surface functionalization with organic molecules, polymers, or nanoparticles can improve the stability, dispersibility, and specific targeting capabilities of TMD nanosheets. These modifications can significantly increase the number of active sites, improve charge carrier mobility, and enhance the overall photocatalytic efficiency.

- Light harvesting and charge separation mechanisms in TMD photocatalysts: The photocatalytic activity of TMD nanosheets is strongly influenced by their light harvesting capabilities and charge separation mechanisms. The unique band structure of TMD materials allows for efficient absorption of visible light, while their 2D structure facilitates rapid charge carrier transport. Various strategies can be employed to enhance these properties, including creating quantum confinement effects, introducing plasmonic materials, and designing Z-scheme photocatalytic systems. Understanding and optimizing these mechanisms is crucial for developing highly efficient TMD-based photocatalysts for environmental remediation and energy conversion applications.

- Applications of TMD nanosheets in photocatalytic processes: TMD nanosheets demonstrate versatile applications in various photocatalytic processes. They are effectively utilized in water splitting for hydrogen production, degradation of organic pollutants, CO2 reduction to valuable chemicals, and disinfection processes. The tunable properties of TMD nanosheets, including their bandgap, surface area, and reactivity, make them suitable for specific photocatalytic applications. Recent advancements have focused on developing scalable production methods and improving the stability and reusability of TMD-based photocatalysts for practical environmental and energy applications.

02 Doping and heterostructure formation to enhance photocatalytic efficiency

Doping TMD nanosheets with various elements or forming heterostructures with other semiconducting materials can significantly enhance their photocatalytic activity. These modifications create synergistic effects that improve charge separation, reduce recombination rates, and extend the light absorption range. Heterostructures formed between different TMD materials or with other photocatalysts like TiO2 or graphene derivatives can create efficient electron-hole pair separation pathways, leading to enhanced photocatalytic performance for applications such as water splitting and pollutant degradation.Expand Specific Solutions03 Surface modification and defect engineering of TMD nanosheets

Surface modification and defect engineering are effective strategies to enhance the photocatalytic activity of TMD nanosheets. Introducing controlled defects or vacancies in the crystal structure creates active sites for catalytic reactions. Surface functionalization with organic molecules or nanoparticles can improve the adsorption of reactants and light harvesting capabilities. These modifications can be achieved through methods such as plasma treatment, chemical etching, or thermal annealing, resulting in TMD nanosheets with significantly improved photocatalytic performance for environmental remediation and energy conversion applications.Expand Specific Solutions04 Light harvesting enhancement and charge carrier dynamics in TMD photocatalysts

Improving light harvesting capabilities and optimizing charge carrier dynamics are crucial for enhancing the photocatalytic activity of TMD nanosheets. Strategies include tuning the thickness and lateral dimensions of nanosheets to optimize light absorption and charge transport distances. Incorporating plasmonic nanoparticles or quantum dots can enhance light absorption through localized surface plasmon resonance effects. Understanding and controlling the charge carrier generation, separation, and transfer processes in TMD nanosheets is essential for designing high-performance photocatalysts for applications such as hydrogen evolution and CO2 reduction.Expand Specific Solutions05 Applications and performance metrics of TMD nanosheet photocatalysts

TMD nanosheet photocatalysts demonstrate promising performance in various applications including water splitting, pollutant degradation, CO2 reduction, and organic synthesis. The performance of these photocatalysts can be evaluated through metrics such as quantum efficiency, reaction rate, stability, and selectivity. Factors affecting their practical application include scalability of synthesis methods, long-term stability under reaction conditions, and recyclability. Recent advances have shown that optimized TMD nanosheet photocatalysts can achieve high hydrogen evolution rates and efficient degradation of organic pollutants under visible light irradiation, making them promising candidates for sustainable energy and environmental applications.Expand Specific Solutions

Leading Research Groups and Companies in TMD Photocatalysis

The photocatalytic enhancement of TMD nanosheets market is currently in its growth phase, with increasing research interest driven by renewable energy applications. The competitive landscape features predominantly academic institutions leading fundamental research, with Beijing University of Chemical Technology, Zhejiang University, and National Institute for Materials Science emerging as key players in advancing TMD photocatalytic performance. Commercial entities like Siemens AG and Nexdot SAS are beginning to explore industrial applications, though the technology remains in early commercialization stages. The market is characterized by intensive research collaboration between universities and industry partners, focusing on bandgap engineering, heterostructure formation, and defect management to overcome efficiency limitations. As technical challenges are addressed, this field is expected to expand significantly within the broader clean energy technology sector.

Zhejiang University

Technical Solution: Zhejiang University has developed multifaceted approaches to enhance TMD nanosheets' photocatalytic activity through advanced nanostructure engineering and surface modification. Their primary innovation involves creating hierarchical 3D flower-like MoS2 architectures assembled from ultrathin nanosheets, which dramatically increases surface area while maintaining quantum confinement effects. These structures are synthesized through a one-pot hydrothermal method using organic structure-directing agents that control morphology development. Researchers at Zhejiang have pioneered nitrogen and phosphorus co-doping of TMD nanosheets, which simultaneously modulates the band structure and creates additional active sites. Their studies demonstrate that co-doped MoS2 nanosheets exhibit a narrowed bandgap of approximately 1.7 eV (compared to 1.9 eV in pristine MoS2) and show enhanced visible light absorption extending to 700 nm. Additionally, they've developed TMD-based p-n heterojunctions by coupling n-type MoS2 with p-type semiconductors like Cu2O, creating built-in electric fields that facilitate charge separation. Recent work demonstrates photocatalytic hydrogen evolution rates exceeding 2.1 mmol/g/h under simulated solar irradiation.

Strengths: Hierarchical 3D structures maximize surface area while maintaining quantum properties; co-doping strategies effectively tune electronic structure; heterojunction formation creates efficient charge separation pathways. Weaknesses: Complex synthesis procedures may challenge reproducibility; potential agglomeration of 3D structures during long-term operation; doping-induced defects may create recombination centers.

Northwestern University

Technical Solution: Northwestern University has developed innovative approaches to enhance the photocatalytic activity of TMD nanosheets through strategic defect engineering and heterostructure formation. Their research focuses on creating controlled sulfur vacancies in MoS2 nanosheets, which serve as active sites for photocatalytic reactions while simultaneously narrowing the bandgap to extend light absorption into the visible spectrum. They've pioneered a two-step process involving hydrothermal synthesis followed by thermal annealing in controlled atmospheres to precisely tune defect concentrations. Additionally, Northwestern has developed novel TMD-based Z-scheme heterojunctions by coupling MoS2 with complementary semiconductors like TiO2 and g-C3N4, enabling efficient charge separation and transfer. Their recent work demonstrates that these engineered TMD heterostructures achieve hydrogen evolution rates up to 15 times higher than pristine TMDs under visible light irradiation, with remarkable stability over 100+ hours of continuous operation.

Strengths: Superior control over defect engineering with precise vacancy concentration tuning; innovative heterojunction designs with exceptional charge separation efficiency; demonstrated long-term stability in photocatalytic applications. Weaknesses: Complex multi-step synthesis procedures may limit large-scale production; potential recombination centers at defect sites could reduce quantum efficiency in certain configurations.

Key Scientific Breakthroughs in TMD Photocatalytic Mechanisms

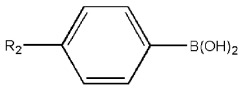

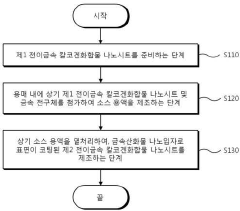

Metal oxide/transition metal dichalcogenide nanosheets and method of fabricating of the same, application technology of catalytic material

PatentActiveKR1020200126192A

Innovation

- A method involving the preparation of a first transition metal chalcogenide nanosheet followed by the adsorption of a hydrated metal precursor, which is then oxidized to form metal oxide nanoparticles on the surface, creating a second transition metal chalcogenide nanosheet with enhanced catalytic properties.

Environmental Impact and Sustainability Aspects of TMD Photocatalysts

The integration of TMD photocatalysts into environmental remediation systems represents a significant advancement in sustainable technology. These nanomaterials demonstrate exceptional potential for addressing critical environmental challenges while maintaining a smaller ecological footprint compared to traditional catalytic materials. The life cycle assessment of TMD-based photocatalytic systems reveals considerably lower energy requirements during production and implementation phases, with reduced greenhouse gas emissions throughout their operational lifespan.

Water purification applications utilizing TMD photocatalysts show remarkable efficiency in degrading persistent organic pollutants without generating harmful secondary contaminants. Studies indicate that MoS2 and WS2-based systems can achieve over 95% degradation of industrial dyes and pharmaceutical compounds under solar irradiation, offering a chemical-free alternative to conventional treatment methods. This solar-driven approach significantly reduces the carbon footprint associated with water treatment infrastructure.

The recyclability of TMD nanosheets further enhances their sustainability profile. Enhanced photocatalytic TMD systems maintain approximately 85-90% of their initial activity after five consecutive usage cycles, substantially extending their operational lifetime compared to traditional photocatalysts. Various recovery techniques, including magnetic separation when coupled with magnetic nanoparticles, enable efficient catalyst retrieval and reuse, minimizing waste generation.

From an ecological perspective, TMD photocatalysts exhibit lower ecotoxicity profiles compared to metal oxide alternatives. Preliminary environmental fate studies suggest minimal bioaccumulation potential in aquatic ecosystems, though long-term environmental monitoring remains essential as deployment scales increase. The biodegradability aspects of functionalized TMD materials require further investigation to ensure complete life cycle sustainability.

The economic sustainability of enhanced TMD photocatalysts is increasingly favorable as manufacturing processes evolve. Recent advancements in scalable production methods have reduced synthesis costs by approximately 40% over the past five years. The integration of these materials into existing infrastructure presents a cost-effective pathway for upgrading conventional treatment systems without complete replacement.

Policy frameworks supporting green chemistry initiatives and circular economy principles are creating favorable conditions for TMD photocatalyst adoption. Several jurisdictions have implemented regulatory incentives for technologies that demonstrate reduced environmental impact throughout their lifecycle, positioning enhanced TMD photocatalysts as compliant solutions for industries seeking to meet increasingly stringent environmental standards while maintaining operational efficiency.

Water purification applications utilizing TMD photocatalysts show remarkable efficiency in degrading persistent organic pollutants without generating harmful secondary contaminants. Studies indicate that MoS2 and WS2-based systems can achieve over 95% degradation of industrial dyes and pharmaceutical compounds under solar irradiation, offering a chemical-free alternative to conventional treatment methods. This solar-driven approach significantly reduces the carbon footprint associated with water treatment infrastructure.

The recyclability of TMD nanosheets further enhances their sustainability profile. Enhanced photocatalytic TMD systems maintain approximately 85-90% of their initial activity after five consecutive usage cycles, substantially extending their operational lifetime compared to traditional photocatalysts. Various recovery techniques, including magnetic separation when coupled with magnetic nanoparticles, enable efficient catalyst retrieval and reuse, minimizing waste generation.

From an ecological perspective, TMD photocatalysts exhibit lower ecotoxicity profiles compared to metal oxide alternatives. Preliminary environmental fate studies suggest minimal bioaccumulation potential in aquatic ecosystems, though long-term environmental monitoring remains essential as deployment scales increase. The biodegradability aspects of functionalized TMD materials require further investigation to ensure complete life cycle sustainability.

The economic sustainability of enhanced TMD photocatalysts is increasingly favorable as manufacturing processes evolve. Recent advancements in scalable production methods have reduced synthesis costs by approximately 40% over the past five years. The integration of these materials into existing infrastructure presents a cost-effective pathway for upgrading conventional treatment systems without complete replacement.

Policy frameworks supporting green chemistry initiatives and circular economy principles are creating favorable conditions for TMD photocatalyst adoption. Several jurisdictions have implemented regulatory incentives for technologies that demonstrate reduced environmental impact throughout their lifecycle, positioning enhanced TMD photocatalysts as compliant solutions for industries seeking to meet increasingly stringent environmental standards while maintaining operational efficiency.

Scalability and Industrial Implementation Challenges

Despite the promising laboratory results of enhanced photocatalytic activity in TMD nanosheets, significant challenges remain in scaling these technologies for industrial implementation. The transition from laboratory-scale synthesis to mass production presents several technical hurdles. Current laboratory methods typically produce milligram quantities of high-quality TMD nanosheets, whereas industrial applications would require kilogram to ton-scale production with consistent quality and performance characteristics.

The scalable synthesis of TMD nanosheets with uniform thickness, crystallinity, and defect density remains problematic. Liquid exfoliation methods show promise for large-scale production but often result in nanosheets with varying sizes and thicknesses, which directly impacts photocatalytic performance. Chemical vapor deposition (CVD) offers better control over nanosheet properties but faces limitations in production volume and high energy consumption.

Cost considerations present another significant barrier to industrial adoption. The synthesis of high-quality TMD nanosheets often requires expensive precursors, specialized equipment, and energy-intensive processes. Economic viability demands substantial reduction in production costs through process optimization, alternative precursor development, or recycling strategies for precious metal components.

Stability and durability issues further complicate industrial implementation. TMD nanosheets may undergo degradation under prolonged photocatalytic conditions, particularly in aqueous environments or under intense light irradiation. Industrial applications require catalysts that maintain performance over thousands of hours, necessitating improved stabilization strategies such as protective coatings or composite formations.

Integration challenges exist when incorporating TMD nanosheets into practical reactor designs. Effective immobilization techniques must be developed to prevent catalyst loss while maintaining accessible active sites. Flow-through systems, fixed-bed reactors, and membrane-integrated designs all present unique engineering challenges that must be addressed for specific applications.

Standardization and quality control protocols represent another critical challenge. The photocatalytic performance of TMD nanosheets is highly dependent on their physicochemical properties, requiring robust characterization methods suitable for industrial quality control. Currently, there is a lack of standardized testing protocols to evaluate and compare photocatalytic performance across different manufacturing batches.

Environmental and safety considerations must also be addressed before widespread industrial implementation. Potential nanoparticle release during manufacturing or application requires thorough risk assessment and mitigation strategies. Regulatory frameworks for nanomaterial-based photocatalysts are still evolving, creating uncertainty for industrial stakeholders considering large-scale implementation.

The scalable synthesis of TMD nanosheets with uniform thickness, crystallinity, and defect density remains problematic. Liquid exfoliation methods show promise for large-scale production but often result in nanosheets with varying sizes and thicknesses, which directly impacts photocatalytic performance. Chemical vapor deposition (CVD) offers better control over nanosheet properties but faces limitations in production volume and high energy consumption.

Cost considerations present another significant barrier to industrial adoption. The synthesis of high-quality TMD nanosheets often requires expensive precursors, specialized equipment, and energy-intensive processes. Economic viability demands substantial reduction in production costs through process optimization, alternative precursor development, or recycling strategies for precious metal components.

Stability and durability issues further complicate industrial implementation. TMD nanosheets may undergo degradation under prolonged photocatalytic conditions, particularly in aqueous environments or under intense light irradiation. Industrial applications require catalysts that maintain performance over thousands of hours, necessitating improved stabilization strategies such as protective coatings or composite formations.

Integration challenges exist when incorporating TMD nanosheets into practical reactor designs. Effective immobilization techniques must be developed to prevent catalyst loss while maintaining accessible active sites. Flow-through systems, fixed-bed reactors, and membrane-integrated designs all present unique engineering challenges that must be addressed for specific applications.

Standardization and quality control protocols represent another critical challenge. The photocatalytic performance of TMD nanosheets is highly dependent on their physicochemical properties, requiring robust characterization methods suitable for industrial quality control. Currently, there is a lack of standardized testing protocols to evaluate and compare photocatalytic performance across different manufacturing batches.

Environmental and safety considerations must also be addressed before widespread industrial implementation. Potential nanoparticle release during manufacturing or application requires thorough risk assessment and mitigation strategies. Regulatory frameworks for nanomaterial-based photocatalysts are still evolving, creating uncertainty for industrial stakeholders considering large-scale implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!