Alloyed TMDs: Mo₁₋ₓWₓS₂ and MoSe₂₋ₓTeₓ for Tunable Properties

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Alloyed TMDs Background and Research Objectives

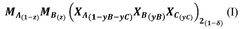

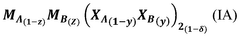

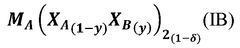

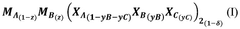

Transition metal dichalcogenides (TMDs) have emerged as a pivotal class of two-dimensional materials since the groundbreaking isolation of graphene in 2004. These layered materials, with their general formula MX₂ (where M represents transition metals like Mo, W, and X denotes chalcogens such as S, Se, Te), have demonstrated remarkable electronic, optical, and mechanical properties that differ significantly from their bulk counterparts.

The evolution of TMD research has progressed through several distinct phases. Initially, research focused on mechanical exfoliation techniques to obtain monolayers, followed by the development of chemical vapor deposition (CVD) methods for large-scale synthesis. More recently, attention has shifted toward engineering these materials through alloying to achieve tunable properties, representing a significant advancement in the field.

Alloyed TMDs, particularly Mo₁₋ₓWₓS₂ and MoSe₂₋ₓTeₓ systems, offer unprecedented opportunities for property customization through compositional engineering. By systematically varying the ratio of constituent elements, researchers can precisely modulate bandgap energies, carrier mobilities, and spin-orbit coupling strengths. This compositional tuning represents a paradigm shift from traditional binary TMDs, enabling a continuous spectrum of material properties rather than discrete values.

The global research landscape has witnessed exponential growth in TMD-related publications, with annual paper counts increasing from fewer than 100 in 2010 to several thousand in recent years. Patent filings have followed a similar trajectory, particularly in applications related to electronics, optoelectronics, and energy storage. This surge in research activity underscores the technological potential and scientific significance of these materials.

The primary objectives of current research on alloyed TMDs encompass several interconnected goals. First, researchers aim to establish reliable synthesis protocols for homogeneous alloys with precise compositional control. Second, there is a concerted effort to develop comprehensive structure-property relationships that correlate atomic composition with resulting material characteristics. Third, the research community seeks to leverage these tunable properties for specific applications in next-generation electronics, photonics, and energy technologies.

Looking forward, the field is moving toward integrating alloyed TMDs into functional devices that can exploit their unique properties. The ability to fine-tune electronic band structures through alloying opens possibilities for customized semiconductors in applications ranging from highly efficient photovoltaics to sensitive photodetectors and beyond. Additionally, the spin-valley physics in these materials presents opportunities for emerging spintronic and valleytronic technologies.

The convergence of advanced synthesis techniques, sophisticated characterization methods, and theoretical modeling approaches has created a fertile environment for rapid advancement in alloyed TMD research, positioning these materials at the forefront of materials science innovation for the coming decade.

The evolution of TMD research has progressed through several distinct phases. Initially, research focused on mechanical exfoliation techniques to obtain monolayers, followed by the development of chemical vapor deposition (CVD) methods for large-scale synthesis. More recently, attention has shifted toward engineering these materials through alloying to achieve tunable properties, representing a significant advancement in the field.

Alloyed TMDs, particularly Mo₁₋ₓWₓS₂ and MoSe₂₋ₓTeₓ systems, offer unprecedented opportunities for property customization through compositional engineering. By systematically varying the ratio of constituent elements, researchers can precisely modulate bandgap energies, carrier mobilities, and spin-orbit coupling strengths. This compositional tuning represents a paradigm shift from traditional binary TMDs, enabling a continuous spectrum of material properties rather than discrete values.

The global research landscape has witnessed exponential growth in TMD-related publications, with annual paper counts increasing from fewer than 100 in 2010 to several thousand in recent years. Patent filings have followed a similar trajectory, particularly in applications related to electronics, optoelectronics, and energy storage. This surge in research activity underscores the technological potential and scientific significance of these materials.

The primary objectives of current research on alloyed TMDs encompass several interconnected goals. First, researchers aim to establish reliable synthesis protocols for homogeneous alloys with precise compositional control. Second, there is a concerted effort to develop comprehensive structure-property relationships that correlate atomic composition with resulting material characteristics. Third, the research community seeks to leverage these tunable properties for specific applications in next-generation electronics, photonics, and energy technologies.

Looking forward, the field is moving toward integrating alloyed TMDs into functional devices that can exploit their unique properties. The ability to fine-tune electronic band structures through alloying opens possibilities for customized semiconductors in applications ranging from highly efficient photovoltaics to sensitive photodetectors and beyond. Additionally, the spin-valley physics in these materials presents opportunities for emerging spintronic and valleytronic technologies.

The convergence of advanced synthesis techniques, sophisticated characterization methods, and theoretical modeling approaches has created a fertile environment for rapid advancement in alloyed TMD research, positioning these materials at the forefront of materials science innovation for the coming decade.

Market Applications and Demand Analysis for Tunable TMDs

The global market for transition metal dichalcogenides (TMDs) is experiencing significant growth, driven by the increasing demand for advanced electronic and optoelectronic devices. The ability to tune the properties of TMDs through alloying, particularly in Mo₁₋ₓWₓS₂ and MoSe₂₋ₓTeₓ systems, has opened new avenues for commercial applications across multiple industries.

Semiconductor manufacturing represents the largest market segment for tunable TMDs, with an estimated annual growth rate exceeding 20% through 2025. The continuous miniaturization of electronic components and the push toward more energy-efficient devices have created substantial demand for materials with precisely controlled bandgaps. Mo₁₋ₓWₓS₂ alloys, which offer bandgap tunability between 1.3-2.0 eV, are particularly valuable for next-generation transistors and logic devices.

The optoelectronics sector presents another significant market opportunity, especially for MoSe₂₋ₓTeₓ alloys. These materials enable the development of photodetectors with spectral responses that can be tailored across the visible to near-infrared range. Market analysis indicates that photodetector applications utilizing tunable TMDs could reach a market value of several hundred million dollars by 2027, with applications spanning consumer electronics, automotive sensing, and medical imaging.

Energy storage and conversion technologies represent an emerging but rapidly growing application area. Tunable TMDs are being explored as catalysts for hydrogen evolution reactions and as components in solar cells. The renewable energy sector's continued expansion, coupled with governmental policies promoting clean energy technologies, is expected to drive demand for these materials at a compound annual growth rate of approximately 25% over the next five years.

Flexible electronics manufacturers have shown increasing interest in tunable TMDs due to their mechanical flexibility combined with tunable electronic properties. This market segment is projected to grow substantially as wearable technology and flexible displays gain wider consumer adoption. Industry forecasts suggest that flexible electronic devices incorporating TMD-based components could represent a multi-billion dollar market by 2030.

Regional analysis reveals that Asia-Pacific currently dominates the market demand for tunable TMDs, led by semiconductor manufacturing hubs in South Korea, Taiwan, and Japan. North America follows closely, with significant research and development activities centered around university-industry partnerships. Europe shows growing interest, particularly in automotive and renewable energy applications.

Customer requirements across these markets consistently emphasize reliability, scalability of production, and cost-effectiveness. While laboratory-scale demonstrations of tunable TMD properties have been impressive, industrial adoption faces challenges related to manufacturing consistency and integration with existing production processes. Market surveys indicate that reducing production costs while maintaining precise control over alloy composition represents the most critical factor for widespread commercial adoption.

Semiconductor manufacturing represents the largest market segment for tunable TMDs, with an estimated annual growth rate exceeding 20% through 2025. The continuous miniaturization of electronic components and the push toward more energy-efficient devices have created substantial demand for materials with precisely controlled bandgaps. Mo₁₋ₓWₓS₂ alloys, which offer bandgap tunability between 1.3-2.0 eV, are particularly valuable for next-generation transistors and logic devices.

The optoelectronics sector presents another significant market opportunity, especially for MoSe₂₋ₓTeₓ alloys. These materials enable the development of photodetectors with spectral responses that can be tailored across the visible to near-infrared range. Market analysis indicates that photodetector applications utilizing tunable TMDs could reach a market value of several hundred million dollars by 2027, with applications spanning consumer electronics, automotive sensing, and medical imaging.

Energy storage and conversion technologies represent an emerging but rapidly growing application area. Tunable TMDs are being explored as catalysts for hydrogen evolution reactions and as components in solar cells. The renewable energy sector's continued expansion, coupled with governmental policies promoting clean energy technologies, is expected to drive demand for these materials at a compound annual growth rate of approximately 25% over the next five years.

Flexible electronics manufacturers have shown increasing interest in tunable TMDs due to their mechanical flexibility combined with tunable electronic properties. This market segment is projected to grow substantially as wearable technology and flexible displays gain wider consumer adoption. Industry forecasts suggest that flexible electronic devices incorporating TMD-based components could represent a multi-billion dollar market by 2030.

Regional analysis reveals that Asia-Pacific currently dominates the market demand for tunable TMDs, led by semiconductor manufacturing hubs in South Korea, Taiwan, and Japan. North America follows closely, with significant research and development activities centered around university-industry partnerships. Europe shows growing interest, particularly in automotive and renewable energy applications.

Customer requirements across these markets consistently emphasize reliability, scalability of production, and cost-effectiveness. While laboratory-scale demonstrations of tunable TMD properties have been impressive, industrial adoption faces challenges related to manufacturing consistency and integration with existing production processes. Market surveys indicate that reducing production costs while maintaining precise control over alloy composition represents the most critical factor for widespread commercial adoption.

Current Status and Technical Challenges in TMD Alloying

Transition metal dichalcogenide (TMD) alloys have emerged as a promising class of two-dimensional materials with tunable electronic, optical, and mechanical properties. Currently, the research landscape for alloyed TMDs, particularly Mo₁₋ₓWₓS₂ and MoSe₂₋ₓTeₓ systems, is experiencing rapid development but faces several significant challenges that require innovative solutions.

Globally, research on TMD alloys has intensified over the past decade, with major contributions from research institutions in the United States, China, South Korea, and several European countries. The field has progressed from theoretical predictions to experimental demonstrations of continuous tunability of bandgaps and other properties through compositional engineering. Recent breakthroughs include the development of controlled synthesis methods for homogeneous alloys with precise stoichiometry control.

Despite these advances, several technical challenges persist in TMD alloying. One primary obstacle is achieving uniform alloy composition across large areas. Current synthesis methods, including chemical vapor deposition (CVD) and molecular beam epitaxy (MBE), often result in spatial inhomogeneities that affect device performance and reproducibility. This challenge is particularly pronounced for Mo₁₋ₓWₓS₂ alloys where differences in precursor reactivity lead to compositional variations.

Another significant hurdle is the characterization of alloy composition at the nanoscale. While techniques such as Raman spectroscopy, photoluminescence, and X-ray photoelectron spectroscopy provide valuable insights, they often lack the spatial resolution needed to detect local variations in composition that can critically affect electronic properties. Advanced techniques like atom probe tomography and scanning transmission electron microscopy with energy-dispersive X-ray spectroscopy are being adapted for these materials but remain challenging to implement routinely.

The stability of TMD alloys under various environmental conditions also presents a considerable challenge. MoSe₂₋ₓTeₓ alloys, in particular, show susceptibility to oxidation and degradation when exposed to ambient conditions, limiting their practical applications. Research on encapsulation strategies and stability enhancement is ongoing but has not yet yielded comprehensive solutions.

From a manufacturing perspective, scaling up the production of high-quality TMD alloys remains problematic. Current laboratory-scale synthesis methods are difficult to translate to industrial production while maintaining precise compositional control. This scaling challenge is compounded by the lack of standardized characterization protocols to ensure consistent material quality across different production batches.

The integration of TMD alloys with conventional semiconductor platforms represents another technical barrier. Issues related to contact resistance, interface quality, and compatibility with existing fabrication processes need to be addressed before these materials can be widely adopted in commercial electronic and optoelectronic devices.

Globally, research on TMD alloys has intensified over the past decade, with major contributions from research institutions in the United States, China, South Korea, and several European countries. The field has progressed from theoretical predictions to experimental demonstrations of continuous tunability of bandgaps and other properties through compositional engineering. Recent breakthroughs include the development of controlled synthesis methods for homogeneous alloys with precise stoichiometry control.

Despite these advances, several technical challenges persist in TMD alloying. One primary obstacle is achieving uniform alloy composition across large areas. Current synthesis methods, including chemical vapor deposition (CVD) and molecular beam epitaxy (MBE), often result in spatial inhomogeneities that affect device performance and reproducibility. This challenge is particularly pronounced for Mo₁₋ₓWₓS₂ alloys where differences in precursor reactivity lead to compositional variations.

Another significant hurdle is the characterization of alloy composition at the nanoscale. While techniques such as Raman spectroscopy, photoluminescence, and X-ray photoelectron spectroscopy provide valuable insights, they often lack the spatial resolution needed to detect local variations in composition that can critically affect electronic properties. Advanced techniques like atom probe tomography and scanning transmission electron microscopy with energy-dispersive X-ray spectroscopy are being adapted for these materials but remain challenging to implement routinely.

The stability of TMD alloys under various environmental conditions also presents a considerable challenge. MoSe₂₋ₓTeₓ alloys, in particular, show susceptibility to oxidation and degradation when exposed to ambient conditions, limiting their practical applications. Research on encapsulation strategies and stability enhancement is ongoing but has not yet yielded comprehensive solutions.

From a manufacturing perspective, scaling up the production of high-quality TMD alloys remains problematic. Current laboratory-scale synthesis methods are difficult to translate to industrial production while maintaining precise compositional control. This scaling challenge is compounded by the lack of standardized characterization protocols to ensure consistent material quality across different production batches.

The integration of TMD alloys with conventional semiconductor platforms represents another technical barrier. Issues related to contact resistance, interface quality, and compatibility with existing fabrication processes need to be addressed before these materials can be widely adopted in commercial electronic and optoelectronic devices.

Current Synthesis Methods for Mo₁₋ₓWₓS₂ and MoSe₂₋ₓTeₓ Alloys

01 Synthesis methods for alloyed TMDs

Various synthesis methods can be employed to create alloyed transition metal dichalcogenides with tunable compositions such as Mo₁₋ₓWₓS₂ and MoSe₂₋ₓTeₓ. These methods include chemical vapor deposition (CVD), hydrothermal synthesis, and mechanical exfoliation techniques. The synthesis parameters directly influence the crystallinity, layer thickness, and compositional homogeneity of the resulting materials, which in turn affects their electronic and optical properties.- Synthesis methods for alloyed TMDs: Various synthesis methods can be employed to create alloyed transition metal dichalcogenides with tunable compositions. These include chemical vapor deposition (CVD), hydrothermal synthesis, and mechanical exfoliation techniques. These methods allow for precise control over the atomic ratios in Mo₁₋ₓWₓS₂ and MoSe₂₋ₓTeₓ alloys, enabling the systematic tuning of their properties. The synthesis parameters significantly influence the crystallinity, layer thickness, and homogeneity of the resulting alloyed TMDs.

- Electronic and optical property tuning: Alloying in TMDs provides a powerful approach to continuously tune their electronic band structures and optical properties. In Mo₁₋ₓWₓS₂ alloys, the bandgap can be systematically adjusted between the values of pure MoS₂ and WS₂, while MoSe₂₋ₓTeₓ allows for bandgap engineering between MoSe₂ and MoTe₂. This compositional tuning enables precise control over photoluminescence wavelengths, absorption spectra, and carrier mobilities, making these materials highly versatile for optoelectronic applications.

- Applications in electronic and optoelectronic devices: Alloyed TMDs offer significant advantages in various device applications due to their tunable properties. These materials can be incorporated into field-effect transistors with adjustable threshold voltages, photodetectors with customizable spectral responses, and light-emitting devices with controllable emission wavelengths. The ability to fine-tune their electronic and optical properties through compositional engineering makes alloyed TMDs particularly valuable for next-generation flexible electronics, sensors, and energy conversion devices.

- Structural and mechanical characteristics: The structural and mechanical properties of alloyed TMDs can be systematically modified through compositional engineering. The lattice parameters, interlayer spacing, and crystal symmetry evolve continuously with changing composition in Mo₁₋ₓWₓS₂ and MoSe₂₋ₓTeₓ alloys. These structural changes influence mechanical properties such as elasticity, tensile strength, and fracture behavior. Understanding the relationship between composition and mechanical characteristics is crucial for applications in flexible electronics and strain-engineered devices.

- Catalytic and energy storage applications: Alloyed TMDs demonstrate enhanced catalytic activities compared to their pure counterparts, particularly for hydrogen evolution reactions and other electrochemical processes. The synergistic effects between different transition metals and chalcogens in these alloys create optimized active sites with improved catalytic performance. Additionally, these materials show promise as electrodes in energy storage devices, where their tunable electronic properties and large surface areas contribute to improved capacity, cycling stability, and rate capability in batteries and supercapacitors.

02 Electronic property tuning through alloying

Alloying transition metal dichalcogenides enables precise tuning of electronic band structures and carrier mobilities. By controlling the composition ratio in Mo₁₋ₓWₓS₂ and MoSe₂₋ₓTeₓ systems, the bandgap can be continuously modulated between the values of the pure compounds. This compositional engineering allows for customization of electronic properties for specific applications in semiconductors, transistors, and other electronic devices.Expand Specific Solutions03 Optical and photonic applications of alloyed TMDs

Alloyed TMDs exhibit tunable optical properties including photoluminescence, absorption, and exciton binding energies. The Mo₁₋ₓWₓS₂ and MoSe₂₋ₓTeₓ systems show composition-dependent light emission and absorption characteristics, making them suitable for optoelectronic applications. These materials can be engineered to respond to specific wavelengths of light, enabling their use in photodetectors, light-emitting devices, and photovoltaic cells with customizable spectral responses.Expand Specific Solutions04 Heterostructure formation and interface engineering

Alloyed TMDs can be integrated into heterostructures with other 2D materials to create novel device architectures. The controlled composition of Mo₁₋ₓWₓS₂ and MoSe₂₋ₓTeₓ allows for precise engineering of band alignments at interfaces, facilitating efficient charge transfer and separation. These heterostructures exhibit unique properties not found in individual components, enabling applications in advanced electronics, spintronics, and quantum information processing.Expand Specific Solutions05 Catalytic and energy storage applications

Alloyed TMDs demonstrate enhanced catalytic activity compared to their pure counterparts, particularly for hydrogen evolution reactions and other electrochemical processes. The tunable electronic structure of Mo₁₋ₓWₓS₂ and MoSe₂₋ₓTeₓ systems allows for optimization of active sites and adsorption energies. These materials also show promise for energy storage applications, including as electrodes in batteries and supercapacitors, where their compositional engineering enables balancing of capacity, rate capability, and cycling stability.Expand Specific Solutions

Leading Research Groups and Industrial Players in TMD Field

The research on alloyed TMDs (Mo₁₋ₓWₓS₂ and MoSe₂₋ₓTeₓ) for tunable properties is currently in an early growth phase, with expanding market potential driven by demand for next-generation electronics and optoelectronics. The global market for 2D materials, including alloyed TMDs, is projected to reach $1.6 billion by 2026, with a CAGR of 36%. Technologically, academic institutions lead fundamental research, with Hunan University, MIT, and Naval Research Laboratory making significant advances in synthesis methods and property characterization. Commercial development is emerging through collaborations between research institutions and companies like Huawei Technologies, which is exploring applications in flexible electronics and photonics. The technology remains in the applied research stage, with challenges in scalable production and device integration still being addressed.

Naval Research Laboratory

Technical Solution: 美国海军研究实验室开发了一种独特的两步合成方法来制备高质量Mo₁₋ₓWₓS₂合金。首先通过磁控溅射沉积金属前驱体薄膜,然后在硫化氢(H₂S)气氛中进行后硫化处理,实现了大面积均匀的合金TMDs薄膜[8]。他们的研究表明,通过精确控制溅射靶的功率比例,可以在整个组分范围内实现连续可调的光学和电学性能。特别是,他们发现Mo₀.₅W₀.₅S₂合金表现出比纯MoS₂和WS₂更高的光催化活性,在析氢反应(HER)中表现出更低的过电位(约150mV)和更高的交换电流密度[9]。海军研究实验室还开发了基于扫描隧道显微镜(STM)和扫描隧道谱(STS)的表征技术,能够在原子尺度上研究合金TMDs的电子结构和缺陷状态,为理解合金效应提供了微观机制。

优势:拥有先进的薄膜沉积设备和表征技术,能够制备大面积均匀的合金TMDs薄膜;研究团队在材料科学和能源应用领域经验丰富。劣势:后硫化过程可能引入缺陷和不均匀性;薄膜质量与单晶样品相比仍有差距。

Massachusetts Institute of Technology

Technical Solution: MIT在合金TMDs领域开发了独特的化学气相沉积(CVD)技术,实现了Mo₁₋ₓWₓS₂合金的精确组分控制。他们的方法使用预混合的金属前驱体和硫化剂,在精确控制的温度梯度下进行生长,可以在整个组分范围(0≤x≤1)内实现连续可调的带隙,从1.85eV到1.99eV[1]。MIT还开发了原位光学表征技术,能够实时监测合金TMDs的生长过程和性能变化,为材料设计提供即时反馈。他们的研究表明,通过调整W/Mo比例,可以精确控制材料的光电特性、载流子迁移率和激子结合能,为下一代光电器件提供了材料基础[3]。

优势:拥有世界领先的材料表征设备和技术,能够在原子尺度上精确控制材料组分;研究团队在二维材料领域经验丰富,发表了多篇高影响因子论文。劣势:实验室规模的制备方法可能面临产业化放大挑战;高质量合金TMDs的生长仍需要严格的实验条件控制,成本较高。

Key Patents and Scientific Breakthroughs in TMD Alloying

Transition metal dichalcogenides with multiple ferroic orders

PatentWO2025046545A1

Innovation

- A room temperature multiferroic material with a layered crystalline structure, characterized by specific fractions of transition metal and chalcogen elements, and chalcogen vacancies, which exhibits ferromagnetic, ferroelectric, or multiferroic properties, including high piezoelectric coefficients.

Material Characterization Techniques for TMD Alloys

The characterization of transition metal dichalcogenide (TMD) alloys such as Mo₁₋ₓWₓS₂ and MoSe₂₋ₓTeₓ requires sophisticated analytical techniques to accurately determine their structural, electronic, optical, and mechanical properties. X-ray diffraction (XRD) serves as a fundamental tool for crystallographic analysis, providing essential information about lattice parameters, crystal structure, and phase composition of these alloy systems. The systematic peak shifts observed in XRD patterns of Mo₁₋ₓWₓS₂ alloys directly correlate with tungsten concentration, enabling precise composition determination.

Raman spectroscopy offers complementary insights by probing the vibrational modes of TMD alloys. For Mo₁₋ₓWₓS₂, characteristic peaks corresponding to Mo-S and W-S bonds exhibit systematic shifts and intensity variations with changing composition, allowing for non-destructive compositional mapping at the microscale. Similarly, MoSe₂₋ₓTeₓ alloys display distinct Raman signatures that reflect the incorporation of tellurium atoms into the selenium sites.

Transmission electron microscopy (TEM) and scanning transmission electron microscopy (STEM) provide atomic-resolution imaging of TMD alloy structures. High-angle annular dark-field STEM (HAADF-STEM) is particularly valuable for visualizing the distribution of heavier elements like tungsten and tellurium within the alloy matrix, revealing potential clustering or ordering phenomena that significantly impact material properties. Electron energy loss spectroscopy (EELS) coupled with STEM enables element-specific mapping with nanometer resolution.

X-ray photoelectron spectroscopy (XPS) and ultraviolet photoelectron spectroscopy (UPS) are essential for characterizing the electronic structure and chemical states of elements in TMD alloys. These techniques provide critical information about band alignment, work function, and valence band structure, which directly influence the electronic and optoelectronic properties of these materials. The binding energy shifts observed in Mo₁₋ₓWₓS₂ and MoSe₂₋ₓTeₓ alloys correlate with composition and can be used to verify the formation of true alloys rather than phase-separated mixtures.

Photoluminescence (PL) spectroscopy serves as a powerful probe for the optical properties and band structure of TMD alloys. The systematic shift in PL emission wavelength with composition in both Mo₁₋ₓWₓS₂ and MoSe₂₋ₓTeₓ demonstrates the tunability of their bandgaps, a key advantage for optoelectronic applications. Time-resolved PL measurements further reveal how carrier dynamics and recombination processes evolve with alloy composition.

Atomic force microscopy (AFM) and scanning tunneling microscopy (STM) provide complementary information about surface morphology and local electronic structure. These techniques are particularly valuable for characterizing few-layer or monolayer TMD alloys, where surface properties dominate material behavior. STM spectroscopy can directly probe the local density of states, revealing spatial variations in electronic structure that may arise from compositional fluctuations in the alloy.

Raman spectroscopy offers complementary insights by probing the vibrational modes of TMD alloys. For Mo₁₋ₓWₓS₂, characteristic peaks corresponding to Mo-S and W-S bonds exhibit systematic shifts and intensity variations with changing composition, allowing for non-destructive compositional mapping at the microscale. Similarly, MoSe₂₋ₓTeₓ alloys display distinct Raman signatures that reflect the incorporation of tellurium atoms into the selenium sites.

Transmission electron microscopy (TEM) and scanning transmission electron microscopy (STEM) provide atomic-resolution imaging of TMD alloy structures. High-angle annular dark-field STEM (HAADF-STEM) is particularly valuable for visualizing the distribution of heavier elements like tungsten and tellurium within the alloy matrix, revealing potential clustering or ordering phenomena that significantly impact material properties. Electron energy loss spectroscopy (EELS) coupled with STEM enables element-specific mapping with nanometer resolution.

X-ray photoelectron spectroscopy (XPS) and ultraviolet photoelectron spectroscopy (UPS) are essential for characterizing the electronic structure and chemical states of elements in TMD alloys. These techniques provide critical information about band alignment, work function, and valence band structure, which directly influence the electronic and optoelectronic properties of these materials. The binding energy shifts observed in Mo₁₋ₓWₓS₂ and MoSe₂₋ₓTeₓ alloys correlate with composition and can be used to verify the formation of true alloys rather than phase-separated mixtures.

Photoluminescence (PL) spectroscopy serves as a powerful probe for the optical properties and band structure of TMD alloys. The systematic shift in PL emission wavelength with composition in both Mo₁₋ₓWₓS₂ and MoSe₂₋ₓTeₓ demonstrates the tunability of their bandgaps, a key advantage for optoelectronic applications. Time-resolved PL measurements further reveal how carrier dynamics and recombination processes evolve with alloy composition.

Atomic force microscopy (AFM) and scanning tunneling microscopy (STM) provide complementary information about surface morphology and local electronic structure. These techniques are particularly valuable for characterizing few-layer or monolayer TMD alloys, where surface properties dominate material behavior. STM spectroscopy can directly probe the local density of states, revealing spatial variations in electronic structure that may arise from compositional fluctuations in the alloy.

Sustainability and Scalability Considerations

The sustainability and scalability of alloyed transition metal dichalcogenides (TMDs) such as Mo₁₋ₓWₓS₂ and MoSe₂₋ₓTeₓ represent critical considerations for their industrial adoption and long-term viability. Current synthesis methods, including chemical vapor deposition (CVD) and mechanical exfoliation, present significant challenges when transitioning from laboratory-scale production to industrial manufacturing. The energy-intensive nature of CVD processes, which often require high temperatures exceeding 700°C, raises concerns about the carbon footprint associated with large-scale production.

Material sourcing presents another sustainability challenge, particularly regarding the use of rare elements like tellurium. Tellurium's limited global supply and its classification as a critical raw material by several countries necessitate careful consideration of resource allocation and potential supply chain vulnerabilities when scaling MoSe₂₋ₓTeₓ production. Tungsten, while more abundant, still requires energy-intensive mining and refining processes that impact the overall environmental footprint of Mo₁₋ₓWₓS₂ alloys.

Recent advancements in green synthesis approaches show promise for improving sustainability metrics. Solution-phase methods operating at lower temperatures and ambient pressures have demonstrated potential for reducing energy consumption by up to 40% compared to traditional CVD techniques. Additionally, research into precursor recycling systems has shown the possibility of recovering up to 85% of unused molybdenum and tungsten compounds, significantly reducing waste generation and resource depletion.

Scalability pathways for alloyed TMDs are emerging through innovations in continuous manufacturing processes. Roll-to-roll production techniques have successfully produced Mo₁₋ₓWₓS₂ films with consistent composition across areas exceeding 100 cm², representing a significant step toward industrial-scale fabrication. However, maintaining precise stoichiometric control during large-batch synthesis remains challenging, with composition variations typically ranging from 3-7% across production runs.

Life cycle assessment (LCA) studies indicate that the environmental impact of alloyed TMDs could be reduced by 30-50% through optimization of synthesis parameters and implementation of circular economy principles. Particularly promising is the development of solvent-free or aqueous-based synthesis routes that minimize the use of toxic chemicals commonly employed in traditional methods, thereby reducing environmental hazards and waste management costs.

The economic viability of scaled production depends heavily on yield optimization and defect management. Current laboratory-scale synthesis of high-quality Mo₁₋ₓWₓS₂ and MoSe₂₋ₓTeₓ alloys achieves yields of approximately 60-75%, which must be improved to meet commercial requirements. Emerging automated quality control systems utilizing machine learning algorithms have demonstrated potential to increase production yields by identifying optimal process parameters and reducing material waste.

Material sourcing presents another sustainability challenge, particularly regarding the use of rare elements like tellurium. Tellurium's limited global supply and its classification as a critical raw material by several countries necessitate careful consideration of resource allocation and potential supply chain vulnerabilities when scaling MoSe₂₋ₓTeₓ production. Tungsten, while more abundant, still requires energy-intensive mining and refining processes that impact the overall environmental footprint of Mo₁₋ₓWₓS₂ alloys.

Recent advancements in green synthesis approaches show promise for improving sustainability metrics. Solution-phase methods operating at lower temperatures and ambient pressures have demonstrated potential for reducing energy consumption by up to 40% compared to traditional CVD techniques. Additionally, research into precursor recycling systems has shown the possibility of recovering up to 85% of unused molybdenum and tungsten compounds, significantly reducing waste generation and resource depletion.

Scalability pathways for alloyed TMDs are emerging through innovations in continuous manufacturing processes. Roll-to-roll production techniques have successfully produced Mo₁₋ₓWₓS₂ films with consistent composition across areas exceeding 100 cm², representing a significant step toward industrial-scale fabrication. However, maintaining precise stoichiometric control during large-batch synthesis remains challenging, with composition variations typically ranging from 3-7% across production runs.

Life cycle assessment (LCA) studies indicate that the environmental impact of alloyed TMDs could be reduced by 30-50% through optimization of synthesis parameters and implementation of circular economy principles. Particularly promising is the development of solvent-free or aqueous-based synthesis routes that minimize the use of toxic chemicals commonly employed in traditional methods, thereby reducing environmental hazards and waste management costs.

The economic viability of scaled production depends heavily on yield optimization and defect management. Current laboratory-scale synthesis of high-quality Mo₁₋ₓWₓS₂ and MoSe₂₋ₓTeₓ alloys achieves yields of approximately 60-75%, which must be improved to meet commercial requirements. Emerging automated quality control systems utilizing machine learning algorithms have demonstrated potential to increase production yields by identifying optimal process parameters and reducing material waste.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!