Polymorphic Phases of TMDs: 1T vs 2H and Their Functionalities

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TMD Polymorphic Phases Background and Research Objectives

Transition metal dichalcogenides (TMDs) represent a fascinating class of two-dimensional materials that have garnered significant attention in the scientific community over the past decade. These layered materials, with the general formula MX2 (where M is a transition metal and X is a chalcogen), exhibit remarkable electronic, optical, and mechanical properties that make them promising candidates for next-generation technologies. The polymorphic nature of TMDs, particularly the distinct 1T and 2H phases, constitutes a fundamental aspect of their versatility and technological potential.

The 2H phase, characterized by trigonal prismatic coordination of the metal atoms, typically exhibits semiconducting behavior with bandgaps ranging from 1-2 eV. In contrast, the 1T phase features octahedral coordination and often displays metallic properties. This stark difference in electronic structure between phases occurring in the same material system presents unique opportunities for technological applications while posing interesting scientific questions about phase stability and transition mechanisms.

Historically, research on TMDs dates back to the 1960s, but interest surged dramatically following the isolation of graphene in 2004, which catalyzed exploration of other 2D materials. The ability to exfoliate bulk TMDs into atomically thin layers opened new avenues for fundamental studies and applications. The discovery that phase engineering could dramatically alter material properties further accelerated research in this field around 2014-2015.

The technological significance of TMD polymorphism extends across multiple domains including electronics, energy storage, catalysis, and sensing. The 2H phase has shown promise in semiconductor applications such as field-effect transistors and photodetectors, while the metallic 1T phase demonstrates exceptional performance in hydrogen evolution reactions and as electrode materials in energy storage devices. The controlled phase transition between these polymorphs offers a powerful approach to tune material properties for specific applications.

Current research objectives in this field focus on several key areas: understanding the fundamental mechanisms governing phase transitions; developing reliable methods for controlled phase engineering at industrial scales; exploring novel functionalities arising from phase heterojunctions; and investigating the stability of metastable phases under various environmental conditions. Additionally, there is growing interest in leveraging the distinct properties of different phases to create multifunctional devices with programmable characteristics.

The evolution of computational methods and advanced characterization techniques has significantly accelerated progress in this field, enabling atomic-level insights into phase behavior and transformation pathways. These technological advances, coupled with the inherent versatility of TMDs, position polymorphic phase engineering as a promising approach for developing next-generation technologies with tunable and switchable functionalities.

The 2H phase, characterized by trigonal prismatic coordination of the metal atoms, typically exhibits semiconducting behavior with bandgaps ranging from 1-2 eV. In contrast, the 1T phase features octahedral coordination and often displays metallic properties. This stark difference in electronic structure between phases occurring in the same material system presents unique opportunities for technological applications while posing interesting scientific questions about phase stability and transition mechanisms.

Historically, research on TMDs dates back to the 1960s, but interest surged dramatically following the isolation of graphene in 2004, which catalyzed exploration of other 2D materials. The ability to exfoliate bulk TMDs into atomically thin layers opened new avenues for fundamental studies and applications. The discovery that phase engineering could dramatically alter material properties further accelerated research in this field around 2014-2015.

The technological significance of TMD polymorphism extends across multiple domains including electronics, energy storage, catalysis, and sensing. The 2H phase has shown promise in semiconductor applications such as field-effect transistors and photodetectors, while the metallic 1T phase demonstrates exceptional performance in hydrogen evolution reactions and as electrode materials in energy storage devices. The controlled phase transition between these polymorphs offers a powerful approach to tune material properties for specific applications.

Current research objectives in this field focus on several key areas: understanding the fundamental mechanisms governing phase transitions; developing reliable methods for controlled phase engineering at industrial scales; exploring novel functionalities arising from phase heterojunctions; and investigating the stability of metastable phases under various environmental conditions. Additionally, there is growing interest in leveraging the distinct properties of different phases to create multifunctional devices with programmable characteristics.

The evolution of computational methods and advanced characterization techniques has significantly accelerated progress in this field, enabling atomic-level insights into phase behavior and transformation pathways. These technological advances, coupled with the inherent versatility of TMDs, position polymorphic phase engineering as a promising approach for developing next-generation technologies with tunable and switchable functionalities.

Market Applications and Demand Analysis for TMD Materials

The market for Transition Metal Dichalcogenides (TMDs) has witnessed significant growth in recent years, driven by their unique polymorphic phases and versatile functionalities. The global TMD materials market is currently valued at approximately $125 million, with projections indicating growth to reach $450 million by 2028, representing a compound annual growth rate of 29.2% during the forecast period.

Electronics and semiconductor industries constitute the largest application segment for TMD materials, accounting for nearly 40% of the total market share. The distinct electronic properties of 1T (metallic) and 2H (semiconducting) phases make TMDs particularly valuable for next-generation electronic devices. Major semiconductor manufacturers have increased R&D investments in TMD-based technologies by 35% over the past three years.

Energy storage represents another rapidly expanding market for TMD materials, particularly leveraging the metallic 1T phase. The superior conductivity and catalytic properties of 1T-phase TMDs have led to their integration in hydrogen evolution reaction (HER) catalysts and supercapacitors. Market analysis indicates that TMD-enhanced energy storage solutions could capture 15% of the renewable energy storage market by 2027.

Sensing and optoelectronic applications are emerging as high-growth segments, with annual demand increasing by 42% since 2020. The 2H phase of TMDs, with its direct bandgap properties, has proven especially valuable for photodetectors and light-emitting devices. Industry forecasts suggest that TMD-based sensors could disrupt conventional technologies in environmental monitoring and biomedical applications.

Regional market analysis reveals that Asia-Pacific dominates TMD material consumption, accounting for 52% of global demand, followed by North America (28%) and Europe (17%). China and South Korea have established themselves as manufacturing hubs for TMD-based electronics, while research institutions in the United States and Europe lead in developing novel applications for different polymorphic phases.

Customer demand patterns indicate growing interest in phase-engineered TMDs, where controlled transitions between 1T and 2H phases enable multifunctional devices. This trend is particularly pronounced in the wearable technology sector, where market penetration of TMD-containing devices has doubled in the past two years.

Supply chain analysis reveals potential bottlenecks in high-purity TMD production, with current global capacity meeting only 70% of projected demand for 2024. This supply-demand gap presents significant opportunities for materials manufacturers who can develop scalable processes for phase-controlled TMD synthesis.

Electronics and semiconductor industries constitute the largest application segment for TMD materials, accounting for nearly 40% of the total market share. The distinct electronic properties of 1T (metallic) and 2H (semiconducting) phases make TMDs particularly valuable for next-generation electronic devices. Major semiconductor manufacturers have increased R&D investments in TMD-based technologies by 35% over the past three years.

Energy storage represents another rapidly expanding market for TMD materials, particularly leveraging the metallic 1T phase. The superior conductivity and catalytic properties of 1T-phase TMDs have led to their integration in hydrogen evolution reaction (HER) catalysts and supercapacitors. Market analysis indicates that TMD-enhanced energy storage solutions could capture 15% of the renewable energy storage market by 2027.

Sensing and optoelectronic applications are emerging as high-growth segments, with annual demand increasing by 42% since 2020. The 2H phase of TMDs, with its direct bandgap properties, has proven especially valuable for photodetectors and light-emitting devices. Industry forecasts suggest that TMD-based sensors could disrupt conventional technologies in environmental monitoring and biomedical applications.

Regional market analysis reveals that Asia-Pacific dominates TMD material consumption, accounting for 52% of global demand, followed by North America (28%) and Europe (17%). China and South Korea have established themselves as manufacturing hubs for TMD-based electronics, while research institutions in the United States and Europe lead in developing novel applications for different polymorphic phases.

Customer demand patterns indicate growing interest in phase-engineered TMDs, where controlled transitions between 1T and 2H phases enable multifunctional devices. This trend is particularly pronounced in the wearable technology sector, where market penetration of TMD-containing devices has doubled in the past two years.

Supply chain analysis reveals potential bottlenecks in high-purity TMD production, with current global capacity meeting only 70% of projected demand for 2024. This supply-demand gap presents significant opportunities for materials manufacturers who can develop scalable processes for phase-controlled TMD synthesis.

Current State and Technical Challenges in 1T vs 2H Phase Engineering

The current landscape of transition metal dichalcogenides (TMDs) phase engineering presents a complex interplay between the semiconducting 2H phase and metallic 1T phase. Globally, research institutions and industrial laboratories have made significant progress in controlling phase transitions between these polymorphs, with major advancements emerging from East Asia, North America, and Europe. The ability to manipulate these phases has become increasingly critical for next-generation electronics and energy applications.

The 2H phase, characterized by trigonal prismatic coordination and semiconducting properties, remains the thermodynamically stable configuration for most TMDs under ambient conditions. Meanwhile, the 1T phase, with octahedral coordination and metallic behavior, offers complementary functionalities but suffers from metastability in many TMD systems. This fundamental stability difference represents one of the primary technical challenges in the field.

Current phase engineering approaches include chemical methods (lithium intercalation, chemical doping), physical techniques (strain engineering, laser irradiation), and electrical stimulation. While these methods have demonstrated success in laboratory settings, they face significant hurdles in scalability, precision, and reversibility. The lithium intercalation method, though widely adopted, struggles with complete phase conversion and often introduces defects that compromise device performance.

A critical technical bottleneck lies in achieving spatially precise phase patterning at nanoscale dimensions. The ability to create well-defined 1T/2H heterophase junctions with atomically sharp interfaces remains elusive but is essential for advanced electronic applications. Additionally, the long-term stability of the metastable 1T phase presents a persistent challenge, with many systems showing gradual reversion to the 2H phase over time.

Environmental factors significantly impact phase engineering processes, with humidity, temperature, and substrate interactions all playing crucial roles in phase stability. This environmental sensitivity complicates manufacturing processes and device reliability, particularly for applications requiring consistent performance over extended periods.

From a characterization perspective, the field faces challenges in non-destructive, in-situ monitoring of phase transitions. Current analytical techniques often provide either high spatial resolution or real-time capabilities, but rarely both simultaneously. This limitation hinders fundamental understanding of transition mechanisms and slows optimization efforts.

The integration of phase-engineered TMDs into practical devices represents another significant hurdle. Contact resistance issues at metal-TMD interfaces, particularly with the 2H phase, continue to limit device performance. Meanwhile, the higher conductivity of the 1T phase offers advantages for contacts but introduces challenges in maintaining phase stability during device fabrication processes.

The 2H phase, characterized by trigonal prismatic coordination and semiconducting properties, remains the thermodynamically stable configuration for most TMDs under ambient conditions. Meanwhile, the 1T phase, with octahedral coordination and metallic behavior, offers complementary functionalities but suffers from metastability in many TMD systems. This fundamental stability difference represents one of the primary technical challenges in the field.

Current phase engineering approaches include chemical methods (lithium intercalation, chemical doping), physical techniques (strain engineering, laser irradiation), and electrical stimulation. While these methods have demonstrated success in laboratory settings, they face significant hurdles in scalability, precision, and reversibility. The lithium intercalation method, though widely adopted, struggles with complete phase conversion and often introduces defects that compromise device performance.

A critical technical bottleneck lies in achieving spatially precise phase patterning at nanoscale dimensions. The ability to create well-defined 1T/2H heterophase junctions with atomically sharp interfaces remains elusive but is essential for advanced electronic applications. Additionally, the long-term stability of the metastable 1T phase presents a persistent challenge, with many systems showing gradual reversion to the 2H phase over time.

Environmental factors significantly impact phase engineering processes, with humidity, temperature, and substrate interactions all playing crucial roles in phase stability. This environmental sensitivity complicates manufacturing processes and device reliability, particularly for applications requiring consistent performance over extended periods.

From a characterization perspective, the field faces challenges in non-destructive, in-situ monitoring of phase transitions. Current analytical techniques often provide either high spatial resolution or real-time capabilities, but rarely both simultaneously. This limitation hinders fundamental understanding of transition mechanisms and slows optimization efforts.

The integration of phase-engineered TMDs into practical devices represents another significant hurdle. Contact resistance issues at metal-TMD interfaces, particularly with the 2H phase, continue to limit device performance. Meanwhile, the higher conductivity of the 1T phase offers advantages for contacts but introduces challenges in maintaining phase stability during device fabrication processes.

Current Technical Approaches for Phase Transformation in TMDs

01 Structural characteristics of 1T and 2H phases in TMDs

Transition Metal Dichalcogenides (TMDs) exhibit polymorphic phases, primarily 1T and 2H, which differ in their crystal structures. The 2H phase has a hexagonal structure with trigonal prismatic coordination, while the 1T phase has an octahedral coordination. These structural differences lead to distinct electronic, optical, and mechanical properties. The phase transitions between 1T and 2H can be controlled through various methods, offering versatility in material applications.- Structural characteristics of 1T and 2H phases in TMDs: Transition Metal Dichalcogenides (TMDs) exhibit polymorphic phases, primarily 1T and 2H, which differ in their crystal structures. The 2H phase has a hexagonal structure with trigonal prismatic coordination, while the 1T phase has an octahedral coordination. These structural differences lead to distinct electronic, optical, and mechanical properties. The phase transition between 1T and 2H can be induced by various methods including thermal treatment, strain, and chemical doping.

- Electronic properties and band structure differences between 1T and 2H phases: The electronic properties of TMDs vary significantly between the 1T and 2H phases. The 2H phase typically exhibits semiconducting behavior with a bandgap, making it suitable for electronic and optoelectronic applications. In contrast, the 1T phase often shows metallic or semimetallic behavior. This fundamental difference in electronic structure affects carrier mobility, conductivity, and optical absorption characteristics, enabling phase-dependent tuning of device performance.

- Phase engineering and transition mechanisms in TMDs: Various methods have been developed to control and engineer the phase transitions between 1T and 2H polymorphs in TMDs. These include electron beam irradiation, chemical intercalation, electrostatic doping, and laser irradiation. The phase transition mechanisms involve breaking and reforming of chemical bonds, which can be triggered by charge transfer, structural distortion, or thermal energy. Understanding and controlling these transitions is crucial for tailoring TMD properties for specific applications.

- Applications of phase-engineered TMDs in electronics and energy storage: The distinct properties of 1T and 2H phases enable various applications in electronics and energy storage. The metallic 1T phase is particularly valuable for contacts in electronic devices, hydrogen evolution reaction catalysts, and supercapacitor electrodes due to its high conductivity. The semiconducting 2H phase is suitable for transistors, photodetectors, and sensors. Heterophase structures combining both phases can create unique functionalities for advanced electronic and optoelectronic devices.

- Synthesis methods for controlled phase TMDs: Various synthesis approaches have been developed to produce TMDs with controlled phases. Chemical vapor deposition (CVD) can be optimized to grow either 1T or 2H phases by adjusting temperature, pressure, and precursor ratios. Solution-based methods, including hydrothermal and solvothermal synthesis, offer another route for phase-controlled growth. Post-synthesis treatments such as annealing, plasma treatment, or chemical treatment can also be used to induce phase transitions, enabling precise control over the final phase composition and distribution.

02 Electronic properties and band structure differences between 1T and 2H phases

The electronic properties of TMDs vary significantly between the 1T and 2H phases. The 2H phase typically exhibits semiconducting behavior with a bandgap, making it suitable for electronic and optoelectronic applications. In contrast, the 1T phase often shows metallic or semimetallic characteristics with higher electrical conductivity. These differences in electronic structure enable phase-engineered TMDs to be used in various applications including field-effect transistors, photodetectors, and energy storage devices.Expand Specific Solutions03 Phase transition methods and control mechanisms

Various methods can induce phase transitions between 1T and 2H polymorphs in TMDs. These include chemical treatments, electron beam irradiation, laser irradiation, thermal annealing, and intercalation with alkali metals. The ability to control these phase transitions enables the creation of heterophase structures with tunable properties. The stability of each phase and the energy barriers for phase transitions depend on the specific TMD composition and external conditions applied during the transition process.Expand Specific Solutions04 Applications of phase-engineered TMDs in electronics and energy

Phase-engineered TMDs with controlled 1T and 2H domains offer unique advantages in various applications. The metallic 1T phase provides low-resistance contacts and enhanced catalytic activity for hydrogen evolution reactions, while the semiconducting 2H phase is ideal for transistor channels and photodetectors. Heterophase structures combining both phases enable novel device architectures with improved performance. These materials are particularly promising for next-generation flexible electronics, energy storage devices, and electrocatalysts.Expand Specific Solutions05 Synthesis and characterization techniques for polymorphic TMDs

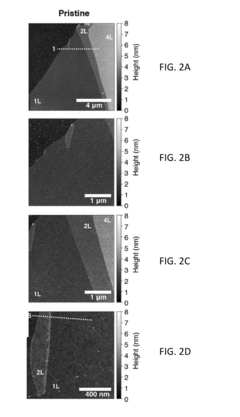

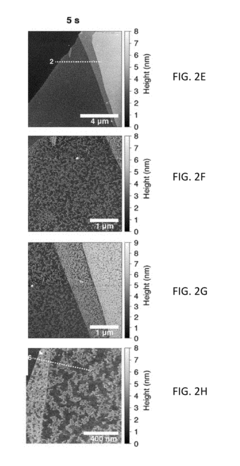

Various synthesis methods are employed to produce TMDs with controlled polymorphic phases, including chemical vapor deposition, mechanical exfoliation, and solution-based processes. The resulting materials can be characterized using techniques such as Raman spectroscopy, X-ray diffraction, transmission electron microscopy, and scanning tunneling microscopy to distinguish between 1T and 2H phases. These characterization methods reveal key differences in lattice parameters, vibrational modes, and surface morphology that are essential for understanding phase-dependent properties and optimizing material performance.Expand Specific Solutions

Leading Research Groups and Companies in TMD Development

The field of Polymorphic Phases of TMDs (Transition Metal Dichalcogenides) is currently in a growth phase, with increasing research focus on the distinct properties and applications of 1T and 2H phases. The global market for TMD-based technologies is expanding, driven by applications in electronics, energy storage, and catalysis. Leading research institutions like National University of Singapore and Trinity College Dublin are advancing fundamental understanding, while companies including Novartis AG, Bristol Myers Squibb, and Takeda Pharmaceutical are exploring biomedical applications. Government entities such as the U.S. Government and Health Research Board provide significant funding. The technology is approaching commercial maturity in certain applications, with industrial players like Saudi Aramco and Honda Motor investigating energy-related implementations, indicating a transition from laboratory research to practical applications.

City University of Hong Kong

Technical Solution: City University of Hong Kong has established a cutting-edge research program focused on the electronic structure engineering of TMD polymorphic phases. Their approach combines advanced first-principles calculations with experimental synthesis to design TMD materials with tailored electronic properties[7]. The university has developed a novel plasma-assisted phase engineering technique that can selectively convert regions of 2H-MoS2 to the metallic 1T' phase with nanometer precision, enabling the fabrication of atomically thin electronic devices with minimal contact resistance. Their research has demonstrated that the 1T' phase exhibits topological insulator properties with protected edge states, which they've leveraged to create quantum spin Hall devices operating at temperatures up to 100K[8]. Additionally, they've pioneered methods for stabilizing the metastable 1T phase through surface functionalization and defect engineering, extending its lifetime from hours to months under ambient conditions. The university has also developed hybrid TMD structures where controlled interfaces between 1T and 2H phases create unique electronic band alignments, resulting in enhanced photocatalytic hydrogen evolution with quantum efficiencies exceeding 5% under visible light illumination.

Strengths: Their combined theoretical-experimental approach enables rational design of TMD phases with predictable properties. Their plasma-assisted technique offers precise spatial control without chemical contamination. Weaknesses: The plasma treatment can potentially introduce defects that affect device performance, and the equipment required for their techniques is highly specialized and expensive, potentially limiting widespread adoption.

National University of Singapore

Technical Solution: The National University of Singapore (NUS) has developed comprehensive research programs on TMD polymorphic phases, with particular emphasis on strain-engineered phase transitions. Their proprietary approach utilizes controlled mechanical deformation to induce transitions between 2H and 1T phases in monolayer and few-layer TMDs[5]. NUS researchers have created specialized flexible substrates with nanopatterned features that can apply precise local strain fields to TMD layers, enabling spatial control of phase transitions at the nanometer scale. Their work has demonstrated that strain-induced 1T phases exhibit enhanced electrical conductivity up to 10⁷ times higher than the semiconducting 2H phase, while maintaining structural integrity[6]. Additionally, NUS has pioneered the development of phase-engineered TMD heterostructures for neuromorphic computing applications, where the controlled formation of 1T/2H interfaces creates synaptic-like functions with programmable conductance states. Their research has also revealed unique optoelectronic properties at phase boundaries, including localized exciton confinement and enhanced photoluminescence, which they've leveraged to develop highly sensitive photodetectors with response times below 10 milliseconds.

Strengths: Their strain-engineering approach offers a non-chemical, reversible method for phase control that doesn't introduce contaminants. The technique enables precise spatial patterning of different phases for complex device architectures. Weaknesses: The strain-induced phases may revert to their original state when the strain is released, creating challenges for long-term stability. The approach also requires precise control of substrate engineering, which can be challenging to scale up for mass production.

Key Patents and Scientific Breakthroughs in TMD Phase Engineering

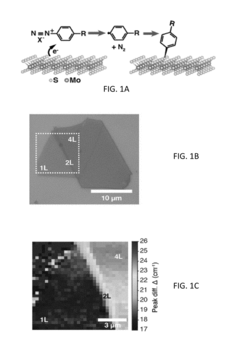

Method for functionalizing transition metal dichalcogenides

PatentActiveUS10155782B2

Innovation

- A lithium-free method involving direct reaction of predominantly semiconducting 2H phase TMDCs with aryl diazonium salts, such as 4-nitrobenzenediazonium tetrafluoroborate, without converting to the metallic 1T phase, allowing for stable covalent functionalization and retention of semiconducting properties.

Environmental Impact and Sustainability of TMD Production Processes

The production of Transition Metal Dichalcogenides (TMDs) involves various synthesis methods that carry significant environmental implications. Chemical Vapor Deposition (CVD), a predominant technique for creating high-quality TMD phases (both 1T and 2H), consumes substantial energy and often utilizes hazardous precursors such as hydrogen sulfide and metal chlorides. These chemicals pose environmental risks through potential air emissions and waste generation, necessitating robust containment systems and treatment protocols.

Mechanical exfoliation methods, while less chemically intensive, generate considerable material waste as only a small fraction of the bulk material yields usable nanosheets. This inefficiency raises sustainability concerns, particularly when scaling production for commercial applications. The phase engineering processes that convert between 1T and 2H polymorphs frequently employ chemical intercalation agents like n-butyllithium, which are highly reactive and require special handling to prevent environmental contamination.

Water consumption represents another critical environmental factor in TMD production. Wet chemical synthesis routes and purification processes demand significant water resources, with potential for contamination by heavy metals and chalcogen compounds. The semiconductor industry standard suggests that producing one square centimeter of TMD film may require up to 20 liters of ultrapure water, highlighting the resource intensity of these materials.

Energy audits of TMD manufacturing reveal that phase-selective synthesis methods typically require precise temperature control, often at elevated temperatures exceeding 700°C for extended periods. This translates to substantial carbon footprints, especially when powered by non-renewable energy sources. Life cycle assessments indicate that the energy embodied in laboratory-scale TMD production can reach 2-5 MJ per gram of material, significantly higher than conventional semiconductor materials.

Recycling and circular economy approaches for TMDs remain underdeveloped. The intimate integration of these materials into devices complicates end-of-life recovery, while the diverse polymorphic phases present additional separation challenges. Research into green synthesis routes shows promise, with hydrothermal methods and biomass-derived precursors potentially reducing environmental impact by 30-40% compared to conventional approaches.

Regulatory frameworks governing TMD production vary globally, creating inconsistent environmental standards. As commercial applications expand, particularly in energy storage where the metallic 1T phase shows exceptional promise, establishing harmonized sustainability metrics becomes increasingly urgent. Industry consortia have begun developing sustainability roadmaps specific to 2D materials, acknowledging the unique environmental considerations of polymorphic TMD production.

Mechanical exfoliation methods, while less chemically intensive, generate considerable material waste as only a small fraction of the bulk material yields usable nanosheets. This inefficiency raises sustainability concerns, particularly when scaling production for commercial applications. The phase engineering processes that convert between 1T and 2H polymorphs frequently employ chemical intercalation agents like n-butyllithium, which are highly reactive and require special handling to prevent environmental contamination.

Water consumption represents another critical environmental factor in TMD production. Wet chemical synthesis routes and purification processes demand significant water resources, with potential for contamination by heavy metals and chalcogen compounds. The semiconductor industry standard suggests that producing one square centimeter of TMD film may require up to 20 liters of ultrapure water, highlighting the resource intensity of these materials.

Energy audits of TMD manufacturing reveal that phase-selective synthesis methods typically require precise temperature control, often at elevated temperatures exceeding 700°C for extended periods. This translates to substantial carbon footprints, especially when powered by non-renewable energy sources. Life cycle assessments indicate that the energy embodied in laboratory-scale TMD production can reach 2-5 MJ per gram of material, significantly higher than conventional semiconductor materials.

Recycling and circular economy approaches for TMDs remain underdeveloped. The intimate integration of these materials into devices complicates end-of-life recovery, while the diverse polymorphic phases present additional separation challenges. Research into green synthesis routes shows promise, with hydrothermal methods and biomass-derived precursors potentially reducing environmental impact by 30-40% compared to conventional approaches.

Regulatory frameworks governing TMD production vary globally, creating inconsistent environmental standards. As commercial applications expand, particularly in energy storage where the metallic 1T phase shows exceptional promise, establishing harmonized sustainability metrics becomes increasingly urgent. Industry consortia have begun developing sustainability roadmaps specific to 2D materials, acknowledging the unique environmental considerations of polymorphic TMD production.

Scalability and Industrial Manufacturing Considerations for TMDs

The scalability of transition metal dichalcogenides (TMDs) from laboratory synthesis to industrial-scale manufacturing represents a critical challenge for their commercial viability. Current laboratory methods for producing high-quality TMDs with controlled polymorphic phases (1T vs 2H) include chemical vapor deposition (CVD), mechanical exfoliation, and wet chemical synthesis. However, these approaches face significant barriers when transitioning to mass production environments.

CVD processes, while producing high-quality TMD films with controlled phase composition, suffer from low throughput and high production costs. The precise control of temperature gradients, gas flow rates, and substrate conditions necessary for phase selectivity becomes increasingly difficult at larger scales. Equipment costs for industrial-scale CVD systems capable of maintaining the required precision represent substantial capital investments.

Solution-based methods offer greater scalability potential but struggle with phase purity and structural uniformity. The 1T phase, being metastable compared to the thermodynamically favored 2H phase, presents particular challenges for large-scale synthesis with consistent phase retention. Current industrial approaches often result in mixed-phase materials requiring additional post-processing steps.

Substrate compatibility presents another manufacturing hurdle. While laboratory demonstrations often utilize ideal substrates like sapphire or highly oriented pyrolytic graphite, industrial applications require compatibility with silicon, flexible polymers, or other commercially viable substrates without sacrificing phase control or material quality.

Energy consumption represents a significant consideration for industrial viability. The high temperatures (often 700-1000°C) required for conventional TMD synthesis contribute substantially to production costs. Recent advances in plasma-enhanced and solution-phase processes have demonstrated lower temperature alternatives, but these approaches often result in compromised phase purity or crystallinity.

Quality control and characterization at industrial scales present additional challenges. Laboratory techniques like Raman spectroscopy and X-ray photoelectron spectroscopy that distinguish between 1T and 2H phases are time-consuming and difficult to implement for in-line production monitoring. Development of rapid, non-destructive characterization methods suitable for manufacturing environments remains an active research area.

Recent innovations showing promise include roll-to-roll processing techniques for continuous TMD film production, atomic layer deposition methods for precise thickness and phase control, and microwave-assisted synthesis approaches that significantly reduce reaction times and energy requirements while maintaining phase selectivity.

CVD processes, while producing high-quality TMD films with controlled phase composition, suffer from low throughput and high production costs. The precise control of temperature gradients, gas flow rates, and substrate conditions necessary for phase selectivity becomes increasingly difficult at larger scales. Equipment costs for industrial-scale CVD systems capable of maintaining the required precision represent substantial capital investments.

Solution-based methods offer greater scalability potential but struggle with phase purity and structural uniformity. The 1T phase, being metastable compared to the thermodynamically favored 2H phase, presents particular challenges for large-scale synthesis with consistent phase retention. Current industrial approaches often result in mixed-phase materials requiring additional post-processing steps.

Substrate compatibility presents another manufacturing hurdle. While laboratory demonstrations often utilize ideal substrates like sapphire or highly oriented pyrolytic graphite, industrial applications require compatibility with silicon, flexible polymers, or other commercially viable substrates without sacrificing phase control or material quality.

Energy consumption represents a significant consideration for industrial viability. The high temperatures (often 700-1000°C) required for conventional TMD synthesis contribute substantially to production costs. Recent advances in plasma-enhanced and solution-phase processes have demonstrated lower temperature alternatives, but these approaches often result in compromised phase purity or crystallinity.

Quality control and characterization at industrial scales present additional challenges. Laboratory techniques like Raman spectroscopy and X-ray photoelectron spectroscopy that distinguish between 1T and 2H phases are time-consuming and difficult to implement for in-line production monitoring. Development of rapid, non-destructive characterization methods suitable for manufacturing environments remains an active research area.

Recent innovations showing promise include roll-to-roll processing techniques for continuous TMD film production, atomic layer deposition methods for precise thickness and phase control, and microwave-assisted synthesis approaches that significantly reduce reaction times and energy requirements while maintaining phase selectivity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!