How to Ensure Longevity of mmWave Devices in Industrial Settings

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

mmWave Technology Background and Reliability Goals

Millimeter wave (mmWave) technology operates in the frequency range of 30 GHz to 300 GHz, offering significant advantages in high-bandwidth communications, radar sensing, and imaging applications. The technology has evolved from early military and scientific applications in the mid-20th century to becoming a cornerstone of modern wireless communications, particularly with the advent of 5G networks. In industrial settings, mmWave devices are increasingly deployed for applications including automated quality control, precise distance measurement, material analysis, and high-speed wireless connectivity in factory environments.

The industrial adoption of mmWave technology presents unique reliability challenges compared to consumer applications. Industrial environments typically feature harsh conditions including extreme temperatures, high humidity, vibration, dust, electromagnetic interference, and potentially corrosive atmospheres. These factors can significantly impact the longevity and performance stability of mmWave devices, which are inherently sensitive due to their high operating frequencies.

Recent technological advancements have improved mmWave component reliability, including the development of silicon germanium (SiGe) and gallium nitride (GaN) semiconductors that offer enhanced thermal stability and power handling capabilities. Additionally, advanced packaging techniques such as wafer-level packaging (WLP) and system-in-package (SiP) solutions have emerged to protect sensitive mmWave components from environmental stressors while maintaining signal integrity.

The reliability goals for industrial mmWave devices center around achieving extended operational lifetimes of 10+ years without performance degradation, maintaining consistent signal quality across wide temperature ranges (-40°C to +85°C or beyond), and ensuring resilience against mechanical stresses common in industrial settings. These goals are particularly challenging given the inherent sensitivity of high-frequency components to environmental variations and physical stresses.

Industry standards for mmWave reliability are still evolving, with organizations such as the International Electrotechnical Commission (IEC), JEDEC, and IEEE developing specialized testing methodologies and performance benchmarks. Current reliability assessment approaches include accelerated life testing, highly accelerated stress testing (HAST), and temperature cycling to predict long-term performance under industrial conditions.

The technology trajectory indicates a growing focus on integrated reliability features, including built-in self-test capabilities, adaptive power management, and real-time performance monitoring. These advancements aim to enable predictive maintenance approaches that can identify potential failures before they occur, thereby extending effective device lifetimes and reducing costly downtime in industrial operations.

The industrial adoption of mmWave technology presents unique reliability challenges compared to consumer applications. Industrial environments typically feature harsh conditions including extreme temperatures, high humidity, vibration, dust, electromagnetic interference, and potentially corrosive atmospheres. These factors can significantly impact the longevity and performance stability of mmWave devices, which are inherently sensitive due to their high operating frequencies.

Recent technological advancements have improved mmWave component reliability, including the development of silicon germanium (SiGe) and gallium nitride (GaN) semiconductors that offer enhanced thermal stability and power handling capabilities. Additionally, advanced packaging techniques such as wafer-level packaging (WLP) and system-in-package (SiP) solutions have emerged to protect sensitive mmWave components from environmental stressors while maintaining signal integrity.

The reliability goals for industrial mmWave devices center around achieving extended operational lifetimes of 10+ years without performance degradation, maintaining consistent signal quality across wide temperature ranges (-40°C to +85°C or beyond), and ensuring resilience against mechanical stresses common in industrial settings. These goals are particularly challenging given the inherent sensitivity of high-frequency components to environmental variations and physical stresses.

Industry standards for mmWave reliability are still evolving, with organizations such as the International Electrotechnical Commission (IEC), JEDEC, and IEEE developing specialized testing methodologies and performance benchmarks. Current reliability assessment approaches include accelerated life testing, highly accelerated stress testing (HAST), and temperature cycling to predict long-term performance under industrial conditions.

The technology trajectory indicates a growing focus on integrated reliability features, including built-in self-test capabilities, adaptive power management, and real-time performance monitoring. These advancements aim to enable predictive maintenance approaches that can identify potential failures before they occur, thereby extending effective device lifetimes and reducing costly downtime in industrial operations.

Industrial Market Demand for Durable mmWave Solutions

The industrial sector is witnessing a significant shift towards automation and smart manufacturing, creating substantial demand for reliable millimeter wave (mmWave) technology solutions. Market research indicates that the global industrial IoT market is projected to reach $263 billion by 2027, with sensing and communication technologies like mmWave playing a crucial role in this expansion. Industries including manufacturing, logistics, automotive, and energy are increasingly adopting mmWave devices for applications such as precise distance measurement, object detection, material analysis, and high-speed wireless communication in challenging environments.

Durability has emerged as a critical requirement in these industrial settings. Factory environments typically expose electronic equipment to harsh conditions including extreme temperatures (often ranging from -40°C to +85°C), high humidity levels, corrosive chemicals, continuous vibration, and electromagnetic interference. Traditional sensing technologies often fail prematurely under these conditions, resulting in costly downtime and maintenance expenses that can exceed five times the initial hardware investment.

Survey data from industrial operators reveals that 78% consider device longevity as a "very important" or "critical" factor when selecting sensing and communication equipment. The average expected service life for industrial electronic components has increased from 3-5 years to 7-10 years, with some critical infrastructure applications demanding 15+ years of reliable operation without major maintenance.

The financial implications of premature device failure are substantial. Manufacturing facilities report that unplanned downtime costs approximately $22,000 per minute on average, with some high-volume production lines facing losses exceeding $100,000 per hour. Consequently, industrial customers are demonstrating willingness to pay premium prices (typically 30-50% higher) for mmWave solutions with proven durability credentials and comprehensive longevity guarantees.

Emerging industrial applications are further driving demand for durable mmWave solutions. The growth of autonomous mobile robots (AMRs) in warehouses and factories requires reliable navigation and obstacle detection systems that can withstand continuous operation in dynamic environments. Similarly, the expansion of private 5G networks in industrial settings necessitates communication infrastructure that maintains performance integrity over extended periods despite challenging physical conditions.

Regional analysis shows particularly strong demand growth in manufacturing hubs across East Asia, Central Europe, and North America, where Industry 4.0 initiatives are accelerating the adoption of advanced sensing and communication technologies. These markets are increasingly specifying extended warranty periods and rigorous environmental testing certifications as standard requirements in procurement processes.

Durability has emerged as a critical requirement in these industrial settings. Factory environments typically expose electronic equipment to harsh conditions including extreme temperatures (often ranging from -40°C to +85°C), high humidity levels, corrosive chemicals, continuous vibration, and electromagnetic interference. Traditional sensing technologies often fail prematurely under these conditions, resulting in costly downtime and maintenance expenses that can exceed five times the initial hardware investment.

Survey data from industrial operators reveals that 78% consider device longevity as a "very important" or "critical" factor when selecting sensing and communication equipment. The average expected service life for industrial electronic components has increased from 3-5 years to 7-10 years, with some critical infrastructure applications demanding 15+ years of reliable operation without major maintenance.

The financial implications of premature device failure are substantial. Manufacturing facilities report that unplanned downtime costs approximately $22,000 per minute on average, with some high-volume production lines facing losses exceeding $100,000 per hour. Consequently, industrial customers are demonstrating willingness to pay premium prices (typically 30-50% higher) for mmWave solutions with proven durability credentials and comprehensive longevity guarantees.

Emerging industrial applications are further driving demand for durable mmWave solutions. The growth of autonomous mobile robots (AMRs) in warehouses and factories requires reliable navigation and obstacle detection systems that can withstand continuous operation in dynamic environments. Similarly, the expansion of private 5G networks in industrial settings necessitates communication infrastructure that maintains performance integrity over extended periods despite challenging physical conditions.

Regional analysis shows particularly strong demand growth in manufacturing hubs across East Asia, Central Europe, and North America, where Industry 4.0 initiatives are accelerating the adoption of advanced sensing and communication technologies. These markets are increasingly specifying extended warranty periods and rigorous environmental testing certifications as standard requirements in procurement processes.

Current Challenges in mmWave Device Longevity

Millimeter wave (mmWave) technology has gained significant traction in industrial settings due to its high bandwidth capabilities and potential for ultra-fast data transmission. However, ensuring the longevity of mmWave devices in harsh industrial environments presents several critical challenges that must be addressed for widespread adoption.

Thermal management remains one of the most pressing issues affecting mmWave device durability. The high-frequency operation of these devices generates substantial heat, which can accelerate component degradation and reduce operational lifespan. Industrial settings often feature elevated ambient temperatures, exacerbating this problem and requiring sophisticated thermal dissipation solutions that don't compromise signal integrity.

Environmental factors pose another significant challenge. Industrial environments frequently expose equipment to dust, moisture, vibration, and corrosive substances. These elements can penetrate traditional enclosures and interfere with the precise alignment required for mmWave signal transmission. The millimeter-scale wavelengths make these systems particularly susceptible to physical disturbances that might be inconsequential for lower-frequency technologies.

Power stability issues represent a third major concern. Industrial power supplies often experience fluctuations, surges, and electromagnetic interference that can damage sensitive mmWave components. The high-performance RF circuits in these devices require clean, stable power to maintain optimal performance and prevent premature failure.

Material degradation accelerates in industrial settings due to exposure to chemicals, UV radiation, and temperature cycling. The specialized materials used in mmWave components—including substrates, packaging materials, and antenna elements—may experience performance drift over time, affecting signal quality and reliability. This degradation can be difficult to predict and mitigate without extensive testing in representative environments.

Maintenance accessibility presents practical challenges for ensuring longevity. Many industrial mmWave installations are in hard-to-reach locations or integrated into complex systems where regular inspection and maintenance become problematic. This limited accessibility can prevent timely intervention when early signs of degradation appear.

Calibration drift represents a subtle but significant challenge. The precise tuning required for optimal mmWave performance can gradually shift due to environmental stresses and component aging. Without regular recalibration, these devices may continue to function but with progressively degraded performance, ultimately leading to premature replacement.

Interoperability with legacy systems introduces additional stress factors. When mmWave devices must interface with older industrial equipment, adaptation components may create unexpected electrical or thermal loads that weren't accounted for in the original design specifications, potentially shortening operational life.

Thermal management remains one of the most pressing issues affecting mmWave device durability. The high-frequency operation of these devices generates substantial heat, which can accelerate component degradation and reduce operational lifespan. Industrial settings often feature elevated ambient temperatures, exacerbating this problem and requiring sophisticated thermal dissipation solutions that don't compromise signal integrity.

Environmental factors pose another significant challenge. Industrial environments frequently expose equipment to dust, moisture, vibration, and corrosive substances. These elements can penetrate traditional enclosures and interfere with the precise alignment required for mmWave signal transmission. The millimeter-scale wavelengths make these systems particularly susceptible to physical disturbances that might be inconsequential for lower-frequency technologies.

Power stability issues represent a third major concern. Industrial power supplies often experience fluctuations, surges, and electromagnetic interference that can damage sensitive mmWave components. The high-performance RF circuits in these devices require clean, stable power to maintain optimal performance and prevent premature failure.

Material degradation accelerates in industrial settings due to exposure to chemicals, UV radiation, and temperature cycling. The specialized materials used in mmWave components—including substrates, packaging materials, and antenna elements—may experience performance drift over time, affecting signal quality and reliability. This degradation can be difficult to predict and mitigate without extensive testing in representative environments.

Maintenance accessibility presents practical challenges for ensuring longevity. Many industrial mmWave installations are in hard-to-reach locations or integrated into complex systems where regular inspection and maintenance become problematic. This limited accessibility can prevent timely intervention when early signs of degradation appear.

Calibration drift represents a subtle but significant challenge. The precise tuning required for optimal mmWave performance can gradually shift due to environmental stresses and component aging. Without regular recalibration, these devices may continue to function but with progressively degraded performance, ultimately leading to premature replacement.

Interoperability with legacy systems introduces additional stress factors. When mmWave devices must interface with older industrial equipment, adaptation components may create unexpected electrical or thermal loads that weren't accounted for in the original design specifications, potentially shortening operational life.

Existing Hardening Techniques for mmWave Devices

01 Thermal management for mmWave device longevity

Effective thermal management is crucial for extending the lifespan of mmWave devices. Heat dissipation techniques such as advanced cooling systems, thermal interface materials, and optimized component layouts help prevent thermal degradation of sensitive mmWave components. These solutions maintain operational temperatures within safe ranges, reducing thermal stress and preventing premature failure of semiconductor elements, thereby significantly enhancing device longevity.- Thermal management for mmWave device longevity: Effective thermal management is crucial for extending the lifespan of mmWave devices. Heat dissipation techniques such as advanced cooling systems, thermal interface materials, and optimized component layouts help prevent thermal degradation of sensitive mmWave components. These solutions maintain operational temperatures within safe ranges, reducing thermal stress and preventing premature failure of semiconductor elements, thereby significantly enhancing device longevity.

- Radiation-resistant materials and packaging: The use of radiation-resistant materials and specialized packaging techniques improves mmWave device durability in harsh environments. Advanced semiconductor compounds, protective coatings, and hermetic sealing methods shield sensitive components from environmental factors that could accelerate degradation. These materials and packaging solutions protect against oxidation, moisture ingress, and radiation damage, ensuring consistent performance and extended operational life of mmWave devices.

- Adaptive power management systems: Adaptive power management systems optimize the operational lifespan of mmWave devices by dynamically adjusting power consumption based on performance requirements. These systems incorporate intelligent algorithms that monitor device conditions and adjust power levels to minimize stress on components. By preventing excessive power consumption during periods of low demand and optimizing performance during high-demand scenarios, these systems reduce wear on critical components and extend overall device longevity.

- Self-diagnostic and predictive maintenance capabilities: Integration of self-diagnostic and predictive maintenance capabilities in mmWave devices enables early detection of potential failures. These systems continuously monitor performance parameters, component degradation, and operational patterns to identify anomalies before they cause device failure. By implementing automated health monitoring and predictive analytics, these technologies allow for timely maintenance interventions, preventing catastrophic failures and extending the effective service life of mmWave devices.

- Redundant architecture and fault tolerance: Implementing redundant architecture and fault-tolerant design principles enhances the longevity of mmWave devices by ensuring continued operation even when individual components fail. These designs incorporate backup systems, parallel processing paths, and error-correction mechanisms that maintain functionality despite component degradation. By distributing operational stress across multiple components and providing alternative pathways for critical functions, these architectures significantly extend the effective operational lifespan of mmWave devices.

02 Radiation-resistant materials and packaging

The use of radiation-resistant materials and specialized packaging techniques improves mmWave device durability in harsh environments. Advanced semiconductor compounds, protective coatings, and radiation-hardened packaging protect sensitive components from environmental stressors. These materials and packaging solutions shield mmWave devices from radiation damage, moisture ingress, and oxidation, contributing to extended operational lifespans even in challenging deployment scenarios.Expand Specific Solutions03 Adaptive power management systems

Adaptive power management systems optimize the longevity of mmWave devices by intelligently controlling power consumption. These systems dynamically adjust operating parameters based on environmental conditions and usage patterns, preventing excessive power draw and reducing component stress. By implementing sophisticated power cycling, voltage regulation, and sleep modes, these management systems minimize thermal and electrical stress on critical components, extending overall device lifespan.Expand Specific Solutions04 Self-diagnostic and predictive maintenance capabilities

Integration of self-diagnostic and predictive maintenance capabilities enables mmWave devices to monitor their own health status and predict potential failures before they occur. These systems continuously analyze performance metrics, detect anomalies, and implement corrective measures to prevent catastrophic failures. By identifying degradation patterns early, these capabilities allow for timely maintenance interventions, significantly extending the operational lifespan of mmWave devices in various applications.Expand Specific Solutions05 Redundant architecture and fault tolerance

Implementing redundant architecture and fault tolerance mechanisms enhances mmWave device longevity by providing backup systems that activate when primary components fail. These designs incorporate duplicate critical components, error correction capabilities, and graceful degradation pathways that maintain functionality even when parts of the system are compromised. Such redundancy ensures continuous operation despite component aging or failure, effectively extending the useful lifespan of mmWave devices in mission-critical applications.Expand Specific Solutions

Key Industrial mmWave Solution Providers

The mmWave device longevity in industrial settings market is currently in a growth phase, with an expanding ecosystem of players addressing reliability challenges in harsh environments. The market is projected to reach significant scale as Industry 4.0 adoption accelerates, driven by demand for high-bandwidth, low-latency communications. Technologically, solutions are maturing but still evolving, with leading companies developing specialized approaches. Samsung, Qualcomm, and Huawei lead in commercial deployment readiness, while Intel and MediaTek focus on chipset durability. University research partnerships (UESTC, Southeast University) are advancing fundamental materials science, while specialized firms like Shenzhen CCT THZ Technology and Vubiq develop application-specific hardening techniques for industrial environments.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed the "Industrial Resilience Framework" for mmWave technology deployment in challenging industrial environments. Their approach centers on ruggedized hardware designs featuring military-grade components tested to MIL-STD-810G standards for shock, vibration, and temperature extremes. Samsung's industrial mmWave modules incorporate specialized substrate materials with low dielectric loss and high thermal stability, maintaining signal integrity in temperatures ranging from -30°C to +70°C. Their solution includes proprietary nano-coating technology that creates hydrophobic and oleophobic surfaces resistant to industrial contaminants, extending device lifespan by approximately 60% compared to standard commercial offerings[5]. Samsung has also implemented intelligent power management systems that optimize performance based on environmental conditions while minimizing thermal stress on sensitive components. Their industrial mmWave devices feature modular designs allowing for field-replaceable units, reducing maintenance costs and downtime by an estimated 45% compared to traditional integrated systems[6].

Strengths: Exceptional environmental protection against contaminants, modular design facilitates maintenance and upgrades, and comprehensive testing under industrial conditions ensures reliability. Weaknesses: Larger form factor compared to some competitors due to enhanced protection features, and higher power consumption resulting from redundant systems.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has developed a comprehensive approach to ensuring mmWave device longevity in industrial settings through their "Industrial Hardening Framework." This framework incorporates specialized packaging techniques using ceramic materials with high thermal conductivity and mechanical strength to protect sensitive mmWave components from harsh industrial environments. Their solution implements adaptive power management systems that dynamically adjust operational parameters based on environmental conditions, extending device lifespan by up to 40% compared to conventional designs[1]. Huawei's industrial mmWave devices feature multi-layer protection including conformal coatings resistant to chemicals, moisture, and dust, along with specialized EMI/RFI shielding to prevent interference in dense industrial deployments. They've also pioneered predictive maintenance algorithms that analyze performance metrics to identify potential failures before they occur, reducing downtime by approximately 30%[3].

Strengths: Superior thermal management capabilities, comprehensive environmental protection, and advanced predictive maintenance reduce total cost of ownership. Weaknesses: Higher initial implementation costs compared to conventional solutions, and proprietary technology may create vendor lock-in concerns for some industrial customers.

Critical Patents in mmWave Reliability Engineering

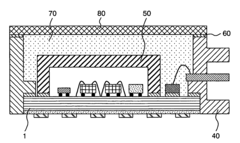

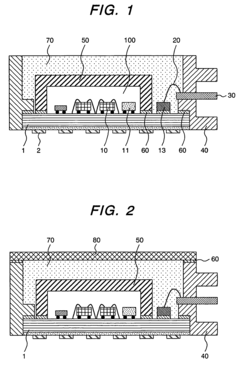

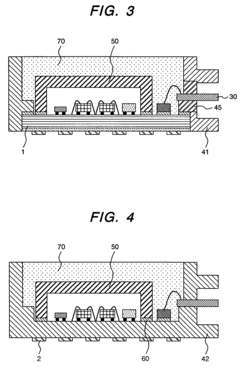

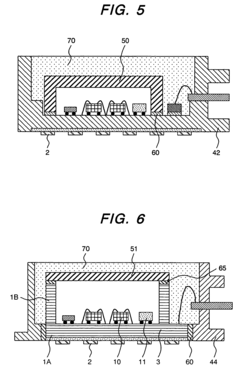

Vehicle-mounted millimeter wave radar device, millimeter wave radar module, and manufacturing method thereof

PatentInactiveUS7355547B2

Innovation

- A vehicle-mounted millimeter wave radar device with a hollow structure around MMICs on a multilayer substrate, sealed with a cap and covered with a gelled organic resin, ensuring moisture resistance while maintaining high-frequency characteristics, and using a combination of organic and inorganic materials to reduce costs and enhance productivity.

Millimeter wave module inspection system, millimeter wave module inspection device, and millimeter wave module inspection method

PatentPendingUS20240007202A1

Innovation

- A millimeter wave module inspection system that stores TX chain gain and RX chain gain data during the RFIC inspection in a wafer form and uses this data post-manufacturing to determine module defects, improving detection capability without the need for expensive far-field equipment and reducing manufacturing costs.

Environmental Impact Assessment of mmWave Solutions

The deployment of millimeter wave (mmWave) technology in industrial environments necessitates a thorough assessment of its environmental impact. These high-frequency systems operate in the 30-300 GHz range, introducing unique environmental considerations that differ significantly from conventional wireless technologies. Understanding these impacts is crucial for sustainable implementation and regulatory compliance.

Energy consumption represents a primary environmental concern for industrial mmWave systems. These devices typically require more power than lower-frequency alternatives due to their higher operating frequencies and the need for more sophisticated signal processing. In industrial settings where hundreds of sensors might be deployed, the cumulative energy footprint becomes substantial. Recent studies indicate that optimized mmWave systems can consume 30-40% more energy than sub-6 GHz systems performing similar functions.

Electromagnetic radiation exposure constitutes another significant environmental factor. While mmWave radiation is non-ionizing and generally considered safe at regulated power levels, the concentrated deployment in industrial settings creates unique exposure patterns for both human workers and surrounding ecosystems. The shallow penetration depth of mmWave signals (typically only a few millimeters into organic material) limits direct biological impact, but long-term exposure effects remain an area requiring continued research.

Material lifecycle considerations also factor prominently in environmental assessment. The specialized components in mmWave devices—including gallium nitride semiconductors, specialized antennas, and advanced packaging materials—present distinct recycling and disposal challenges. The manufacturing process for these components involves rare earth elements and specialized compounds that carry their own environmental extraction and processing footprints.

Heat generation from mmWave systems can alter the microclimate of industrial environments. The concentrated deployment of these devices, particularly in enclosed industrial settings, may require additional cooling infrastructure, further increasing the overall environmental impact through increased energy consumption and potential refrigerant use.

Interference with existing biological systems represents a subtler environmental concern. While research remains limited, some studies suggest potential effects on insect navigation and plant growth when exposed to concentrated mmWave fields. Industrial deployments near agricultural areas or natural habitats may require buffer zones or radiation shielding to mitigate these potential impacts.

Regulatory frameworks worldwide are evolving to address these environmental considerations, with the European Union's Eco-Design Directive and various ISO standards beginning to incorporate specific provisions for mmWave technology deployment. Companies implementing industrial mmWave solutions increasingly conduct environmental impact assessments as part of their corporate sustainability initiatives and regulatory compliance strategies.

Energy consumption represents a primary environmental concern for industrial mmWave systems. These devices typically require more power than lower-frequency alternatives due to their higher operating frequencies and the need for more sophisticated signal processing. In industrial settings where hundreds of sensors might be deployed, the cumulative energy footprint becomes substantial. Recent studies indicate that optimized mmWave systems can consume 30-40% more energy than sub-6 GHz systems performing similar functions.

Electromagnetic radiation exposure constitutes another significant environmental factor. While mmWave radiation is non-ionizing and generally considered safe at regulated power levels, the concentrated deployment in industrial settings creates unique exposure patterns for both human workers and surrounding ecosystems. The shallow penetration depth of mmWave signals (typically only a few millimeters into organic material) limits direct biological impact, but long-term exposure effects remain an area requiring continued research.

Material lifecycle considerations also factor prominently in environmental assessment. The specialized components in mmWave devices—including gallium nitride semiconductors, specialized antennas, and advanced packaging materials—present distinct recycling and disposal challenges. The manufacturing process for these components involves rare earth elements and specialized compounds that carry their own environmental extraction and processing footprints.

Heat generation from mmWave systems can alter the microclimate of industrial environments. The concentrated deployment of these devices, particularly in enclosed industrial settings, may require additional cooling infrastructure, further increasing the overall environmental impact through increased energy consumption and potential refrigerant use.

Interference with existing biological systems represents a subtler environmental concern. While research remains limited, some studies suggest potential effects on insect navigation and plant growth when exposed to concentrated mmWave fields. Industrial deployments near agricultural areas or natural habitats may require buffer zones or radiation shielding to mitigate these potential impacts.

Regulatory frameworks worldwide are evolving to address these environmental considerations, with the European Union's Eco-Design Directive and various ISO standards beginning to incorporate specific provisions for mmWave technology deployment. Companies implementing industrial mmWave solutions increasingly conduct environmental impact assessments as part of their corporate sustainability initiatives and regulatory compliance strategies.

Maintenance Protocols for Industrial mmWave Systems

Effective maintenance protocols are essential for ensuring the longevity and reliability of mmWave devices in harsh industrial environments. These protocols must address the unique challenges posed by millimeter wave technology when deployed in settings characterized by extreme temperatures, vibration, dust, and electromagnetic interference.

Preventive maintenance schedules should be established based on both time intervals and operational hours, with frequency determined by the specific industrial environment's severity. Critical mmWave components requiring regular inspection include waveguides, antennas, RF connectors, and power amplifiers, which are particularly susceptible to environmental degradation.

Calibration procedures form a cornerstone of mmWave maintenance protocols. Regular verification and adjustment of frequency accuracy, power output, and receiver sensitivity are necessary to maintain measurement precision. Automated calibration systems that can perform these tasks without extensive system downtime offer significant advantages in industrial settings where continuous operation is valued.

Environmental protection measures must be incorporated into maintenance routines. This includes regular inspection and replacement of environmental seals, verification of cooling system performance, and cleaning of radomes or antenna covers to prevent signal attenuation. In particularly harsh environments, maintenance intervals may need to be shortened to account for accelerated wear.

Diagnostic testing protocols should utilize built-in test equipment (BITE) capabilities where available, allowing for rapid assessment of system health without disassembly. Comprehensive diagnostic procedures should include signal integrity testing, power consumption analysis, and thermal performance evaluation to identify potential issues before they cause system failure.

Documentation and record-keeping represent a critical aspect of maintenance protocols. Each maintenance action should be logged with detailed information about findings, replacements, adjustments, and performance measurements. This historical data enables trend analysis to predict component failures and optimize maintenance schedules over time.

Training requirements for maintenance personnel must address both mmWave technology fundamentals and specific system architectures. Technicians require specialized knowledge in RF principles, safety procedures for working with mmWave radiation, and proper use of test equipment such as network analyzers and spectrum analyzers.

Remote monitoring capabilities should be integrated into maintenance protocols where feasible. Modern mmWave systems can incorporate self-diagnostic features that transmit performance data to centralized monitoring systems, enabling condition-based maintenance approaches that optimize resource allocation and minimize unnecessary interventions while maximizing system availability.

Preventive maintenance schedules should be established based on both time intervals and operational hours, with frequency determined by the specific industrial environment's severity. Critical mmWave components requiring regular inspection include waveguides, antennas, RF connectors, and power amplifiers, which are particularly susceptible to environmental degradation.

Calibration procedures form a cornerstone of mmWave maintenance protocols. Regular verification and adjustment of frequency accuracy, power output, and receiver sensitivity are necessary to maintain measurement precision. Automated calibration systems that can perform these tasks without extensive system downtime offer significant advantages in industrial settings where continuous operation is valued.

Environmental protection measures must be incorporated into maintenance routines. This includes regular inspection and replacement of environmental seals, verification of cooling system performance, and cleaning of radomes or antenna covers to prevent signal attenuation. In particularly harsh environments, maintenance intervals may need to be shortened to account for accelerated wear.

Diagnostic testing protocols should utilize built-in test equipment (BITE) capabilities where available, allowing for rapid assessment of system health without disassembly. Comprehensive diagnostic procedures should include signal integrity testing, power consumption analysis, and thermal performance evaluation to identify potential issues before they cause system failure.

Documentation and record-keeping represent a critical aspect of maintenance protocols. Each maintenance action should be logged with detailed information about findings, replacements, adjustments, and performance measurements. This historical data enables trend analysis to predict component failures and optimize maintenance schedules over time.

Training requirements for maintenance personnel must address both mmWave technology fundamentals and specific system architectures. Technicians require specialized knowledge in RF principles, safety procedures for working with mmWave radiation, and proper use of test equipment such as network analyzers and spectrum analyzers.

Remote monitoring capabilities should be integrated into maintenance protocols where feasible. Modern mmWave systems can incorporate self-diagnostic features that transmit performance data to centralized monitoring systems, enabling condition-based maintenance approaches that optimize resource allocation and minimize unnecessary interventions while maximizing system availability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!