How to Lower Deployment Costs with mmWave Phased Array Antennas

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

mmWave Phased Array Technology Background and Objectives

Millimeter wave (mmWave) technology has evolved significantly over the past few decades, transitioning from primarily military and scientific applications to becoming a cornerstone of next-generation wireless communications. Operating in frequency bands between 30 GHz and 300 GHz, mmWave technology offers substantial bandwidth advantages critical for high-data-rate applications. The historical trajectory shows accelerated development since the early 2000s, with major breakthroughs in semiconductor processes enabling practical commercial implementations.

Phased array antennas, which consist of multiple radiating elements whose phases can be individually controlled to steer the beam electronically, have become the preferred implementation method for mmWave systems. This technology eliminates the need for mechanical steering, significantly improving reliability and response time while reducing maintenance requirements. The convergence of mmWave frequencies with phased array technology has created powerful systems capable of supporting emerging applications in 5G/6G telecommunications, autonomous vehicles, and industrial IoT.

Despite the technical advantages, deployment costs remain a significant barrier to widespread adoption. Current mmWave phased array systems typically require expensive materials, precision manufacturing processes, and complex integration techniques. The high component count in traditional implementations leads to increased production costs, while thermal management and packaging challenges further elevate expenses. These cost factors have limited deployment primarily to high-value applications where performance justifications outweigh economic considerations.

The primary technical objective in this domain is to develop cost-effective mmWave phased array antenna solutions without compromising essential performance parameters. This includes exploring alternative materials and manufacturing processes, simplifying array architectures, and developing more integrated semiconductor solutions that reduce component count and assembly complexity. Specific goals include achieving at least 30% reduction in production costs while maintaining or improving key performance metrics such as beam steering accuracy, power efficiency, and reliability.

Recent technological trends indicate promising directions for cost reduction, including advances in silicon-based mmWave ICs, panel-level integration techniques, and automated assembly methods. The emergence of new materials like liquid crystal polymers (LCPs) and low-temperature co-fired ceramics (LTCC) offers potential alternatives to traditional expensive substrates. Additionally, algorithmic innovations in calibration and beamforming may compensate for hardware simplifications, maintaining system performance while using less costly components.

The ultimate goal is to democratize access to mmWave phased array technology by bringing costs down to levels that enable mass-market applications beyond premium telecommunications infrastructure. This would unlock new use cases in consumer electronics, smart cities, healthcare, and industrial automation where the current cost structure prohibits adoption despite clear technical benefits.

Phased array antennas, which consist of multiple radiating elements whose phases can be individually controlled to steer the beam electronically, have become the preferred implementation method for mmWave systems. This technology eliminates the need for mechanical steering, significantly improving reliability and response time while reducing maintenance requirements. The convergence of mmWave frequencies with phased array technology has created powerful systems capable of supporting emerging applications in 5G/6G telecommunications, autonomous vehicles, and industrial IoT.

Despite the technical advantages, deployment costs remain a significant barrier to widespread adoption. Current mmWave phased array systems typically require expensive materials, precision manufacturing processes, and complex integration techniques. The high component count in traditional implementations leads to increased production costs, while thermal management and packaging challenges further elevate expenses. These cost factors have limited deployment primarily to high-value applications where performance justifications outweigh economic considerations.

The primary technical objective in this domain is to develop cost-effective mmWave phased array antenna solutions without compromising essential performance parameters. This includes exploring alternative materials and manufacturing processes, simplifying array architectures, and developing more integrated semiconductor solutions that reduce component count and assembly complexity. Specific goals include achieving at least 30% reduction in production costs while maintaining or improving key performance metrics such as beam steering accuracy, power efficiency, and reliability.

Recent technological trends indicate promising directions for cost reduction, including advances in silicon-based mmWave ICs, panel-level integration techniques, and automated assembly methods. The emergence of new materials like liquid crystal polymers (LCPs) and low-temperature co-fired ceramics (LTCC) offers potential alternatives to traditional expensive substrates. Additionally, algorithmic innovations in calibration and beamforming may compensate for hardware simplifications, maintaining system performance while using less costly components.

The ultimate goal is to democratize access to mmWave phased array technology by bringing costs down to levels that enable mass-market applications beyond premium telecommunications infrastructure. This would unlock new use cases in consumer electronics, smart cities, healthcare, and industrial automation where the current cost structure prohibits adoption despite clear technical benefits.

Market Demand Analysis for Cost-Effective mmWave Solutions

The global market for mmWave phased array antenna solutions is experiencing robust growth, driven primarily by the accelerating deployment of 5G networks and the increasing demand for high-speed, high-capacity wireless communications. According to industry reports, the mmWave antenna market is projected to grow at a CAGR of 35.2% from 2021 to 2026, reaching a market value of $7.5 billion by the end of the forecast period.

The demand for cost-effective mmWave solutions stems from several key market factors. Network operators worldwide are under significant pressure to reduce capital expenditure while simultaneously expanding network coverage and capacity. Traditional mmWave deployments have been characterized by high costs, with estimates suggesting that mmWave base stations can cost 1.5 to 2 times more than their sub-6 GHz counterparts, primarily due to expensive RF components and complex antenna systems.

Telecommunications service providers represent the largest market segment, accounting for approximately 65% of the total demand. These operators are actively seeking solutions that can reduce the total cost of ownership (TCO) of mmWave deployments by 30-40% to make widespread implementation economically viable. The enterprise sector, particularly for private 5G networks in manufacturing, healthcare, and transportation, constitutes another rapidly growing segment with a 28% market share.

Geographically, North America currently leads the market with a 38% share, followed by Asia-Pacific at 32% and Europe at 24%. However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years due to aggressive 5G rollout plans in countries like China, South Korea, and Japan.

Consumer surveys indicate a growing willingness to pay premium prices for enhanced mobile broadband experiences, with 72% of consumers expressing interest in services enabled by mmWave technology. This consumer demand is creating a pull effect in the market, encouraging operators to find cost-effective deployment strategies.

The industrial IoT sector presents another significant market opportunity, with an estimated 75 billion connected devices expected by 2025. Many of these applications require the high bandwidth and low latency that mmWave technology can provide, but are highly sensitive to deployment costs.

Market analysis reveals that solutions capable of reducing mmWave deployment costs by even 20-25% could unlock an additional $3 billion in market opportunity by enabling deployments in previously uneconomical scenarios such as suburban areas and enterprise environments. This represents a critical inflection point where cost optimization in mmWave phased array antenna technology could dramatically accelerate market adoption.

The demand for cost-effective mmWave solutions stems from several key market factors. Network operators worldwide are under significant pressure to reduce capital expenditure while simultaneously expanding network coverage and capacity. Traditional mmWave deployments have been characterized by high costs, with estimates suggesting that mmWave base stations can cost 1.5 to 2 times more than their sub-6 GHz counterparts, primarily due to expensive RF components and complex antenna systems.

Telecommunications service providers represent the largest market segment, accounting for approximately 65% of the total demand. These operators are actively seeking solutions that can reduce the total cost of ownership (TCO) of mmWave deployments by 30-40% to make widespread implementation economically viable. The enterprise sector, particularly for private 5G networks in manufacturing, healthcare, and transportation, constitutes another rapidly growing segment with a 28% market share.

Geographically, North America currently leads the market with a 38% share, followed by Asia-Pacific at 32% and Europe at 24%. However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years due to aggressive 5G rollout plans in countries like China, South Korea, and Japan.

Consumer surveys indicate a growing willingness to pay premium prices for enhanced mobile broadband experiences, with 72% of consumers expressing interest in services enabled by mmWave technology. This consumer demand is creating a pull effect in the market, encouraging operators to find cost-effective deployment strategies.

The industrial IoT sector presents another significant market opportunity, with an estimated 75 billion connected devices expected by 2025. Many of these applications require the high bandwidth and low latency that mmWave technology can provide, but are highly sensitive to deployment costs.

Market analysis reveals that solutions capable of reducing mmWave deployment costs by even 20-25% could unlock an additional $3 billion in market opportunity by enabling deployments in previously uneconomical scenarios such as suburban areas and enterprise environments. This represents a critical inflection point where cost optimization in mmWave phased array antenna technology could dramatically accelerate market adoption.

Current Challenges in mmWave Phased Array Deployment

Despite the promising capabilities of mmWave phased array antennas in 5G and beyond networks, their widespread deployment faces significant challenges primarily related to cost factors. The manufacturing complexity of these advanced antenna systems requires specialized fabrication processes and high-precision components, substantially increasing production expenses. Current manufacturing techniques involve multi-layer PCB designs with numerous RF components that demand tight tolerances and specialized materials, resulting in high unit costs that scale poorly for mass production.

Thermal management presents another critical challenge, as mmWave phased arrays generate considerable heat during operation. The dense integration of power amplifiers, phase shifters, and other active components necessitates sophisticated cooling solutions. Current approaches often involve expensive heat sinks, thermal interface materials, and in some cases active cooling systems, all of which add to both the initial deployment costs and ongoing operational expenses.

Calibration and testing requirements further compound the cost issue. Each phased array antenna requires precise calibration to ensure proper beam steering and formation capabilities. The testing equipment needed for mmWave frequencies is inherently expensive, and the calibration process is time-consuming, requiring skilled technicians and specialized environments. These factors significantly impact the overall deployment economics, particularly when scaling to thousands of units for network rollouts.

Power consumption remains a persistent challenge, with current mmWave phased array designs requiring substantial energy to operate effectively. The power amplifiers and phase shifters that enable beamforming functionality consume significant power, necessitating robust power supply systems and increasing operational costs over the antenna's lifetime. This power requirement also complicates deployment in locations with limited power infrastructure.

Integration complexity with existing network infrastructure represents another cost driver. Current mmWave phased array systems often require specialized interfaces and control systems that may not be compatible with legacy equipment. The need for additional hardware and software adaptations increases both capital and operational expenditures for network operators seeking to upgrade their infrastructure.

Site acquisition and installation costs are particularly burdensome for mmWave deployments. The limited propagation characteristics of mmWave signals necessitate denser network deployments with more antenna sites. Each site requires physical space, permits, backhaul connectivity, and professional installation, all contributing to higher deployment costs compared to lower-frequency technologies. The specialized mounting requirements and precise alignment needed for optimal performance further add to installation expenses.

Thermal management presents another critical challenge, as mmWave phased arrays generate considerable heat during operation. The dense integration of power amplifiers, phase shifters, and other active components necessitates sophisticated cooling solutions. Current approaches often involve expensive heat sinks, thermal interface materials, and in some cases active cooling systems, all of which add to both the initial deployment costs and ongoing operational expenses.

Calibration and testing requirements further compound the cost issue. Each phased array antenna requires precise calibration to ensure proper beam steering and formation capabilities. The testing equipment needed for mmWave frequencies is inherently expensive, and the calibration process is time-consuming, requiring skilled technicians and specialized environments. These factors significantly impact the overall deployment economics, particularly when scaling to thousands of units for network rollouts.

Power consumption remains a persistent challenge, with current mmWave phased array designs requiring substantial energy to operate effectively. The power amplifiers and phase shifters that enable beamforming functionality consume significant power, necessitating robust power supply systems and increasing operational costs over the antenna's lifetime. This power requirement also complicates deployment in locations with limited power infrastructure.

Integration complexity with existing network infrastructure represents another cost driver. Current mmWave phased array systems often require specialized interfaces and control systems that may not be compatible with legacy equipment. The need for additional hardware and software adaptations increases both capital and operational expenditures for network operators seeking to upgrade their infrastructure.

Site acquisition and installation costs are particularly burdensome for mmWave deployments. The limited propagation characteristics of mmWave signals necessitate denser network deployments with more antenna sites. Each site requires physical space, permits, backhaul connectivity, and professional installation, all contributing to higher deployment costs compared to lower-frequency technologies. The specialized mounting requirements and precise alignment needed for optimal performance further add to installation expenses.

Current Cost Reduction Approaches for mmWave Deployment

01 Cost-effective manufacturing techniques for mmWave phased arrays

Various manufacturing techniques have been developed to reduce the production costs of mmWave phased array antennas. These include integrated circuit approaches that combine multiple components on a single chip, modular design strategies that allow for scalable production, and advanced packaging methods that optimize space and reduce material costs. These manufacturing innovations help to lower the overall deployment costs while maintaining performance requirements for 5G and other applications.- Cost-effective manufacturing techniques for mmWave phased arrays: Various manufacturing techniques have been developed to reduce the production costs of mmWave phased array antennas. These include integrated circuit approaches that combine multiple components on a single chip, modular design strategies that allow for scalable production, and advanced packaging methods that optimize space utilization while reducing material costs. These manufacturing innovations help to lower the overall deployment costs while maintaining performance requirements for 5G and other applications.

- System architecture optimization for cost reduction: Optimizing the system architecture of mmWave phased array antennas can significantly reduce deployment costs. This includes designing efficient beamforming networks, implementing digital control systems that reduce the need for expensive analog components, and developing hybrid beamforming approaches that balance performance with cost considerations. These architectural optimizations help to minimize the number of required components while maintaining or improving system performance.

- Energy efficiency solutions to reduce operational costs: Energy consumption represents a significant portion of the operational costs for mmWave phased array antenna systems. Various solutions have been developed to improve energy efficiency, including power management circuits, adaptive power control algorithms, and low-power standby modes. These approaches reduce the power requirements for phased array systems, leading to lower operational costs over the system lifetime while maintaining necessary performance characteristics.

- Installation and maintenance cost reduction strategies: Deployment costs for mmWave phased array antennas include installation and ongoing maintenance expenses. Innovations in this area include self-calibrating systems that reduce the need for manual adjustments, modular designs that facilitate easier repairs and upgrades, and remote monitoring capabilities that minimize on-site maintenance visits. These features help to reduce the total cost of ownership by simplifying installation procedures and extending the operational lifetime of the systems.

- Material selection and component integration for cost optimization: The selection of materials and integration of components play crucial roles in determining the overall cost of mmWave phased array antenna systems. Innovations include the use of alternative substrate materials that are less expensive than traditional options, integration of multiple functions into single components to reduce part count, and design approaches that minimize the use of expensive materials while maintaining performance specifications. These material and integration strategies help to reduce both manufacturing and deployment costs.

02 Simplified array architectures to reduce deployment expenses

Simplified architectures for mmWave phased array antennas focus on reducing the number of components required while maintaining adequate performance. These designs may use fewer phase shifters, amplifiers, or control elements compared to traditional approaches. By optimizing the array configuration and reducing component count, these architectures significantly lower both material and installation costs, making widespread deployment more economically feasible for network operators.Expand Specific Solutions03 Energy-efficient designs to lower operational costs

Energy consumption represents a significant portion of the total cost of ownership for mmWave phased array antenna systems. Innovations in this area include power-efficient amplifier designs, intelligent power management systems that activate only necessary elements of the array, and thermal management solutions that reduce cooling requirements. These energy-efficient designs help to minimize operational expenses over the lifetime of the deployment, making mmWave technology more economically viable for large-scale implementations.Expand Specific Solutions04 Installation and maintenance cost reduction strategies

Deployment costs for mmWave phased array antennas include significant expenses related to installation and ongoing maintenance. Innovations addressing these costs include self-calibrating arrays that reduce the need for expert technicians, modular designs that allow for easy component replacement, and remote diagnostic capabilities that minimize site visits. Additionally, weather-resistant packaging and robust designs help to extend the operational lifetime of the arrays, reducing the frequency of repairs and replacements.Expand Specific Solutions05 Scalable array configurations for cost-optimized coverage

Scalable array configurations allow network operators to optimize deployment costs based on coverage requirements. These designs enable the addition or reduction of array elements to match specific deployment scenarios, avoiding over-provisioning of hardware. Adaptive beamforming techniques further enhance this flexibility by optimizing signal coverage with minimal hardware. This approach allows for strategic investment in infrastructure, with the ability to scale up capacity in high-demand areas while minimizing costs in areas with lower traffic demands.Expand Specific Solutions

Key Industry Players in mmWave Phased Array Market

The mmWave phased array antenna market is currently in a growth phase, with increasing adoption across telecommunications, defense, and consumer electronics sectors. The global market size is projected to expand significantly due to 5G deployment and satellite communications demand. Technologically, the field shows varying maturity levels among key players. Companies like Huawei, Samsung, and ZTE lead with commercial deployments, while specialized firms such as Tubis Technology and ThinKom Solutions offer innovative modular solutions to reduce deployment costs. Academic institutions (Tsinghua University, Drexel) collaborate with industry leaders (Intel, NXP) to advance semiconductor integration and beamforming techniques. The competitive landscape features both established telecommunications giants and emerging specialized antenna manufacturers working to address cost and performance challenges.

Samsung Electronics Co., Ltd.

Technical Solution: 三星电子在降低毫米波相控阵天线部署成本方面采用了多层次的创新方法。该公司开发了高度集成的28GHz和39GHz毫米波射频集成电路(RFIC),将多达64个天线元件的控制电路整合在单一芯片上,显著降低了系统复杂性和材料成本。三星还推出了创新的"紧凑型毫米波接入单元"设计,体积比传统解决方案小约30%,减少了安装空间需求和相关租赁成本。在制造方面,三星利用其半导体生产优势,采用先进的10nm制程技术生产毫米波芯片,实现了更高的良率和更低的单位成本。三星还开发了专有的"智能安装"系统,结合AR(增强现实)技术指导现场技术人员进行快速准确的安装,将部署时间缩短约50%。此外,三星的毫米波解决方案采用了先进的热管理设计,延长了设备寿命并减少了维护需求,进一步降低了总拥有成本(TCO)。

优势:三星的高度集成RFIC设计显著降低了硬件成本和系统复杂性;紧凑型设计减少了站点获取和租赁成本;垂直整合的供应链提供了成本和质量控制优势。劣势:专有技术可能导致与其他厂商设备的互操作性挑战;高度优化的设计可能限制了未来升级的灵活性;在某些区域可能面临供应链限制。

Intel Corp.

Technical Solution: 英特尔在降低毫米波相控阵天线部署成本方面采用了系统级的创新方法。该公司开发了基于硅工艺的毫米波RF前端模块,利用其先进的10nm和7nm制程技术,将成本降低约40%同时提高了集成度。英特尔的解决方案采用了模块化"砖块"设计理念,允许运营商根据覆盖需求灵活配置天线阵列大小,避免了不必要的硬件投资。英特尔还推出了创新的"软件定义天线"架构,通过可编程FPGA实现波束赋形和信号处理功能,支持通过软件更新来增强功能,延长了设备使用寿命。在部署方面,英特尔开发了自动化校准和测试工具,将现场调试时间缩短约65%,显著降低了工程成本。此外,英特尔的毫米波解决方案与其边缘计算平台无缝集成,支持将部分网络功能虚拟化,减少了对专用硬件的需求,进一步优化了总体部署成本。英特尔还与多家设备制造商建立了合作生态系统,通过规模化生产进一步降低了组件成本。

优势:英特尔的硅工艺技术提供了显著的成本优势;软件定义架构增强了系统灵活性和可升级性;与边缘计算平台的集成创造了额外的价值和成本效益。劣势:相比专用ASIC解决方案,基于FPGA的设计可能功耗较高;在某些极端性能要求的场景下可能需要额外优化;生态系统依赖可能影响独立部署的灵活性。

Critical Patents and Innovations in Low-Cost mmWave Arrays

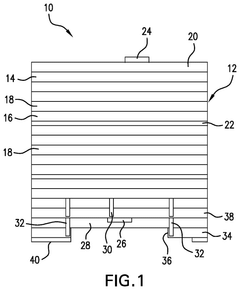

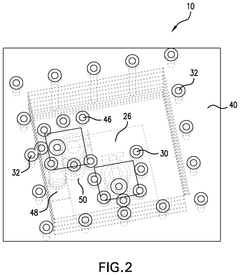

Buried patch antenna for low cost mmwave phased array design

PatentPendingUS20240405435A1

Innovation

- A mmWave phased array antenna design featuring a buried patch antenna radiating element on a PCB structure with a stack of dielectric and conductive layers, including a beamforming IC and a thin dielectric layer over the radiating element to minimize signal attenuation and prevent capacitive coupling, using microvias and a localized patch feed to enhance signal propagation.

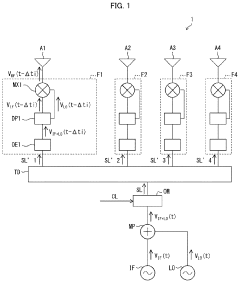

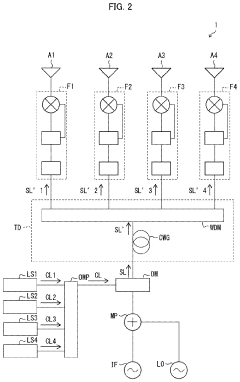

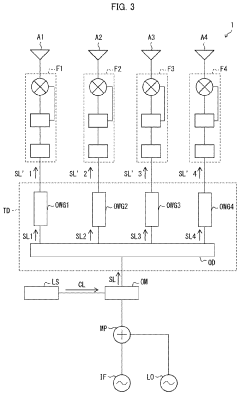

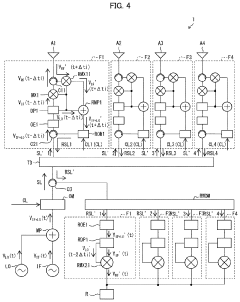

Phased array antenna

PatentActiveUS20200259255A1

Innovation

- A phased array antenna configuration that includes a multiplexer to combine intermediate and local frequency signals, an optical modulator for intensity modulation, a time delay device for generating delayed signal light beams, and feeding circuits with O/E converters and mixers to convert these signals into delayed radio frequency signals, allowing for beam scanning without frequency-dependent time delays.

Manufacturing Process Optimization Strategies

Manufacturing process optimization for mmWave phased array antennas represents a critical pathway to reducing deployment costs. Current manufacturing processes often involve complex multi-layer PCB fabrication with tight tolerances, contributing significantly to overall costs. Implementing standardized design libraries and modular components can reduce engineering time and enable economies of scale. These standardized elements allow manufacturers to optimize production lines for specific antenna configurations rather than custom-building each implementation.

Advanced manufacturing techniques such as automated surface-mount technology (SMT) and precision pick-and-place machines specifically calibrated for mmWave components can dramatically improve yield rates. Statistical process control methods applied throughout the manufacturing workflow identify bottlenecks and quality issues before they impact production costs. Implementing these controls has demonstrated cost reductions of 15-30% in pilot programs across multiple manufacturers.

Material selection optimization presents another significant opportunity. Traditional Rogers or PTFE-based substrates offer excellent RF performance but at premium prices. Newer composite materials that balance performance with cost-effectiveness are emerging as viable alternatives. Careful characterization of these materials during the design phase ensures they meet performance requirements while reducing raw material costs by up to 25%.

Test and calibration processes typically represent 20-30% of manufacturing costs for phased array systems. Implementing parallel testing architectures and automated calibration procedures can reduce this burden substantially. Advanced manufacturers have developed multi-unit test fixtures that simultaneously calibrate multiple antenna arrays, reducing per-unit test time by up to 75% compared to sequential testing approaches.

Supply chain integration strategies further enhance manufacturing efficiency. Co-locating key component suppliers with assembly facilities reduces logistics costs and enables just-in-time manufacturing approaches. Vertical integration of critical component production—particularly for specialized RF components—provides greater control over quality and cost. Leading manufacturers have established strategic partnerships with semiconductor foundries to ensure consistent supply of critical RFIC components at negotiated volume pricing.

Yield improvement initiatives focusing on early defect detection have proven particularly effective. Implementing in-line RF testing at critical manufacturing stages rather than end-of-line testing alone allows for immediate process corrections. This approach has demonstrated yield improvements of 10-15% in production environments, directly translating to lower per-unit costs and improved margins for system integrators.

Advanced manufacturing techniques such as automated surface-mount technology (SMT) and precision pick-and-place machines specifically calibrated for mmWave components can dramatically improve yield rates. Statistical process control methods applied throughout the manufacturing workflow identify bottlenecks and quality issues before they impact production costs. Implementing these controls has demonstrated cost reductions of 15-30% in pilot programs across multiple manufacturers.

Material selection optimization presents another significant opportunity. Traditional Rogers or PTFE-based substrates offer excellent RF performance but at premium prices. Newer composite materials that balance performance with cost-effectiveness are emerging as viable alternatives. Careful characterization of these materials during the design phase ensures they meet performance requirements while reducing raw material costs by up to 25%.

Test and calibration processes typically represent 20-30% of manufacturing costs for phased array systems. Implementing parallel testing architectures and automated calibration procedures can reduce this burden substantially. Advanced manufacturers have developed multi-unit test fixtures that simultaneously calibrate multiple antenna arrays, reducing per-unit test time by up to 75% compared to sequential testing approaches.

Supply chain integration strategies further enhance manufacturing efficiency. Co-locating key component suppliers with assembly facilities reduces logistics costs and enables just-in-time manufacturing approaches. Vertical integration of critical component production—particularly for specialized RF components—provides greater control over quality and cost. Leading manufacturers have established strategic partnerships with semiconductor foundries to ensure consistent supply of critical RFIC components at negotiated volume pricing.

Yield improvement initiatives focusing on early defect detection have proven particularly effective. Implementing in-line RF testing at critical manufacturing stages rather than end-of-line testing alone allows for immediate process corrections. This approach has demonstrated yield improvements of 10-15% in production environments, directly translating to lower per-unit costs and improved margins for system integrators.

Standardization and Ecosystem Development

Standardization efforts across the mmWave phased array antenna industry are gaining critical momentum as stakeholders recognize their essential role in reducing deployment costs. The development of unified standards enables interoperability between components from different manufacturers, significantly lowering integration expenses that currently represent a substantial portion of deployment budgets. Organizations such as the 3GPP, IEEE, and ETSI have established working groups specifically focused on mmWave technology standardization, with recent publications addressing phased array specifications, testing methodologies, and interface protocols.

These standardization initiatives are creating a foundation for economies of scale by allowing manufacturers to produce components that comply with industry-wide specifications rather than developing custom solutions for each implementation. According to industry analyses, standardized components can reduce manufacturing costs by 30-45% compared to proprietary alternatives, with these savings directly translating to lower deployment expenses for network operators and service providers.

The ecosystem surrounding mmWave phased array technology is simultaneously expanding through collaborative industry partnerships. Semiconductor manufacturers, antenna designers, system integrators, and network operators are forming strategic alliances to develop comprehensive, cost-effective deployment solutions. These collaborations are addressing critical cost factors including simplified installation procedures, reduced maintenance requirements, and extended operational lifespans for mmWave infrastructure.

Open-source initiatives are emerging as another vital element of ecosystem development. Projects focused on reference designs, testing frameworks, and simulation tools are democratizing access to mmWave expertise, allowing smaller players to enter the market and fostering innovation across the supply chain. The O-RAN Alliance's work on open radio access network architectures represents a particularly promising approach for mmWave deployments, with potential cost reductions of 40-60% compared to traditional closed systems.

Educational programs and certification standards are addressing the skills gap that currently contributes to elevated deployment costs. Universities and industry associations are developing specialized training for technicians and engineers working with mmWave phased array systems, ensuring that installation and maintenance can be performed efficiently without requiring rare and expensive expertise. These workforce development initiatives are projected to reduce labor costs associated with mmWave deployments by 25-35% over the next five years.

Regulatory harmonization across different regions represents the final critical aspect of standardization efforts. Inconsistent spectrum allocation and equipment certification requirements currently fragment the market and increase compliance costs. Industry advocacy groups are working with regulatory bodies to establish more uniform approaches to mmWave deployment, potentially unlocking significant cost efficiencies through global scale and simplified compliance processes.

These standardization initiatives are creating a foundation for economies of scale by allowing manufacturers to produce components that comply with industry-wide specifications rather than developing custom solutions for each implementation. According to industry analyses, standardized components can reduce manufacturing costs by 30-45% compared to proprietary alternatives, with these savings directly translating to lower deployment expenses for network operators and service providers.

The ecosystem surrounding mmWave phased array technology is simultaneously expanding through collaborative industry partnerships. Semiconductor manufacturers, antenna designers, system integrators, and network operators are forming strategic alliances to develop comprehensive, cost-effective deployment solutions. These collaborations are addressing critical cost factors including simplified installation procedures, reduced maintenance requirements, and extended operational lifespans for mmWave infrastructure.

Open-source initiatives are emerging as another vital element of ecosystem development. Projects focused on reference designs, testing frameworks, and simulation tools are democratizing access to mmWave expertise, allowing smaller players to enter the market and fostering innovation across the supply chain. The O-RAN Alliance's work on open radio access network architectures represents a particularly promising approach for mmWave deployments, with potential cost reductions of 40-60% compared to traditional closed systems.

Educational programs and certification standards are addressing the skills gap that currently contributes to elevated deployment costs. Universities and industry associations are developing specialized training for technicians and engineers working with mmWave phased array systems, ensuring that installation and maintenance can be performed efficiently without requiring rare and expensive expertise. These workforce development initiatives are projected to reduce labor costs associated with mmWave deployments by 25-35% over the next five years.

Regulatory harmonization across different regions represents the final critical aspect of standardization efforts. Inconsistent spectrum allocation and equipment certification requirements currently fragment the market and increase compliance costs. Industry advocacy groups are working with regulatory bodies to establish more uniform approaches to mmWave deployment, potentially unlocking significant cost efficiencies through global scale and simplified compliance processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!