How to Ensure Quality Control in Isocyanate Applications?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate QC Objectives

Quality control in isocyanate applications is a critical aspect of ensuring product safety, performance, and regulatory compliance. The primary objectives of quality control in this domain encompass several key areas that address the unique properties and challenges associated with isocyanates.

One of the foremost objectives is to maintain the purity and stability of isocyanate compounds throughout the production and application processes. This involves implementing rigorous testing protocols to detect and prevent contamination, as well as monitoring storage conditions to minimize degradation. Isocyanates are highly reactive substances, and even small impurities can significantly impact their performance and safety characteristics.

Another crucial objective is to ensure precise control over the isocyanate-to-polyol ratio in polyurethane formulations. This ratio directly affects the final product's physical and chemical properties, including strength, flexibility, and durability. Achieving consistent and accurate mixing ratios is essential for producing high-quality polyurethane products that meet specified performance criteria.

Monitoring and controlling reaction conditions form another vital aspect of isocyanate quality control. This includes maintaining optimal temperature, pressure, and humidity levels during processing and curing stages. Proper control of these parameters is crucial for achieving desired product characteristics and preventing defects such as incomplete curing or excessive foaming.

Safety considerations are paramount in isocyanate applications due to their potential health hazards. Quality control objectives must include stringent measures to prevent worker exposure and environmental release. This involves implementing robust containment systems, personal protective equipment protocols, and air quality monitoring in production and application areas.

Ensuring batch-to-batch consistency is another key objective, particularly for large-scale industrial applications. This requires comprehensive documentation and traceability systems, as well as statistical process control methods to identify and address variations in raw materials or production processes that could affect product quality.

Compliance with regulatory standards and industry specifications is an overarching objective of isocyanate quality control. This includes adhering to guidelines set by organizations such as OSHA, EPA, and industry-specific bodies. Regular audits and certification processes are essential to demonstrate ongoing compliance and maintain product quality standards.

Lastly, continuous improvement in quality control methodologies is a critical objective. This involves staying abreast of technological advancements in analytical techniques, investing in state-of-the-art testing equipment, and fostering a culture of innovation in quality assurance practices. By continuously refining and enhancing quality control processes, manufacturers can improve product performance, reduce waste, and maintain a competitive edge in the market.

One of the foremost objectives is to maintain the purity and stability of isocyanate compounds throughout the production and application processes. This involves implementing rigorous testing protocols to detect and prevent contamination, as well as monitoring storage conditions to minimize degradation. Isocyanates are highly reactive substances, and even small impurities can significantly impact their performance and safety characteristics.

Another crucial objective is to ensure precise control over the isocyanate-to-polyol ratio in polyurethane formulations. This ratio directly affects the final product's physical and chemical properties, including strength, flexibility, and durability. Achieving consistent and accurate mixing ratios is essential for producing high-quality polyurethane products that meet specified performance criteria.

Monitoring and controlling reaction conditions form another vital aspect of isocyanate quality control. This includes maintaining optimal temperature, pressure, and humidity levels during processing and curing stages. Proper control of these parameters is crucial for achieving desired product characteristics and preventing defects such as incomplete curing or excessive foaming.

Safety considerations are paramount in isocyanate applications due to their potential health hazards. Quality control objectives must include stringent measures to prevent worker exposure and environmental release. This involves implementing robust containment systems, personal protective equipment protocols, and air quality monitoring in production and application areas.

Ensuring batch-to-batch consistency is another key objective, particularly for large-scale industrial applications. This requires comprehensive documentation and traceability systems, as well as statistical process control methods to identify and address variations in raw materials or production processes that could affect product quality.

Compliance with regulatory standards and industry specifications is an overarching objective of isocyanate quality control. This includes adhering to guidelines set by organizations such as OSHA, EPA, and industry-specific bodies. Regular audits and certification processes are essential to demonstrate ongoing compliance and maintain product quality standards.

Lastly, continuous improvement in quality control methodologies is a critical objective. This involves staying abreast of technological advancements in analytical techniques, investing in state-of-the-art testing equipment, and fostering a culture of innovation in quality assurance practices. By continuously refining and enhancing quality control processes, manufacturers can improve product performance, reduce waste, and maintain a competitive edge in the market.

Market Demand Analysis

The market demand for quality control in isocyanate applications has been steadily increasing due to the growing use of isocyanates in various industries. Isocyanates are crucial components in the production of polyurethanes, which find extensive applications in automotive, construction, furniture, and electronics sectors. The global polyurethane market, driven by isocyanate demand, is projected to reach significant growth in the coming years.

Quality control in isocyanate applications is becoming increasingly critical due to stringent regulations and safety concerns. Isocyanates are known for their potential health hazards, particularly respiratory issues, making proper handling and application essential. This has led to a surge in demand for advanced quality control measures and technologies across the supply chain, from manufacturing to end-use applications.

The automotive industry represents a major market for isocyanate-based products, particularly in the production of seat cushions, headliners, and insulation materials. With the automotive sector's emphasis on lightweight materials and improved fuel efficiency, the demand for high-quality polyurethane components is expected to rise, driving the need for robust quality control processes.

The construction industry is another significant consumer of isocyanate-based products, primarily in insulation materials and sealants. As energy efficiency standards become more stringent worldwide, the demand for high-performance insulation materials is increasing, necessitating advanced quality control measures to ensure consistent product performance and safety.

The furniture industry also contributes substantially to the market demand for quality-controlled isocyanate applications. Memory foam mattresses and upholstered furniture rely heavily on polyurethane foams, requiring precise control of isocyanate reactions to achieve desired comfort and durability properties.

Environmental concerns and sustainability initiatives are shaping market trends in isocyanate applications. There is a growing demand for bio-based isocyanates and environmentally friendly production processes, which in turn requires sophisticated quality control measures to ensure product consistency and performance.

The electronics industry is emerging as a promising market for isocyanate applications, particularly in the production of protective coatings and encapsulants for electronic components. As electronic devices become more compact and sensitive, the need for high-quality, precisely controlled isocyanate-based materials is expected to increase.

Overall, the market demand for quality control in isocyanate applications is driven by a combination of regulatory pressures, safety concerns, performance requirements, and sustainability goals across multiple industries. This trend is expected to continue, fostering innovation in quality control technologies and methodologies specific to isocyanate handling and processing.

Quality control in isocyanate applications is becoming increasingly critical due to stringent regulations and safety concerns. Isocyanates are known for their potential health hazards, particularly respiratory issues, making proper handling and application essential. This has led to a surge in demand for advanced quality control measures and technologies across the supply chain, from manufacturing to end-use applications.

The automotive industry represents a major market for isocyanate-based products, particularly in the production of seat cushions, headliners, and insulation materials. With the automotive sector's emphasis on lightweight materials and improved fuel efficiency, the demand for high-quality polyurethane components is expected to rise, driving the need for robust quality control processes.

The construction industry is another significant consumer of isocyanate-based products, primarily in insulation materials and sealants. As energy efficiency standards become more stringent worldwide, the demand for high-performance insulation materials is increasing, necessitating advanced quality control measures to ensure consistent product performance and safety.

The furniture industry also contributes substantially to the market demand for quality-controlled isocyanate applications. Memory foam mattresses and upholstered furniture rely heavily on polyurethane foams, requiring precise control of isocyanate reactions to achieve desired comfort and durability properties.

Environmental concerns and sustainability initiatives are shaping market trends in isocyanate applications. There is a growing demand for bio-based isocyanates and environmentally friendly production processes, which in turn requires sophisticated quality control measures to ensure product consistency and performance.

The electronics industry is emerging as a promising market for isocyanate applications, particularly in the production of protective coatings and encapsulants for electronic components. As electronic devices become more compact and sensitive, the need for high-quality, precisely controlled isocyanate-based materials is expected to increase.

Overall, the market demand for quality control in isocyanate applications is driven by a combination of regulatory pressures, safety concerns, performance requirements, and sustainability goals across multiple industries. This trend is expected to continue, fostering innovation in quality control technologies and methodologies specific to isocyanate handling and processing.

Challenges in Isocyanate QC

Quality control in isocyanate applications presents several significant challenges due to the reactive nature of these compounds and their sensitivity to environmental factors. One of the primary difficulties lies in maintaining the stability of isocyanates during storage and handling. These chemicals are highly reactive with moisture, which can lead to unwanted side reactions and degradation of product quality. This necessitates stringent storage conditions and careful handling procedures to prevent exposure to humidity.

Another major challenge is the precise control of reaction conditions during isocyanate applications. Temperature, pressure, and mixing ratios must be carefully monitored and adjusted to ensure optimal product performance. Even slight deviations can result in significant variations in the final product's properties, such as hardness, flexibility, or adhesion strength. This requires sophisticated process control systems and highly trained operators to maintain consistency across production batches.

The measurement and analysis of isocyanate content pose additional difficulties in quality control. Traditional analytical methods often involve time-consuming and complex procedures, which can delay production and increase costs. Moreover, the high reactivity of isocyanates can interfere with accurate measurements, leading to potential errors in quality assessment. This challenge has driven the need for more rapid and reliable analytical techniques specifically tailored for isocyanate applications.

Safety considerations also play a crucial role in isocyanate quality control. These compounds can be hazardous if not handled properly, potentially causing respiratory irritation and sensitization. Implementing robust safety protocols while maintaining efficient production processes requires a delicate balance. This includes the use of appropriate personal protective equipment, proper ventilation systems, and regular health monitoring for workers exposed to isocyanates.

The variability in raw material quality can further complicate quality control efforts. Isocyanates and their precursors may exhibit batch-to-batch variations that can impact the final product's performance. This necessitates rigorous incoming material inspection and potentially adjustments to process parameters to compensate for these variations. Establishing strong supplier relationships and implementing comprehensive raw material specifications are essential strategies to mitigate this challenge.

Lastly, the increasing demand for environmentally friendly and sustainable products presents new quality control challenges in isocyanate applications. Developing and implementing green chemistry principles while maintaining product performance requires innovative approaches to formulation and process design. This includes exploring bio-based isocyanates, reducing volatile organic compound (VOC) emissions, and optimizing reaction efficiencies to minimize waste generation.

Another major challenge is the precise control of reaction conditions during isocyanate applications. Temperature, pressure, and mixing ratios must be carefully monitored and adjusted to ensure optimal product performance. Even slight deviations can result in significant variations in the final product's properties, such as hardness, flexibility, or adhesion strength. This requires sophisticated process control systems and highly trained operators to maintain consistency across production batches.

The measurement and analysis of isocyanate content pose additional difficulties in quality control. Traditional analytical methods often involve time-consuming and complex procedures, which can delay production and increase costs. Moreover, the high reactivity of isocyanates can interfere with accurate measurements, leading to potential errors in quality assessment. This challenge has driven the need for more rapid and reliable analytical techniques specifically tailored for isocyanate applications.

Safety considerations also play a crucial role in isocyanate quality control. These compounds can be hazardous if not handled properly, potentially causing respiratory irritation and sensitization. Implementing robust safety protocols while maintaining efficient production processes requires a delicate balance. This includes the use of appropriate personal protective equipment, proper ventilation systems, and regular health monitoring for workers exposed to isocyanates.

The variability in raw material quality can further complicate quality control efforts. Isocyanates and their precursors may exhibit batch-to-batch variations that can impact the final product's performance. This necessitates rigorous incoming material inspection and potentially adjustments to process parameters to compensate for these variations. Establishing strong supplier relationships and implementing comprehensive raw material specifications are essential strategies to mitigate this challenge.

Lastly, the increasing demand for environmentally friendly and sustainable products presents new quality control challenges in isocyanate applications. Developing and implementing green chemistry principles while maintaining product performance requires innovative approaches to formulation and process design. This includes exploring bio-based isocyanates, reducing volatile organic compound (VOC) emissions, and optimizing reaction efficiencies to minimize waste generation.

Current QC Techniques

01 Chemical analysis methods for isocyanate quality control

Various chemical analysis techniques are employed to assess the quality of isocyanates. These methods may include spectroscopic analysis, chromatography, and titration to determine purity, composition, and reactivity of isocyanate compounds. Such analyses help ensure the consistency and reliability of isocyanate products in industrial applications.- Analytical methods for isocyanate quality control: Various analytical techniques are employed to assess the quality of isocyanates. These methods may include spectroscopic analysis, chromatography, and chemical titration. Such techniques help in determining the purity, composition, and reactivity of isocyanates, ensuring they meet the required specifications for industrial applications.

- Process monitoring and control in isocyanate production: Implementing robust process monitoring and control systems is crucial for maintaining isocyanate quality. This involves real-time monitoring of reaction parameters, such as temperature, pressure, and reactant ratios. Advanced control algorithms and feedback systems can be used to make adjustments during production, ensuring consistent quality and minimizing defects.

- Purification and separation techniques: Purification and separation methods play a vital role in isocyanate quality control. These may include distillation, crystallization, and membrane separation processes. Such techniques help remove impurities and byproducts, resulting in higher-quality isocyanates that meet stringent industry standards.

- Storage and handling protocols: Proper storage and handling of isocyanates are essential for maintaining their quality. This includes controlling environmental factors such as temperature, humidity, and exposure to contaminants. Implementing appropriate packaging, transportation, and storage protocols helps prevent degradation and ensures the isocyanates retain their desired properties until use.

- Quality control in isocyanate-based product formulation: Quality control measures extend to the formulation of products using isocyanates. This involves careful selection and testing of raw materials, optimizing reaction conditions, and evaluating the final product properties. Techniques such as rheological analysis, curing studies, and performance testing are employed to ensure the finished products meet the required specifications.

02 Process monitoring and control in isocyanate production

Implementing real-time monitoring and control systems in isocyanate production processes is crucial for maintaining quality. This may involve the use of sensors, automated sampling, and advanced process control algorithms to continuously assess and adjust production parameters, ensuring consistent product quality and minimizing variations.Expand Specific Solutions03 Impurity detection and removal in isocyanates

Identifying and eliminating impurities is a critical aspect of isocyanate quality control. Advanced detection methods, such as mass spectrometry or high-performance liquid chromatography, are used to identify trace contaminants. Purification techniques, including distillation or recrystallization, may be employed to remove these impurities and improve product quality.Expand Specific Solutions04 Stability and storage considerations for isocyanates

Ensuring the stability of isocyanates during storage and transportation is essential for maintaining product quality. This involves developing appropriate packaging materials, storage conditions, and handling procedures to prevent degradation or unwanted reactions. Stability testing and shelf-life studies are conducted to determine optimal storage conditions and expiration dates.Expand Specific Solutions05 Quality control in isocyanate-based polymer production

Quality control measures for isocyanates extend to their use in polymer production, such as polyurethanes. This includes monitoring reaction kinetics, assessing the physical properties of the resulting polymers, and ensuring consistent performance in end-use applications. Techniques like rheometry, thermal analysis, and mechanical testing are employed to evaluate the quality of isocyanate-based polymers.Expand Specific Solutions

Key Industry Players

The market for isocyanate applications is in a mature growth stage, with a global market size estimated to exceed $30 billion by 2025. The technology has reached a high level of maturity, with established players like Wanhua Chemical, Covestro, and BASF dominating the industry. These companies have developed advanced quality control processes and are investing in R&D to improve product performance and sustainability. Emerging players such as Hanwha Solutions and Resonac are also making strides in innovation, particularly in eco-friendly formulations. The competitive landscape is characterized by a focus on product differentiation, cost optimization, and expanding applications in sectors like automotive, construction, and electronics.

Wanhua Chemical Group Co., Ltd.

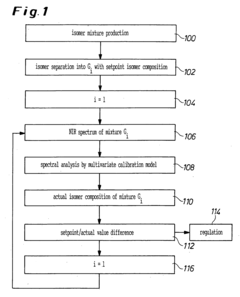

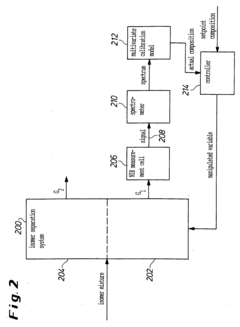

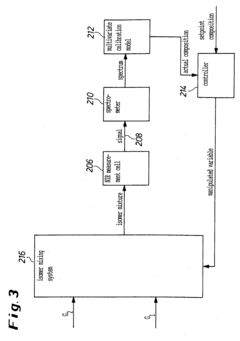

Technical Solution: Wanhua Chemical Group has developed advanced quality control systems for isocyanate applications, focusing on real-time monitoring and process optimization. Their approach includes implementing inline NIR spectroscopy for continuous composition analysis[1], coupled with advanced statistical process control (SPC) techniques. They have also introduced a proprietary reactive purge compound technology that significantly reduces contamination risks during product changeovers[2]. Additionally, Wanhua has implemented a comprehensive traceability system that tracks raw materials through the entire production process, ensuring consistent quality and facilitating rapid problem identification and resolution[3].

Strengths: Cutting-edge monitoring technology, innovative purge compounds, and comprehensive traceability. Weaknesses: Potentially higher implementation costs and complexity in training personnel for advanced systems.

Covestro Deutschland AG

Technical Solution: Covestro has developed a multi-faceted approach to quality control in isocyanate applications. Their system incorporates advanced robotics and automation for precise dosing and mixing, minimizing human error[4]. They have also implemented a closed-loop feedback system that continuously adjusts process parameters based on real-time quality measurements. Covestro's quality control strategy includes the use of high-precision rheometers for viscosity monitoring and control, ensuring consistent product properties[5]. Furthermore, they have developed a novel online moisture detection system specifically for isocyanate handling, which helps prevent unwanted side reactions and maintain product integrity[6].

Strengths: High level of automation, advanced process control, and specialized moisture detection. Weaknesses: Potential over-reliance on technology and high initial investment costs.

Innovative QC Technologies

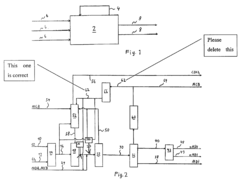

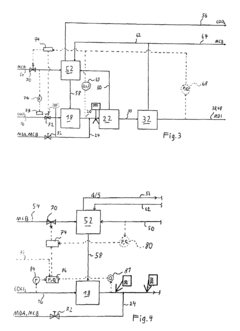

Process for controlling a production process

PatentInactiveEP1932828A2

Innovation

- The process controls the phosgene and solvent feed streams as primary variables, allowing for independent control of subsystems and optimization of the isocyanate production process, enabling the recovery of unused reactants and reducing unwanted substances, thereby stabilizing and automating the process while minimizing production costs.

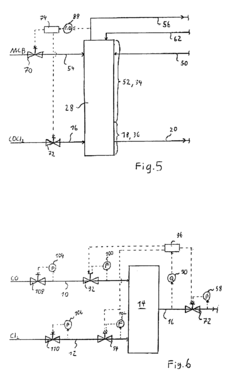

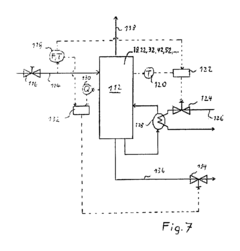

Method and device for determining the isomer composition in isocyanate production processes

PatentActiveUS20050003553A1

Innovation

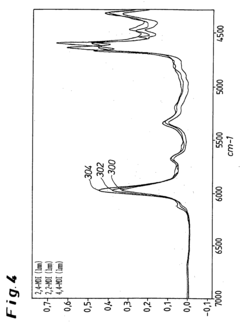

- The use of near-infrared (NIR) spectroscopy in conjunction with chemometric calibration models to determine isomer concentrations in isocyanate isomer mixtures, allowing for real-time monitoring and regulation of isomer production systems, eliminating the need for manual sampling and reducing time delays.

Safety Regulations

Safety regulations play a crucial role in ensuring quality control and protecting workers in isocyanate applications. The Occupational Safety and Health Administration (OSHA) has established stringent guidelines for handling isocyanates, which are known for their potential health hazards. These regulations mandate the implementation of engineering controls, such as proper ventilation systems and enclosed processes, to minimize worker exposure to isocyanate vapors and aerosols.

Personal protective equipment (PPE) is another critical aspect of safety regulations. Workers must wear appropriate respiratory protection, chemical-resistant gloves, and protective clothing when handling isocyanates. Regular fit testing and maintenance of respirators are essential to ensure their effectiveness. Additionally, employers are required to provide comprehensive training programs to educate workers about the hazards associated with isocyanates and proper handling procedures.

Exposure monitoring is a key component of safety regulations in isocyanate applications. Employers must conduct regular air sampling to assess worker exposure levels and ensure they remain below permissible limits. This data helps in evaluating the effectiveness of control measures and identifying areas for improvement. In cases where exposure levels exceed recommended limits, immediate corrective actions must be taken.

Emergency response procedures are also mandated by safety regulations. Facilities working with isocyanates must have well-defined protocols for spill containment, decontamination, and medical emergencies. This includes the availability of eyewash stations, safety showers, and first aid equipment in easily accessible locations.

Record-keeping and documentation are essential aspects of compliance with safety regulations. Employers must maintain detailed records of exposure monitoring results, medical surveillance, training sessions, and incident reports. These records serve as valuable resources for continuous improvement of safety practices and demonstrate compliance during regulatory inspections.

Safety regulations also address the storage and handling of isocyanates. Proper storage facilities with temperature control, spill containment, and fire suppression systems are required. Transportation of isocyanates must comply with Department of Transportation (DOT) regulations, including proper labeling, packaging, and documentation.

Regular safety audits and inspections are mandated to ensure ongoing compliance with regulations. These audits help identify potential hazards, assess the effectiveness of control measures, and implement corrective actions. Continuous improvement of safety practices is encouraged through the review and update of safety protocols based on new research, incident investigations, and industry best practices.

Personal protective equipment (PPE) is another critical aspect of safety regulations. Workers must wear appropriate respiratory protection, chemical-resistant gloves, and protective clothing when handling isocyanates. Regular fit testing and maintenance of respirators are essential to ensure their effectiveness. Additionally, employers are required to provide comprehensive training programs to educate workers about the hazards associated with isocyanates and proper handling procedures.

Exposure monitoring is a key component of safety regulations in isocyanate applications. Employers must conduct regular air sampling to assess worker exposure levels and ensure they remain below permissible limits. This data helps in evaluating the effectiveness of control measures and identifying areas for improvement. In cases where exposure levels exceed recommended limits, immediate corrective actions must be taken.

Emergency response procedures are also mandated by safety regulations. Facilities working with isocyanates must have well-defined protocols for spill containment, decontamination, and medical emergencies. This includes the availability of eyewash stations, safety showers, and first aid equipment in easily accessible locations.

Record-keeping and documentation are essential aspects of compliance with safety regulations. Employers must maintain detailed records of exposure monitoring results, medical surveillance, training sessions, and incident reports. These records serve as valuable resources for continuous improvement of safety practices and demonstrate compliance during regulatory inspections.

Safety regulations also address the storage and handling of isocyanates. Proper storage facilities with temperature control, spill containment, and fire suppression systems are required. Transportation of isocyanates must comply with Department of Transportation (DOT) regulations, including proper labeling, packaging, and documentation.

Regular safety audits and inspections are mandated to ensure ongoing compliance with regulations. These audits help identify potential hazards, assess the effectiveness of control measures, and implement corrective actions. Continuous improvement of safety practices is encouraged through the review and update of safety protocols based on new research, incident investigations, and industry best practices.

Environmental Impact

The environmental impact of isocyanate applications is a critical consideration in quality control processes. Isocyanates, widely used in the production of polyurethanes, can pose significant risks to both human health and the environment if not properly managed. Emissions from isocyanate production and application processes can contribute to air pollution, particularly in the form of volatile organic compounds (VOCs) and hazardous air pollutants (HAPs).

Water contamination is another potential environmental concern associated with isocyanate applications. Improper disposal or accidental release of isocyanates can lead to the contamination of water bodies, affecting aquatic ecosystems and potentially entering the food chain. Furthermore, the production of isocyanates often involves the use of fossil fuels, contributing to greenhouse gas emissions and climate change.

To mitigate these environmental impacts, quality control measures must focus on minimizing emissions and waste throughout the entire lifecycle of isocyanate applications. This includes implementing closed-loop systems in production facilities to reduce fugitive emissions and optimizing application techniques to minimize overspray and material waste. Advanced filtration and scrubbing technologies can be employed to capture and treat air emissions, while proper wastewater treatment systems are essential for managing liquid waste streams.

The development and adoption of more environmentally friendly alternatives to traditional isocyanates is an emerging trend in the industry. Bio-based isocyanates derived from renewable resources offer a promising avenue for reducing the environmental footprint of polyurethane production. Additionally, the use of water-based or solvent-free formulations can significantly reduce VOC emissions associated with isocyanate applications.

Lifecycle assessment (LCA) is a valuable tool for evaluating the environmental impact of isocyanate applications from cradle to grave. By conducting comprehensive LCAs, manufacturers can identify hotspots in their production and application processes, enabling targeted improvements in environmental performance. This approach also supports the development of more sustainable products and processes, aligning with growing consumer demand for environmentally responsible solutions.

Regulatory compliance plays a crucial role in ensuring environmental protection in isocyanate applications. Quality control measures must adhere to increasingly stringent environmental regulations, such as emission limits, waste management protocols, and reporting requirements. Proactive engagement with regulatory bodies and industry associations can help companies stay ahead of evolving environmental standards and implement best practices for environmental stewardship.

Water contamination is another potential environmental concern associated with isocyanate applications. Improper disposal or accidental release of isocyanates can lead to the contamination of water bodies, affecting aquatic ecosystems and potentially entering the food chain. Furthermore, the production of isocyanates often involves the use of fossil fuels, contributing to greenhouse gas emissions and climate change.

To mitigate these environmental impacts, quality control measures must focus on minimizing emissions and waste throughout the entire lifecycle of isocyanate applications. This includes implementing closed-loop systems in production facilities to reduce fugitive emissions and optimizing application techniques to minimize overspray and material waste. Advanced filtration and scrubbing technologies can be employed to capture and treat air emissions, while proper wastewater treatment systems are essential for managing liquid waste streams.

The development and adoption of more environmentally friendly alternatives to traditional isocyanates is an emerging trend in the industry. Bio-based isocyanates derived from renewable resources offer a promising avenue for reducing the environmental footprint of polyurethane production. Additionally, the use of water-based or solvent-free formulations can significantly reduce VOC emissions associated with isocyanate applications.

Lifecycle assessment (LCA) is a valuable tool for evaluating the environmental impact of isocyanate applications from cradle to grave. By conducting comprehensive LCAs, manufacturers can identify hotspots in their production and application processes, enabling targeted improvements in environmental performance. This approach also supports the development of more sustainable products and processes, aligning with growing consumer demand for environmentally responsible solutions.

Regulatory compliance plays a crucial role in ensuring environmental protection in isocyanate applications. Quality control measures must adhere to increasingly stringent environmental regulations, such as emission limits, waste management protocols, and reporting requirements. Proactive engagement with regulatory bodies and industry associations can help companies stay ahead of evolving environmental standards and implement best practices for environmental stewardship.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!