How to Evaluate Polymeric Emulsions via Dynamic Light Scattering

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Dynamic Light Scattering Technology Background and Objectives

Dynamic Light Scattering (DLS) has evolved significantly since its inception in the 1960s, transforming from a specialized laboratory technique into an essential analytical tool across multiple industries. The technology leverages the Brownian motion of particles in suspension to determine their size distribution by analyzing the fluctuations in scattered light intensity. This fundamental principle has remained unchanged, while the instrumentation and analytical capabilities have advanced dramatically over the decades.

The evolution of DLS technology has been marked by significant improvements in laser technology, detector sensitivity, and computational algorithms. Early systems were limited by bulky equipment and manual analysis, whereas modern DLS instruments offer automated measurements with sophisticated data processing capabilities. The miniaturization of components and integration with other analytical techniques have further expanded its applications in various fields.

In the context of polymeric emulsions, DLS has become particularly valuable due to its non-destructive nature and ability to analyze samples across a wide size range (typically from 1 nm to 10 μm). The technology enables researchers to characterize critical parameters such as particle size distribution, polydispersity index, and zeta potential—all crucial for understanding emulsion stability and performance.

Recent technological advancements have focused on enhancing the resolution and sensitivity of DLS measurements, particularly for complex systems like polymeric emulsions that often contain multiple particle populations. Multi-angle DLS systems have emerged to provide more comprehensive characterization, while advances in correlation algorithms have improved the accuracy of size distribution analyses for polydisperse samples.

The primary objective of DLS technology in polymeric emulsion evaluation is to provide rapid, reliable, and reproducible characterization of particle properties without disturbing the sample's native state. This includes monitoring stability over time, detecting aggregation phenomena, and assessing the impact of formulation changes on particle characteristics.

Future development trajectories for DLS technology include integration with artificial intelligence for improved data interpretation, combination with complementary techniques for multiparameter analysis, and development of in-line monitoring systems for real-time process control in industrial settings. These advancements aim to address current limitations related to the analysis of highly concentrated samples and complex mixtures.

The continued evolution of DLS technology is expected to further enhance its capabilities for polymeric emulsion characterization, supporting innovation in industries ranging from pharmaceuticals and cosmetics to paints and food products, where emulsion stability and performance are critical quality attributes.

The evolution of DLS technology has been marked by significant improvements in laser technology, detector sensitivity, and computational algorithms. Early systems were limited by bulky equipment and manual analysis, whereas modern DLS instruments offer automated measurements with sophisticated data processing capabilities. The miniaturization of components and integration with other analytical techniques have further expanded its applications in various fields.

In the context of polymeric emulsions, DLS has become particularly valuable due to its non-destructive nature and ability to analyze samples across a wide size range (typically from 1 nm to 10 μm). The technology enables researchers to characterize critical parameters such as particle size distribution, polydispersity index, and zeta potential—all crucial for understanding emulsion stability and performance.

Recent technological advancements have focused on enhancing the resolution and sensitivity of DLS measurements, particularly for complex systems like polymeric emulsions that often contain multiple particle populations. Multi-angle DLS systems have emerged to provide more comprehensive characterization, while advances in correlation algorithms have improved the accuracy of size distribution analyses for polydisperse samples.

The primary objective of DLS technology in polymeric emulsion evaluation is to provide rapid, reliable, and reproducible characterization of particle properties without disturbing the sample's native state. This includes monitoring stability over time, detecting aggregation phenomena, and assessing the impact of formulation changes on particle characteristics.

Future development trajectories for DLS technology include integration with artificial intelligence for improved data interpretation, combination with complementary techniques for multiparameter analysis, and development of in-line monitoring systems for real-time process control in industrial settings. These advancements aim to address current limitations related to the analysis of highly concentrated samples and complex mixtures.

The continued evolution of DLS technology is expected to further enhance its capabilities for polymeric emulsion characterization, supporting innovation in industries ranging from pharmaceuticals and cosmetics to paints and food products, where emulsion stability and performance are critical quality attributes.

Market Applications and Demand for Polymeric Emulsion Analysis

The global market for polymeric emulsion analysis technologies has experienced significant growth in recent years, driven by increasing demand across multiple industries. The pharmaceutical sector represents one of the largest markets, where precise characterization of drug delivery systems and formulations is critical for product development and quality control. Dynamic Light Scattering (DLS) has become an essential analytical tool in this space, enabling researchers to evaluate particle size distribution, stability, and aggregation behavior of polymeric emulsions used in drug formulations.

In the cosmetics and personal care industry, the demand for advanced emulsion analysis has surged due to consumer preferences for stable, long-lasting products with specific sensory attributes. Manufacturers require precise methods to evaluate the physical properties of their formulations during development and throughout the product lifecycle. DLS technology provides valuable insights into emulsion stability and particle characteristics that directly correlate with product performance and shelf life.

The paints and coatings sector represents another significant market for polymeric emulsion analysis. With the global shift toward water-based formulations due to environmental regulations limiting volatile organic compounds (VOCs), manufacturers increasingly rely on sophisticated analytical techniques to develop high-performance products. DLS enables the evaluation of latex particle size and distribution, which directly impacts coating properties such as gloss, durability, and application behavior.

Food and beverage manufacturers constitute a growing market segment for emulsion analysis technologies. The industry faces increasing pressure to develop stable, natural formulations with clean labels while maintaining desirable sensory properties. DLS provides critical data on emulsion droplet size and stability, helping formulators optimize recipes and processing conditions to achieve desired product characteristics.

The academic and research institution segment also drives substantial demand for advanced analytical capabilities in polymeric emulsion characterization. As fundamental research in colloid science and materials engineering continues to expand, DLS has become a standard technique in laboratories worldwide, supporting both basic research and applied development projects.

Geographically, North America and Europe currently lead the market for polymeric emulsion analysis technologies, with established research infrastructure and stringent regulatory requirements driving adoption. However, the Asia-Pacific region is experiencing the fastest growth rate, fueled by rapid industrialization, increasing R&D investments, and expanding manufacturing capabilities in countries like China, India, and South Korea.

Market analysts project continued growth in demand for sophisticated emulsion analysis technologies, particularly those offering enhanced capabilities such as non-invasive measurements, high sensitivity for polydisperse systems, and automated data interpretation features. As industries continue to develop more complex formulations with specific performance requirements, the value proposition of advanced analytical techniques like DLS will likely strengthen further.

In the cosmetics and personal care industry, the demand for advanced emulsion analysis has surged due to consumer preferences for stable, long-lasting products with specific sensory attributes. Manufacturers require precise methods to evaluate the physical properties of their formulations during development and throughout the product lifecycle. DLS technology provides valuable insights into emulsion stability and particle characteristics that directly correlate with product performance and shelf life.

The paints and coatings sector represents another significant market for polymeric emulsion analysis. With the global shift toward water-based formulations due to environmental regulations limiting volatile organic compounds (VOCs), manufacturers increasingly rely on sophisticated analytical techniques to develop high-performance products. DLS enables the evaluation of latex particle size and distribution, which directly impacts coating properties such as gloss, durability, and application behavior.

Food and beverage manufacturers constitute a growing market segment for emulsion analysis technologies. The industry faces increasing pressure to develop stable, natural formulations with clean labels while maintaining desirable sensory properties. DLS provides critical data on emulsion droplet size and stability, helping formulators optimize recipes and processing conditions to achieve desired product characteristics.

The academic and research institution segment also drives substantial demand for advanced analytical capabilities in polymeric emulsion characterization. As fundamental research in colloid science and materials engineering continues to expand, DLS has become a standard technique in laboratories worldwide, supporting both basic research and applied development projects.

Geographically, North America and Europe currently lead the market for polymeric emulsion analysis technologies, with established research infrastructure and stringent regulatory requirements driving adoption. However, the Asia-Pacific region is experiencing the fastest growth rate, fueled by rapid industrialization, increasing R&D investments, and expanding manufacturing capabilities in countries like China, India, and South Korea.

Market analysts project continued growth in demand for sophisticated emulsion analysis technologies, particularly those offering enhanced capabilities such as non-invasive measurements, high sensitivity for polydisperse systems, and automated data interpretation features. As industries continue to develop more complex formulations with specific performance requirements, the value proposition of advanced analytical techniques like DLS will likely strengthen further.

Current DLS Techniques and Challenges for Polymeric Emulsions

Dynamic Light Scattering (DLS) has emerged as a powerful analytical technique for characterizing polymeric emulsions, offering insights into particle size distribution, stability, and molecular interactions. Current DLS methodologies employ laser light sources that scatter when encountering particles in suspension, with the intensity fluctuations analyzed to determine particle characteristics.

Standard DLS instruments typically utilize photon correlation spectroscopy with detection angles ranging from 90° to 173°, allowing for measurements of particles from approximately 0.3 nm to 10 μm. Modern systems incorporate multi-angle detection capabilities, enhancing resolution and accuracy for polydisperse samples common in polymeric emulsions.

Advanced DLS techniques include non-invasive back-scatter (NIBS) technology, which reduces multiple scattering effects and improves signal quality for concentrated samples. Cross-correlation approaches have also been developed to address multiple scattering challenges in higher concentration emulsions, extending the application range of DLS for industrial formulations.

Despite these advancements, several significant challenges persist in DLS analysis of polymeric emulsions. Polydispersity remains a fundamental limitation, as conventional algorithms struggle to accurately resolve multimodal distributions typical in complex polymer systems. The presence of large particles can overwhelm signals from smaller components, leading to biased results that fail to capture the complete particle size profile.

Sample preparation introduces additional complexities, as dilution—often necessary to reduce multiple scattering—may disrupt the equilibrium state of the emulsion, altering the very properties being measured. Temperature control during measurement is critical yet challenging, as even minor fluctuations can significantly impact Brownian motion and consequently the calculated particle sizes.

For charged polymeric systems, electrostatic interactions can influence diffusion behavior, complicating the interpretation of DLS data. The assumption that particles are spherical—fundamental to standard DLS algorithms—often proves problematic for polymeric emulsions containing non-spherical or irregularly shaped particles.

Real-time monitoring presents another challenge, as traditional DLS instruments typically provide only snapshot measurements rather than continuous analysis of dynamic processes such as aggregation, coalescence, or phase separation. This limitation restricts the application of DLS in studying emulsion stability kinetics under processing conditions.

Data interpretation remains highly dependent on operator expertise, with fitting algorithms requiring careful selection of parameters to avoid artifacts or misinterpretation. The lack of standardized protocols specific to polymeric emulsions further complicates cross-laboratory comparisons and validation of results.

Standard DLS instruments typically utilize photon correlation spectroscopy with detection angles ranging from 90° to 173°, allowing for measurements of particles from approximately 0.3 nm to 10 μm. Modern systems incorporate multi-angle detection capabilities, enhancing resolution and accuracy for polydisperse samples common in polymeric emulsions.

Advanced DLS techniques include non-invasive back-scatter (NIBS) technology, which reduces multiple scattering effects and improves signal quality for concentrated samples. Cross-correlation approaches have also been developed to address multiple scattering challenges in higher concentration emulsions, extending the application range of DLS for industrial formulations.

Despite these advancements, several significant challenges persist in DLS analysis of polymeric emulsions. Polydispersity remains a fundamental limitation, as conventional algorithms struggle to accurately resolve multimodal distributions typical in complex polymer systems. The presence of large particles can overwhelm signals from smaller components, leading to biased results that fail to capture the complete particle size profile.

Sample preparation introduces additional complexities, as dilution—often necessary to reduce multiple scattering—may disrupt the equilibrium state of the emulsion, altering the very properties being measured. Temperature control during measurement is critical yet challenging, as even minor fluctuations can significantly impact Brownian motion and consequently the calculated particle sizes.

For charged polymeric systems, electrostatic interactions can influence diffusion behavior, complicating the interpretation of DLS data. The assumption that particles are spherical—fundamental to standard DLS algorithms—often proves problematic for polymeric emulsions containing non-spherical or irregularly shaped particles.

Real-time monitoring presents another challenge, as traditional DLS instruments typically provide only snapshot measurements rather than continuous analysis of dynamic processes such as aggregation, coalescence, or phase separation. This limitation restricts the application of DLS in studying emulsion stability kinetics under processing conditions.

Data interpretation remains highly dependent on operator expertise, with fitting algorithms requiring careful selection of parameters to avoid artifacts or misinterpretation. The lack of standardized protocols specific to polymeric emulsions further complicates cross-laboratory comparisons and validation of results.

Established DLS Protocols for Polymeric Emulsion Characterization

01 Physical stability assessment of polymeric emulsions

Physical stability is a critical evaluation parameter for polymeric emulsions, which includes measurements of particle size distribution, viscosity changes over time, and phase separation tendencies. These assessments help determine the shelf life and performance reliability of the emulsion under various storage conditions. Methods such as accelerated aging tests, centrifugation, and freeze-thaw cycles are commonly employed to predict long-term stability.- Physical stability evaluation of polymeric emulsions: Physical stability is a critical parameter for evaluating polymeric emulsions. This includes assessment of phase separation, creaming, sedimentation, and flocculation over time. Methods such as centrifugation, freeze-thaw cycling, and accelerated aging tests are commonly used to predict long-term stability. Visual observation, microscopy, and particle size analysis are employed to detect changes in emulsion structure and stability under various storage conditions.

- Rheological properties measurement: Rheological properties are essential evaluation parameters for polymeric emulsions, including viscosity, yield stress, thixotropy, and viscoelastic behavior. These properties influence the processing, application, and end-use performance of emulsions. Measurements are typically conducted using rheometers under varying shear rates and temperatures to understand flow behavior. Rheological characterization helps predict stability, spreadability, and performance characteristics of polymeric emulsions in different application conditions.

- Particle size distribution and morphology analysis: Particle size distribution and morphology are crucial parameters for evaluating polymeric emulsions. These characteristics affect stability, rheology, optical properties, and application performance. Analysis techniques include dynamic light scattering, laser diffraction, microscopy, and image analysis methods. Monitoring changes in particle size over time provides insights into emulsion stability and aging mechanisms. The uniformity of particle size distribution is often quantified using polydispersity index or span values.

- Chemical stability and composition verification: Chemical stability evaluation of polymeric emulsions involves monitoring changes in chemical composition over time and under various conditions. This includes assessment of polymer degradation, crosslinking reactions, pH stability, and interactions between components. Analytical techniques such as spectroscopy, chromatography, and thermal analysis are employed to verify composition and detect chemical changes. These evaluations help predict shelf life and ensure consistent performance throughout the product lifecycle.

- Performance testing and application-specific evaluation: Performance testing of polymeric emulsions involves application-specific evaluations that simulate end-use conditions. This includes adhesion testing, film formation properties, water resistance, mechanical strength, and functional performance metrics relevant to the intended application. Standardized test methods are often employed to ensure reproducibility and comparability of results. These evaluations provide insights into how formulation parameters affect practical performance and help optimize polymeric emulsions for specific applications.

02 Rheological properties measurement

Rheological properties are essential evaluation parameters for polymeric emulsions, including viscosity, elasticity, and flow behavior under different shear conditions. These measurements provide insights into the emulsion's processing characteristics, application performance, and structural stability. Advanced rheometers are used to determine parameters such as yield stress, thixotropy, and viscoelastic moduli, which are crucial for predicting how the emulsion will behave during manufacturing, storage, and end-use applications.Expand Specific Solutions03 Particle size and distribution analysis

Particle size and distribution analysis is fundamental in evaluating polymeric emulsions, as these parameters directly influence stability, appearance, and performance properties. Various techniques including dynamic light scattering, laser diffraction, and microscopic imaging are employed to characterize the droplet size distribution. The uniformity index, polydispersity, and mean particle diameter are key metrics that determine emulsion quality and functional attributes in applications ranging from coatings to pharmaceutical formulations.Expand Specific Solutions04 Chemical composition and purity analysis

Chemical composition and purity analysis of polymeric emulsions involves evaluating the concentration of active ingredients, residual monomers, surfactants, and potential contaminants. Techniques such as chromatography, spectroscopy, and thermal analysis are employed to verify formulation consistency and detect impurities that might affect performance or safety. These analyses ensure batch-to-batch consistency and compliance with regulatory specifications, particularly important for emulsions used in sensitive applications like pharmaceuticals or food products.Expand Specific Solutions05 Performance testing under application conditions

Performance testing evaluates how polymeric emulsions function under actual application conditions, including adhesion strength, film formation properties, water resistance, and durability. These tests simulate real-world usage scenarios to predict in-service behavior and longevity. Application-specific parameters such as drying time, coating thickness uniformity, substrate compatibility, and resistance to environmental factors are measured to ensure the emulsion meets the required performance specifications for its intended use.Expand Specific Solutions

Leading Manufacturers and Research Groups in DLS Instrumentation

The polymeric emulsion evaluation via Dynamic Light Scattering (DLS) market is in a growth phase, with increasing adoption across pharmaceutical, chemical, and materials science sectors. The global market size for DLS technology is expanding steadily, driven by rising demand for nanoparticle characterization. Leading players include specialized instrumentation companies like Wyatt Technology and Tosoh Bioscience, alongside diversified chemical corporations such as BASF, Solvay, and FUJIFILM. Academic institutions like Beijing University of Chemical Technology and Virginia Commonwealth University contribute significant research advancements. The technology has reached moderate maturity with established methodologies, though innovations continue in real-time monitoring capabilities, as demonstrated by Fluence Analytics' recent developments in continuous polymer characterization systems.

Wyatt Technology LLC

Technical Solution: Wyatt Technology has developed advanced multi-angle dynamic light scattering (MADLS) systems specifically designed for polymeric emulsion characterization. Their technology combines traditional DLS with multi-angle detection to provide comprehensive size distribution analysis of polydisperse emulsion systems. Their DYNAMICS software platform integrates with their DLS instruments to offer automated batch measurements, temperature control studies, and time-resolved analysis of emulsion stability. Wyatt's DynaPro® NanoStar® instrument incorporates temperature control from 4°C to 70°C to study temperature-dependent behavior of polymer emulsions, while their DynaPro® Plate Reader enables high-throughput screening of multiple emulsion formulations simultaneously. The company has also developed proprietary algorithms that better resolve multimodal distributions common in polymer emulsions, addressing the limitations of conventional cumulants analysis.

Strengths: Superior resolution of multimodal distributions; integrated temperature control capabilities; high-throughput screening options; specialized software for emulsion stability analysis. Weaknesses: Higher cost compared to basic DLS systems; complex data interpretation requiring specialized training; limited penetration in emerging markets.

Evonik Operations GmbH

Technical Solution: Evonik has developed a comprehensive approach to polymeric emulsion characterization utilizing advanced dynamic light scattering techniques integrated with their formulation development workflow. Their DLS methodology incorporates specialized sample preparation protocols designed specifically for their wide range of specialty polymer emulsions used in coatings, adhesives, and personal care applications. Evonik's approach combines traditional DLS measurements with their proprietary SPHERITM technology for comprehensive particle characterization, allowing simultaneous evaluation of size distribution, zeta potential, and rheological properties of complex emulsion systems. Their laboratories employ temperature-controlled DLS measurements to assess emulsion stability across application-relevant conditions, with automated time-sequence measurements to quantify aggregation kinetics and shelf-life predictions. Evonik has also developed correlation algorithms that better account for the complex scattering patterns of their structured polymeric emulsions, improving measurement accuracy for systems containing multiple particle populations.

Strengths: Integration of DLS with comprehensive formulation development; specialized protocols for industrial applications; combined particle size and stability assessment; extensive application expertise. Weaknesses: Technologies primarily developed for internal use rather than instrument sales; less focus on academic research applications; limited public disclosure of methodological details.

Key Innovations in DLS Data Processing Algorithms

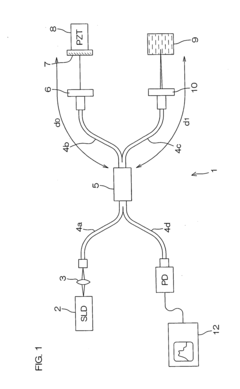

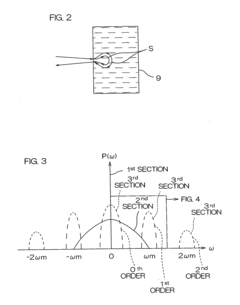

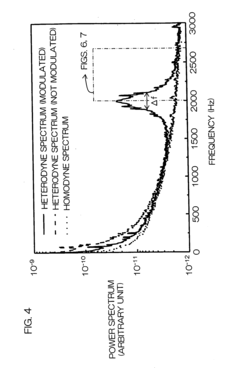

Dynamic light scattering measurement apparatus using phase modulation interference method

PatentInactiveUS20050122528A1

Innovation

- A dynamic light scattering measurement apparatus utilizing a low coherence light source, phase modulation, and a specific light path length normalization (s/L ≤ 3) to selectively extract the single-scattered spectrum component from multiple scattering media, enabling precise measurement of particle dynamics.

Sample Preparation Optimization for Accurate DLS Measurements

Sample preparation represents a critical determinant in the accuracy and reliability of Dynamic Light Scattering (DLS) measurements for polymeric emulsions. The quality of data obtained through DLS analysis directly correlates with how meticulously samples are prepared. Optimization begins with understanding the concentration requirements specific to polymeric systems, as both excessively dilute and overly concentrated samples can lead to measurement artifacts.

For polymeric emulsions, maintaining sample concentrations between 0.1-1.0% w/v typically provides optimal scattering intensity while minimizing multiple scattering effects. This concentration range ensures sufficient signal-to-noise ratio while preventing particle interactions that could skew size distribution results. Researchers should establish calibration curves for their specific polymer systems to determine the ideal concentration window.

Filtration protocols constitute another essential aspect of sample preparation. Polymeric emulsions should be filtered through membranes with appropriate pore sizes (typically 0.2-0.45 μm) to remove dust particles and aggregates that could otherwise dominate scattering signals. Selection of filter material is equally important, as some polymers may adsorb to certain membrane materials, potentially altering the sample composition.

Temperature equilibration prior to measurement cannot be overlooked. Polymeric emulsions should be allowed to equilibrate at the measurement temperature for at least 15 minutes to ensure thermal stability and eliminate convection currents that could be misinterpreted as particle movement. This is particularly crucial for temperature-sensitive polymers that may undergo phase transitions within the experimental temperature range.

The choice of dispersant medium significantly impacts DLS measurements. The dispersant should provide adequate colloidal stability while maintaining optical clarity. For aqueous polymeric emulsions, buffer composition, ionic strength, and pH must be carefully controlled as these parameters influence the electrical double layer around particles and consequently their hydrodynamic behavior.

Sample homogenization techniques warrant careful consideration. Gentle mixing methods such as slow inversion or low-speed vortexing are preferable to sonication or high-shear mixing, which may disrupt the integrity of polymeric emulsion structures. The timing between sample preparation and measurement should be standardized to account for potential time-dependent phenomena such as particle aggregation or polymer relaxation.

Cuvette selection and cleaning procedures represent the final critical elements in sample preparation. Disposable plastic cuvettes minimize contamination risks but may introduce background scattering, while high-quality glass or quartz cuvettes provide superior optical properties but require rigorous cleaning protocols to prevent cross-contamination between measurements.

For polymeric emulsions, maintaining sample concentrations between 0.1-1.0% w/v typically provides optimal scattering intensity while minimizing multiple scattering effects. This concentration range ensures sufficient signal-to-noise ratio while preventing particle interactions that could skew size distribution results. Researchers should establish calibration curves for their specific polymer systems to determine the ideal concentration window.

Filtration protocols constitute another essential aspect of sample preparation. Polymeric emulsions should be filtered through membranes with appropriate pore sizes (typically 0.2-0.45 μm) to remove dust particles and aggregates that could otherwise dominate scattering signals. Selection of filter material is equally important, as some polymers may adsorb to certain membrane materials, potentially altering the sample composition.

Temperature equilibration prior to measurement cannot be overlooked. Polymeric emulsions should be allowed to equilibrate at the measurement temperature for at least 15 minutes to ensure thermal stability and eliminate convection currents that could be misinterpreted as particle movement. This is particularly crucial for temperature-sensitive polymers that may undergo phase transitions within the experimental temperature range.

The choice of dispersant medium significantly impacts DLS measurements. The dispersant should provide adequate colloidal stability while maintaining optical clarity. For aqueous polymeric emulsions, buffer composition, ionic strength, and pH must be carefully controlled as these parameters influence the electrical double layer around particles and consequently their hydrodynamic behavior.

Sample homogenization techniques warrant careful consideration. Gentle mixing methods such as slow inversion or low-speed vortexing are preferable to sonication or high-shear mixing, which may disrupt the integrity of polymeric emulsion structures. The timing between sample preparation and measurement should be standardized to account for potential time-dependent phenomena such as particle aggregation or polymer relaxation.

Cuvette selection and cleaning procedures represent the final critical elements in sample preparation. Disposable plastic cuvettes minimize contamination risks but may introduce background scattering, while high-quality glass or quartz cuvettes provide superior optical properties but require rigorous cleaning protocols to prevent cross-contamination between measurements.

Complementary Techniques for Comprehensive Emulsion Analysis

While Dynamic Light Scattering (DLS) provides valuable insights into polymeric emulsion characteristics, a comprehensive analysis requires integration with complementary analytical techniques. Microscopy techniques, particularly Transmission Electron Microscopy (TEM) and Scanning Electron Microscopy (SEM), offer direct visualization of emulsion droplets, providing morphological information that DLS cannot capture. These techniques can reveal irregularities in particle shape and surface features that significantly impact emulsion stability and performance.

Rheological measurements complement DLS by characterizing flow behavior and viscoelastic properties of polymeric emulsions. Oscillatory rheology and viscosity profiling across different shear rates provide critical information about emulsion structure and stability under various processing conditions. These measurements are particularly valuable for predicting emulsion behavior during manufacturing processes and end-use applications.

Zeta potential analysis serves as an essential companion to DLS measurements by quantifying the electrical charge at the particle-liquid interface. This parameter directly correlates with emulsion stability through electrostatic repulsion mechanisms. Emulsions with zeta potential values exceeding ±30 mV typically demonstrate superior stability against coalescence and flocculation, offering predictive insights beyond what DLS alone can provide.

Spectroscopic techniques including FTIR (Fourier Transform Infrared) and Raman spectroscopy enable chemical characterization of both the continuous and dispersed phases. These methods can identify functional groups at interfaces and detect chemical changes during emulsion aging, providing molecular-level insights that complement the physical parameters measured by DLS.

Thermal analysis techniques such as Differential Scanning Calorimetry (DSC) reveal phase transitions and thermal stability characteristics of polymeric emulsions. When combined with DLS temperature trend analysis, these measurements create a comprehensive profile of emulsion behavior across temperature ranges relevant to processing and application conditions.

Advanced scattering techniques including Small-Angle X-ray Scattering (SAXS) and Small-Angle Neutron Scattering (SANS) provide structural information at different length scales compared to DLS. These techniques can probe internal structures within emulsion droplets and characterize interfaces with nanometer resolution, offering complementary structural insights particularly valuable for complex multi-component emulsion systems.

Rheological measurements complement DLS by characterizing flow behavior and viscoelastic properties of polymeric emulsions. Oscillatory rheology and viscosity profiling across different shear rates provide critical information about emulsion structure and stability under various processing conditions. These measurements are particularly valuable for predicting emulsion behavior during manufacturing processes and end-use applications.

Zeta potential analysis serves as an essential companion to DLS measurements by quantifying the electrical charge at the particle-liquid interface. This parameter directly correlates with emulsion stability through electrostatic repulsion mechanisms. Emulsions with zeta potential values exceeding ±30 mV typically demonstrate superior stability against coalescence and flocculation, offering predictive insights beyond what DLS alone can provide.

Spectroscopic techniques including FTIR (Fourier Transform Infrared) and Raman spectroscopy enable chemical characterization of both the continuous and dispersed phases. These methods can identify functional groups at interfaces and detect chemical changes during emulsion aging, providing molecular-level insights that complement the physical parameters measured by DLS.

Thermal analysis techniques such as Differential Scanning Calorimetry (DSC) reveal phase transitions and thermal stability characteristics of polymeric emulsions. When combined with DLS temperature trend analysis, these measurements create a comprehensive profile of emulsion behavior across temperature ranges relevant to processing and application conditions.

Advanced scattering techniques including Small-Angle X-ray Scattering (SAXS) and Small-Angle Neutron Scattering (SANS) provide structural information at different length scales compared to DLS. These techniques can probe internal structures within emulsion droplets and characterize interfaces with nanometer resolution, offering complementary structural insights particularly valuable for complex multi-component emulsion systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!