How to Foster Innovation in Graphene Battery Research?

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphene Battery Innovation Landscape and Objectives

Graphene battery technology represents a frontier in energy storage innovation, promising to revolutionize various sectors from consumer electronics to electric vehicles. The landscape of graphene battery research has evolved rapidly over the past decade, driven by the exceptional properties of graphene, including its high electrical conductivity, mechanical strength, and large surface area.

The primary objective in this field is to harness graphene's unique characteristics to develop batteries with significantly improved performance metrics. Researchers aim to create batteries with higher energy density, faster charging capabilities, longer cycle life, and enhanced safety profiles compared to conventional lithium-ion batteries. These advancements could potentially lead to electric vehicles with extended ranges, smartphones that charge in minutes, and grid-scale energy storage solutions with improved efficiency.

Current trends in graphene battery innovation focus on several key areas. One major direction is the development of graphene-enhanced electrodes, where graphene is incorporated into both anodes and cathodes to improve conductivity and structural stability. Another area of intense research is the use of graphene as a conductive additive in electrolytes, potentially enabling the use of high-capacity electrode materials that were previously impractical due to conductivity limitations.

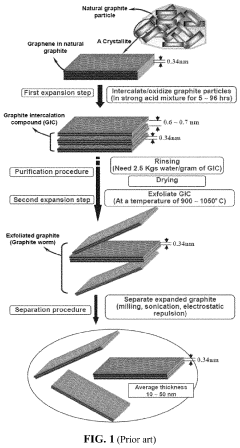

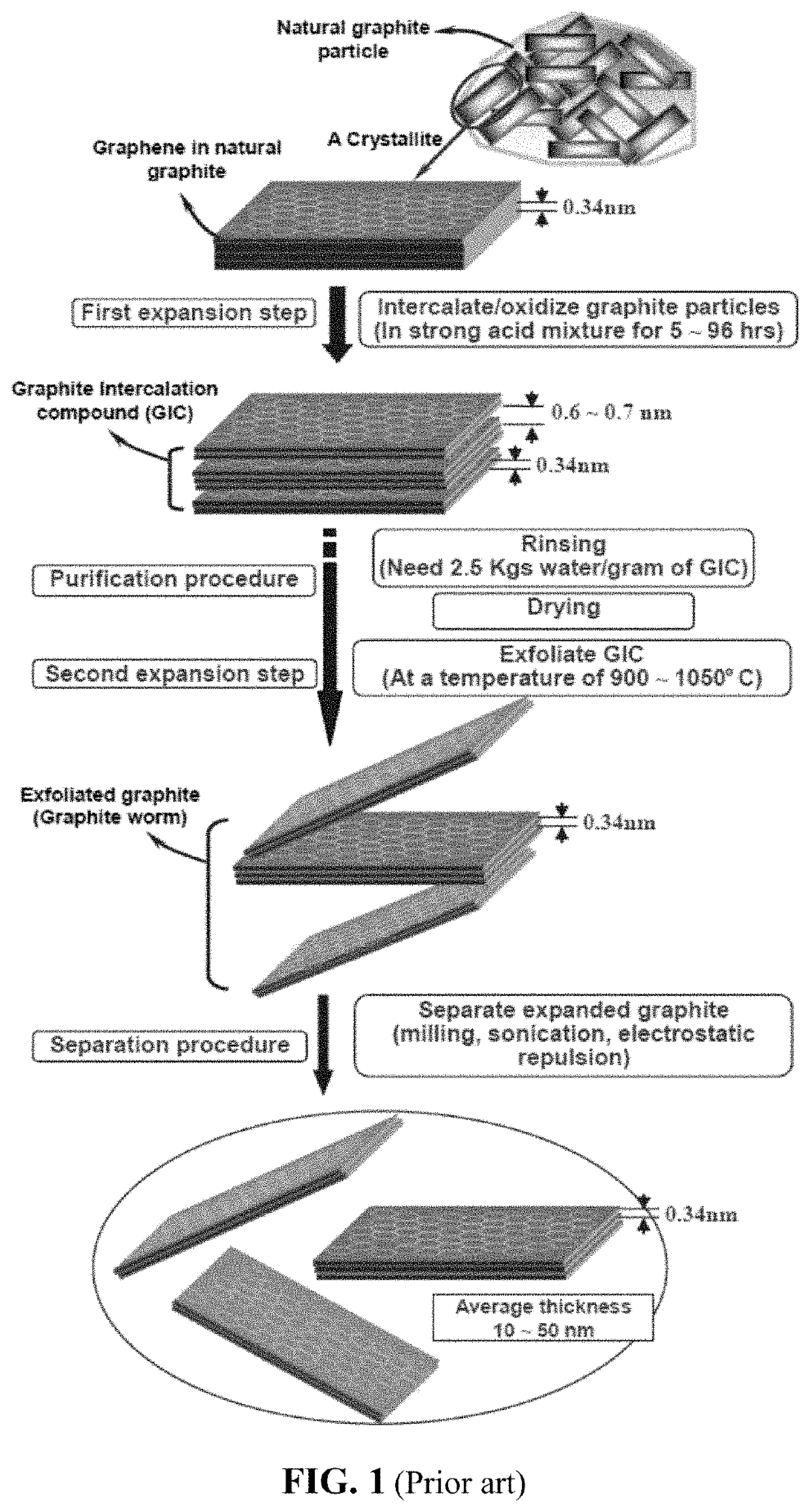

The evolution of graphene synthesis methods has also played a crucial role in advancing battery technology. From mechanical exfoliation to chemical vapor deposition and liquid-phase exfoliation, each new method has opened up possibilities for scalable production and integration of graphene into battery components. The goal is to develop manufacturing processes that can produce high-quality graphene at scale and at a cost that makes commercial implementation viable.

Interdisciplinary collaboration has emerged as a key driver of innovation in this field. Materials scientists, chemists, physicists, and engineers are working together to address challenges at every level, from fundamental material properties to system-level integration. This collaborative approach is essential for overcoming the multifaceted challenges associated with graphene battery development.

Looking ahead, the objectives for graphene battery research include pushing the boundaries of energy density beyond 400 Wh/kg, achieving charging times of less than 15 minutes for large-scale batteries, and extending cycle life to over 1000 cycles without significant degradation. Additionally, there is a growing focus on sustainability, with efforts to develop graphene batteries that are more environmentally friendly in terms of materials used and end-of-life recycling.

The primary objective in this field is to harness graphene's unique characteristics to develop batteries with significantly improved performance metrics. Researchers aim to create batteries with higher energy density, faster charging capabilities, longer cycle life, and enhanced safety profiles compared to conventional lithium-ion batteries. These advancements could potentially lead to electric vehicles with extended ranges, smartphones that charge in minutes, and grid-scale energy storage solutions with improved efficiency.

Current trends in graphene battery innovation focus on several key areas. One major direction is the development of graphene-enhanced electrodes, where graphene is incorporated into both anodes and cathodes to improve conductivity and structural stability. Another area of intense research is the use of graphene as a conductive additive in electrolytes, potentially enabling the use of high-capacity electrode materials that were previously impractical due to conductivity limitations.

The evolution of graphene synthesis methods has also played a crucial role in advancing battery technology. From mechanical exfoliation to chemical vapor deposition and liquid-phase exfoliation, each new method has opened up possibilities for scalable production and integration of graphene into battery components. The goal is to develop manufacturing processes that can produce high-quality graphene at scale and at a cost that makes commercial implementation viable.

Interdisciplinary collaboration has emerged as a key driver of innovation in this field. Materials scientists, chemists, physicists, and engineers are working together to address challenges at every level, from fundamental material properties to system-level integration. This collaborative approach is essential for overcoming the multifaceted challenges associated with graphene battery development.

Looking ahead, the objectives for graphene battery research include pushing the boundaries of energy density beyond 400 Wh/kg, achieving charging times of less than 15 minutes for large-scale batteries, and extending cycle life to over 1000 cycles without significant degradation. Additionally, there is a growing focus on sustainability, with efforts to develop graphene batteries that are more environmentally friendly in terms of materials used and end-of-life recycling.

Market Potential for Graphene-Enhanced Energy Storage

The market potential for graphene-enhanced energy storage is substantial and rapidly expanding. As the global demand for more efficient and sustainable energy solutions continues to grow, graphene-based technologies are poised to revolutionize the battery industry. The unique properties of graphene, including its high electrical conductivity, mechanical strength, and large surface area, make it an ideal material for improving battery performance.

In the electric vehicle (EV) sector, graphene-enhanced batteries could significantly extend driving ranges and reduce charging times, addressing two of the most pressing concerns for EV adoption. This potential has attracted the attention of major automotive manufacturers and battery producers, who are investing heavily in research and development. The EV battery market alone is projected to grow at a compound annual growth rate (CAGR) of over 25% in the coming years, with graphene technologies playing an increasingly important role.

Consumer electronics represent another key market for graphene-enhanced energy storage. Smartphones, laptops, and wearable devices could benefit from batteries with higher capacity, faster charging capabilities, and longer lifespans. As consumers demand more from their devices, manufacturers are exploring graphene-based solutions to meet these needs. The consumer electronics battery market is expected to reach several billion dollars by 2025, with graphene technologies potentially capturing a significant share.

The renewable energy sector also presents a substantial opportunity for graphene-enhanced energy storage. As wind and solar power generation becomes more prevalent, the need for efficient and large-scale energy storage solutions grows. Graphene-based supercapacitors and advanced batteries could provide the necessary storage capacity and rapid charge/discharge capabilities required for grid stabilization and energy management.

Industrial applications, including power tools, robotics, and aerospace, represent additional markets with significant potential for graphene-enhanced energy storage. These sectors require high-performance batteries that can withstand extreme conditions and deliver consistent power output. Graphene's durability and thermal management properties make it well-suited for these demanding applications.

However, realizing this market potential requires overcoming several challenges. Cost-effective production of high-quality graphene at scale remains a significant hurdle. Additionally, integrating graphene into existing battery manufacturing processes and ensuring long-term stability and safety are critical areas that need further development. Despite these challenges, the potential benefits of graphene-enhanced energy storage continue to drive investment and innovation in the field.

As research progresses and manufacturing techniques improve, the market for graphene-enhanced energy storage is expected to expand rapidly across multiple sectors. This growth will likely be fueled by increasing demand for high-performance energy storage solutions in electric vehicles, consumer electronics, renewable energy systems, and industrial applications. The companies and countries that successfully develop and commercialize graphene-based battery technologies stand to gain a significant competitive advantage in the global energy storage market.

In the electric vehicle (EV) sector, graphene-enhanced batteries could significantly extend driving ranges and reduce charging times, addressing two of the most pressing concerns for EV adoption. This potential has attracted the attention of major automotive manufacturers and battery producers, who are investing heavily in research and development. The EV battery market alone is projected to grow at a compound annual growth rate (CAGR) of over 25% in the coming years, with graphene technologies playing an increasingly important role.

Consumer electronics represent another key market for graphene-enhanced energy storage. Smartphones, laptops, and wearable devices could benefit from batteries with higher capacity, faster charging capabilities, and longer lifespans. As consumers demand more from their devices, manufacturers are exploring graphene-based solutions to meet these needs. The consumer electronics battery market is expected to reach several billion dollars by 2025, with graphene technologies potentially capturing a significant share.

The renewable energy sector also presents a substantial opportunity for graphene-enhanced energy storage. As wind and solar power generation becomes more prevalent, the need for efficient and large-scale energy storage solutions grows. Graphene-based supercapacitors and advanced batteries could provide the necessary storage capacity and rapid charge/discharge capabilities required for grid stabilization and energy management.

Industrial applications, including power tools, robotics, and aerospace, represent additional markets with significant potential for graphene-enhanced energy storage. These sectors require high-performance batteries that can withstand extreme conditions and deliver consistent power output. Graphene's durability and thermal management properties make it well-suited for these demanding applications.

However, realizing this market potential requires overcoming several challenges. Cost-effective production of high-quality graphene at scale remains a significant hurdle. Additionally, integrating graphene into existing battery manufacturing processes and ensuring long-term stability and safety are critical areas that need further development. Despite these challenges, the potential benefits of graphene-enhanced energy storage continue to drive investment and innovation in the field.

As research progresses and manufacturing techniques improve, the market for graphene-enhanced energy storage is expected to expand rapidly across multiple sectors. This growth will likely be fueled by increasing demand for high-performance energy storage solutions in electric vehicles, consumer electronics, renewable energy systems, and industrial applications. The companies and countries that successfully develop and commercialize graphene-based battery technologies stand to gain a significant competitive advantage in the global energy storage market.

Current Challenges in Graphene Battery Development

Despite the promising potential of graphene batteries, several significant challenges hinder their widespread adoption and commercialization. One of the primary obstacles is the scalability of graphene production. While laboratory-scale synthesis methods have been developed, translating these processes to industrial-scale production while maintaining consistent quality and properties remains a formidable task.

The high cost of graphene production is another major hurdle. Current manufacturing processes are expensive, making graphene batteries economically unviable for mass-market applications. This cost factor significantly limits their competitiveness against established battery technologies, such as lithium-ion batteries.

Stability and longevity issues also pose significant challenges. Graphene's high surface area can lead to undesirable side reactions, potentially causing capacity fade and reduced cycle life. Researchers are still grappling with ways to mitigate these effects and ensure long-term stability of graphene-based battery components.

Integration of graphene into existing battery architectures presents another set of challenges. Optimizing the interface between graphene and other battery materials, such as electrolytes and current collectors, is crucial for maximizing performance. However, achieving seamless integration while maintaining the unique properties of graphene is a complex task that requires further research and development.

Safety concerns also need to be addressed. While graphene itself is generally considered safe, its use in battery systems introduces new variables that must be thoroughly investigated. Potential issues such as thermal runaway, short-circuiting, and electrolyte decomposition need to be carefully studied and mitigated.

Standardization and quality control pose additional challenges. The lack of universally accepted standards for graphene quality and characterization makes it difficult to ensure consistency across different batches and suppliers. This variability can lead to inconsistent battery performance and hinder large-scale manufacturing efforts.

Environmental and sustainability considerations also present challenges. While graphene batteries have the potential to be more environmentally friendly than traditional batteries, the entire life cycle, including production, use, and disposal, needs to be carefully evaluated to ensure true sustainability.

Overcoming these challenges requires a multidisciplinary approach, combining expertise from materials science, electrochemistry, engineering, and manufacturing. Collaborative efforts between academia, industry, and government agencies are essential to address these complex issues and unlock the full potential of graphene batteries.

The high cost of graphene production is another major hurdle. Current manufacturing processes are expensive, making graphene batteries economically unviable for mass-market applications. This cost factor significantly limits their competitiveness against established battery technologies, such as lithium-ion batteries.

Stability and longevity issues also pose significant challenges. Graphene's high surface area can lead to undesirable side reactions, potentially causing capacity fade and reduced cycle life. Researchers are still grappling with ways to mitigate these effects and ensure long-term stability of graphene-based battery components.

Integration of graphene into existing battery architectures presents another set of challenges. Optimizing the interface between graphene and other battery materials, such as electrolytes and current collectors, is crucial for maximizing performance. However, achieving seamless integration while maintaining the unique properties of graphene is a complex task that requires further research and development.

Safety concerns also need to be addressed. While graphene itself is generally considered safe, its use in battery systems introduces new variables that must be thoroughly investigated. Potential issues such as thermal runaway, short-circuiting, and electrolyte decomposition need to be carefully studied and mitigated.

Standardization and quality control pose additional challenges. The lack of universally accepted standards for graphene quality and characterization makes it difficult to ensure consistency across different batches and suppliers. This variability can lead to inconsistent battery performance and hinder large-scale manufacturing efforts.

Environmental and sustainability considerations also present challenges. While graphene batteries have the potential to be more environmentally friendly than traditional batteries, the entire life cycle, including production, use, and disposal, needs to be carefully evaluated to ensure true sustainability.

Overcoming these challenges requires a multidisciplinary approach, combining expertise from materials science, electrochemistry, engineering, and manufacturing. Collaborative efforts between academia, industry, and government agencies are essential to address these complex issues and unlock the full potential of graphene batteries.

Existing Approaches to Graphene Battery Fabrication

01 Graphene-based electrode materials

Graphene is used as an electrode material in batteries due to its high conductivity and large surface area. This innovation enhances the battery's performance, including faster charging rates and increased energy density. Graphene electrodes can be combined with other materials to further improve battery characteristics.- Graphene-based electrode materials: Graphene is used as an electrode material in batteries due to its high conductivity and large surface area. This innovation enhances the battery's performance, including faster charging rates and increased energy density. Graphene electrodes can be combined with other materials to further improve battery characteristics.

- Graphene-enhanced electrolytes: Incorporating graphene or graphene oxide into battery electrolytes improves ionic conductivity and stability. This innovation leads to better overall battery performance, including enhanced cycle life and improved safety characteristics. The graphene-enhanced electrolytes can be used in various types of batteries, including lithium-ion and sodium-ion batteries.

- Graphene-based composite materials: Composite materials combining graphene with other substances, such as metal oxides or polymers, are developed to create advanced battery components. These composites often exhibit synergistic effects, leading to improved capacity, cycling stability, and mechanical properties compared to traditional battery materials.

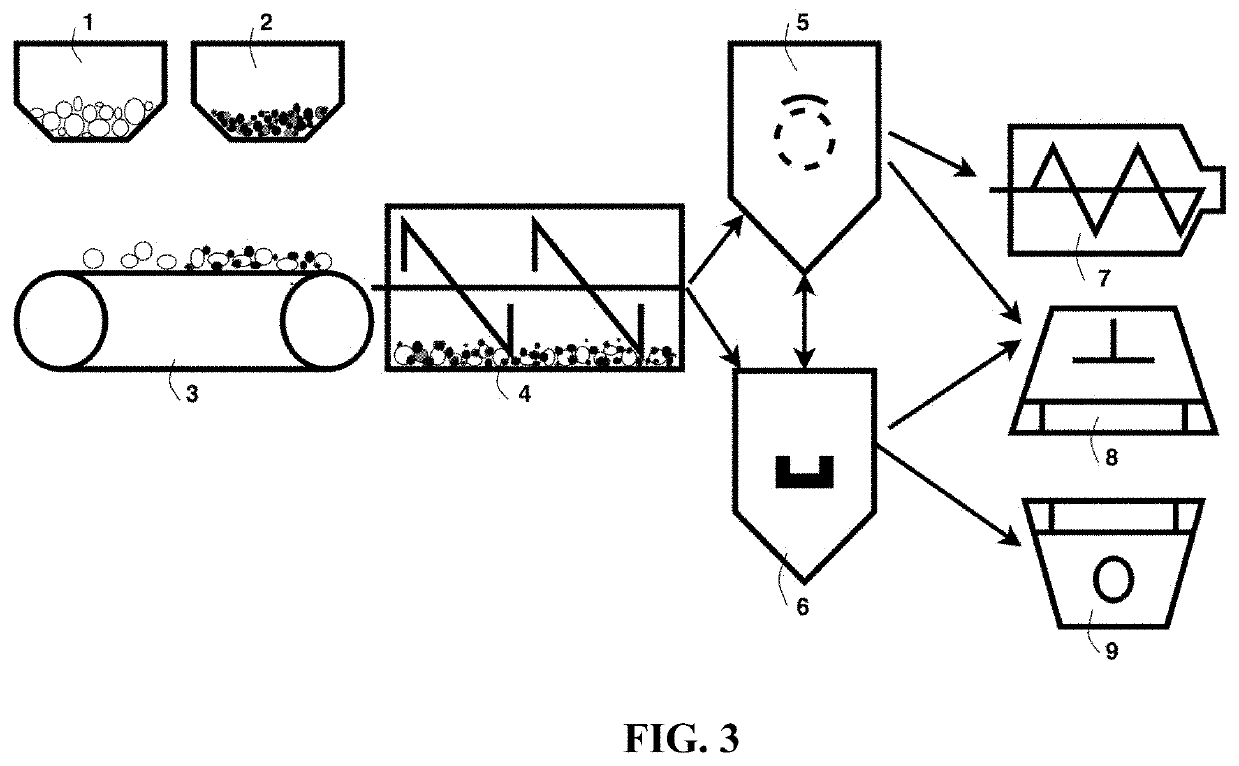

- Graphene production and processing for battery applications: Innovative methods for producing and processing graphene specifically for battery applications are developed. These techniques focus on creating high-quality graphene with controlled properties, such as specific surface area, defect density, and functionalization, tailored for optimal battery performance.

- Graphene-enabled flexible and wearable batteries: Graphene's unique properties are utilized to create flexible and wearable battery designs. These innovations enable the development of thin, lightweight, and bendable energy storage devices suitable for integration into wearable electronics and flexible devices. The graphene-based flexible batteries often exhibit improved durability and performance compared to conventional flexible battery technologies.

02 Graphene-enhanced electrolytes

Incorporating graphene or graphene oxide into battery electrolytes improves ionic conductivity and stability. This innovation leads to better overall battery performance, including enhanced cycle life and improved safety characteristics. The graphene-enhanced electrolytes can be used in various types of batteries, including lithium-ion and sodium-ion batteries.Expand Specific Solutions03 Graphene-based composite materials

Composite materials combining graphene with other substances, such as metal oxides or polymers, are developed for use in battery components. These composites often exhibit synergistic effects, leading to improved capacity, cycling stability, and mechanical properties compared to traditional battery materials.Expand Specific Solutions04 Graphene manufacturing processes for battery applications

Novel methods for producing and processing graphene specifically for battery applications are developed. These processes focus on creating graphene with tailored properties, such as controlled defects or functionalization, to optimize its performance in batteries. Innovations in scalable production techniques are also explored to enable commercial implementation.Expand Specific Solutions05 Graphene-enabled flexible and wearable batteries

Graphene's unique properties are leveraged to create flexible and wearable battery designs. These innovations focus on developing thin, lightweight, and bendable batteries that can be integrated into various devices and wearable technologies. The use of graphene enables improved energy density and mechanical flexibility in these novel battery formats.Expand Specific Solutions

Key Players in Graphene Battery Research and Development

The graphene battery research field is in a dynamic growth phase, with significant market potential driven by the increasing demand for high-performance energy storage solutions. The market size is expanding rapidly, attracting investments from both established companies and startups. Technologically, graphene batteries are still in the early stages of maturity, with ongoing research to overcome challenges in scalability and cost-effectiveness. Key players like Honeycomb Battery Co., Global Graphene Group, and Vorbeck Materials Corp. are leading innovation efforts, while academic institutions such as The University of Queensland and Northwestern University contribute fundamental research. The competitive landscape is diverse, with collaborations between industry and academia accelerating progress towards commercialization.

Global Graphene Group, Inc.

Technical Solution: Global Graphene Group (G3) is pioneering graphene-enhanced battery technology through their subsidiary, Honeycomb Battery. They have developed a silicon-graphene composite anode material that significantly increases energy density and cycle life of lithium-ion batteries[1]. Their approach involves using graphene to stabilize silicon particles, preventing degradation during charge-discharge cycles. G3 has also created a graphene-based coating for cathodes, which enhances conductivity and protects against electrolyte degradation[2]. Additionally, they are exploring graphene's potential in solid-state electrolytes to improve safety and energy density[3].

Strengths: Comprehensive graphene integration across battery components, established intellectual property, and proven performance improvements. Weaknesses: Potential high production costs and scalability challenges associated with graphene manufacturing.

Vorbeck Materials Corp.

Technical Solution: Vorbeck Materials specializes in graphene-based materials and their application in energy storage. Their proprietary Vor-x® graphene technology is being applied to develop high-performance battery electrodes. Vorbeck's approach involves creating a three-dimensional graphene network within battery electrodes, significantly improving conductivity and surface area[13]. This structure allows for faster ion transport and higher energy density. They are also developing graphene-enhanced current collectors that reduce overall battery weight while improving performance[14]. Vorbeck's research extends to graphene-based flexible batteries, targeting applications in wearable technology and IoT devices. Additionally, they are exploring graphene's potential in improving the safety of high-energy-density batteries by enhancing thermal management and mechanical stability[15].

Strengths: Proprietary graphene production technology, diverse applications of graphene in battery components, and established partnerships in the energy storage industry. Weaknesses: Potential challenges in scaling production to meet large-scale battery manufacturing demands, competition from larger, more established battery material suppliers.

Breakthrough Patents in Graphene Battery Technology

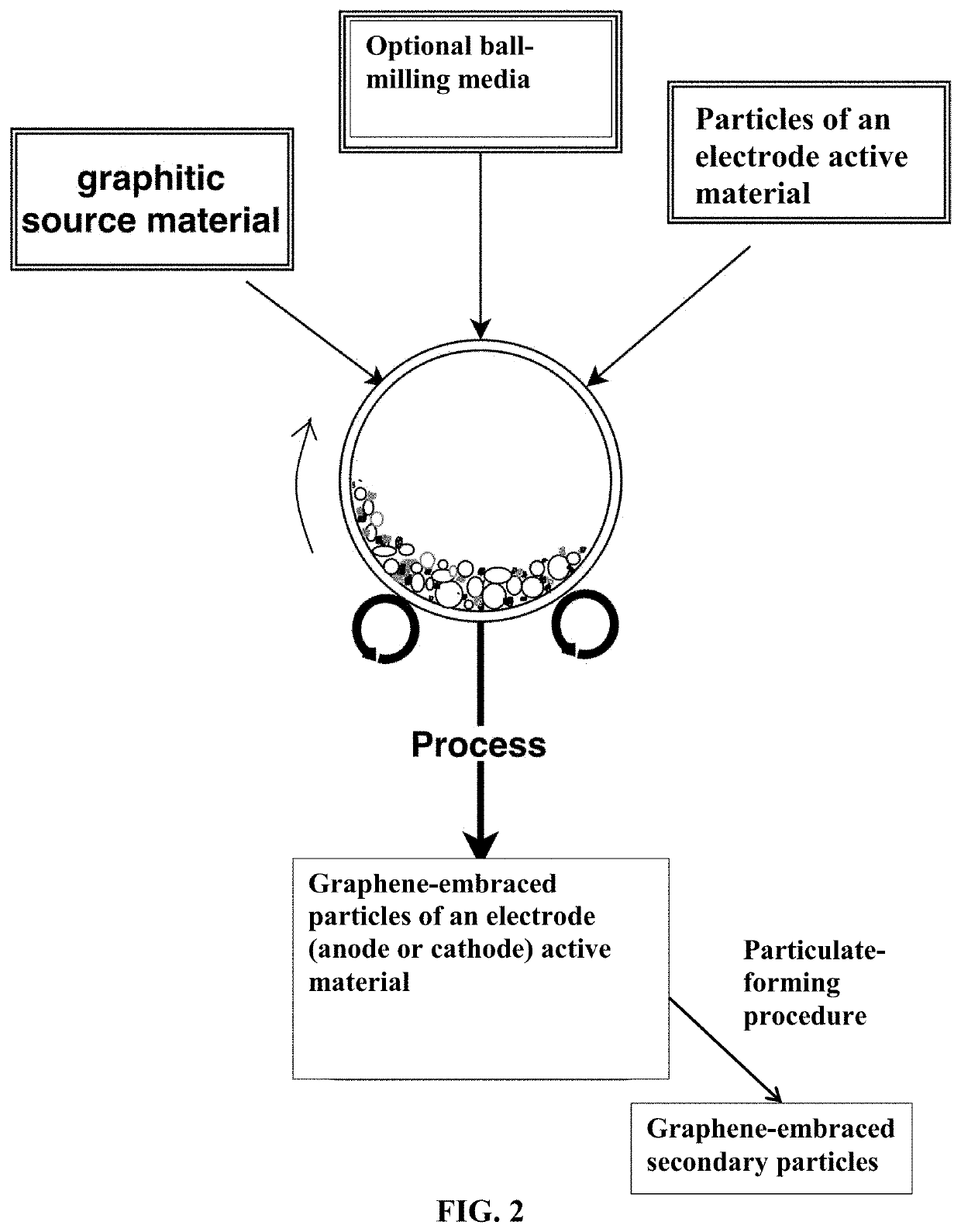

Method of producing multi-level graphene-protected cathode active material particles for battery applications

PatentActiveUS20190372100A1

Innovation

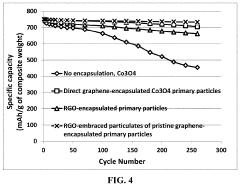

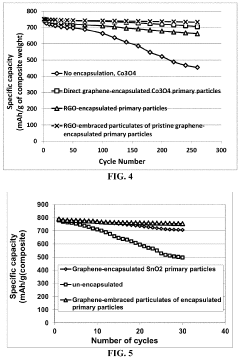

- The use of graphene-embraced particulates, where primary particles of anode or cathode active materials are encapsulated with multiple sheets of graphene, providing mechanical protection and conductivity, and optionally combined with a conductive additive, to enhance cycle stability and capacity.

Multi-level graphene-protected anode active material particles for fast-charging lithium-ion batteries

PatentInactiveUS20190379039A1

Innovation

- The use of graphene-embraced particulates, where primary particles of anode or cathode active materials are encapsulated with multiple sheets of graphene, providing mechanical protection and enhanced conductivity, and optionally combined with a conductive additive, to form a composite that improves cycle stability and high-rate capability.

Collaborative Research Initiatives for Graphene Batteries

Collaborative research initiatives play a crucial role in fostering innovation within graphene battery research. By bringing together diverse expertise and resources, these initiatives can accelerate progress and overcome challenges in this rapidly evolving field.

One key aspect of collaborative research is the establishment of interdisciplinary teams. Graphene battery development requires knowledge from various domains, including materials science, electrochemistry, and engineering. By forming teams that combine experts from these fields, researchers can tackle complex problems from multiple angles, leading to more comprehensive and innovative solutions.

Public-private partnerships are another essential component of collaborative research initiatives. Government agencies, academic institutions, and private companies can pool their resources and knowledge to drive innovation forward. These partnerships can provide funding, access to advanced facilities, and opportunities for knowledge transfer between sectors.

International collaborations are particularly valuable in graphene battery research. Different countries may have unique strengths in various aspects of the technology, such as material synthesis, characterization techniques, or manufacturing processes. By fostering international cooperation, researchers can leverage global expertise and resources to accelerate progress.

Open innovation platforms and consortia can facilitate knowledge sharing and collaborative problem-solving. These platforms allow researchers from different organizations to work together on common challenges, share data, and build upon each other's findings. Such open collaboration can lead to breakthroughs that might not be possible within the confines of a single institution.

Standardization efforts are crucial for collaborative research in graphene batteries. Developing common protocols for material characterization, performance testing, and safety evaluation can ensure consistency across different research groups and facilitate the comparison of results. This standardization can accelerate the development and commercialization of graphene battery technologies.

Collaborative research initiatives should also focus on talent development and knowledge transfer. Joint training programs, workshops, and exchange programs can help cultivate the next generation of researchers and engineers in graphene battery technology. These initiatives can ensure a continuous influx of fresh ideas and maintain the momentum of innovation in the field.

By implementing these collaborative research strategies, the graphene battery research community can foster a more innovative and dynamic ecosystem. This approach can lead to faster progress, more efficient use of resources, and ultimately, the development of advanced graphene-based energy storage solutions that can revolutionize various industries and applications.

One key aspect of collaborative research is the establishment of interdisciplinary teams. Graphene battery development requires knowledge from various domains, including materials science, electrochemistry, and engineering. By forming teams that combine experts from these fields, researchers can tackle complex problems from multiple angles, leading to more comprehensive and innovative solutions.

Public-private partnerships are another essential component of collaborative research initiatives. Government agencies, academic institutions, and private companies can pool their resources and knowledge to drive innovation forward. These partnerships can provide funding, access to advanced facilities, and opportunities for knowledge transfer between sectors.

International collaborations are particularly valuable in graphene battery research. Different countries may have unique strengths in various aspects of the technology, such as material synthesis, characterization techniques, or manufacturing processes. By fostering international cooperation, researchers can leverage global expertise and resources to accelerate progress.

Open innovation platforms and consortia can facilitate knowledge sharing and collaborative problem-solving. These platforms allow researchers from different organizations to work together on common challenges, share data, and build upon each other's findings. Such open collaboration can lead to breakthroughs that might not be possible within the confines of a single institution.

Standardization efforts are crucial for collaborative research in graphene batteries. Developing common protocols for material characterization, performance testing, and safety evaluation can ensure consistency across different research groups and facilitate the comparison of results. This standardization can accelerate the development and commercialization of graphene battery technologies.

Collaborative research initiatives should also focus on talent development and knowledge transfer. Joint training programs, workshops, and exchange programs can help cultivate the next generation of researchers and engineers in graphene battery technology. These initiatives can ensure a continuous influx of fresh ideas and maintain the momentum of innovation in the field.

By implementing these collaborative research strategies, the graphene battery research community can foster a more innovative and dynamic ecosystem. This approach can lead to faster progress, more efficient use of resources, and ultimately, the development of advanced graphene-based energy storage solutions that can revolutionize various industries and applications.

Environmental Impact of Graphene Battery Production

The environmental impact of graphene battery production is a critical consideration in the development and adoption of this innovative technology. As graphene batteries emerge as a promising solution for energy storage, it is essential to assess their ecological footprint throughout the entire lifecycle.

The production of graphene itself involves energy-intensive processes, which can contribute to greenhouse gas emissions if not managed properly. However, advancements in manufacturing techniques, such as chemical vapor deposition and liquid-phase exfoliation, are continuously improving the efficiency and reducing the environmental impact of graphene synthesis.

Water usage and potential contamination are significant concerns in graphene battery production. The manufacturing process requires substantial amounts of water for cooling and cleaning purposes. Implementing closed-loop water systems and advanced filtration technologies can mitigate these issues, ensuring responsible water management and minimizing the release of potentially harmful substances into the environment.

The use of chemicals in graphene battery production also poses environmental risks. Solvents and other reagents used in the manufacturing process must be carefully handled and disposed of to prevent soil and water pollution. Developing green chemistry approaches and exploring bio-based alternatives for these chemicals can significantly reduce the environmental impact of production.

Recycling and end-of-life management of graphene batteries present both challenges and opportunities. While the recyclability of graphene-based materials is generally high, the complex composition of batteries requires specialized recycling processes. Establishing efficient recycling infrastructure and designing batteries with ease of disassembly in mind can help maximize material recovery and minimize waste.

Energy consumption during the production phase is another crucial factor to consider. Implementing renewable energy sources in manufacturing facilities can substantially reduce the carbon footprint of graphene battery production. Additionally, optimizing production processes for energy efficiency can further minimize environmental impact.

The potential for graphene batteries to enable more widespread adoption of renewable energy technologies should also be factored into their overall environmental assessment. By providing more efficient and longer-lasting energy storage solutions, graphene batteries could play a significant role in reducing global dependence on fossil fuels and mitigating climate change.

As research in graphene battery technology progresses, it is imperative to integrate life cycle assessment (LCA) methodologies into the development process. This approach will help identify and address potential environmental hotspots early in the innovation cycle, ensuring that the benefits of graphene batteries are not outweighed by unintended ecological consequences.

The production of graphene itself involves energy-intensive processes, which can contribute to greenhouse gas emissions if not managed properly. However, advancements in manufacturing techniques, such as chemical vapor deposition and liquid-phase exfoliation, are continuously improving the efficiency and reducing the environmental impact of graphene synthesis.

Water usage and potential contamination are significant concerns in graphene battery production. The manufacturing process requires substantial amounts of water for cooling and cleaning purposes. Implementing closed-loop water systems and advanced filtration technologies can mitigate these issues, ensuring responsible water management and minimizing the release of potentially harmful substances into the environment.

The use of chemicals in graphene battery production also poses environmental risks. Solvents and other reagents used in the manufacturing process must be carefully handled and disposed of to prevent soil and water pollution. Developing green chemistry approaches and exploring bio-based alternatives for these chemicals can significantly reduce the environmental impact of production.

Recycling and end-of-life management of graphene batteries present both challenges and opportunities. While the recyclability of graphene-based materials is generally high, the complex composition of batteries requires specialized recycling processes. Establishing efficient recycling infrastructure and designing batteries with ease of disassembly in mind can help maximize material recovery and minimize waste.

Energy consumption during the production phase is another crucial factor to consider. Implementing renewable energy sources in manufacturing facilities can substantially reduce the carbon footprint of graphene battery production. Additionally, optimizing production processes for energy efficiency can further minimize environmental impact.

The potential for graphene batteries to enable more widespread adoption of renewable energy technologies should also be factored into their overall environmental assessment. By providing more efficient and longer-lasting energy storage solutions, graphene batteries could play a significant role in reducing global dependence on fossil fuels and mitigating climate change.

As research in graphene battery technology progresses, it is imperative to integrate life cycle assessment (LCA) methodologies into the development process. This approach will help identify and address potential environmental hotspots early in the innovation cycle, ensuring that the benefits of graphene batteries are not outweighed by unintended ecological consequences.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!