How to Harness Ferrofluid for Improved Heat Management?

Ferrofluid Heat Management Background and Objectives

Ferrofluids, a unique class of magnetic nanofluids, have garnered significant attention in recent years for their potential applications in thermal management systems. These colloidal suspensions of magnetic nanoparticles in a carrier fluid exhibit remarkable properties that make them particularly suitable for heat transfer applications. The evolution of ferrofluid technology can be traced back to the 1960s when NASA first developed them for controlling fluids in space. Since then, the field has witnessed substantial advancements, with researchers exploring various compositions and applications.

The primary objective of harnessing ferrofluids for improved heat management is to leverage their unique thermophysical properties to enhance heat transfer efficiency in various systems. These properties include high thermal conductivity, controllable viscosity, and the ability to be manipulated by external magnetic fields. By exploiting these characteristics, researchers aim to develop more efficient cooling systems, thermal energy storage devices, and heat dissipation mechanisms for a wide range of applications, from electronics to industrial processes.

One of the key trends driving the development of ferrofluid-based heat management solutions is the increasing demand for more compact and efficient thermal management systems in electronics and power generation. As devices become smaller and more powerful, traditional cooling methods are reaching their limits, necessitating innovative approaches. Ferrofluids offer a promising solution due to their ability to enhance heat transfer rates and their adaptability to various geometries and operating conditions.

The technological trajectory of ferrofluid heat management is focused on several key areas. These include optimizing the composition of ferrofluids to maximize their thermal properties, developing novel heat exchanger designs that capitalize on the unique behavior of ferrofluids in magnetic fields, and creating adaptive cooling systems that can respond dynamically to changing thermal loads. Additionally, researchers are exploring the integration of ferrofluids with other emerging technologies, such as nanostructured surfaces and phase change materials, to create hybrid thermal management solutions with superior performance.

As the field progresses, the goals extend beyond merely improving heat transfer efficiency. Researchers are also aiming to address challenges such as long-term stability of ferrofluids, scalability of production processes, and compatibility with existing thermal management infrastructure. Furthermore, there is a growing emphasis on developing environmentally friendly ferrofluid formulations that can contribute to sustainable thermal management practices.

In conclusion, the background and objectives of ferrofluid heat management research reflect a dynamic and rapidly evolving field with significant potential to revolutionize thermal management across various industries. The ongoing efforts to harness the unique properties of ferrofluids for improved heat management are driven by the pressing need for more efficient and adaptable thermal solutions in an increasingly technology-dependent world.

Market Analysis for Ferrofluid Cooling Solutions

The market for ferrofluid cooling solutions is experiencing significant growth, driven by the increasing demand for efficient thermal management systems across various industries. As electronic devices become more compact and powerful, the need for innovative cooling technologies has intensified, positioning ferrofluid-based solutions as a promising alternative to traditional cooling methods.

The global market for thermal management technologies is projected to reach substantial value in the coming years, with ferrofluid cooling solutions expected to capture a growing share. Key industries driving this demand include electronics, automotive, aerospace, and medical devices. In the electronics sector, the rise of high-performance computing, data centers, and 5G infrastructure has created a pressing need for advanced cooling solutions that can handle increased heat generation in confined spaces.

Automotive applications represent another significant market opportunity for ferrofluid cooling. As electric vehicles gain popularity, efficient battery thermal management becomes crucial for enhancing performance and extending battery life. Ferrofluid-based cooling systems offer potential advantages in terms of weight reduction and improved heat dissipation compared to conventional liquid cooling methods.

In the aerospace industry, the trend towards more electric aircraft and the development of advanced avionics systems are creating new opportunities for ferrofluid cooling applications. The ability of ferrofluids to operate in various orientations and under different gravitational conditions makes them particularly attractive for aerospace thermal management.

The medical device market is also showing interest in ferrofluid cooling solutions, particularly for applications in medical imaging equipment and laser systems. The precise temperature control and uniform heat distribution offered by ferrofluids can enhance the performance and reliability of sensitive medical instruments.

Market analysis indicates that North America and Asia-Pacific are the leading regions in terms of ferrofluid cooling technology adoption and market growth. This is largely due to the concentration of electronics manufacturing, automotive industries, and research institutions in these regions. Europe is also emerging as a significant market, driven by stringent energy efficiency regulations and the push for sustainable technologies.

Key factors influencing market growth include ongoing research and development efforts to improve ferrofluid properties, increasing investments in thermal management technologies, and growing awareness of the benefits of ferrofluid-based cooling systems. However, challenges such as high initial costs and the need for specialized manufacturing processes may impact market penetration in some sectors.

Current Challenges in Ferrofluid-based Thermal Management

Despite the promising potential of ferrofluid-based thermal management systems, several significant challenges currently hinder their widespread adoption and optimal performance. One of the primary obstacles is the long-term stability of ferrofluids. Over time, these magnetic nanofluids tend to experience particle agglomeration and sedimentation, which can lead to a reduction in their thermal conductivity and overall heat transfer efficiency. This degradation of performance poses a significant hurdle for applications requiring sustained, reliable operation.

Another critical challenge lies in the precise control of ferrofluid behavior under varying magnetic field strengths and thermal conditions. The complex interplay between magnetic forces, thermal gradients, and fluid dynamics makes it difficult to predict and optimize the performance of ferrofluid-based cooling systems across a wide range of operational scenarios. This unpredictability can result in inconsistent heat dissipation and potential hotspots, particularly in applications with fluctuating heat loads.

The scalability of ferrofluid-based thermal management solutions presents another significant challenge. While these systems have shown promise in small-scale laboratory experiments, translating this success to larger, industrial-scale applications has proven difficult. Issues such as maintaining uniform magnetic field distribution over larger areas and managing larger volumes of ferrofluid without compromising performance are yet to be fully resolved.

Compatibility with existing thermal management infrastructure is also a concern. Integrating ferrofluid-based systems into conventional cooling setups often requires significant modifications to accommodate the unique properties of these magnetic nanofluids. This can lead to increased complexity and cost, potentially offsetting the benefits gained from improved thermal conductivity.

Furthermore, the environmental and health impacts of ferrofluids are not yet fully understood. The potential release of nanoparticles into the environment, either through leaks or during disposal, raises concerns about long-term ecological effects and human health risks. This uncertainty creates regulatory challenges and may impede the adoption of ferrofluid-based thermal management solutions in certain industries or applications.

Lastly, the cost-effectiveness of ferrofluid-based systems remains a significant barrier. The production of high-quality, stable ferrofluids can be expensive, and the additional components required for magnetic field generation and control add to the overall system cost. Demonstrating a clear return on investment, particularly in comparison to more established cooling technologies, is crucial for wider industry acceptance and implementation.

Existing Ferrofluid Heat Management Techniques

01 Ferrofluid-based heat management in electronic devices

Ferrofluids are used in electronic devices for efficient heat dissipation. The magnetic properties of ferrofluids allow for controlled movement and positioning within the device, enhancing heat transfer from components to cooling systems. This approach improves overall thermal management and device performance.- Ferrofluid-based cooling systems for electronic devices: Ferrofluids are used in cooling systems for electronic devices, particularly in heat sinks and thermal management solutions. These systems utilize the magnetic properties of ferrofluids to enhance heat transfer and improve cooling efficiency in compact electronic components.

- Ferrofluid seals for rotating shafts: Ferrofluids are employed in sealing applications for rotating shafts, particularly in high-speed machinery. These seals provide effective containment of lubricants and prevent contamination while also contributing to heat management through their thermal conductivity properties.

- Magnetic field-controlled heat transfer in ferrofluids: The application of magnetic fields to ferrofluids is used to control and enhance heat transfer. This technique allows for dynamic adjustment of thermal conductivity and convection properties, enabling more efficient and responsive heat management systems.

- Ferrofluid-based bearings for thermal management: Ferrofluids are utilized in bearing systems to provide both lubrication and heat dissipation. These bearings offer improved thermal management in high-speed rotating machinery, combining the benefits of magnetic fluid properties with efficient heat transfer capabilities.

- Nanoparticle-enhanced ferrofluids for heat transfer: Advanced ferrofluids incorporating nanoparticles are developed to enhance thermal conductivity and heat transfer properties. These nanoparticle-enhanced ferrofluids offer improved performance in various heat management applications, from cooling systems to thermal energy storage.

02 Ferrofluid seals for thermal management

Ferrofluid seals are employed in various applications to provide effective thermal management. These seals offer low friction, high thermal conductivity, and the ability to maintain a hermetic seal while allowing for heat transfer. They are particularly useful in rotating machinery and bearings.Expand Specific Solutions03 Magnetic field-controlled ferrofluid heat transfer

Heat transfer in ferrofluids can be controlled and enhanced through the application of magnetic fields. This technique allows for precise manipulation of the ferrofluid's flow and thermal properties, enabling efficient heat management in various systems and devices.Expand Specific Solutions04 Ferrofluid-based cooling systems for industrial applications

Ferrofluids are utilized in industrial cooling systems to improve heat dissipation and thermal management. These systems leverage the unique properties of ferrofluids to enhance heat transfer efficiency in large-scale equipment and processes.Expand Specific Solutions05 Nanoparticle-enhanced ferrofluids for heat management

Advanced ferrofluids incorporating nanoparticles are developed to enhance thermal conductivity and heat transfer capabilities. These nanoparticle-enhanced ferrofluids offer improved performance in various heat management applications, from electronics cooling to industrial processes.Expand Specific Solutions

Key Players in Ferrofluid and Thermal Management Industries

The competition landscape for harnessing ferrofluid for improved heat management is in an early growth stage, with significant potential for market expansion. The global market size for ferrofluid-based thermal management solutions is expected to grow rapidly as industries seek more efficient cooling technologies. While the technology is still evolving, several key players are driving innovation. Universities like Nanyang Technological University and the Swiss Federal Institute of Technology are conducting advanced research, while companies such as Microsoft Technology Licensing and Panasonic Intellectual Property Management are developing practical applications. The involvement of major energy companies like Shell and TotalEnergies indicates the technology's potential in industrial settings. As the technology matures, we can expect increased competition and market consolidation.

Shell Internationale Research Maatschappij BV

University of South Carolina

Innovative Ferrofluid Properties for Enhanced Heat Transfer

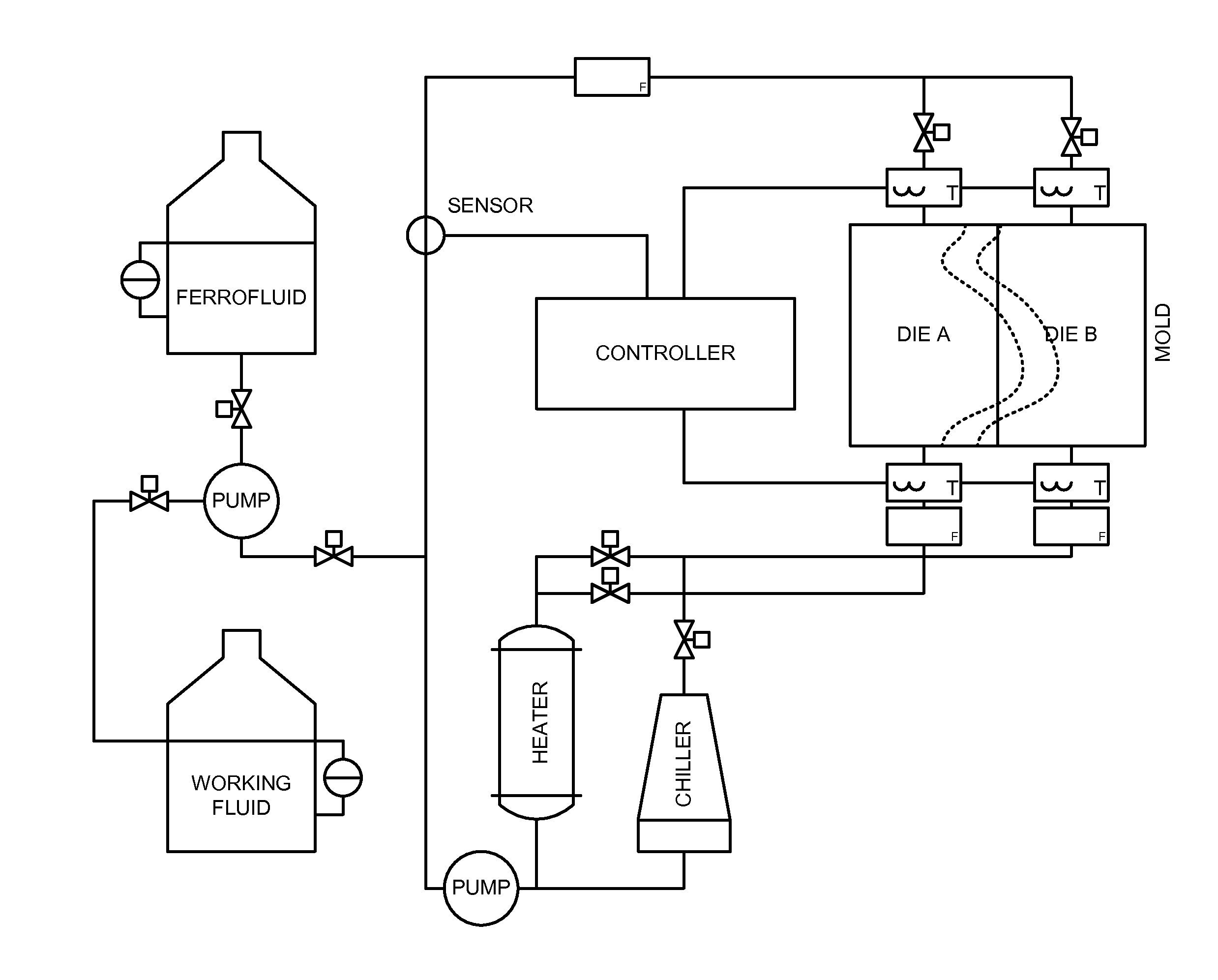

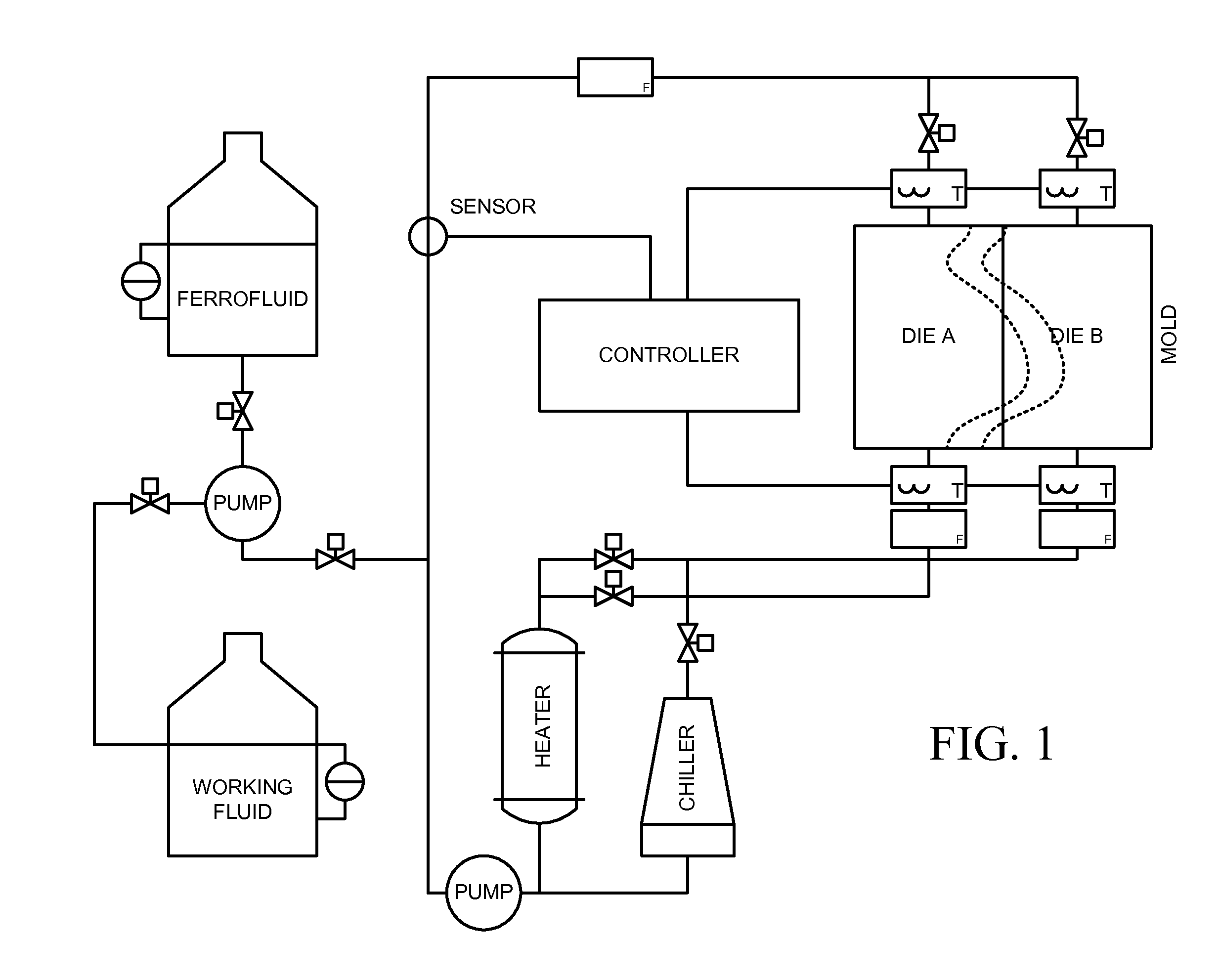

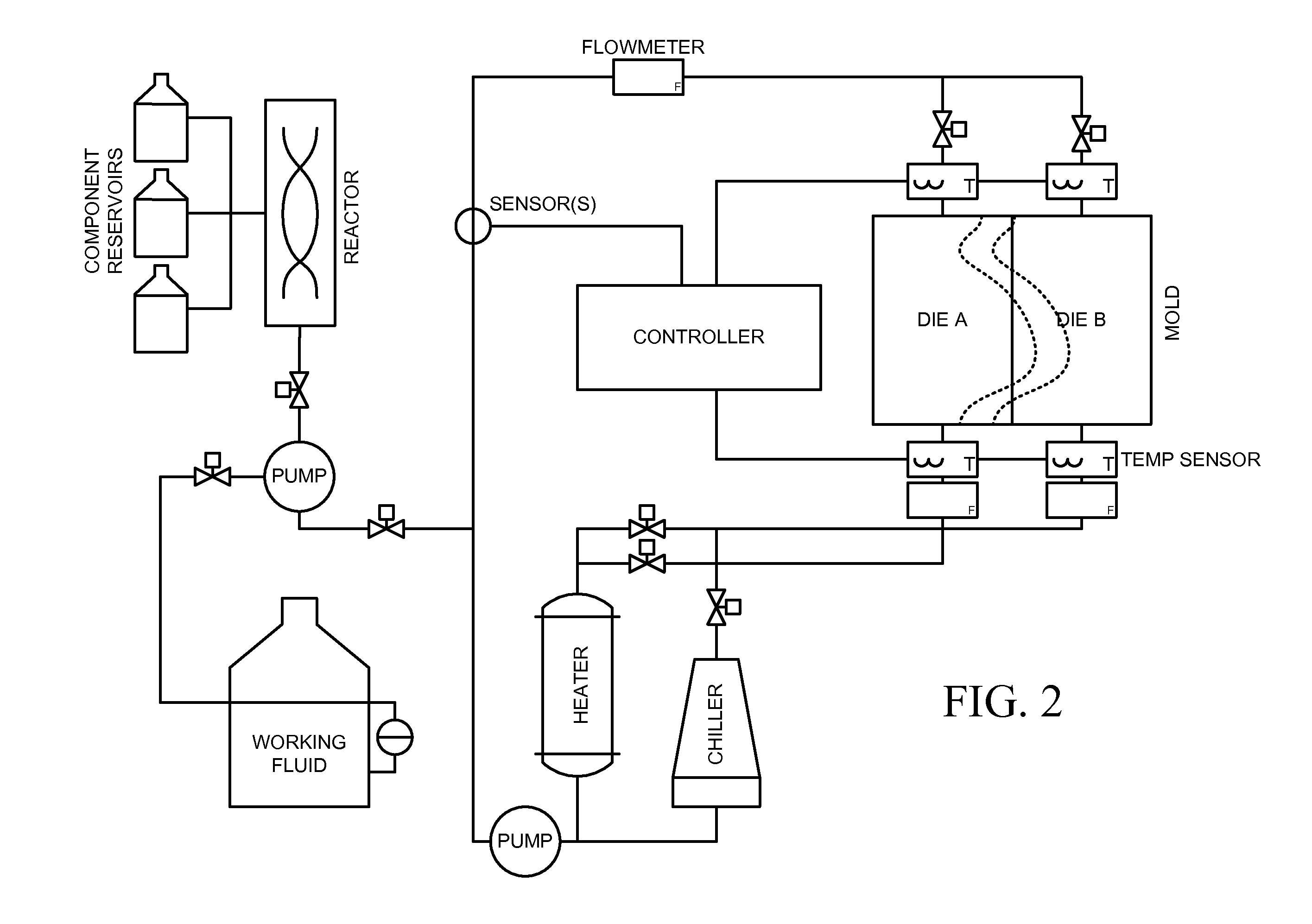

- A thermomagnetically pumped ferrofluid system that uses a conduit filled with magnetic nanoparticles, where a magnetic element upstream of the heat source drives the ferrofluid flow without external pumping, leveraging the thermomagnetic pumping force induced by the heat source and controlled by magnetization, allowing for self-regulation and efficient heat transfer.

- A method involving the preparation of a consistent ferrofluid with particles less than 5 nm in diameter, which can be economically added to heat transfer fluids and monitored/controlled using direct measurement techniques to achieve enhanced heat transfer efficiency, utilizing an in-line reactor for cost-effective manufacturing and compatibility with existing water treatment additives.

Environmental Impact of Ferrofluid Cooling Technologies

The environmental impact of ferrofluid cooling technologies is a critical consideration as these innovative solutions gain traction in heat management applications. Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, offer unique properties that can enhance thermal management efficiency. However, their widespread adoption necessitates a thorough examination of potential environmental consequences.

One of the primary environmental concerns associated with ferrofluid cooling technologies is the potential for nanoparticle release into ecosystems. The magnetic nanoparticles used in ferrofluids, typically iron oxides, may pose risks if they escape containment and enter water bodies or soil. While these particles are generally considered to have low toxicity, their long-term effects on aquatic and terrestrial ecosystems remain under investigation. Proper containment and disposal protocols are essential to mitigate this risk.

The production of ferrofluids also raises environmental considerations. The synthesis of magnetic nanoparticles often involves energy-intensive processes and the use of chemical surfactants. Optimizing these production methods to reduce energy consumption and minimize the use of potentially harmful chemicals is crucial for improving the overall environmental footprint of ferrofluid-based cooling systems.

On the positive side, ferrofluid cooling technologies have the potential to significantly enhance the energy efficiency of various heat management applications. By improving heat transfer and enabling more compact cooling systems, ferrofluids can contribute to reduced energy consumption in electronic devices, industrial processes, and renewable energy systems. This increased efficiency translates to lower greenhouse gas emissions and reduced resource depletion associated with power generation.

The recyclability and reusability of ferrofluids present both challenges and opportunities from an environmental perspective. While the magnetic properties of ferrofluids facilitate their recovery and potential reuse, the separation of nanoparticles from the carrier fluid may require additional processing steps. Developing efficient recycling methods for spent ferrofluids is essential to minimize waste and conserve resources.

As ferrofluid cooling technologies advance, ongoing research into their environmental impact is crucial. This includes assessing the potential for bioaccumulation of nanoparticles in food chains, evaluating the long-term stability of ferrofluids in various environmental conditions, and exploring biodegradable alternatives for carrier fluids. By addressing these environmental considerations proactively, the industry can ensure that the benefits of ferrofluid-based heat management solutions are realized without compromising ecological integrity.

Safety Considerations in Ferrofluid Heat Management Applications

The implementation of ferrofluid in heat management systems necessitates careful consideration of safety aspects to ensure reliable and secure operation. Ferrofluids, being colloidal suspensions of magnetic nanoparticles, present unique challenges that must be addressed to mitigate potential risks in various applications.

One primary safety concern is the potential for leakage or spillage of ferrofluid. Given its magnetic properties and fluid nature, containment is crucial to prevent contamination of surrounding components or environmental release. Robust sealing mechanisms and containment systems must be designed and implemented to withstand operational stresses, temperature fluctuations, and potential mechanical shocks.

The magnetic properties of ferrofluids also raise electromagnetic compatibility (EMC) concerns. In electronic applications, proper shielding and isolation techniques must be employed to prevent interference with sensitive components or nearby equipment. This is particularly critical in scenarios where ferrofluid-based heat management systems are integrated into complex electronic assemblies or industrial machinery.

Thermal stability is another key safety consideration. While ferrofluids are designed to enhance heat transfer, their performance and safety can be compromised at extreme temperatures. It is essential to establish and adhere to operational temperature limits to prevent degradation of the ferrofluid, which could lead to reduced efficiency or potential system failures.

The chemical composition of ferrofluids introduces additional safety requirements. Many ferrofluids contain surfactants and carrier fluids that may be flammable or toxic. Proper handling procedures, including the use of personal protective equipment (PPE) during maintenance or replacement, must be established. Furthermore, disposal of used or degraded ferrofluid must comply with environmental regulations to prevent ecological harm.

Long-term stability and aging effects of ferrofluids in heat management applications require ongoing monitoring and maintenance protocols. Regular inspections and performance assessments should be conducted to detect any signs of degradation, such as particle agglomeration or carrier fluid evaporation, which could compromise safety and efficiency.

In biomedical applications, such as targeted drug delivery or hyperthermia treatment, biocompatibility and potential toxicity of ferrofluids must be rigorously evaluated. Extensive testing and compliance with medical safety standards are imperative to ensure patient safety and prevent adverse reactions.

Lastly, the development of comprehensive safety guidelines, training programs, and emergency response procedures is essential for organizations implementing ferrofluid-based heat management solutions. These should cover proper handling, storage, operation, and disposal practices, as well as protocols for addressing potential accidents or system failures.