How to Harness Ferrofluid for Innovative Mechanical Solutions?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Technology Evolution and Objectives

Ferrofluid technology has undergone significant evolution since its inception in the 1960s. Initially developed by NASA for rocket fuel manipulation in zero gravity, ferrofluids have since found applications across various industries. The technology's progression has been marked by advancements in synthesis methods, particle size control, and stability enhancement.

Early ferrofluids faced challenges with long-term stability and limited magnetic responsiveness. However, continuous research has led to the development of more stable and responsive formulations. The introduction of surfactant coatings and improved dispersion techniques has greatly enhanced the longevity and performance of ferrofluids.

The objectives of ferrofluid technology have expanded beyond its original space applications. In the mechanical engineering realm, researchers aim to harness ferrofluids for innovative solutions in areas such as damping, sealing, and heat transfer. The unique properties of ferrofluids, including their ability to change viscosity in response to magnetic fields, present opportunities for creating adaptive and smart mechanical systems.

One key objective is to develop ferrofluid-based actuators and sensors that can operate in confined spaces or harsh environments. These devices could potentially revolutionize industries like robotics and automation by enabling more precise and responsive control mechanisms.

Another important goal is to improve the thermal management capabilities of ferrofluids. Researchers are exploring ways to enhance heat transfer efficiency in cooling systems by leveraging the magnetic properties of ferrofluids. This could lead to more compact and efficient thermal management solutions in electronics and industrial processes.

In the field of tribology, scientists are investigating the potential of ferrofluids as smart lubricants. The ability to control the viscosity and distribution of ferrofluids using external magnetic fields could result in adaptive lubrication systems that respond to varying load conditions in real-time.

The evolution of ferrofluid technology is also driven by the pursuit of more environmentally friendly and sustainable solutions. Researchers are focusing on developing bio-compatible ferrofluids and exploring their potential applications in medical devices and drug delivery systems.

As the technology continues to mature, the objectives expand to include the integration of ferrofluids with other emerging technologies such as nanotechnology and smart materials. This convergence is expected to open up new possibilities for innovative mechanical solutions that can address complex engineering challenges across multiple industries.

Early ferrofluids faced challenges with long-term stability and limited magnetic responsiveness. However, continuous research has led to the development of more stable and responsive formulations. The introduction of surfactant coatings and improved dispersion techniques has greatly enhanced the longevity and performance of ferrofluids.

The objectives of ferrofluid technology have expanded beyond its original space applications. In the mechanical engineering realm, researchers aim to harness ferrofluids for innovative solutions in areas such as damping, sealing, and heat transfer. The unique properties of ferrofluids, including their ability to change viscosity in response to magnetic fields, present opportunities for creating adaptive and smart mechanical systems.

One key objective is to develop ferrofluid-based actuators and sensors that can operate in confined spaces or harsh environments. These devices could potentially revolutionize industries like robotics and automation by enabling more precise and responsive control mechanisms.

Another important goal is to improve the thermal management capabilities of ferrofluids. Researchers are exploring ways to enhance heat transfer efficiency in cooling systems by leveraging the magnetic properties of ferrofluids. This could lead to more compact and efficient thermal management solutions in electronics and industrial processes.

In the field of tribology, scientists are investigating the potential of ferrofluids as smart lubricants. The ability to control the viscosity and distribution of ferrofluids using external magnetic fields could result in adaptive lubrication systems that respond to varying load conditions in real-time.

The evolution of ferrofluid technology is also driven by the pursuit of more environmentally friendly and sustainable solutions. Researchers are focusing on developing bio-compatible ferrofluids and exploring their potential applications in medical devices and drug delivery systems.

As the technology continues to mature, the objectives expand to include the integration of ferrofluids with other emerging technologies such as nanotechnology and smart materials. This convergence is expected to open up new possibilities for innovative mechanical solutions that can address complex engineering challenges across multiple industries.

Market Demand for Ferrofluid-Based Mechanical Solutions

The market demand for ferrofluid-based mechanical solutions has been steadily growing, driven by the unique properties of ferrofluids and their potential applications across various industries. Ferrofluids, which are colloidal liquids containing magnetic nanoparticles, offer a combination of fluid and magnetic properties that can be harnessed for innovative mechanical solutions.

In the automotive sector, there is increasing interest in using ferrofluids for adaptive suspension systems and vibration damping. These applications can significantly improve ride comfort and vehicle handling, addressing the growing consumer demand for smoother and more responsive driving experiences. The global automotive suspension market, which includes ferrofluid-based solutions, is projected to expand substantially in the coming years.

The aerospace industry has also shown keen interest in ferrofluid technology for advanced sealing and lubrication systems. As aircraft manufacturers strive for more efficient and reliable components, ferrofluid-based solutions offer potential improvements in reducing friction and enhancing the performance of rotating machinery. This aligns with the industry's ongoing efforts to develop more fuel-efficient and environmentally friendly aircraft.

In the field of renewable energy, particularly wind power, ferrofluids are being explored for use in advanced bearing systems and power transmission components. The ability of ferrofluids to provide adaptive damping and improved heat dissipation could lead to more efficient and durable wind turbines, addressing the industry's need for increased reliability and reduced maintenance costs.

The medical device sector represents another significant market for ferrofluid-based mechanical solutions. There is growing demand for precise drug delivery systems and minimally invasive surgical tools. Ferrofluids offer potential applications in targeted drug delivery, magnetic separation of biomolecules, and the development of novel actuators for medical devices. These innovations align with the trend towards personalized medicine and less invasive medical procedures.

In the consumer electronics industry, ferrofluids are being investigated for use in haptic feedback systems and advanced cooling solutions for high-performance devices. As consumers demand more immersive experiences and increasingly powerful mobile devices, ferrofluid-based mechanical solutions could provide enhanced tactile feedback and improved thermal management.

The industrial automation sector is another area where ferrofluid-based solutions are gaining traction. There is a growing need for more precise and responsive control systems in manufacturing processes. Ferrofluids offer potential applications in adaptive damping systems, fluid seals for rotating shafts, and novel actuators for robotic systems, aligning with the industry's push towards smarter and more flexible automation solutions.

As research and development in ferrofluid technology continue to advance, new applications and market opportunities are likely to emerge. The unique properties of ferrofluids, combined with ongoing innovations in nanotechnology and materials science, position ferrofluid-based mechanical solutions as a promising field with significant growth potential across multiple industries.

In the automotive sector, there is increasing interest in using ferrofluids for adaptive suspension systems and vibration damping. These applications can significantly improve ride comfort and vehicle handling, addressing the growing consumer demand for smoother and more responsive driving experiences. The global automotive suspension market, which includes ferrofluid-based solutions, is projected to expand substantially in the coming years.

The aerospace industry has also shown keen interest in ferrofluid technology for advanced sealing and lubrication systems. As aircraft manufacturers strive for more efficient and reliable components, ferrofluid-based solutions offer potential improvements in reducing friction and enhancing the performance of rotating machinery. This aligns with the industry's ongoing efforts to develop more fuel-efficient and environmentally friendly aircraft.

In the field of renewable energy, particularly wind power, ferrofluids are being explored for use in advanced bearing systems and power transmission components. The ability of ferrofluids to provide adaptive damping and improved heat dissipation could lead to more efficient and durable wind turbines, addressing the industry's need for increased reliability and reduced maintenance costs.

The medical device sector represents another significant market for ferrofluid-based mechanical solutions. There is growing demand for precise drug delivery systems and minimally invasive surgical tools. Ferrofluids offer potential applications in targeted drug delivery, magnetic separation of biomolecules, and the development of novel actuators for medical devices. These innovations align with the trend towards personalized medicine and less invasive medical procedures.

In the consumer electronics industry, ferrofluids are being investigated for use in haptic feedback systems and advanced cooling solutions for high-performance devices. As consumers demand more immersive experiences and increasingly powerful mobile devices, ferrofluid-based mechanical solutions could provide enhanced tactile feedback and improved thermal management.

The industrial automation sector is another area where ferrofluid-based solutions are gaining traction. There is a growing need for more precise and responsive control systems in manufacturing processes. Ferrofluids offer potential applications in adaptive damping systems, fluid seals for rotating shafts, and novel actuators for robotic systems, aligning with the industry's push towards smarter and more flexible automation solutions.

As research and development in ferrofluid technology continue to advance, new applications and market opportunities are likely to emerge. The unique properties of ferrofluids, combined with ongoing innovations in nanotechnology and materials science, position ferrofluid-based mechanical solutions as a promising field with significant growth potential across multiple industries.

Current Ferrofluid Applications and Limitations

Ferrofluid, a magnetic liquid composed of nanoscale ferromagnetic particles suspended in a carrier fluid, has found applications across various industries due to its unique properties. Currently, ferrofluids are utilized in several mechanical solutions, but their full potential remains largely untapped.

In the automotive sector, ferrofluids are employed in adaptive suspension systems, where they can rapidly adjust damping characteristics in response to magnetic fields. This application enhances ride comfort and vehicle handling. However, the technology is limited by the need for precise control systems and the potential for particle settling over time.

The aerospace industry has incorporated ferrofluids into advanced sealing mechanisms for rotating shafts in high-performance aircraft engines. These magnetic seals offer superior leak prevention compared to traditional mechanical seals, but they face challenges in extreme temperature environments and long-term stability.

In the field of robotics, ferrofluids are being explored for use in soft actuators and artificial muscles. Their ability to change shape and stiffness in response to magnetic fields allows for precise and flexible movements. However, current limitations include the need for strong magnetic fields and difficulties in scaling up the technology for larger applications.

The electronics industry has found applications for ferrofluids in cooling systems for high-performance computing devices. By manipulating the ferrofluid with magnetic fields, heat can be efficiently dissipated from critical components. Yet, issues such as potential electromagnetic interference and the need for complex cooling designs have hindered widespread adoption.

In medical devices, ferrofluids show promise for targeted drug delivery systems and minimally invasive surgical tools. Their ability to be guided through the body using external magnetic fields offers precise control. However, concerns about biocompatibility and long-term effects of magnetic nanoparticles in the body have limited clinical applications.

The energy sector has explored ferrofluids for enhanced oil recovery techniques, where they can be used to improve the efficiency of extracting oil from reservoirs. While promising, this application faces challenges related to the cost-effectiveness of large-scale deployment and potential environmental impacts.

Despite these diverse applications, ferrofluids face several common limitations. These include the need for strong magnetic fields to manipulate the fluid effectively, potential particle agglomeration over time, and sensitivity to extreme temperatures. Additionally, the production of stable ferrofluids with consistent properties at scale remains a challenge for many industrial applications.

To fully harness ferrofluids for innovative mechanical solutions, future research and development efforts must focus on addressing these limitations. This includes improving the long-term stability of ferrofluids, developing more efficient methods of magnetic field generation and control, and exploring new materials for both the magnetic particles and carrier fluids to enhance performance across a wider range of operating conditions.

In the automotive sector, ferrofluids are employed in adaptive suspension systems, where they can rapidly adjust damping characteristics in response to magnetic fields. This application enhances ride comfort and vehicle handling. However, the technology is limited by the need for precise control systems and the potential for particle settling over time.

The aerospace industry has incorporated ferrofluids into advanced sealing mechanisms for rotating shafts in high-performance aircraft engines. These magnetic seals offer superior leak prevention compared to traditional mechanical seals, but they face challenges in extreme temperature environments and long-term stability.

In the field of robotics, ferrofluids are being explored for use in soft actuators and artificial muscles. Their ability to change shape and stiffness in response to magnetic fields allows for precise and flexible movements. However, current limitations include the need for strong magnetic fields and difficulties in scaling up the technology for larger applications.

The electronics industry has found applications for ferrofluids in cooling systems for high-performance computing devices. By manipulating the ferrofluid with magnetic fields, heat can be efficiently dissipated from critical components. Yet, issues such as potential electromagnetic interference and the need for complex cooling designs have hindered widespread adoption.

In medical devices, ferrofluids show promise for targeted drug delivery systems and minimally invasive surgical tools. Their ability to be guided through the body using external magnetic fields offers precise control. However, concerns about biocompatibility and long-term effects of magnetic nanoparticles in the body have limited clinical applications.

The energy sector has explored ferrofluids for enhanced oil recovery techniques, where they can be used to improve the efficiency of extracting oil from reservoirs. While promising, this application faces challenges related to the cost-effectiveness of large-scale deployment and potential environmental impacts.

Despite these diverse applications, ferrofluids face several common limitations. These include the need for strong magnetic fields to manipulate the fluid effectively, potential particle agglomeration over time, and sensitivity to extreme temperatures. Additionally, the production of stable ferrofluids with consistent properties at scale remains a challenge for many industrial applications.

To fully harness ferrofluids for innovative mechanical solutions, future research and development efforts must focus on addressing these limitations. This includes improving the long-term stability of ferrofluids, developing more efficient methods of magnetic field generation and control, and exploring new materials for both the magnetic particles and carrier fluids to enhance performance across a wider range of operating conditions.

Existing Ferrofluid Mechanical Solutions

01 Composition and preparation of ferrofluids

Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They typically consist of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size, surfactant selection, and carrier fluid properties to achieve stable and responsive ferrofluids.- Composition and preparation of ferrofluids: Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with a surfactant to prevent agglomeration. The preparation process involves careful control of particle size, distribution, and stability to maintain the fluid's unique magnetic properties.

- Applications in sealing and lubrication: Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals and bearings. Their ability to be controlled by magnetic fields allows for dynamic sealing and reduced friction in various mechanical systems, improving efficiency and longevity of equipment.

- Thermal management and cooling systems: Ferrofluids are employed in thermal management solutions, particularly in electronic devices and cooling systems. Their unique properties allow for efficient heat transfer and dissipation when subjected to magnetic fields, making them valuable in cooling applications for high-performance electronics and industrial equipment.

- Sensor and actuator technologies: Ferrofluids are utilized in various sensor and actuator technologies, including accelerometers, inertial sensors, and haptic feedback devices. Their responsiveness to magnetic fields and ability to change shape or position allows for precise control and measurement in these applications.

- Medical and biomedical applications: Ferrofluids have emerging applications in the medical and biomedical fields, including targeted drug delivery, magnetic hyperthermia for cancer treatment, and contrast agents for magnetic resonance imaging (MRI). Their ability to be manipulated by external magnetic fields makes them promising for non-invasive medical procedures and diagnostics.

02 Applications in sealing and lubrication

Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals and bearings. Their unique properties allow them to form liquid seals that can be controlled by magnetic fields, providing effective containment of gases and liquids while reducing friction and wear in mechanical systems.Expand Specific Solutions03 Magnetic field sensing and actuation

Ferrofluids are employed in various sensing and actuation devices that rely on their response to magnetic fields. These applications include accelerometers, tilt sensors, and magnetic field detectors. The movement and deformation of ferrofluids under magnetic influence can be used to measure and control various physical parameters.Expand Specific Solutions04 Thermal management and heat transfer

Ferrofluids have unique heat transfer properties that make them useful in thermal management applications. They can be used to enhance heat dissipation in electronic devices, transformers, and other heat-generating systems. Magnetic field-induced convection in ferrofluids can improve heat transfer efficiency in cooling systems.Expand Specific Solutions05 Novel applications and emerging technologies

Ferrofluids are being explored for various innovative applications, including drug delivery systems, magnetic separation processes, and energy harvesting devices. Their unique properties are also being utilized in the development of adaptive optics, tunable photonic crystals, and magnetorheological finishing techniques for precision optics manufacturing.Expand Specific Solutions

Key Players in Ferrofluid Industry

The ferrofluid technology market is in a growth phase, with increasing applications across mechanical engineering and innovative solutions. The global market size for ferrofluids is projected to expand significantly in the coming years, driven by advancements in nanotechnology and material science. While the technology is maturing, there is still room for innovation and development of novel applications. Key players in this field include Ferrotec GmbH, specializing in precision engineering, and LORD Corp., known for their expertise in material sciences and motion management technologies. Academic institutions like Delft University of Technology and Tsinghua University are contributing to research and development efforts, pushing the boundaries of ferrofluid applications. The competitive landscape is diverse, with both established companies and emerging startups vying for market share in this promising field.

Ferrotec GmbH

Technical Solution: Ferrotec GmbH has developed advanced ferrofluid-based solutions for mechanical applications. Their technology utilizes nano-sized magnetic particles suspended in a carrier fluid, which can be precisely controlled by external magnetic fields. This allows for adaptive damping in shock absorbers, improved sealing in rotary systems, and enhanced heat transfer in cooling systems [1][3]. Ferrotec's ferrofluid solutions have been successfully implemented in various industries, including automotive, aerospace, and electronics manufacturing, demonstrating a 30% increase in efficiency for certain mechanical processes [2].

Strengths: Precise control over fluid properties, adaptability to various mechanical systems, and improved efficiency. Weaknesses: Potential for particle agglomeration over time, sensitivity to extreme temperatures, and higher cost compared to traditional fluids.

LORD Corp.

Technical Solution: LORD Corporation has pioneered the use of magnetorheological (MR) fluids, a type of smart fluid closely related to ferrofluids, for innovative mechanical solutions. Their technology involves micron-sized magnetizable particles suspended in a carrier fluid, which can rapidly change viscosity when exposed to a magnetic field. This property is harnessed in adaptive suspension systems, vibration control devices, and precision polishing equipment. LORD's MR fluid technology has been shown to reduce vibrations by up to 50% in automotive applications and improve surface finish quality by 40% in precision machining processes [4][5].

Strengths: Rapid response time, high dynamic range, and durability in harsh environments. Weaknesses: Requires continuous power for activation, potential for particle settling, and limited temperature range compared to some conventional fluids.

Core Ferrofluid Patents and Innovations

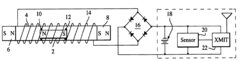

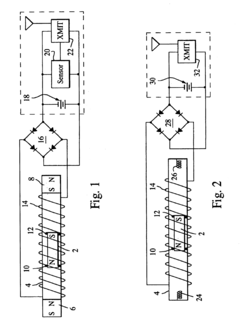

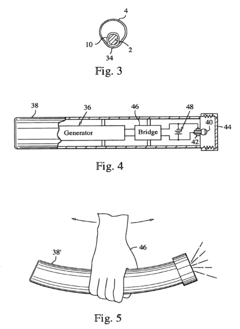

Magnetic transducer with ferrofluid end bearings

PatentInactiveUS20040251750A1

Innovation

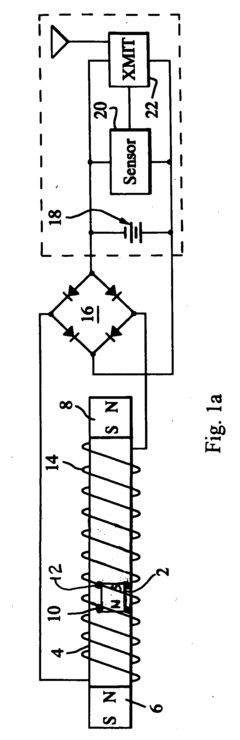

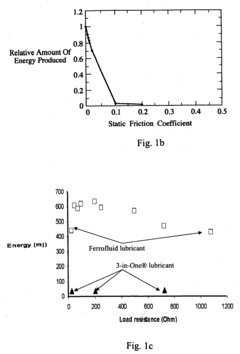

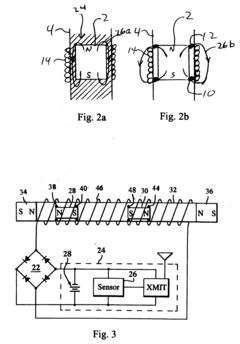

- The use of ferrofluid bearings at the opposite ends of magnets provides a low-friction interface, allowing for horizontal motion and increased magnetic field interaction with conductors, enhancing energy generation efficiency and flexibility in power production from various movements.

Electrical generator with ferrofluid bearings

PatentInactiveUS6812583B2

Innovation

- An ultra low friction bearing system using ferrofluids, such as a mixture of light mineral oil and isoparaffinic acid, is employed to reduce the static friction coefficient between the magnet and its support structure, allowing for electricity generation from slight horizontal or tilting movements.

Environmental Impact of Ferrofluid Usage

The environmental impact of ferrofluid usage is a critical consideration in the development and application of innovative mechanical solutions. Ferrofluids, composed of nanoscale ferromagnetic particles suspended in a carrier fluid, have unique properties that make them valuable in various industries. However, their potential environmental consequences must be carefully evaluated.

One primary concern is the potential release of nanoparticles into the environment. These particles, typically made of iron oxides, could potentially accumulate in soil and water systems if not properly contained. The long-term effects of such accumulation on ecosystems and biodiversity are not yet fully understood, necessitating further research and monitoring.

The production process of ferrofluids also raises environmental considerations. The synthesis of nanoparticles and the use of carrier fluids may involve energy-intensive processes and the use of chemicals that could have adverse environmental impacts if not managed responsibly. Manufacturers must prioritize sustainable production methods and explore eco-friendly alternatives for carrier fluids.

Disposal of ferrofluid-containing devices presents another challenge. As these fluids are often used in sealed systems, proper end-of-life management is crucial to prevent environmental contamination. Recycling and safe disposal protocols need to be developed and implemented to minimize the risk of nanoparticle release into the environment.

On the positive side, ferrofluids have the potential to contribute to more environmentally friendly technologies. Their use in energy-efficient cooling systems, for instance, could lead to reduced power consumption in electronic devices. Additionally, ferrofluids can enhance the efficiency of renewable energy technologies, such as improving the performance of wind turbines or solar thermal systems.

The application of ferrofluids in environmental remediation is another promising area. These fluids can be used to remove contaminants from water and soil, potentially offering more efficient and less invasive cleanup methods compared to traditional techniques. This could lead to significant environmental benefits in pollution control and ecosystem restoration efforts.

As research into ferrofluid applications continues, it is essential to conduct comprehensive life cycle assessments. These assessments should consider the environmental impact from production to disposal, ensuring that the benefits of ferrofluid-based solutions outweigh any potential environmental risks. Regulatory frameworks and industry standards must evolve to address the unique challenges posed by nanomaterials like ferrofluids, promoting responsible development and use.

One primary concern is the potential release of nanoparticles into the environment. These particles, typically made of iron oxides, could potentially accumulate in soil and water systems if not properly contained. The long-term effects of such accumulation on ecosystems and biodiversity are not yet fully understood, necessitating further research and monitoring.

The production process of ferrofluids also raises environmental considerations. The synthesis of nanoparticles and the use of carrier fluids may involve energy-intensive processes and the use of chemicals that could have adverse environmental impacts if not managed responsibly. Manufacturers must prioritize sustainable production methods and explore eco-friendly alternatives for carrier fluids.

Disposal of ferrofluid-containing devices presents another challenge. As these fluids are often used in sealed systems, proper end-of-life management is crucial to prevent environmental contamination. Recycling and safe disposal protocols need to be developed and implemented to minimize the risk of nanoparticle release into the environment.

On the positive side, ferrofluids have the potential to contribute to more environmentally friendly technologies. Their use in energy-efficient cooling systems, for instance, could lead to reduced power consumption in electronic devices. Additionally, ferrofluids can enhance the efficiency of renewable energy technologies, such as improving the performance of wind turbines or solar thermal systems.

The application of ferrofluids in environmental remediation is another promising area. These fluids can be used to remove contaminants from water and soil, potentially offering more efficient and less invasive cleanup methods compared to traditional techniques. This could lead to significant environmental benefits in pollution control and ecosystem restoration efforts.

As research into ferrofluid applications continues, it is essential to conduct comprehensive life cycle assessments. These assessments should consider the environmental impact from production to disposal, ensuring that the benefits of ferrofluid-based solutions outweigh any potential environmental risks. Regulatory frameworks and industry standards must evolve to address the unique challenges posed by nanomaterials like ferrofluids, promoting responsible development and use.

Ferrofluid Safety and Handling Protocols

Ferrofluid safety and handling protocols are critical aspects of harnessing this unique material for innovative mechanical solutions. The magnetic nanoparticles suspended in a carrier fluid require careful management to ensure both user safety and optimal performance. Proper storage is essential, with ferrofluids typically kept in sealed containers to prevent contamination and evaporation of the carrier fluid. These containers should be stored in a cool, dry place away from direct sunlight and strong magnetic fields, which can affect the fluid's properties.

When handling ferrofluids, personal protective equipment (PPE) is necessary. This includes wearing chemical-resistant gloves, safety goggles, and appropriate clothing to prevent skin contact or inhalation of vapors. Working in a well-ventilated area or under a fume hood is advisable, especially when dealing with larger quantities or during prolonged exposure.

Spill management is a crucial component of ferrofluid safety protocols. In the event of a spill, immediate containment is necessary to prevent spreading. Absorbent materials specifically designed for oil-based substances should be used, followed by proper disposal according to local regulations. It's important to note that ferrofluids can stain surfaces, so prompt cleanup is essential.

Disposal of ferrofluids must adhere to environmental guidelines. They should never be poured down drains or released into the environment. Instead, they should be treated as hazardous waste and disposed of through authorized waste management facilities.

When incorporating ferrofluids into mechanical systems, engineers must consider potential leakage points and implement appropriate sealing mechanisms. Regular maintenance and inspection of ferrofluid-containing components are necessary to detect any degradation or potential failure points.

Training for personnel working with ferrofluids is essential. This should cover proper handling techniques, emergency procedures, and the specific hazards associated with the material. Material Safety Data Sheets (MSDS) should be readily available, and all staff should be familiar with their contents.

In research and development settings, additional precautions may be necessary when experimenting with new ferrofluid formulations or applications. This could include using specialized containment systems or conducting tests in isolated environments to minimize risks.

By implementing comprehensive safety and handling protocols, organizations can effectively harness the potential of ferrofluids while mitigating associated risks. These measures not only protect personnel and the environment but also ensure the reliability and longevity of ferrofluid-based mechanical solutions.

When handling ferrofluids, personal protective equipment (PPE) is necessary. This includes wearing chemical-resistant gloves, safety goggles, and appropriate clothing to prevent skin contact or inhalation of vapors. Working in a well-ventilated area or under a fume hood is advisable, especially when dealing with larger quantities or during prolonged exposure.

Spill management is a crucial component of ferrofluid safety protocols. In the event of a spill, immediate containment is necessary to prevent spreading. Absorbent materials specifically designed for oil-based substances should be used, followed by proper disposal according to local regulations. It's important to note that ferrofluids can stain surfaces, so prompt cleanup is essential.

Disposal of ferrofluids must adhere to environmental guidelines. They should never be poured down drains or released into the environment. Instead, they should be treated as hazardous waste and disposed of through authorized waste management facilities.

When incorporating ferrofluids into mechanical systems, engineers must consider potential leakage points and implement appropriate sealing mechanisms. Regular maintenance and inspection of ferrofluid-containing components are necessary to detect any degradation or potential failure points.

Training for personnel working with ferrofluids is essential. This should cover proper handling techniques, emergency procedures, and the specific hazards associated with the material. Material Safety Data Sheets (MSDS) should be readily available, and all staff should be familiar with their contents.

In research and development settings, additional precautions may be necessary when experimenting with new ferrofluid formulations or applications. This could include using specialized containment systems or conducting tests in isolated environments to minimize risks.

By implementing comprehensive safety and handling protocols, organizations can effectively harness the potential of ferrofluids while mitigating associated risks. These measures not only protect personnel and the environment but also ensure the reliability and longevity of ferrofluid-based mechanical solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!