How to Implement Advanced Monitoring for Isocyanate Emissions?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Monitoring Background and Objectives

Isocyanates are a group of highly reactive chemicals widely used in the production of polyurethanes, which find applications in various industries such as automotive, construction, and furniture manufacturing. The monitoring of isocyanate emissions has become increasingly important due to their potential health and environmental impacts. This report aims to explore the background and objectives of implementing advanced monitoring systems for isocyanate emissions.

The development of isocyanate monitoring techniques has evolved significantly over the past few decades. Initially, basic methods such as colorimetric tubes and paper tape monitors were used for detecting isocyanate vapors. However, these methods lacked precision and real-time capabilities. As awareness of the health risks associated with isocyanate exposure grew, more sophisticated monitoring technologies emerged.

Current trends in isocyanate monitoring focus on real-time, continuous measurement systems that can provide accurate and reliable data. Advanced technologies such as Fourier Transform Infrared (FTIR) spectroscopy, Ion Mobility Spectrometry (IMS), and High-Performance Liquid Chromatography (HPLC) have been adapted for isocyanate detection. These methods offer improved sensitivity, selectivity, and the ability to monitor multiple isocyanate species simultaneously.

The primary objective of implementing advanced monitoring for isocyanate emissions is to enhance workplace safety and environmental protection. By providing real-time data on isocyanate concentrations, these systems enable rapid response to potential exposure incidents and help maintain compliance with increasingly stringent regulatory standards. Additionally, advanced monitoring supports process optimization in manufacturing facilities, potentially leading to reduced emissions and improved product quality.

Another key goal is to develop more portable and user-friendly monitoring devices. This would allow for wider deployment of monitoring systems, including in small-scale operations and field applications. Miniaturization of analytical instruments and integration with wireless communication technologies are driving progress in this area.

Improving the specificity and sensitivity of isocyanate detection methods remains a critical objective. This includes the ability to differentiate between various isocyanate species and detect ultra-low concentrations, which is essential for assessing long-term exposure risks and environmental impact.

The integration of artificial intelligence and machine learning algorithms into monitoring systems represents an emerging trend. These technologies have the potential to enhance data analysis, predict emission patterns, and provide early warning of potential equipment failures or process deviations that could lead to increased emissions.

In conclusion, the field of isocyanate emission monitoring is rapidly evolving, driven by the need for more effective health and environmental protection measures. The objectives of implementing advanced monitoring systems extend beyond mere compliance, aiming to create safer workplaces, optimize industrial processes, and contribute to sustainable manufacturing practices.

The development of isocyanate monitoring techniques has evolved significantly over the past few decades. Initially, basic methods such as colorimetric tubes and paper tape monitors were used for detecting isocyanate vapors. However, these methods lacked precision and real-time capabilities. As awareness of the health risks associated with isocyanate exposure grew, more sophisticated monitoring technologies emerged.

Current trends in isocyanate monitoring focus on real-time, continuous measurement systems that can provide accurate and reliable data. Advanced technologies such as Fourier Transform Infrared (FTIR) spectroscopy, Ion Mobility Spectrometry (IMS), and High-Performance Liquid Chromatography (HPLC) have been adapted for isocyanate detection. These methods offer improved sensitivity, selectivity, and the ability to monitor multiple isocyanate species simultaneously.

The primary objective of implementing advanced monitoring for isocyanate emissions is to enhance workplace safety and environmental protection. By providing real-time data on isocyanate concentrations, these systems enable rapid response to potential exposure incidents and help maintain compliance with increasingly stringent regulatory standards. Additionally, advanced monitoring supports process optimization in manufacturing facilities, potentially leading to reduced emissions and improved product quality.

Another key goal is to develop more portable and user-friendly monitoring devices. This would allow for wider deployment of monitoring systems, including in small-scale operations and field applications. Miniaturization of analytical instruments and integration with wireless communication technologies are driving progress in this area.

Improving the specificity and sensitivity of isocyanate detection methods remains a critical objective. This includes the ability to differentiate between various isocyanate species and detect ultra-low concentrations, which is essential for assessing long-term exposure risks and environmental impact.

The integration of artificial intelligence and machine learning algorithms into monitoring systems represents an emerging trend. These technologies have the potential to enhance data analysis, predict emission patterns, and provide early warning of potential equipment failures or process deviations that could lead to increased emissions.

In conclusion, the field of isocyanate emission monitoring is rapidly evolving, driven by the need for more effective health and environmental protection measures. The objectives of implementing advanced monitoring systems extend beyond mere compliance, aiming to create safer workplaces, optimize industrial processes, and contribute to sustainable manufacturing practices.

Market Demand for Isocyanate Emission Control

The market demand for isocyanate emission control has been steadily increasing due to growing environmental concerns and stricter regulatory requirements. Isocyanates, widely used in the production of polyurethanes, adhesives, and coatings, pose significant health risks when released into the environment. This has led to a surge in demand for advanced monitoring and control systems across various industries.

In the automotive sector, the push for more sustainable manufacturing processes has driven the adoption of isocyanate emission control technologies. Major automakers are investing in state-of-the-art monitoring systems to ensure compliance with environmental regulations and improve worker safety. The construction industry, another significant user of isocyanate-based products, is also experiencing increased demand for emission control solutions, particularly in urban areas where air quality is a major concern.

The healthcare sector has emerged as a key driver of market growth for isocyanate emission control. Hospitals and medical facilities are implementing advanced monitoring systems to protect patients and staff from potential exposure. This trend has been accelerated by the COVID-19 pandemic, which has heightened awareness of air quality and safety measures in healthcare settings.

The electronics manufacturing industry, particularly in Asia, has seen a sharp rise in demand for isocyanate emission control technologies. As production volumes increase and environmental regulations tighten, manufacturers are seeking more efficient and reliable monitoring solutions to maintain compliance and protect workers.

Market analysts project substantial growth in the global isocyanate emission control market over the next five years. This growth is attributed to increasing industrialization in developing countries, stricter environmental regulations worldwide, and growing awareness of occupational health and safety issues.

The demand for real-time monitoring solutions is particularly strong, as industries seek to prevent emissions before they occur rather than simply detecting them after the fact. This has led to the development of more sophisticated sensor technologies and data analytics platforms capable of providing instant alerts and predictive maintenance recommendations.

Small and medium-sized enterprises (SMEs) are also contributing to market growth, as they seek cost-effective solutions to comply with regulations and improve their environmental performance. This has created opportunities for innovative startups offering scalable and affordable emission control technologies.

As the market expands, there is a growing need for integrated solutions that combine emission monitoring with broader environmental management systems. This trend is driving collaboration between emission control specialists and providers of enterprise resource planning (ERP) and manufacturing execution systems (MES), creating more comprehensive and user-friendly platforms for industrial users.

In the automotive sector, the push for more sustainable manufacturing processes has driven the adoption of isocyanate emission control technologies. Major automakers are investing in state-of-the-art monitoring systems to ensure compliance with environmental regulations and improve worker safety. The construction industry, another significant user of isocyanate-based products, is also experiencing increased demand for emission control solutions, particularly in urban areas where air quality is a major concern.

The healthcare sector has emerged as a key driver of market growth for isocyanate emission control. Hospitals and medical facilities are implementing advanced monitoring systems to protect patients and staff from potential exposure. This trend has been accelerated by the COVID-19 pandemic, which has heightened awareness of air quality and safety measures in healthcare settings.

The electronics manufacturing industry, particularly in Asia, has seen a sharp rise in demand for isocyanate emission control technologies. As production volumes increase and environmental regulations tighten, manufacturers are seeking more efficient and reliable monitoring solutions to maintain compliance and protect workers.

Market analysts project substantial growth in the global isocyanate emission control market over the next five years. This growth is attributed to increasing industrialization in developing countries, stricter environmental regulations worldwide, and growing awareness of occupational health and safety issues.

The demand for real-time monitoring solutions is particularly strong, as industries seek to prevent emissions before they occur rather than simply detecting them after the fact. This has led to the development of more sophisticated sensor technologies and data analytics platforms capable of providing instant alerts and predictive maintenance recommendations.

Small and medium-sized enterprises (SMEs) are also contributing to market growth, as they seek cost-effective solutions to comply with regulations and improve their environmental performance. This has created opportunities for innovative startups offering scalable and affordable emission control technologies.

As the market expands, there is a growing need for integrated solutions that combine emission monitoring with broader environmental management systems. This trend is driving collaboration between emission control specialists and providers of enterprise resource planning (ERP) and manufacturing execution systems (MES), creating more comprehensive and user-friendly platforms for industrial users.

Current Challenges in Isocyanate Detection

The detection and monitoring of isocyanate emissions present several significant challenges in current industrial and environmental settings. One of the primary difficulties lies in the highly reactive nature of isocyanates, which can rapidly transform or degrade in the atmosphere. This reactivity makes it challenging to accurately measure and quantify isocyanate concentrations in real-time, as the compounds may change or dissipate before analysis can be completed.

Another major hurdle is the low concentration levels at which isocyanates become harmful to human health. Occupational exposure limits for isocyanates are typically in the parts per billion (ppb) range, requiring extremely sensitive detection methods. Achieving such high sensitivity while maintaining accuracy and reliability in diverse environmental conditions is a complex technical challenge.

The variety of isocyanate compounds used in industry further complicates detection efforts. Different isocyanates may require specific detection techniques, making it difficult to develop a universal monitoring solution. This diversity necessitates the development of multi-analyte detection systems or the implementation of multiple specialized sensors, increasing the complexity and cost of monitoring systems.

Interference from other airborne compounds is another significant challenge in isocyanate detection. Many industrial environments contain a complex mixture of chemicals that can interfere with isocyanate measurements, leading to false positives or negatives. Developing selective detection methods that can accurately distinguish isocyanates from other similar compounds is crucial for reliable monitoring.

The need for continuous, real-time monitoring presents additional challenges. Many current detection methods rely on sample collection followed by laboratory analysis, which introduces delays and may not capture rapid fluctuations in isocyanate levels. Developing robust, field-deployable sensors capable of providing instant, continuous measurements remains a significant technical hurdle.

Miniaturization and portability of detection equipment pose further challenges. While large-scale analytical instruments can achieve high sensitivity and selectivity, there is a growing demand for compact, portable devices for personal monitoring and on-site inspections. Balancing performance with size and cost constraints is a ongoing challenge in the field of isocyanate detection.

Lastly, the integration of advanced data analytics and IoT capabilities into isocyanate monitoring systems presents both opportunities and challenges. Developing systems that can not only detect isocyanates but also process and transmit data in real-time, potentially alerting workers or triggering automated responses, requires addressing complex issues of data management, connectivity, and system reliability in industrial environments.

Another major hurdle is the low concentration levels at which isocyanates become harmful to human health. Occupational exposure limits for isocyanates are typically in the parts per billion (ppb) range, requiring extremely sensitive detection methods. Achieving such high sensitivity while maintaining accuracy and reliability in diverse environmental conditions is a complex technical challenge.

The variety of isocyanate compounds used in industry further complicates detection efforts. Different isocyanates may require specific detection techniques, making it difficult to develop a universal monitoring solution. This diversity necessitates the development of multi-analyte detection systems or the implementation of multiple specialized sensors, increasing the complexity and cost of monitoring systems.

Interference from other airborne compounds is another significant challenge in isocyanate detection. Many industrial environments contain a complex mixture of chemicals that can interfere with isocyanate measurements, leading to false positives or negatives. Developing selective detection methods that can accurately distinguish isocyanates from other similar compounds is crucial for reliable monitoring.

The need for continuous, real-time monitoring presents additional challenges. Many current detection methods rely on sample collection followed by laboratory analysis, which introduces delays and may not capture rapid fluctuations in isocyanate levels. Developing robust, field-deployable sensors capable of providing instant, continuous measurements remains a significant technical hurdle.

Miniaturization and portability of detection equipment pose further challenges. While large-scale analytical instruments can achieve high sensitivity and selectivity, there is a growing demand for compact, portable devices for personal monitoring and on-site inspections. Balancing performance with size and cost constraints is a ongoing challenge in the field of isocyanate detection.

Lastly, the integration of advanced data analytics and IoT capabilities into isocyanate monitoring systems presents both opportunities and challenges. Developing systems that can not only detect isocyanates but also process and transmit data in real-time, potentially alerting workers or triggering automated responses, requires addressing complex issues of data management, connectivity, and system reliability in industrial environments.

Existing Isocyanate Detection Methods

01 Reduction of isocyanate emissions in polyurethane production

Various methods are employed to reduce isocyanate emissions during the production of polyurethane materials. These include using alternative catalysts, modifying reaction conditions, and implementing closed-loop systems to capture and recycle unreacted isocyanates. Such techniques help minimize worker exposure and environmental impact while maintaining product quality.- Reduction of isocyanate emissions in polyurethane production: Various methods are employed to reduce isocyanate emissions during the production of polyurethane materials. These techniques may include optimizing reaction conditions, using alternative catalysts, or implementing closed-loop systems to capture and recycle unreacted isocyanates.

- Isocyanate-free or low-emission coating systems: Development of coating systems that are either isocyanate-free or have significantly reduced isocyanate emissions. These systems may use alternative chemistries or modified isocyanates to achieve desired properties while minimizing harmful emissions.

- Emission control in isocyanate manufacturing processes: Implementation of emission control technologies and process improvements in the manufacturing of isocyanates. This may include scrubbing systems, thermal oxidizers, or other abatement technologies to reduce emissions at the source.

- Monitoring and detection of isocyanate emissions: Development of advanced monitoring and detection systems for isocyanate emissions. These may include real-time sensors, analytical techniques, or portable devices for measuring isocyanate concentrations in air or other media.

- Personal protective equipment for isocyanate exposure: Design and improvement of personal protective equipment (PPE) specifically for protection against isocyanate exposure. This may include specialized respirators, protective clothing, or decontamination systems to minimize worker exposure to isocyanate emissions.

02 Isocyanate-free or low-emission coating technologies

Development of coating technologies that either eliminate or significantly reduce isocyanate emissions. This includes the use of alternative curing agents, water-based systems, and novel polymer chemistries that provide similar performance characteristics to traditional isocyanate-based coatings while minimizing harmful emissions.Expand Specific Solutions03 Emission control in isocyanate manufacturing processes

Implementation of advanced process control and emission abatement technologies in isocyanate manufacturing facilities. This involves the use of scrubbers, thermal oxidizers, and other air pollution control devices to capture and treat isocyanate vapors before they are released into the environment.Expand Specific Solutions04 Monitoring and detection of isocyanate emissions

Development of sensitive and reliable methods for monitoring and detecting isocyanate emissions in industrial settings and ambient air. This includes the use of advanced analytical techniques, real-time monitoring systems, and personal exposure monitors to ensure compliance with safety regulations and environmental standards.Expand Specific Solutions05 Safe handling and disposal of isocyanate-containing materials

Establishment of protocols and technologies for the safe handling, storage, and disposal of isocyanate-containing materials to prevent unintended emissions. This includes the development of specialized containment systems, personal protective equipment, and waste treatment processes to minimize the risk of exposure and environmental contamination.Expand Specific Solutions

Key Players in Isocyanate Monitoring Industry

The implementation of advanced monitoring for isocyanate emissions is in a developing stage, with growing market potential driven by increasing environmental regulations and industrial safety concerns. The technology's maturity varies among key players, with companies like Covestro Deutschland AG, BASF Corp., and Wanhua Chemical Group Co., Ltd. leading in innovation. These firms are investing heavily in R&D to develop more sophisticated and accurate monitoring systems. The market is characterized by a mix of established chemical giants and specialized environmental technology companies, such as LAMTEC Meß- und Regeltechnik für Feuerungen GmbH & Co. KG, which are focusing on niche solutions. As the industry progresses, collaboration between academic institutions like Zhejiang University and industrial partners is becoming crucial for advancing the technology and expanding its applications.

Covestro Deutschland AG

Technical Solution: Covestro has developed an advanced monitoring system for isocyanate emissions utilizing real-time sensors and data analytics. Their approach combines continuous emission monitoring systems (CEMS) with predictive modeling to detect and quantify isocyanate levels in industrial processes. The system employs high-sensitivity spectroscopic sensors capable of detecting isocyanate concentrations as low as parts per billion (ppb) levels[1]. Integrated with a cloud-based data platform, the system provides real-time alerts and trend analysis, enabling proactive emission control. Covestro's solution also incorporates machine learning algorithms to predict potential emission spikes based on process parameters, allowing for preventive actions[2].

Strengths: High sensitivity detection, real-time monitoring, and predictive capabilities. Weaknesses: Potentially high implementation cost and complexity in integrating with existing industrial systems.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical has implemented a comprehensive isocyanate emission monitoring system across its production facilities. Their approach combines traditional sampling methods with advanced online monitoring technologies. The system utilizes Fourier-transform infrared spectroscopy (FTIR) for continuous real-time measurement of isocyanate concentrations in exhaust gases[3]. Wanhua has also developed proprietary software that integrates emission data with production parameters, enabling correlation analysis and process optimization. The company has reported achieving a 99.9% reduction in isocyanate emissions through this advanced monitoring and control system[4]. Additionally, Wanhua employs mobile monitoring units equipped with gas chromatography-mass spectrometry (GC-MS) for periodic verification and calibration of the online monitoring system.

Strengths: Comprehensive approach combining online and offline monitoring, high reduction in emissions achieved. Weaknesses: Potential for high initial investment and ongoing maintenance costs.

Innovative Sensor Technologies for Isocyanates

Measurement of total reactive isocyanate groups in samples using bifunctional nucleophiles such as 1,8-diaminonaphthalene (DAN)

PatentInactiveEP1579207A2

Innovation

- A method using 1,8-diaminonaphthalene (DAN) as a bifunctional nucleophilic isocyanate derivatizing agent that reacts with isocyanates to form a cyclic reaction product, allowing for the detection and quantification of total isocyanate groups regardless of the specific species present, using a two-step process of derivatization and cyclization.

Real-time environmental gas analysis system and method applied to chromatographic instrument

PatentPendingCN118731237A

Innovation

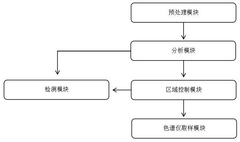

- Design a real-time environmental gas analysis system that collects gas concentration data at different heights on a chromatograph, builds a gas concentration database, divides height areas, sets gas concentration detection thresholds, and uses algorithm models to analyze gas flow rates and diffusion conditions to achieve control. Real-time monitoring of each height area and staged and height-based detection.

Regulatory Framework for Isocyanate Emissions

The regulatory framework for isocyanate emissions has evolved significantly over the years, reflecting growing concerns about the health and environmental impacts of these chemicals. At the international level, organizations such as the World Health Organization (WHO) and the International Labour Organization (ILO) have established guidelines for occupational exposure limits to isocyanates. These guidelines serve as a reference point for many national regulatory bodies.

In the United States, the Occupational Safety and Health Administration (OSHA) has set permissible exposure limits (PELs) for various isocyanates, including toluene diisocyanate (TDI) and methylene bisphenyl isocyanate (MDI). The Environmental Protection Agency (EPA) regulates isocyanate emissions under the Clean Air Act, classifying them as hazardous air pollutants. The EPA's National Emission Standards for Hazardous Air Pollutants (NESHAP) program includes specific requirements for industries that use or produce isocyanates.

The European Union has implemented stringent regulations through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) framework. REACH requires manufacturers and importers to register chemicals, including isocyanates, and provide safety data. The EU has also established occupational exposure limits for isocyanates through directives such as 2017/164/EU.

In Asia, countries like Japan and South Korea have developed their own regulatory frameworks for isocyanate emissions. Japan's Industrial Safety and Health Law sets exposure limits for isocyanates in the workplace, while South Korea's Occupational Safety and Health Act includes similar provisions.

Many countries have implemented specific regulations for industries known to be significant sources of isocyanate emissions, such as automotive manufacturing, construction, and furniture production. These regulations often mandate the use of best available technologies (BAT) for emission control and require regular monitoring and reporting of isocyanate levels.

The trend in regulatory frameworks is towards more comprehensive and stringent controls. This includes lower exposure limits, expanded monitoring requirements, and increased emphasis on worker protection and public health. Some jurisdictions are also moving towards a more integrated approach, considering the entire lifecycle of isocyanate-containing products from production to disposal.

As advanced monitoring technologies for isocyanate emissions become more widely available, regulatory bodies are increasingly incorporating these technologies into their frameworks. This includes requirements for continuous emission monitoring systems (CEMS) in certain industries and the use of real-time monitoring devices for worker exposure assessment.

In the United States, the Occupational Safety and Health Administration (OSHA) has set permissible exposure limits (PELs) for various isocyanates, including toluene diisocyanate (TDI) and methylene bisphenyl isocyanate (MDI). The Environmental Protection Agency (EPA) regulates isocyanate emissions under the Clean Air Act, classifying them as hazardous air pollutants. The EPA's National Emission Standards for Hazardous Air Pollutants (NESHAP) program includes specific requirements for industries that use or produce isocyanates.

The European Union has implemented stringent regulations through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) framework. REACH requires manufacturers and importers to register chemicals, including isocyanates, and provide safety data. The EU has also established occupational exposure limits for isocyanates through directives such as 2017/164/EU.

In Asia, countries like Japan and South Korea have developed their own regulatory frameworks for isocyanate emissions. Japan's Industrial Safety and Health Law sets exposure limits for isocyanates in the workplace, while South Korea's Occupational Safety and Health Act includes similar provisions.

Many countries have implemented specific regulations for industries known to be significant sources of isocyanate emissions, such as automotive manufacturing, construction, and furniture production. These regulations often mandate the use of best available technologies (BAT) for emission control and require regular monitoring and reporting of isocyanate levels.

The trend in regulatory frameworks is towards more comprehensive and stringent controls. This includes lower exposure limits, expanded monitoring requirements, and increased emphasis on worker protection and public health. Some jurisdictions are also moving towards a more integrated approach, considering the entire lifecycle of isocyanate-containing products from production to disposal.

As advanced monitoring technologies for isocyanate emissions become more widely available, regulatory bodies are increasingly incorporating these technologies into their frameworks. This includes requirements for continuous emission monitoring systems (CEMS) in certain industries and the use of real-time monitoring devices for worker exposure assessment.

Health and Safety Implications of Isocyanates

Isocyanates are highly reactive chemicals widely used in the production of polyurethane products, including foams, coatings, and adhesives. While their versatility has made them indispensable in various industries, the health and safety implications of isocyanate exposure are significant and warrant careful consideration.

Exposure to isocyanates primarily occurs through inhalation of vapors or aerosols, as well as skin contact with liquid or aerosolized forms. The most common health effects associated with isocyanate exposure are respiratory irritation and sensitization. Short-term exposure can cause eye, nose, throat, and lung irritation, while long-term exposure may lead to occupational asthma, a potentially debilitating condition characterized by persistent respiratory symptoms and airway hyperresponsiveness.

Skin contact with isocyanates can result in irritation, dermatitis, and sensitization. In some cases, individuals may develop allergic reactions to isocyanates, leading to severe skin rashes or respiratory symptoms upon subsequent exposures, even at very low concentrations. This sensitization can be particularly problematic, as it may force affected workers to leave their jobs or change careers entirely.

The potential for isocyanate-induced occupational asthma is a major concern in workplace safety. Studies have shown that up to 10% of workers exposed to isocyanates may develop occupational asthma, with symptoms persisting even after exposure cessation. This underscores the importance of implementing robust monitoring and control measures to minimize exposure risks.

Neurological effects have also been reported in workers exposed to high levels of isocyanates, including headaches, dizziness, and memory impairment. While less common than respiratory effects, these neurological symptoms highlight the diverse range of health impacts associated with isocyanate exposure.

To address these health and safety concerns, comprehensive monitoring strategies are essential. Advanced monitoring techniques, such as real-time sensors and personal exposure monitors, can provide immediate feedback on isocyanate levels in the workplace. This allows for rapid response to potential exposure incidents and helps in identifying areas or processes that require additional control measures.

Implementing a hierarchy of controls is crucial for managing isocyanate-related risks. This includes engineering controls like ventilation systems and enclosed processes, administrative controls such as worker rotation and training programs, and personal protective equipment (PPE) as a last line of defense. Regular medical surveillance of workers exposed to isocyanates is also vital for early detection of sensitization or other health effects.

Exposure to isocyanates primarily occurs through inhalation of vapors or aerosols, as well as skin contact with liquid or aerosolized forms. The most common health effects associated with isocyanate exposure are respiratory irritation and sensitization. Short-term exposure can cause eye, nose, throat, and lung irritation, while long-term exposure may lead to occupational asthma, a potentially debilitating condition characterized by persistent respiratory symptoms and airway hyperresponsiveness.

Skin contact with isocyanates can result in irritation, dermatitis, and sensitization. In some cases, individuals may develop allergic reactions to isocyanates, leading to severe skin rashes or respiratory symptoms upon subsequent exposures, even at very low concentrations. This sensitization can be particularly problematic, as it may force affected workers to leave their jobs or change careers entirely.

The potential for isocyanate-induced occupational asthma is a major concern in workplace safety. Studies have shown that up to 10% of workers exposed to isocyanates may develop occupational asthma, with symptoms persisting even after exposure cessation. This underscores the importance of implementing robust monitoring and control measures to minimize exposure risks.

Neurological effects have also been reported in workers exposed to high levels of isocyanates, including headaches, dizziness, and memory impairment. While less common than respiratory effects, these neurological symptoms highlight the diverse range of health impacts associated with isocyanate exposure.

To address these health and safety concerns, comprehensive monitoring strategies are essential. Advanced monitoring techniques, such as real-time sensors and personal exposure monitors, can provide immediate feedback on isocyanate levels in the workplace. This allows for rapid response to potential exposure incidents and helps in identifying areas or processes that require additional control measures.

Implementing a hierarchy of controls is crucial for managing isocyanate-related risks. This includes engineering controls like ventilation systems and enclosed processes, administrative controls such as worker rotation and training programs, and personal protective equipment (PPE) as a last line of defense. Regular medical surveillance of workers exposed to isocyanates is also vital for early detection of sensitization or other health effects.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!